1980Mooney

Basic Member-

Posts

3,170 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by 1980Mooney

-

Table showing the 2023 Airport and Airway Trust Fund Excise Taxes Structure Table with 2 columns and 9 rows. The Airport and Airway Trust Fund (AATF) last year paid about 55% of FAA Budget - Should grow to pay for 69% this year 2023 Airport and Airway Trust Fund excise taxes structure Table showing the 2023 Airport and Airway Trust Fund Excise Taxes Structure Table with 2 columns and 9 rows. AATC Revenue Tax Source Rate Domestic passenger ticket tax 7.5% Domestic flight segment tax (excluding flights to or from rural airports) $4.80 per passenger per segment; indexed to the Consumer Price Index Tax on flights between the continental United States and Alaska or Hawaii (or between Alaska and Hawaii) $10.60 per passenger; indexed to the Consumer Price Index International arrival and departure tax $21.10 per passenger; indexed to the Consumer Price Index Tax on mileage awards (frequent flyer awards tax) 7.5% of value of miles Domestic commercial fuel tax 4.3 cents per gallon Domestic general aviation gasoline tax 19.3 cents per gallon Domestic general aviation jet fuel tax 21.8 cents per gallon. Effective after March 31, 2012, a 14.1 cents per gallon surcharge for fuel used in fractional ownership flights Tax on domestic cargo or mail 6.25% on the price paid for transportation of domestic cargo or mail In 2020 Avgas sales nationwide were about 413,000 gallons per day and steadily dropping for the past 40 years. (in 1983 daily sales averaged 1,047,000 gallons per day - about 2 1/2 times more). So we in GA pay about $29 Million towards the 2024 $24 Billion FAA budget. (yes a few are burning Jet-A so it is a bit more). Air Traffic Operations alone (no NextGen R&D/development, no Safety, no facilities, etc) were $9 Billion in 2023. Last year the taxes above (AATF) generated about $13 Billion in revenue for the FAA or about 55% of their budget (remainder from US General Fund). 70% or about $9 Billion was from taxes on passengers on the Commercial flights. Commercial operators use about 31 Million gallons of Jet-A per day or over 11 Billion gallons per year. They pay about $490 Million in taxes on that fuel. In 2024 they project that the Airlines and their pax will fund 69% of the entire $27 Billion FAA Budget (ATC Air Traffic Organization will jump to $10 Billion) General Aviation will pay about 0.3% of the ATC Budget (and only 0.1% of the FAA Budget in total)

-

Good safety reminder, but we aren’t paying for it - Isn’t that the major complaint by the major airlines/pros regarding GA? They would like to see us pay ATC User Fees like their push in 2006, 2011, and I think they were floating it again last year. They see us as a bunch of freeloaders. I doubt that we will dodge the bullet next FAA appropriation in about 4 years. Who knows, maybe then we will get the level of service that we are paying for.

-

Still seems on the high side. @GeeBee with same plane/engine recommended 24-25 gph for operational balance. Also, as he highlighted have you been able to determine if your onboard fuel flow meter is accurate?

