1980Mooney

Verified Member-

Posts

3,706 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by 1980Mooney

-

Did you see these previous discussions on addressing the leak under the wing walk?

-

I have only used brush on wingwalk. Are you repainting your plane or contemplating stripping what you have off and replacing ?

-

Rght out of the gate? Seriously???

1980Mooney replied to Freddb34's topic in Vintage Mooneys (pre-J models)

Why is everyone talking about "giant chunks of gunk"? On Oct. 22 he said here: "There was some sediment built up into clumps that once the tank was completely drained and dried out, turned into a silty powder. They got it all out by flushing it several times until it was cleaned. Just happy to have my plane back and bring it south. " -

What is the specs or Mooney Brake Fluid

1980Mooney replied to DavePage's topic in Modern Mooney Discussion

Back in the mid 90's, my plane was owned in a 4 owner partnership. One of the partners, being helpful during a pre-flight check, noticed the brake fluid reservoir was low and decided to add fluid to the reservoir. He added DOT-3 automotive brake fluid to the existing 5606 without telling the other partners or logging anything.... On a later flight, one of the other partners had one side of the brakes fail during landing. Luckily, he kept it on the runway. They told me it caused the brake fluid and system to gum up. After they had the brake system flushed, repaired and bled, it was the final straw that caused the partnership to break up. They put the plane up for sale. -

Dukes Motor Overhaul. Where? Who? What?

1980Mooney replied to Echo's topic in Vintage Mooneys (pre-J models)

