-

Posts

210 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Pasturepilot

-

Where do they sell all those stolen Garmins?

Pasturepilot replied to Jerry Pressley's topic in General Mooney Talk

Someone will probably step in and say this would never work, because of (insert reason here) but an idea of how they might get away with these shenanigans. Make two raids. Raid one: Only hit birds with incredibly popular avionics installed. You can be ugly with this operation; if some metal gets bent no big deal. Hang on to the boxes nabbed from this trip for raid number two. Raid two: requires more precision, a little more surgical. Armed with the boxes stolen from the first trip, find birds with identical equipment installed. Swap the (assumed to be reported as) stolen box for an identical box. Don’t damage the planes, you don’t want anyone to think these birds were disturbed. The stolen avionics from the first raid would be reported, but with those boxes already installed, nobody would check the serial numbers against the database for a while, until they go in for service. By then the trail is cold, any fingerprints are long covered over and wiped away. This process doubles the effort required before making a sale, but might cover the tracks long enough. The boxes netted in the second raid, similarly, would have been sold and installed before anyone realized THOSE serial numbers were also stolen. Are database updates serial specific, or will they work on any box running the specified hardware? -

How to fix broken baggage door link

Pasturepilot replied to TravelVeteran's topic in Vintage Mooneys (pre-J models)

I mangled my baggage door link at Kitty Hawk last month. Technically, my wife did it but at my direction, so I claim credit for the kill. It bent over so the door wouldn’t open or close, and collapsed on itself covering the screw head I needed access to for removing the thing. Nothing like standing at the birthplace of aviation, with a giant rain cloud about to bust open, and me wrestling the thing loose with a pair of vise grips and a screwdriver. And of course, folks were hanging on the fence to see the flurry of activity on the ramp! Aircraft ownership is so glamorous. If the other sources don’t work out, you might also try Alan Fox. I thought mine was a lost cause but an afternoon with a hammer, an anvil, and a hydraulic press rescued my support and it lives to fly another day. -

Almost any technique you want for try will work on an o-360. I pump the throttle once, push it in again, and start it lean. Push the mixture in when it fires, and pull the throttle to idle. Nothing has to happen in a hurry. Arguably this may be the most forgiving engine ever for hot starts. If you’re having problems with hot starts, get a CFI in the plane with you for a shot. If they have any problem at all, you’ve probably got an ignition problem. I've clown a number of injected engines, some of them hopped up way beyond Lycoming’s wildest dreams. Only time I sweated hot starts was on a four cylinder Lycoming pushing 280 HP. A well serviced ignition system and a decent carb should fire up easily. Hot, cold, any condition.

-

@Cchilton, where in Georgia is your bird? I’m on the north side of Atlanta. A&P, C model owner. If anything mechanical hampers your lunch to move home, holler. Happy to help mount a rescue mission.

-

Hey friends, I just flew a four-day trip shuttling folks between Newark and the Dominican Republic. On the last day, they let us fly over dry ground... to some very dry ground. Phoenix, if we're going to be specific. I was supposed to be deadheading back to NYC but it was the end of the trip, so I chose my own adventure and stuck out my thumb for a direct ride home on a Delta jump seat. Another pilot showed up, also looking to hitchhike and we were chatting at the gate when I made mention of traveling in the Mooney. The guys eyes lit up. "What model?" An old '65 C model, I said, and started rattling off the basics but I didn't have to. This fella has an E model. We chatted at the gate for a while - and for most of the flight back, as we compared ownership notes. He said he signed up for mooneyspace but had never bothered much with it. I think he'll probably make an appearance soon after it became apparent how much good information is here. Without this support network, he and his mechanic were apparently unaware of the CiES fuel senders - they'd hooked up a JPI EDM-900 to the old senders and were getting the same bad fuel management data as before. Other topics that came up were instrument shops that can overhaul stuff for a lot cheaper than running out to replace a busted gyro, how to repair interior plastic pieces, PC system repairs, and Sensorcon CO detectors. Then I realized before I dug into the stacks here, I didn't know squat about these things, and I've been kneed deep in aviation since before I could drive. I'm grateful for y'all, and for the resource we have here. We now resume the normal banter.