-

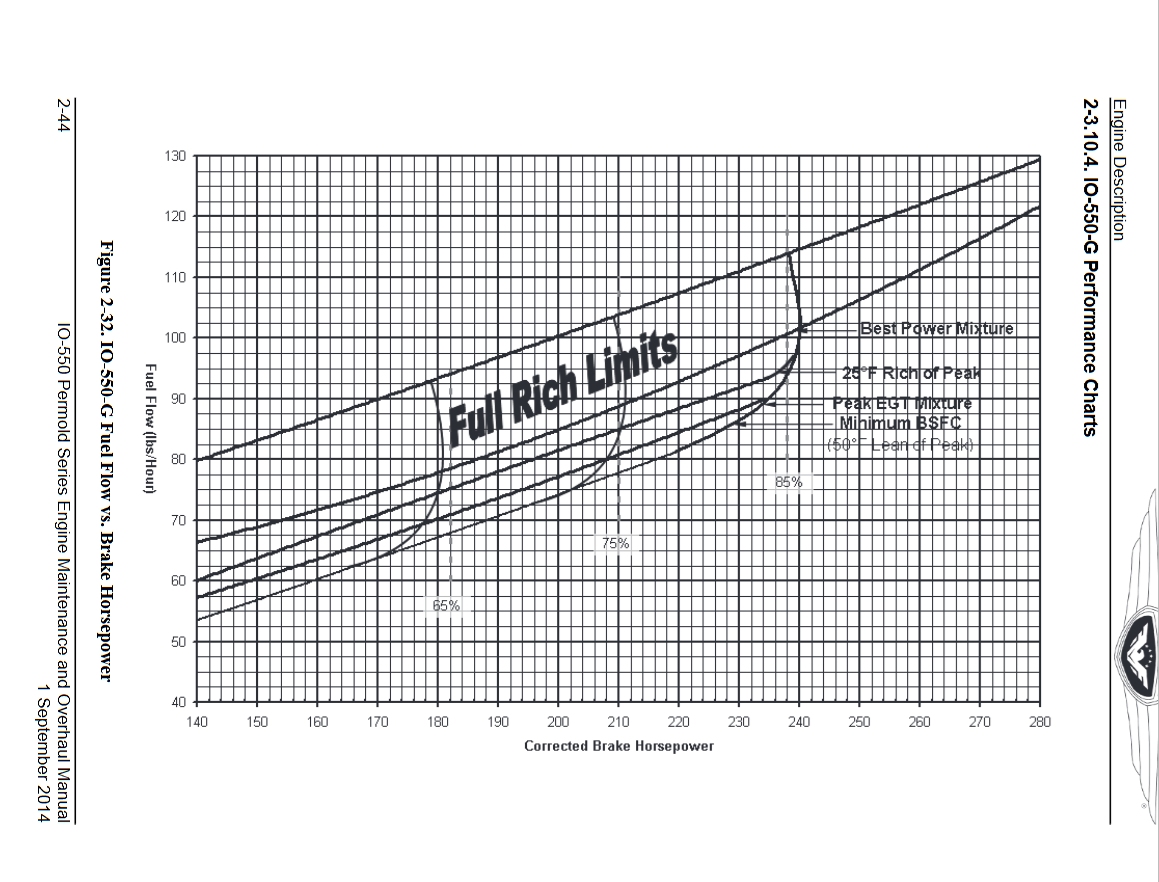

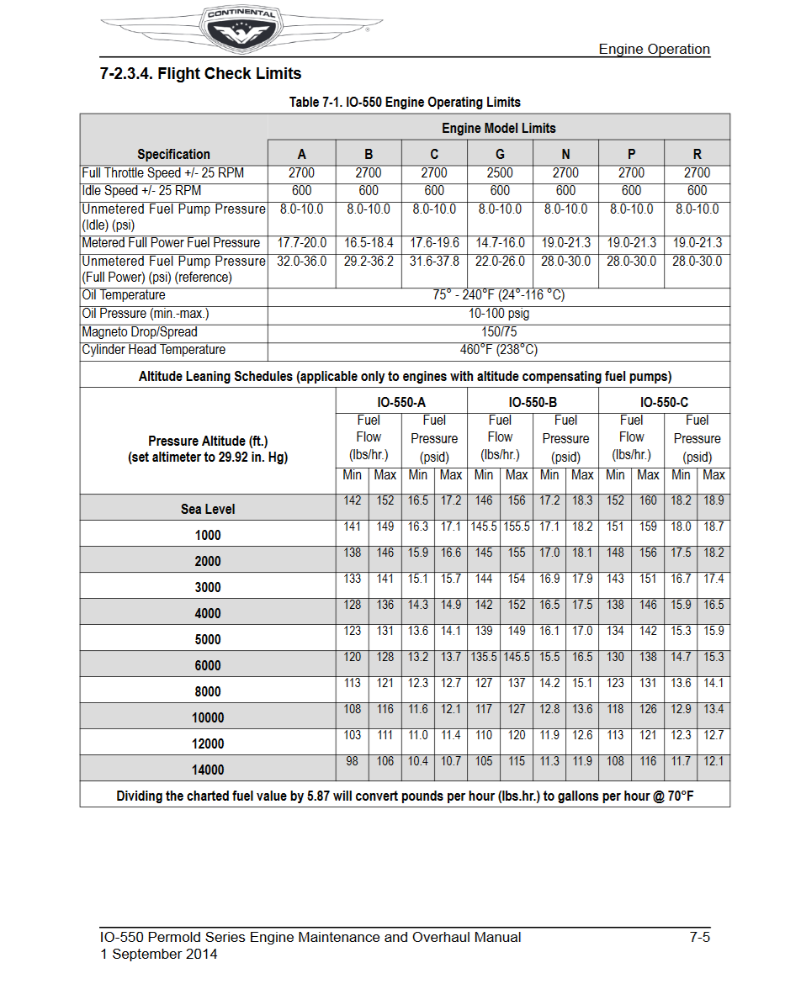

Why are you trying to set up your Continental IO-550 like a 300–310 hp variant running at 2700 RPM when you said you have a derated 280 hp model limited to 2500 RPM? Did your plane get a screaming eagle 310 hp upgrade? If not, you’re asking mechanics to set it up ridiculously rich. That may be why no one is listening to you.

-

Any good A&P knowledgeable in Continental engines should be able to help you. What is your T/O FF currently? Has your engine been set per Continental SID-97 and M-16 already? https://pceonline.com/wp-content/uploads/2017/04/SID97-3GFuelSysSetUp.pdf http://softoutfit.com/static/refs/io550overhaul.pdf

-

All the M20J POH's are posted in the "Downloads" section of MooneySpace. Click on the "Browse" button and you will see the dropdown.

-

I think @GeeBee’s comment and title of this topic highlight the epidemic of Mooney landing phase claims. This sad plane simply illustrates the tip of the iceberg. You yourself said “There is no requirement for a gear up to be reported to the FAA.” which proves the true rate of incidences and claims are higher than those reported in the FAA ASIAS (which no one wants to acknowledge or discuss).

-

Perhaps the better question is: - How much is “baked in” for Mooney incidents in the landing phase? What percentage is our insurance higher because of the higher incidence of landing phase claims (I.e gear-ups, gear collapses, bounces that cause prop strike, porpoises that collapse the nose gear, excess speed/poor energy management due slippery wing cause runway excursions and overshoot, excess speed causing pilot to get behind the curve causing any of the above) - A good comparison would be the cost of exactly the same coverage for * $200,000 M20J vs $200,000 Cessna 182 fixed gear * $275,000 M20K vs $275,000 Cessna Turbo 182 fixed gear

-

You make it sound like all airplane insurance policies are painted with the same brush. Retracts, fixed gear, fast, slow, piston, turboprop, jet - makes no difference. Everything is in the same risk pool and tied to payouts on 737Max and bizjet crash/writeoffs. I wonder why @Parker_Woodruff has told us many times that we pay a premium over similarly valued Cessna 182's. - why it is so hard for new pilot's to get Mooney insurance. And I guess the cost of gear-up repair is a big nothing burger to the insurance companies. - what do you reckon an Acclaim gear-up costs knowdays? - 90,000? $100,000 more? When discussing a $5,000 policy back in 2020:

