1980Mooney

Basic Member-

Posts

3,031 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by 1980Mooney

-

"I can't legally fly my 262 in my boxer shorts with full fuel." The irony in this reality is that all Mooney's since the first M20B in 1961 to the last Acclaim fly on the same wing. The same wing lift that would legally only fly 2,575 lbs in 1961 would legally lift 3,368 lbs nearly 60 years later. And then the Factory had owners salivating that GW might increase another 300-400 lbs on the same wing with only landing gear mods to Long Bodies. So that would be 3,800+ lbs on the same wing that you fly on. The only difference is the power and technique to fly the plane. Indeed, Rocket Engineering boosted the MGW on my Mid Body J from 2,740 lbs to 3,200 lbs with the addition of 100 HP. There were no modifications to the flight controls or fuselage - just more weight in the nose and more weight in the tail to get a signoff from the FAA that was more agreeable back then. It is a paper exercise. Legal maximum weight and safe maximum weight in a Mooney are two different things.....

-

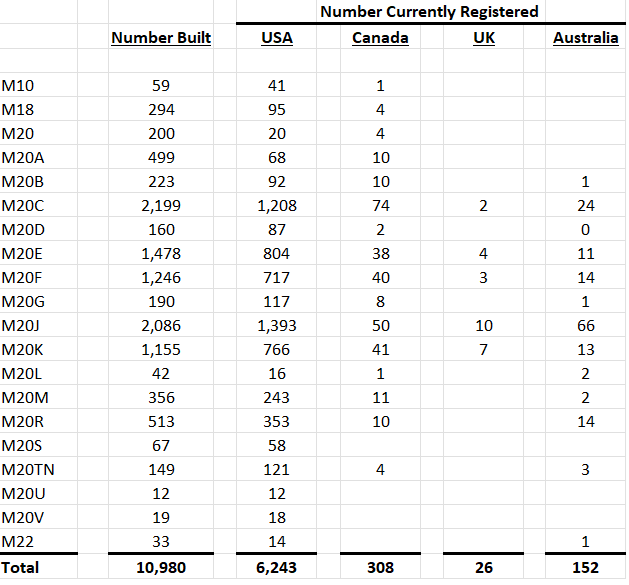

The registered aircraft numbers came from the FAA, Canadian Civil Aircraft Registry, UK Civil Aviation Authority and the Australian Civil Aircraft Register databases. The original numbers produced come from the "Mooney Chronology" https://www.mooneyevents.com/chrono.htm and from 2005 on from the GAMA database production reporting https://gama.aero/facts-and-statistics/quarterly-shipments-and-billings/. You can look at the serial numbers too with the more modern models. In the 50's-60's Mooney just added a sequential serial number to each plane as it was built regardless of whether it was a C, D or E. Ownership changed and practices changed. At least the J and newer make some sense. According to the "Mooney Chronology" some serial numbers were skipped occasionally even with the newer models. I would guess that the worldwide number of Bravos still flying is around 300 or less.

-

Daytona Aircraft Services. Call me when you have a part number?

1980Mooney replied to Jrags's topic in General Mooney Talk

I think a lot of owners here are unrealistic about the entire parts situation. Time and time again many think there is a market for third parties to start building Mooney specific parts that are slow to come from the Factory. Many compare it to the classic car era of the 60's-early 70's (models which typically had sales in the 100's of thousands every year). Look at the numbers. The OP is looking for parts for a M20G. There are only 117 registered in the US and another 8 in Canada. And not all are airworthy and flying. The parts he needs from time to time may or may not be shared with other models. And as @PT20J says there were changes made in production of many specific models. Third parties like McFarlane will chase Cessna 172 because 44,000 have been built - and Piper PA-28 because 33,000 have been built in various flavors. Mooney? - that is a small market to gear up for. -

Daytona Aircraft Services. Call me when you have a part number?