- 16 replies

-

- 18

-

-

-

I made the 500' callout my trigger for a last check. It's a holdover from about 6,000 hours of flying with a similar trigger/action. So "500' AGL" on foreflight now triggers a callout to me of "No Flags, Gear Checked Down, Cleared to Land" Makes me check the CDI to ensure I'm getting a good signal if on an instument approach, green light on the panel, and that I have landing clearance if at a towered airport. Foolproof? no. But a step in the right direction.

-

Best speed upgrade for 64 M20 E

Pasturepilot replied to Pilot boy's topic in Vintage Mooneys (pre-J models)

With decades of evolving modifications between the models and STCs, our birds are all over the W&B envelope. But take a good look at your setup and see if a little weight aft will help. If you can push the CG a little aft, it helps. I don't have any precise numbers for you as far as a fwd/aft CG's effect on speed - maybe someone here will have those for you. But it does have an effect, and it's the cheapest speed mod you're going to come across. See if you can find ways to make the weight productive. Lead bricks would likely have the smallest footprint in your baggage bin, but they're not useful for much other than ballast or as chocks that won't float away in a monsoon. A good toolkit could save your day if you blow a tire tube or badly foul a plug on a cross country trip. One of my long term goals is to build up a small pelican case or similar with a good foam insert to hold tools securely in place. I flew back from the Outer Banks on Friday with a screwdriver, a pair of vise-grips, and the mortal remains of my baggage door hold-open latch rattling against each other in my tool bag. I was worried half to death something had just added itself to my project list until I figured that one out. -

Another useful tool for removing screws is a speed handle. Get one with a knob instead of a cylindrical grip. That way you can use the palm of your hand to apply pressure instead of relying on a firm grip. The speed handle (also called a speeder bar) has several things working in its favor: By changing out screwdriver tips frequently, you'll have best grip. And because you're applying the forces manually, you'll feel if it starts to slip before you've spun a couple revolutions and ruined the screw. Electric drill motors are handy for running screws, but they can cause hours of extra work if they strip out a couple screws. Several shops I've worked in over the years forbade the use of electric screw guns for that reason.

-

It's too late for this, from the looks of things, but if you use a dental pick, you can often clean the paint out of the head before you start trying to remove these kinds of screws to lessen your chances of stripping the heads. Also, a dab of valve lapping compound will sometimes add just enough grip to help.

-

Seeking a source: PC System Nyla-Flow Lines

Pasturepilot replied to Pasturepilot's topic in Vintage Mooneys (pre-J models)

Isn’t that what this forum is for? I mean, other than armchair quarterbacking Mooney’s business choices and making amazing claims at speed and efficiency? -

Seeking a source: PC System Nyla-Flow Lines

Pasturepilot replied to Pasturepilot's topic in Vintage Mooneys (pre-J models)

Quick follow up. Picked up my tubing yesterday finally. Work got all sorts of in the way of my projects. Replaced the red line from the baggage bin, through the left wheel well, and out to the actuator on the aileron. It had two cracks I noticed as work began (one was the one I saw and taped for test before) I found more splits as I worked, but whether they’d been there all along or I was just tearing the line to pieces as I tried to replace it, doesn’t matter I suppose. Tip for anyone replacing their wing line: a dowel or drill bit inserted into the line and given a good wrap of electrical tape can serve as a snake to pull through part of the wing and save opening panels. My wing had no clamps or tight grommets between the actuator and where it passes into the gear well. I could have performed this trick opening the inspection panel just outboard of the gear well and the one at the actuator. Instead, I gave my screwdriver a good workout. Once you’ve got it to the gear well, you can pull through easily and then use the snake method again to make the first turn as it enters the belly. I can’t save anyone much labor from the gear well inward. Turning the corner as it exits the wing into the belly, that line turns aft, and then up into the baggage bin. You’ll want access to the line wherever you can get to it I’ll eventually get all the lines changed over. Quick hop to the nearby concrete runway showed the wing leveler acting with a lot more authority in light turbulence than ever before. Trim knob on the yoke can certainly affect a turn in either direction. Slowly but surely, we’ll get there. (Projects, I mean. When the engine is running, we get wherever we’re going right quickly). -