-

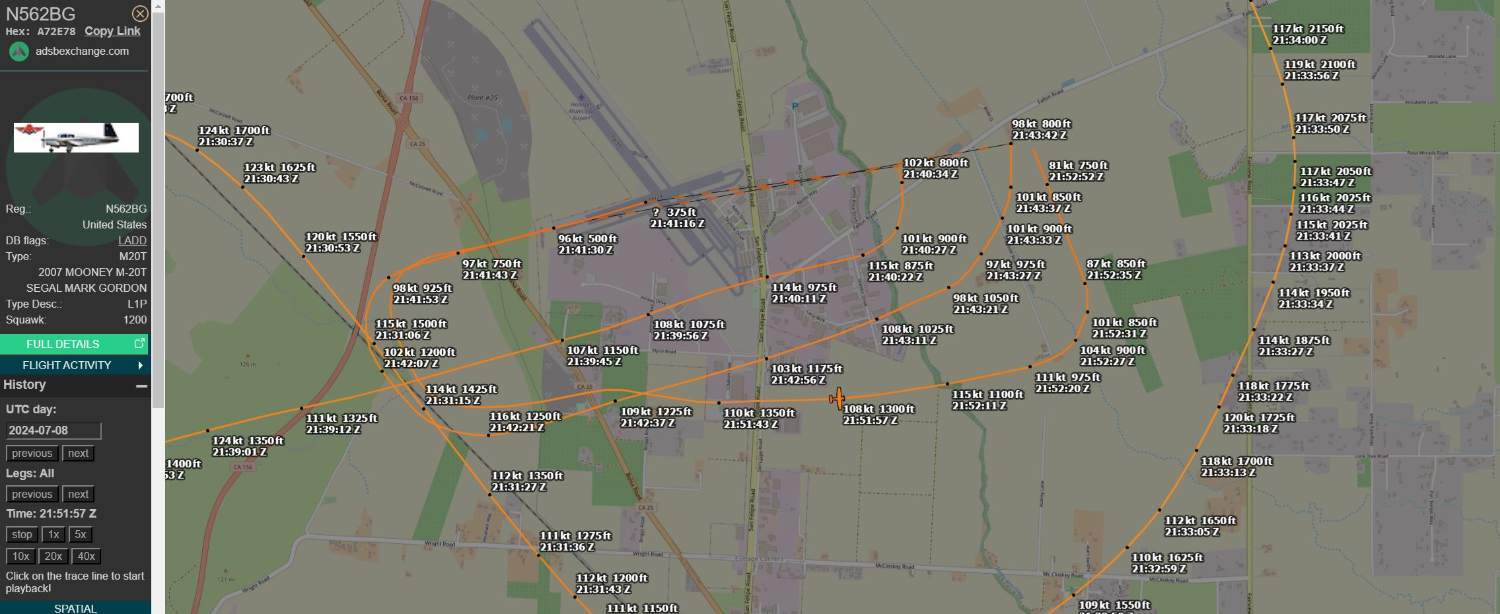

Right. The first two were with the same owner: 2012 https://asn.flightsafety.org/wikibase/287250 2014 https://asn.flightsafety.org/wikibase/198812 In the latest case, the current owner registered it in January 2023. https://www.aircraft.com/aircraft/200917055/n562bg-2007-mooney-acclaim https://www.aircraft.com/aircraft/200921111/n562bg-2007-mooney-acclaim The Instrument Rated owner, age 65 years per internet, if flying, departed Watsonville early afternoon and was at non-towered Hollister practicing landings. Although blocked on FlightAware, ADSBExchange, shows from time stamps, that it appears he flew a touch and go followed by a landing, taxi back and go. The third landing was a gear up. The prior day, July 7, he flew the same pattern at non-towered Watsonville (one touch and go, one land, taxi back and go and one full stop). The July 7 patterns look stabilized. The July 8 patterns, although not complete, make it look like he may have been struggling turning to base and had flown through the centerline on the second landing. Winds were crosswind 12-13 mph from the NW to WNW. On the final pattern he drifted well to the south east while on downwind to Runway 24. https://globe.adsbexchange.com/?icao=a72e78&lat=36.887&lon=-121.401&zoom=14.5&showTrace=2024-07-08&trackLabels×tamp=1635703215 https://globe.adsbexchange.com/?icao=a72e78&lat=36.927&lon=-121.780&zoom=14.5&showTrace=2024-07-07&trackLabels×tamp=1720394500

-

Seeing as how problems during the landing phase appear to be the biggest source of incidents and accidents for Mooney's, one would think that it should be the leading topic of discussion. Instead it seems to morally offend some owners to even mention it. It is very hard to know the actual rate of gear-ups, gear collapses, bounces which porpoise into strikes, overshoots of TDZ or runway excursions that result in damage. Many are not reported publicly. In order to discuss a solution one needs to know the rate at which it occurs and all the factors influencing it. If one finds it emotionally troubling to discuss the facts and circumstances contributing these landing phase incidents and accidents, then just stop reading about Safety and Accidents. Given that the 4 lead topics in in the "Mooney Safety and Accident Discussion" have not been updated in 6-7 years, it is clear that the entire discussion is not very popular and that many prefer a "head in the sand" attitude.

-

One cylinder hotter than the others, should I worry?