1980Mooney replied to Jrags's topic in General Mooney Talk

Except that the M20TN IPC (Illustrated Parts Manual) is not in the downloads. However you can find it in a couple of the discussions in the Acclaim Owners Forum. There is a December 2006 version of the M20TN Service and Maintenance Manual incorrectly posted in the Engine Reference Manual section of the Download Forum. (link below) There is a December 2007 version of the M20TN Illustrated Parts Catalog (IPC) posted in the Acclaim Owners Forum (link below) As @PT20J says it is best to get it from the Factory with updates but if they are slow to provide it or it is more of an introduction for learning the online versions are a good starting point. -

The cost to maintain a GA engine has been skyrocketing. @Fritz1 's all in "overall" numbers may have been accurate at one time but they don't even cover the cost the Lycoming engine when it is sitting in Pennsylvania ready to ship. And @Pinecone's numbers are accurate although AirPower has none in stock. Lycoming just agreed to a new union contract in September. We don't know the terms but the Union turned down a 25-32% wage increase offer in June (per the local newspaper). I suspect there will be price increases when new stock ships. And a Factory Rebuild price needs to include removal, shipping, tax in some locations, new engine mounts, and IRAN -engine mount , oil cooler, hoses, auxiliaries like electric fuel pump etc. and re-installation. I would think someone needs to budget at least $120,000 for a future Bravo Lycoming Factory Rebuilt. With these absurdly high prices it is natural for owners to seek qualified independent shops for overhauls. Not a lot of owners can write a $120,000+ check for what is in reality an overhaul. The owner writing the check has to believe that he is getting a lot of real value. Put another way - if you were looking at 2 equivalent Bravo's, same year, same avionics, paint, interior,: One had a Factory Rebuild 7 years and 450 hours ago - flown by 3 previous owners One had a reputable shop field overhaul 7 years and 450 hours ago - flown by 3 previous owners Would you pay any premium for "Factory Rebuilt"? Or would how the 3 previous owners flew and maintained the Bravo actually overshadow any perceived benefit of a a Factory Rebuild?

-

Avweb says that Lyc and Cont only began offering "rebuilt" when the new airplane engine market tanked in order for the Factories to go after the "overhaul" market with an FAA blessed "marketing distinction/advantage". They note that the Canadian Aviation authority does not recognize "zero time" rebuilt. To them a "rebuild" is just an overhaul of a used engine plain and simple. Please explain how a used Lycoming crankshaft within new limits makes it any better than one with slightly worn journals. A Lycoming crankshaft can go four sizes, Standard, M003, M006 and M010 on the rods and mains. Journals are resurfaced and new proper bearings are used to provide "factory" clearances between journal and bearing. Lycoming does not track individual part duty time - a "within factory limits" crankshaft might have undergone more cycles than one with some journal wear. A Lycoming approved oversize bearing kit to accommodate journal size/wear should provide the same performance and life as the "factory limit" bearing. Maybe I am missing something. https://www.avweb.com/ownership/the-zero-time-myth/

-

Comments to both posts above seem to be referring to independent shops doing overhauls vs Lycoming Factory Rebuilt. However, if you focus upon buying an "overhauled" engine from the Lycoming Factory Overhaul inventory there does not seem to be any difference in quality or precision of the build when comparing Rebuilt to Overhauled - "All Lycoming factory new, rebuilt and overhauled engines are built on the same production assembly line. The same skilled workers build all types of engines, new or overhauled, 4-cylinders or 8-cylinders, and naturally aspirated or turbocharged." Both Rebuilt and Overhauled reuses many used parts. The price difference on AirPower for a Lycoming TIO-540-AF1B Factory OH vs Rebuilt is about $10,000. It seems that one is primarily paying for an extra year of warranty and "zero-time" written in the logbook. From the Lycoming Website Factory Rebuilt – Every part used in building the engine meets or exceeds new part specifications; or the engine is like new. It has a zero time since new and a zero time since major overhaul. Some parts may be used, but they meet the same specifications as a new part. Like new engines, this engine carries a two-year factory warranty up to the hourly overhaul period listed in Service Instruction 1009. This engine choice is for the customers who are looking to have a return on their investment by adding value to their airframe. Overhauled – The parts used to build the engine meet or exceed service limits and specifications. The engine carries the previously accrued total time since new, but has zero time since major overhaul. This engine also carries a one-year factory warranty up to the hourly overhaul period listed in Service Instruction 1009. An overhauled engine is best for the customer who is looking for the most cost-effective option, or for those who accrue hours very quickly and will likely run the engine through the next overhaul cycle. Some parts are no longer available new from the original equipment manufacturers, such as dual magnetos from Bendix/TCM. In these cases, those parts are overhauled by a reputable overhaul facility. All Lycoming factory new, rebuilt and overhauled engines are built on the same production assembly line. The same skilled workers build all types of engines, new or overhauled, 4-cylinders or 8-cylinders, and naturally aspirated or turbocharged.