I think @Andy95W got your answer. Looks like an altitude encoder. Chase that cable and see if it goes to your transponder.

-

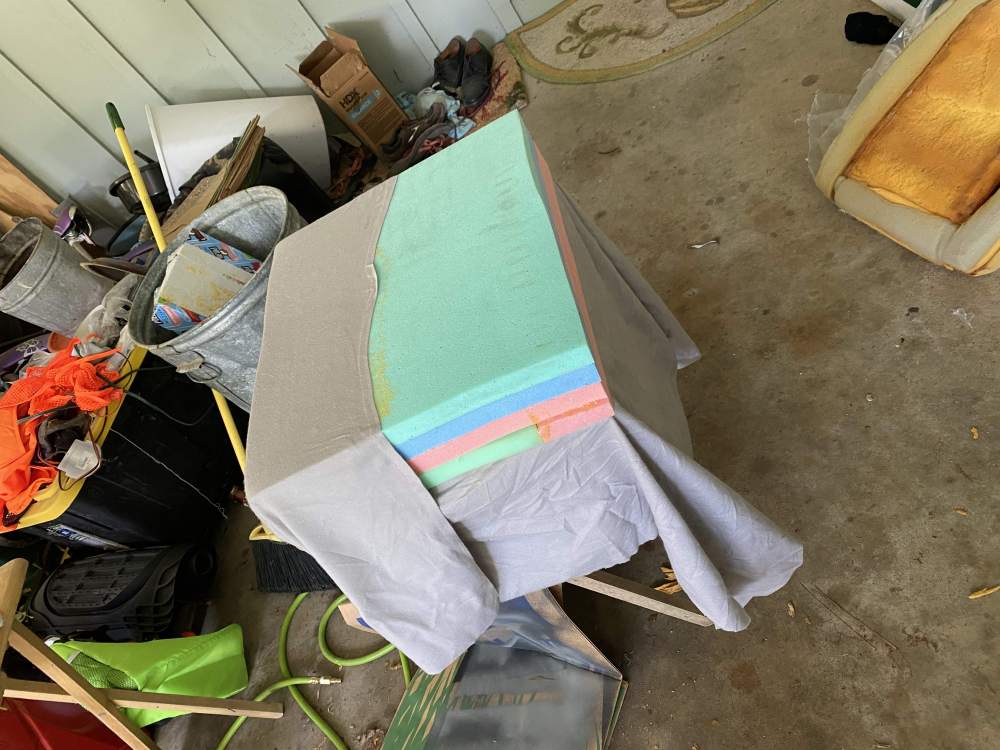

Refitting seat foam: Confor buildup

Pasturepilot replied to Pasturepilot's topic in General Mooney Talk

DAX was a contender. It all came down to what I could get my hands on to knock this project out before I went back to work. The seat covers are held on with plastic retainers so if I wind up unhappy with them, it’s not hard to re-do. -