1980Mooney replied to AndreiC's topic in General Mooney Talk

You never mentioned exhaust temperatures. Do you have an engine monitor that measures exhaust temperatures on each cylinder? If so is #2 in line with the others? -

I think you are right. It is hard to find real world weights of full engines with accessories. Nothing official from Mooney or Lycoming that I can find. Some have posted anywhere from 540 to 590 lbs. dry. Compared to @snowman ‘s current IO-360-A1A, the Bravo upgrade adds 2 cylinders, turbo,intercooler, and TKS will require a second alternator. It will have a heavier engine mount/frame, heavier cowl and a possibly heavier prop (his F shows a 3 blade) hung father out. And although not specifically engine weight, that engine adds about 6-21 lbs of Charlie weights in the tail for CG.

-

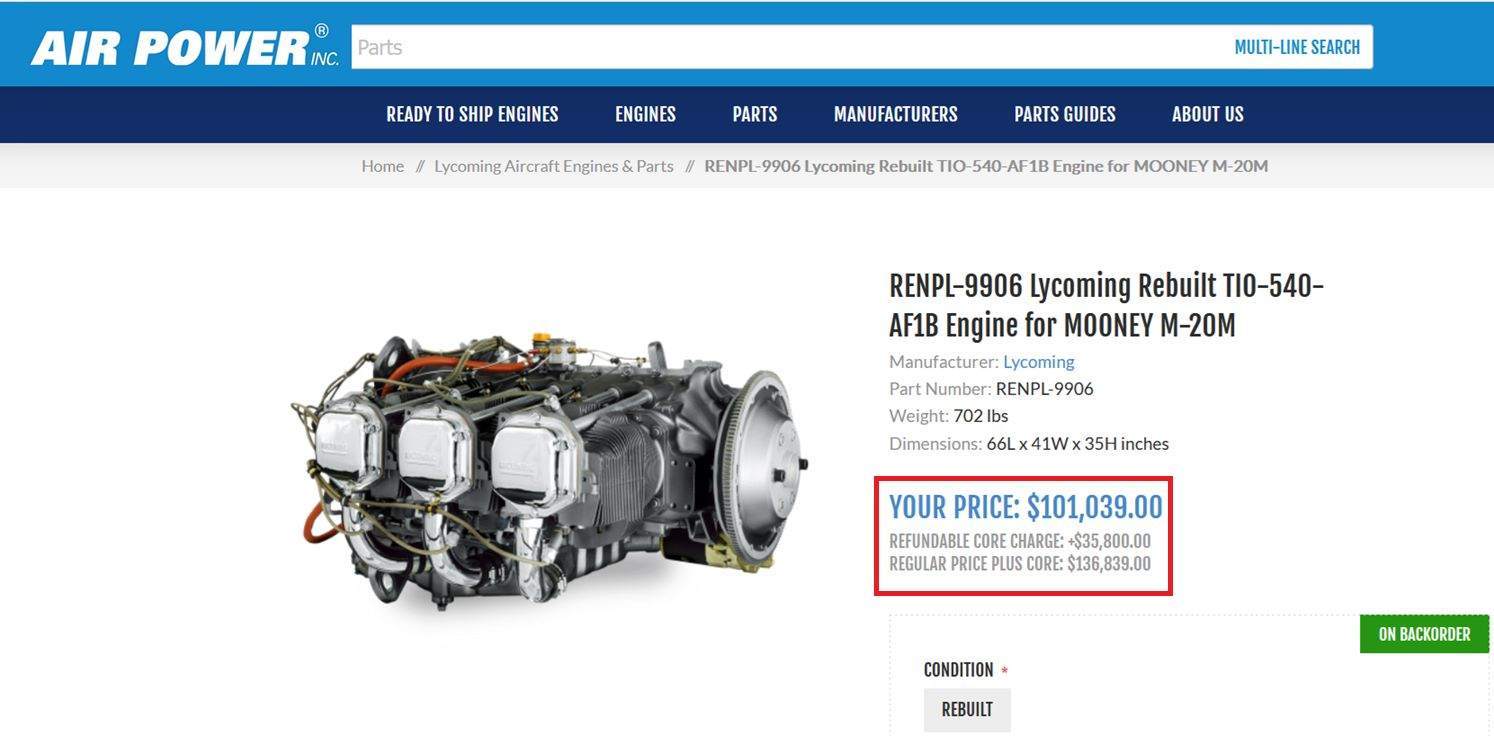

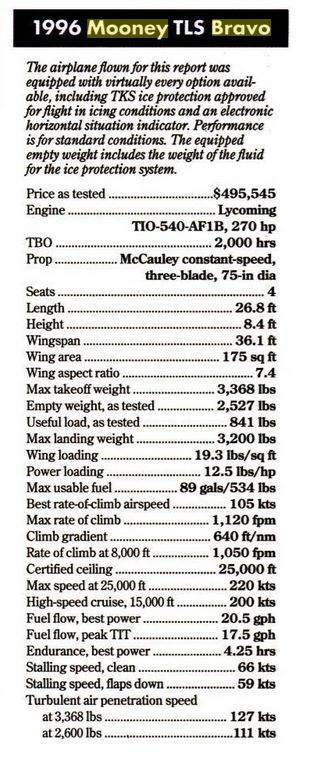

It is not just the extra cost to maintain the single turbo charger, it is just a very expensive engine. And heavy engine (702 lbs). Useful Load for a TKS equiped Bravo is 840 lbs. per Sept, 1996 Flying Magazine test flight of the then newly introduced TLS Bravo. With full fuel (534 lbs.) that leaves only 306 lbs. payload for passengers, crap on the hat rack and luggage. Just make sure to sell it before it needs major engine work.....

-

This may help. It shows serial number range by model by year. Mooney Model Chronology (mooneyevents.com)

-