-

True. 2020-2021 was zero. But Textron has been building them again for the past 2 years unlike Mooney. There is some small demand for them. https://gama.aero/facts-and-statistics/quarterly-shipments-and-billings/

-

Piper built 146 PA-28 last year and 107 this year through Sept. Textron/Cessna built 151 C-172 last year and 120 this year through Sept. built 48 C-182 last year and 38 this year through Sept built 42 C-206 last year and 28 this year through Sept Textron/Bonanza built 3 G36 last year and 3 this year through Sept Read the Cirrus and Diamond numbers and weep.... https://gama.aero/wp-content/uploads/2022ShipmentReport2023-03-10.pdf https://gama.aero/wp-content/uploads/2023ShipmentReport11-21.pdf

-

All the planes mentioned in this thread have "stood the test of time". They are all flying and in demand. And unlike Mooney, the PA28 Pipers, Bo's and 172, 182, 206 Cessna's are still being produced....

-

@N2391Y I am not sure that I understand what your mission is. I looked at your Flightaware and I see a ton of pattern work. If you are trying to build time and get your IFR at a low cost within your budget there are a lot of options - finding a reliable/low maintenance plane with the best panel at the lowest price is probably a priority (that might be the one you are selling....). Retractable gear is going to cost you a $1000 more per year for insurance (maybe more - don't know your hours) and more in Annual. The higher speed of the Mooney may provide you some "psychic income" as you think about the increased speed that you will rarely use or need. But you will not see much difference between the planes discussed in this thread if it is just for getting your Instrument ticket. I understand your dilemma - you have the first year Cardinal with the 150 HP engine which was considered underpowered. There is no real power upgrade path for the original Cardinals because of small fuel tanks, limited fuel system, etc. I can see your need for change. If you have 200-300 nm trips in the future or hauling a person or 2 a M20C can be a good choice - you will see the difference., You will miss the double door, easy entrance and larger cabin of the Cardinal that you are selling. Everything in aviation is a trade-off. An Arrow is somewhere in between but the original 180 hp Arrows which you reference are at the low end of "in between". Perhaps you are not mentioning the 200 HP Arrows due to budget. Have you looked at later model Cardinals also with 180 HP? They will also be an "in between" option which you are familiar.

-

I am curious if you know - If an OPP part is "signed off" by the IA of the current (producing) owner, can the IA for the next owner look at the same part and say that is not airworthy as built and should have never been approved? We hear all the time (Mike Busch writes about it) that different IA's will have different opinions on condition, repairs, airworthiness, etc. It comes up in pre-buys and the first Annual with "a new set of eyes" after a purchase by a new owner ("Pencil Annual's", "Annual from hell", "Catch-up Annual"). In this case you have a part made without engineering drawings, without performance or life/failure testing in operating conditions and are "assuming" it is adequate or better. Two IA's can look at the same thing and form a different conclusion.

-

This raises a few issues. Although well intentioned, would an IA ever sign off on it in an Annual? And if an owner produces such a part, and it fails in the future for the next owner (causing a crash like that E in OK), won’t the current owner (or their heirs if there is a fatality) and insurance company come after the former owner who made the OPP?