My normal flights are rarely more than two hours. I recently pulled a three-hour leg headed to central Florida and realized just how horrible the foam is in my front seats. As the flight bore on, the foam pancaked below me and left me with almost no support -- it was trying to dump me into the gap between seats. I poked around a couple websites that sold Confor (the new name for Temperfoam) memory foam material, but ended up just driving to Spruce. They've got a sandwich of firm/medium/soft that is almost exactly the dimensions of my seat bottom, but lacking a little for height. I bought two of the sandwich blocks and a sheet of soft to add to the top. 3M Spray 77 is a very popular spray adhesive for foam and fabric - and in fact I had a can left over from a car headliner project. In researching this project, it turns out that 3M Spray 74 is actually what you want to use with memory foam though. It ain't cheap but one can got me through the project... just barely. Of course I had to test-drive the foam on my ride home from Spruce! My seats did not seem to have any bolster contours - they were simply flat slabs, so I didn't get as carried away with all the carving, sanding, and shaping that others might have to do. Once I pulled the leather cushion off, though, I did see that at some point, there probably was some contour shape present, it'd just sort of faded away. And, there was a spring on the left and right sides of the seat pan to offer some bolster-type shape/support. I wrapped the springs with webbing to keep them from wearing through the foam. I cut a line into the bottom of the foam, completely through the bottom firm layer and partly into the medium, allowing it to push the sides up a little. To add to this, I ran about a 3" perimeter around the top of soft Confor. It was pretty comfortable but I would need to find a way to either pull the center of the seat cover down, or fill in the middle to keep from having saggy leather syndrome. I found a square of very soft old school foam in the shop and just used that to fill the gap. Reading that air and UV are the enemy of foam over time, I sprayed the cushions with the last of the adhesive and wrapped them in fabric. Not air-tight, not lightproof, but it is a little extra protection and helps to hold everything together. Pulled the cover back into place, and boom. We're in business. It's not the most beautiful fix ever - the front lip is a little more squared than the old one. But you can hardly tell with seats installed. I'd sat on the seats for several hours as I made up the cushions and put the covers back on at home, but wasn't prepared for the difference in the plane. I'm sitting probably a good inch and a half higher, and it makes a huge difference. It actually feels like a slightly larger plane, if that makes sense. I've only flown a short hop to try it out, but it's a bazillion percent better than it was. 10/10 would recommend.

-

Seeking a source: PC System Nyla-Flow Lines

Pasturepilot replied to Pasturepilot's topic in Vintage Mooneys (pre-J models)

I emailed Cecilia. She's a godsend. Got a quick reply. Here's her response: "The tubing is manufactured by Parker, now called "poly-tite". The 3/8 part number has changed to E64 and I believe the 1/4 is now part number E43. I used to purchase it from Fluid Specialties of Tulsa, Oklahoma, maybe give them a try." I searched the Parker website and came up with this: https://www.parker.com/parkerimages/schrader/cat/english/FRL4J004.pdf Page one, that table on the right is what you're after. In case the link is broken one day, here's the part numbers you're after: 1/4 tubing: E-43-R is red E-43-G is green EB-43 is black. 3/8" tubing: E-43-R is red E-64-G is green EB-64 is black The catalog has -0100 after all the above part numbers to denote a 100-foot length. I thought I was gonna end up with spools of the stuff, but the Parker stores will sell it in whatever length you need. We have a network of Colliflower/Parker stores here in Atlanta. https://www.colliflower.com/ I dropped by the store in Douglasville yesterday, and the guys there were great. They had plenty of black hose but not the colored lines, so that's on order and will be waiting on me when I get home from the present trip. It's all like 20-40 cents a foot.Looking forward to my plumbing project soon! Hope this helps in case someone else wants/needs to patch up their bird. I know I've got the one leak in the wheel well, I figure I'll end up finding a few others as I begin replacing the whole collection of lines. -

I missed the part about 15 minutes of normal operation before it headed off onto the weeds. Mine was having left banking issues constantly, but only barely so. I used to have an attitude indicator that did that after an hour or so.... it’d start a slow diving turn although I was level. That may well be a failing TC but I have no knowledge of those. My PC and TC are independent.