It is possible to stay in business building parts for shrinking fleets. Like True Flight Tiger AA-5. But to do it you have to shrink or "right size" for that business. You can't continue to carry the overhead, insurance, legal liability, management of a company that thinks it is still a manufacturer of aircraft. Commander Aircraft was trying to do it for the 112/114 fleet, but they have now failed completely. About | True Flight Aerospace

-

Apparently, you missed this. Key Points: "We currently enjoy good margins manufacturing parts for several other aircraft companies: our main challenge is scaling up." 35 employees "I believe the future lies in composite technology, which allows for rapid production in molds" "Our plan includes refining existing models to build more efficiently and increase their useful load." Interestingly blames the Trump Administration trade wars for the inability of Soaring America (subsidiary of Meijing Group) to continue funding the business resulting in shut down of aircraft manufacturing. That means that Mooney remained a negative cashflow sinkhole with every Ultra that they built.

-

Except Mooney hasn't put a Lycoming in a Mooney in nearly 2 decades. The last Lycoming 4 was installed in the Mooney factory in 1998 and the last Lycoming 6 was installed in 2007. The Lycoming backlog at Vans is because those are non-certified low cost engines. It makes sense that Lycoming would give priority to their higher priced certified engine customers. I don't think that there is a 2 year backlog of Continentals.