-

Soft Spongy Brakes - even after bleeding brakes

1980Mooney replied to LemansJeff's topic in Modern Mooney Discussion

You may be right. But the OP said "I can't find any leaks nor does the reservoir loose any fluid". So it is one or the other or both..... -

Soft Spongy Brakes - even after bleeding brakes

1980Mooney replied to LemansJeff's topic in Modern Mooney Discussion

As Tim says it sounds like the piston seals are leaking. This is not an "external leak". It leaks past the seal as you push. Therefore it just goes back to the Reservoir. See the Service Manual Chapter 32 page 24 . I think you are right -

With the relentless march of advances in avionics technology, I suspect more pilots fly this way than we realize or want to believe. He took off in VMC from Grand Prairie and then from Missouri. Only the take off in Grand Prairie was towered - his stop for fuel and destinations in WI we not - no contact with any flight control required. When so many GA planes have Synthetic Vision, FSI-B for traffic awareness, perhaps Garmin "Visual Approach Guidance" (which doesn't know if you are flying in VMC or in the clag) I bet it becomes more and more tempting to just fly on without talking to anyone - without committing to a restrictive "IFR" flight plan - and then deal with it as it comes - relying upon the onboard technology. This accident pilot has obviously flown with and trusted plenty of fancy and capable avionics. If he had landed successfully, who would have known or cared?

-

"Outsourcing decision making to systems....that exist outside of ourselves could be very useful in avoiding the problems from shortcomings in ....our capabilities,,," Are you suggesting that we rely more upon integrated flight automation?

-

I have an older X3 Conserver (green colored - current ones are blue). That is what the documentation says - you must switch to a mask and turn to "Constant" above 18,000 ft. Then you adjust the dial for altitude (18K, 20K, 22K or 25K) which adjusts the constant flow rate to a rate appropriate for that altitude. The Conserve - pulse on demand feature - only works below 18,000 ft. The Precise Flight mask provides no additional capability and does not conserve O2. Save your money.

-

Removing Bladders in a J wing and reinstalling.

1980Mooney replied to jezzie's topic in General Mooney Talk

An STC is assigned to a specific airframe serial number. As long as the STC is still supported (which it is - Griggs/O&N) then you need the consent of the STC Holder (Griggs/O&N) in order to transfer it to a new airframe/serial number. I have a hunch that they won't do it for liability reasons. Griggs Aircraft Refinishing | Mooney bladders KNR, Inc., wrote a review of bladder application/installation in Mooney's back in 2009. They said it took 55-60 manhours to install the latest 64 gallon 8 bag (4/wing) installation. (includes cutting additional hole for an access panel in each wing in order to instal the 4th bag). If your salvage bags are the 54 gallon 6 bag (3/wing) system then the installation would be 45 hours. However you need to add more hours to remove the bags from the salvage wing. 200910 Ribs Wet or Dry? (knr-inc.com) There was a topic here on MS pirepping the installation. That topic had plenty of pictures of the job in process but sadly they are gone with the switch to the current server/host. If you Google the subject and select "images" some of the pictures remain on Google The last thing is how do you know the condition of the bladder?. Also I don't know how they plumb the separate bags together inside the wing - possible damage on removal? If your salvage bladders are the 6 bag (54 gallon) system you can buy 2 add on bladders to get up to the full 64 gallon "8 bag system". It sounds like that costs about another $3,000 and 15 manhours. They have to cut another access hole in each wing. Installing a new bladder system with a 7 year warranty is one thing - it has plenty of positives. Installing a salvage bladder system - more man hours than a new system, unknown condition and most likely reduced life. - I see a lot of labor expense with questionable life/quality - The only "positive" is the free used bags. - and I am not sure that is a positive. -

Required dual alternator. I think you are right.