-

Hey friends, Came back from a little jaunt to the training center to get my three bounces in the Airbus (sim) and had to pull the button in the yoke. Had a slow pull to the left that overpowered the roll trim knob. As I had the seats out to refresh the seat bottom (Highly endorse this action and will post a separate thread in a day or two), I popped the sidewall off (again, just had it off for annual/refinishing and feared I'd put a screw through a vacuum line). No joy there. Figured the failure was a red line leak out to the left wing after I'd checked all five of the actuators. Yep. The line passing through the left gear well is cracked where it passes through a rib. I'm fairly certain this brittle old line got bumped while I was doing my repaint of the gear well and cleanup in there. I wrapped it in electrical tape and hooked up the shop vac. Works like a champ. Here's my question: Is there a source for the colored nyla-flow lines? I see Spruce has clear ones. Is everyone running clear lines and marking them with colored bands or something? I'd be fine with that route, but if I can track down the properly pigmented lines, that'd be preferable. I need all the help I can get to keep from crossing up those lines. Anyone got sources? Thanks.

-

Tempest fine vs massive w long electrode

Pasturepilot replied to bonal's topic in Vintage Mooneys (pre-J models)

I went with BYs on the bottom a few weeks ago. They certainly load up a lot less now. Figuring on fine wires up top next year, then rotate them to bottom once the BY's start to wear, and run fine wires in all positions from then until overhaul. I'd have gone with fine wires all around, but I'm minding my pennies right now. Pandemic and all - haven't been to work since March. A side note, for doghouse-equipped Mooney owners: I noticed at annual that my spark plug socket wouldn't fit the spark plugs installed, and for some reason the ignition leads were pretty tight against the doghouse roof. I scratched my head and wondered how in the world something like that had changed in the years since I had been away. What HAD changed, is someone had installed Tempest spark plugs. The barrel/top insulator is just a tad longer than the champion spark plugs. In any other make of aircraft, it's probably a non-event, but on my C model it had the leads pushed up against the doghouse. I had one plug that had to be replaced and I just grabbed a Champion from my local supplier. Once I had the two side-by-side the difference was obvious. a UREM40E and a REM40E might be interchangeable but they're not identical. -

I started to work up a progress report, but realizing there’s still plenty of time for this to go south and become a “don’t do this” saga, I put a pin in it. I’ll update once it’s finished. Waiting on some adhesive to show up that I couldn’t find locally.

-

Thanks for chiming in, everyone. Our back seats look beautiful considering the interior is 25-30 years old. The seat backs up front are okay, but the front seat bottoms are showing their age. So is the foam. I'm headed to Spruce in the morning (Atlanta has its drawbacks but driving to Aircraft Spruce ain't one of them) to buy some Confor foam to rebuild the seat bottoms. If I can get that to where I'm happy, I'll combine the experiences here to come up with a plan.. A year into ownership, I'm still chipping away at bigger issues but if I can get the seats a little more comfortable and better looking for a couple hundred bucks, I can afford that detour. Thanks again, y'all. Love the brain trust we have going here.

-

I think it boils down to not having a ton of great airports on the north side of Atlanta. I live within the PDK class D ring, but cannot justify hangar rent there so I drive an hour west of ATL to my Mooney's home. If the guy lives north of Atlanta, the balance of airport/topography/hangar cost probably drove him up there. I have multiple friends and acquaintances with deposits down on the Raptor. While I'm always happy to cheer for the underdog, I've seen too many "too good to be true" airplanes fail to deliver - or worse - after promising low cost and astronomical performance. The Commuter Craft Innovator also comes to mind, and it ended with disaster several months ago. Here's hoping to see more good news from Cherokee County soon, though.

-

Excuse me for breathing some life back into this thread. My front seat bottoms are looking a bit tired. Looking to replace the seat bottom foram (and maybe the backs) with Confor (Temperfoam), but was weighing various methods to care for aging leather. Can anyone here give a PIREP for how the Leatherique holds up a few years after application? I'm hoping I can push a full interior re-do for 5-7 years. Gonna tag @KSMooniac for good measure here. Thanks, friends.

-

I'd go fly with you, but all you would learn is the bad habits. Oh, edit: You need a CFI for insurance. I wouldn't be any help at all, then.