-

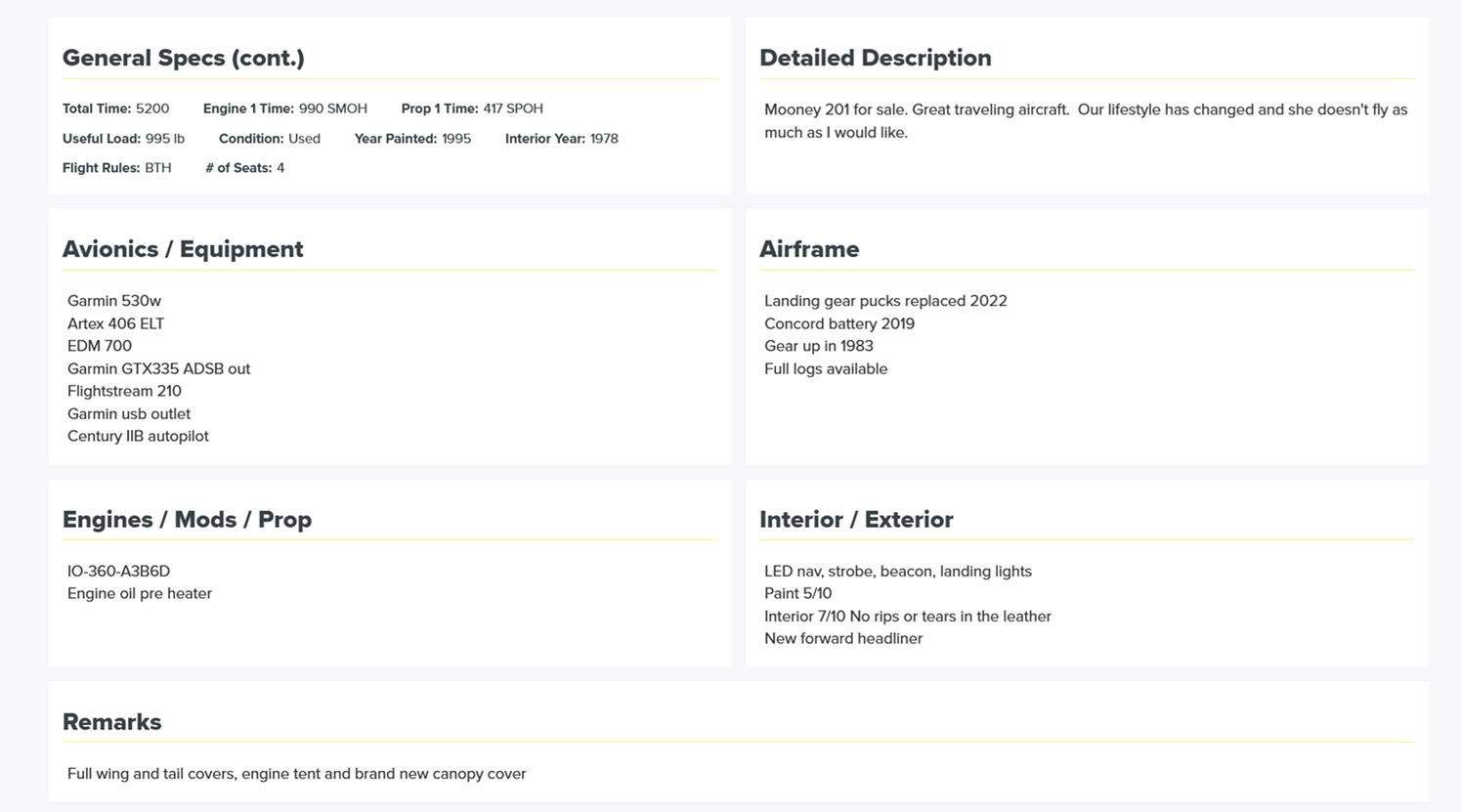

That is a great looking M20J. Resist any thought or comments from anyone here saying "never to early to start thinking about or saving for upgrades". Just learn to fly it, learn more about it, improve your proficiency and enjoy it for now. I also bought a used M20J long ago while working on my PPL. I finished the PPL with the flight school Cessna 172 while flying the Mooney with a Mooney instructor at the same time. Also start working on your Instrument as soon as time, money and life's interruptions permit. It is still on Trade-A-Plane. It looks nicely equipped. I see from the pics that it has Rosen visors.

-

Agreed - good comparisons are hard to come by. But results of the bottom line "acid test" are clear - (does more money come in than goes out) In mid 2001, when Mooney was building about 100 long-bodies per year supposedly efficiently (per VP. Ops Valencia article above) they failed the "acid test" and went bankrupt In late 2019, when Mooney had been building 10-14 long-bodies per year, (inefficiently per comments from Pollack) they ceased all production, laid off 229 employees, including all employees on the aircraft production and parts lines because they were failing the "acid test" and needed to stop the negative cash flow.

-

Think about it another way. Take a Cirrus SR22T vs. an Acclaim Ultra or a SR22 vs and Ovation Ultra If Mooney were building in volume and could get the same volume purchasing discounts as Cirrus what costs are the same and what are different. Same: Continental 550's Hartzell Props Garmin Avionics Tires - Goodyear? Maybe the cost/time to make a modern interior Different: Fixed gear on Cirrus (lower cost) vs Mooney retract (Eaton actuator high cost, etc) Parachute system (CAPS) on Cirrus Composite construction man-hours at Cirrus vs Steel welding, Aluminum fab/riveting manhours at Mooney. I suspect that the man-hours to build a composite Cirrus is much, much less than a Mooney.