-

There are no Mid-body Mooney's currently for sale with FIKI (either on Controller of Trade-A-Plane). There is one M20K 231 on Controller with TKS (inadvertent - Not FIKI). Useful Load is 829 lbs. N231DH. That is probably without the TKS tank filled. I bet UL with deice filled is around 770 lbs. This is barely a 2-person plane for the long-distance flight for which it is optimized. With partial fuel of 65 gallons that leaves 380 lbs for people, baggage, hatrack, etc. Similar dilemma to this: There is a modified M20K - Rocket 305 on Trade-A-Plane, N921Z. Rockets increase the GW 300 lbs over the 2,900 lb M20K. But with the heavier TSIO-520 and full feathering prop you lose a good bit of that. You also lose the economy of the 231 in exchange for speed. It looks like a hangar queen in partial restoration. From the pictures it looks like it has TKS but no mention in the description. Just painted. They highlight that they just installed new insulation. New interior. But "Panel is Factory, Yoke mount for iPad No ADSB.". When the interior was out was the ideal time to replace/modernize avionics, run new wiring, strip out old, install new antenna, etc - Odd, I bet they ran out of money coupled with long delays in available avionics.- got tired of the "project". If you go to an old Aircraft.com advert it does mention TKS but no mention of FIKI. - appears to be "inadvertent" only The plane has suffered two (2) botched landings - AviationDB says that it broke off the left landing gear wheel and damaged right wing in a cross controlled landing in 2001 and in 2011 it hit a runway sign on landing that sheared the nose gear off.

-

Also with the Mooney, you have the center steel tube ( of the windshield/fuselage frame ) exposed. It is easy to lean forward and grab, even with the seat all the way back or with the nose pitched up, in order to stabilize yourself or to pull the seat forward. In a Cessna, in the event of an unexpected seat slide back during take off (and nose pitch up), the only thing to grab and pull on is the yoke. The outcome is deadly.

-

On Beechtalk, there have been comments in the last month that the inventory of Citation jets (a lot are older) is higher than it has been in a long time. Additionally they are seeing the inventory increase in November which is a time that it historically does not increase. They said "asking" prices are staying high but they expect them to drop with the rising inventory. Also the collector car market is a lot like our nearly antique fleet of Mooney's. Per Hagerty's at the end of September: "The Hagerty Market Rating (HMR) dropped 1.2 points this month to 68.33—its lowest value in two years. Although this is not the first time that the Market Rating has decreased for 13 months out of a 15-month timeframe, the current downturn includes the steepest decline in Market Rating history. In the past year, the Market Rating has dropped 9.6 points. Before 2023, the largest single-year drop was only 6.9 points. While still in the “expanding market” range of the spectrum, it’s very likely that the Market Rating will continue to decline as prices soften across the market. The pandemic boom has clearly come to an end." "This month was the first time since August 2017 in which every single metric used to calculate the Hagerty Market Rating dropped." "Despite more than $403 million in sales at the Monterey auctions this month, the Median Sale Price metric decreased two points to its lowest score in over a decade. ... The median sale price at Monterey this year was 13 percent lower than a year ago." Prices will defy gravity only for so long. Yesterday @Steve Dawson posted in "Mooney Market": "Controller gives a pretty good idea of the market. Before Covid there were approximately 90-100 Mooneys for sale, then during Covid the demand increased and the number for sale decreased from 40-50 and the prices went up substantially for everything. This morning there's 95 for sale so the demand is lower and the prices should be going down soon. There's a few ad's showing that the plane has been listed for two years so they're probably overpriced and/or have something wrong with them. "

-

As Paul and John said it is all basically labor. Watch the video below. They show just part of the repair after they have already removed flight control surfaces, (in your case the flap) and removed the damaged area as well as repaired any damaged ribs. Your damage is further inboard and the skin is larger. I can see 80 shop hours - maybe more - at $120/hour plus parts and painting.

- 75 replies

-

- 1

-

-

No telling what he did but it is in error. The firewall is straight at the top and then angles forward. If he used the top of the firewall then he is at least 3.68 inches in error. That gets you to 40.18 inches - still too far forward (limit is 41 inches). Your plane is not nose heavy - the W&B is screwed up.