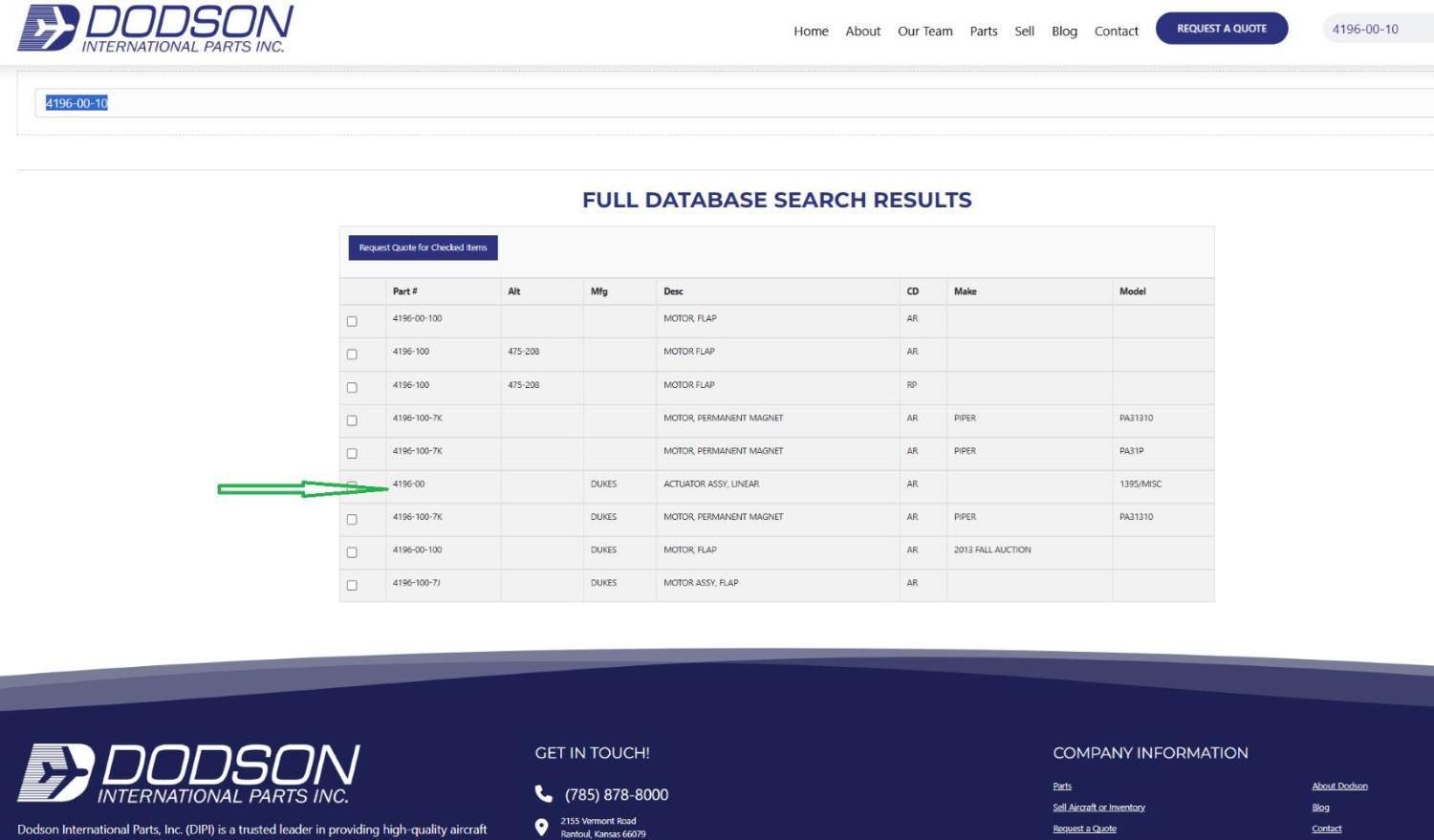

Dodson "might" have a salvage actuator. I say might because it is missing the last 2 numbers of 4196-00-10. -

Dukes Motor Overhaul. Where? Who? What?

1980Mooney replied to Echo's topic in Vintage Mooneys (pre-J models)

Products - Aeromotors As @PT20J says, the list has lots of Dukes fuel pumps but no Dukes actuator motors for some reason. After you open the link above, click on this: https://aeromotorsllc.com/home/products?type=actuator -

Check with @65MooneyPilot. He said that he installed it. I also wonder why it has taken LASAR five years to get around to the "process of renewing their PMA" The current owners of LASAR bought out Paul and Shery Loewen in 2017. Sounds like they sold out the inventory and never started the "process of renewing" the PMA for the past 8 years. Sad - they are the same ones asking us to pay them a $200-$500/month subscription.

-

Transponder antenna replacement questions

1980Mooney replied to LANCECASPER's topic in Avionics/Panel Discussion

Did the antenna blade separate from the base when you were dismantling it? Or was it fractured before you removed it? It looks like a lateral fracture - as if something hit it from the side. Or some ham handed line crew or mechanic pushed on it sideways. Possibly an errant tug slipped under the plane And whacked it? -

The original lampholders were made by Sloan. Try this Sloan lampholder. Compare the length to the Mooney holder on the LASAR page. It’s been a longtime since I rebuilt my glare shield but I think there is a screw on hood or Farrell on the top of the lamp. https://www.surplussales.com/items/112340/panel-mount-lamp-socket/ https://lasar.com/lights/receptacle-glareshield-lights-130285-003

-

Transponder antenna replacement questions

1980Mooney replied to LANCECASPER's topic in Avionics/Panel Discussion

Slanted side facing forward. From a 2020 topic with informative comments by Clarence / former M20Doc. -

The OP’s profile says “M20E”. I was wondering the same thing. I know of a Service Bulletin on the Dukes actuator but not of an AD.

-

Sadly you are correct.

-

It is not just a Verizon problem. I have Windstream/Kinetic internet and am unable to log onto MooneySpace using WiFi. It is the only website that won’t work. However, ATT cellular works fine, either on iPhone of via WiFi hotspot. Likewise I don’t have time to screw with it.

-

One thing not discussed here is the fact that most pilots put almost complete trust in their mechanics/A&P/IA's. This plane was in the hands of a mechanic from Oct 10-21 according the "Right out of the gate" topic. The mechanic conducted the test flight after repair looping the airport at least 4 times and @LANCECASPER congratulated him on the outcome. Most Mooney owners don't join or frequent MooneySpace. The owners that post here are generally way, way up the scale on knowledge of their aircraft and their skill level for diagnosing and repair. I wager that the average Mooney owner has basic knowledge of their planes but have to take the word of their mechanic for most things. Some are quick to say that Baber should have walked away from the plane or that he should have sprung for $thousands on overhaul and repair of entire systems. I bet many have experienced engine power reduction or stoppages only to trust their mechanic it has been repaired and fly on. @neilpilot above says that he had three (3) engine reduction/stoppages, yet they never figured out what caused it and he continued to fly based on his trust in his mechanics. He didn't park the plane. The fourth occurrence did cause an off-field landing that he survived. Had it been on take off, the outcome might have not been survivable. The point is that flying is inherently dangerous. We are flying planes that are generally 20-60 years old. These Mooney's have generally seen many owners and mechanics. Not every problem and repair has been documented over time. A small thing like @neilpilot's fragment of an o'ring can bring your plane down. Even brand-new Mooney's crash due to undetermined equipment failure like M20V Acclaim Ultra, N576CM, in 2019. This is a very sad outcome for an enthusiastic pilot/owner. We can second guess the measures Baber took but I wager that most of us would have handled it the same way. We take risks every time we fly - equipment, weather and personal performance. We try to mitigate risks but we have to trust someone.

-

M20J A3B6D Plane power AL12-P70 install

1980Mooney replied to Martin S.'s topic in Modern Mooney Discussion

The pulleys need to align in the same plane perpendicular to the crankshaft. Otherwise you will experience vibration, accelerated wear, noise or worst - throw the belt. Looks like you answered your own question and have it correct. -

You may be right. Archer acquired the remaining 30 years of the 2005 50-Year Master Lease and subleases from a private company that has been managing the airport for the City of Hawthorne. They also have the exclusive right to acquire 75% of the FBO at Hawthorne. The City of Hawthorne will still own the runways and remains the Landlord for the facilities (as they always have). However it sounds like Archer can operate it as they wish. The Prospectus indicates this will be a commercial hub for air taxis if development is successful. So small jets and turboprops will fly in and drop people off that catch Archer Air Taxis. Flying Mag calls the vision “a flying Grand Central Station “. Can small GA coexist? Probably for now - yes. Longer term - maybe.

-

Thread about corrosion gone?

1980Mooney replied to redbaron1982's topic in Vintage Mooneys (pre-J models)

Yikes, 2X the original estimate. And then the 1 year time related costs like Annual raised it to 3X? -

Thread about corrosion gone?

1980Mooney replied to redbaron1982's topic in Vintage Mooneys (pre-J models)

As referenced above, in his last post before he deleted everything, he said he was going to sell it to salvage for parting out. -

Thread about corrosion gone?

1980Mooney replied to redbaron1982's topic in Vintage Mooneys (pre-J models)

I believe the now vanished post was about a 1967 M20F located in Oklahoma. The owner was distraught that during Annual with a new mechanic, exfoliating corrosion was found in both wings. Based on the pics, the corrosion looked like it had been there quite a while so the last mechanic may have missed it. There was the suggestion that this was from rodent urine. Looking at his N-number on AviationDB, it appears that he bought it in late 2022. Maybe it was missed in the Pre-buy also. He posted pics of having just updated his panel so it looks like he poured a bunch of cash into the plane. Quotes, based upon just pictures, were around $15,000 per wing. Various MS'ers recommended Maxwell, Beagles and one other. In his last post, he lamented that they was probably going to put the plane up for salvage. He said that he was afraid that Maxwell or Beagles would give him a quote but the actual final price would be 2x to 3x more. I responded to his post and said I didn't think that was how Maxwell operated and suggested that he contact @redbaron1982 for firsthand experience with corrosion repair. Then everything was gone. -

LASAR was acquired by the current owners in 2017. This ugly event occurred in 2021-2022. The former owners, the Loewen’s were long,long gone.

-

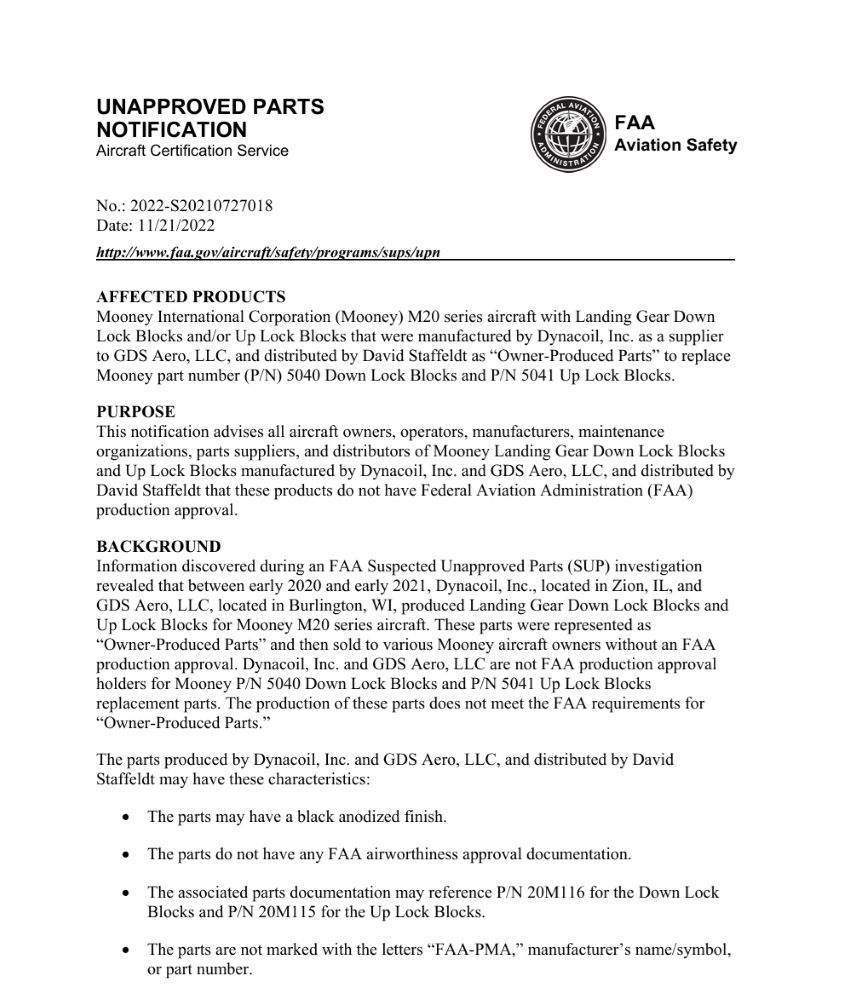

I will make it easy for everyone. Here is the FAA Unapproved Parts Notification (UPN). UPN 2022-S20210727018 In November 2022, the FAA issued an Unapproved Parts Notification (UPN) specifically for Mooney landing gear lock blocks produced as Owner Produced Parts (OPP). It shat upon the people that help produce them and really screwed the Mooney owners that installed them. The FAA immediately rendered those planes "not airworthy". The OPP up and down lock blocks were superior products but immediately became scrap. Notice the last sentence - they really want to rat out those involved in producing this superior part. LASAR got their way and protected their monopoly. The MS'er that was getting them machined has not been on MS for a year. Has "transparent" LASAR fessed up? "If these parts are found in existing inventory or installed in an FAA type-certificated aircraft, the FAA recommends that they be quarantined to prevent installation or use until a determination can be made regarding their eligibility for installation, or replaced with FAA-approved parts. FURTHER INFORMATION You may obtain further information concerning this investigation from the FAA Manufacturing Inspection District Office (MIDO) Section below. In addition to the above recommendations, the FAA would appreciate any information concerning the discovery of the above referenced parts from any source, the means used to identify the source, and the actions taken to remove the parts from the aircraft and/or parts inventories. "

-

Crack in bracket - Main spar fwd gear attach box

1980Mooney replied to Barneyw's topic in Vintage Mooneys (pre-J models)

d. any info (structural repair manual diagrams etc) on the area. e. is that all that is holding the truss in position or is there something more structural behind this bracket attaching the gear assy to the spar? Since you have the Parts Manual, look at Fig. 2, part 027 - " Box Assembly, Gear Attach - LH and RH." Parts 210140-013 and 210140-014 -

Crack in bracket - Main spar fwd gear attach box

1980Mooney replied to Barneyw's topic in Vintage Mooneys (pre-J models)

" I have attached 3 photos the first two is of my aircraft and the last one is a screenshot of an unknown model with a manual gear for reference only because it looks a little different to mine" "b. the differences between the gear attach boxes in the photos." I think the third picture is from a 1961 M20B featured in the Fastback Flying videos on YouTube. -

I bet that 95%+ are oblivious. I suspect that only a minority of active Mooney owners belong to MooneySpace and read this. A miniscule fraction of those owners actively participate on MS - maybe 50? And on Facebook Mooney Pilots, there seem to be a lot of actively commenting members, but the announcements and discussion of "LASARAviation/Mooney" got a few comments and that was it - Facebook Mooney Pilots discussion has moved on. The "Future of Mooney Maintenance is Near" video got two (2) comments. The "but we have never stopped turning wrenches" video got three (3) comments. The "LASAR & Mooney — Building the Next 50 Years of Mooney Aviation " video got two (2) comments. Some of the comments are from "cheerleaders"....not the typical owner.