-

Posts

168 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by brndiar

-

Garmin GFC 500 AP for C, D, E Mooneys

brndiar replied to Greg Ellis's topic in Vintage Mooneys (pre-J models)

I considere upgrade with G5+ GFC 500 Autopilot. Which Navigation Panel would you recommend? GTN 650? Any recommendations? How much would be approximately upgrade cost (hardware + labor)? P.S. 1977 M20C with Engine after TBO + New Prop (ca 50 Hours) thanks, m. -

Hi Please, how much is 10 Degree according to artificial horizon? Did i mark the bottom lines correctly (10,20,30 degrees) ? thanks in advance, m.

-

-

Hi I am looking for Amplifier Servo for my Pathfinder P2A autopilot. There is short circuit in my Servo (the fuse pops up after connection). Contacted my electronics shop, they can´t fix it. After last reparation my Pathfinder P2A autopilot worked for my cca 150 hours. Eventual don´t you have idea what could be wrong and how to repair it? Thanks for any help lg, milos

-

LASAR Oil Cooler Replacement and Guppy Cowling Mod

brndiar replied to hmasing's topic in Vintage Mooneys (pre-J models)

-

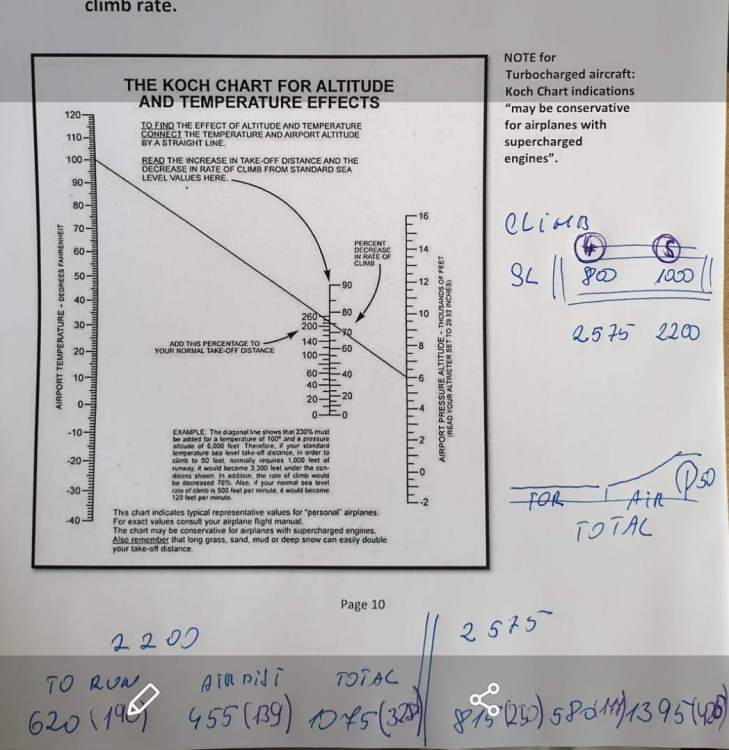

I recently did a takeoff with flaps up at MTOW. .... Concrete RWY, cca 6500 ft long, 25C OAT, Airport 2500 at ft altitude.... slowly rising terrain in the direction of the start..... ...I will never ever start without a flaps at MTOW, regardless of the lenght of the RWY..... lg, m

-

A good thread to the topic: m

-

LASAR Oil Cooler Replacement and Guppy Cowling Mod

brndiar replied to hmasing's topic in Vintage Mooneys (pre-J models)

On the first picture is my idea how to improve the air flow around oil cooler. Picture 2- Important is seal the gap around the starter. lg,m -

LASAR Oil Cooler Replacement and Guppy Cowling Mod

brndiar replied to hmasing's topic in Vintage Mooneys (pre-J models)

Hi. Climbing from cca 3000 ft to 8000 ft yesterday. At the airport (cca 1300 ft was 30 grad C), full power, solo. The engine is 30 Hours after overhaul, new oil cooler, installed Lasar cowl fairing. P.s. never had problems with high oil temperatures with my M20C before repair. On my Zenair Zodiac experimental UL I was trying years ago to solve marginale oil temperatures (of course Rotax engine with water cooled heads, engine with gearbox and dry oil sump...). I changed all available oil coolers, from small to large (available 3 types S,M, L) without significant success. The best result was achieved, wenn I modified the airflow around the oil cooler with deflectors. The airflow around cowling is without sensors ``known unknowns" and is sometimes not according to our ideas. Hopefully not off topic. lg,m -

CYA -100 could be programmed. You have 10 LED diodes which can cower AOA range according to the pilot setting. Wane have resolution of 0,35 degree over a user programmable range of 0-360 degrees. System is easy reprogrammable. Theoretically you can set upper point at VNE and lower point at VSO. However such a setting (personally I didn't try yet) would not be practical, because bei such a setting 16? degrees of AOA would be covered with 10 diodes available on the indicator. When setting a smaller range (VSO ... Vx oder VSO ... VY oder VSO ... Vg) the indicator would be more accurate (till resolution of 0,35 degree). At angles above upper point only top green will be illuminated. Between two set point of AOA only one of 10 LED will illuminate. At lower point will red LED diode start to flash ( clearly visible with peripheral vision) and should be set before horn (in landing configuration) goes on. I would like to have color change at VSO 1.1 and VSO 1.3 so that i do not have to focus repetitively my eyes from distance to indicator and back and indicator could stay covered with peripheral vision only. There is optional audio output from the system und system will operate over voltage 7-35 V DC. Advantage is that performance speed like Vy, VX, Vg occur at fixed Aoa independent of weight or loading. lg,m.

-

Hi, In my opinion "alpha device" should be located within our peripheral vision. For me location next to ASI and below "Pizza piece" of windscreen is ideal, because here i transition my eyes before touchdown. Display is color-coded and transition from one color to another clear visible when perceived with peripheral vision (change from yellow to read at cca 1.1 VSO and from green to yellow at 1.3VSO - at least that's how I would like to have it). The "green up" was in installation Manual (which direction is needed to push-"command" instrument?) . There are indicators from other manufactures with red at top (video below). lg,m

-

I let the CYA 100 angle of attack indicator system mounted on my Bird during Annual (do not have a bill yet). Upper point I set at 75 knots (Solo, no baggage- theoretically between Vy and Vx) and lower point just above flap power off stall. Vso 1.3 should be right where the display changes from green to yellow, Vso 1.1 where it changes from yellow to red. Did "slow flight" exercise in altitude, steep turns, couple of "slow flights down the runway", together 2 hours. I do not have much experience yet, but I was really impressed how quickly it goes from yellow to red. Mainly interesting to me was to see how close to eternity we are in steep turns with airspeed in green. Easy to imagine what happens in uncoordinated sharp turn in stress. Lg, m

-

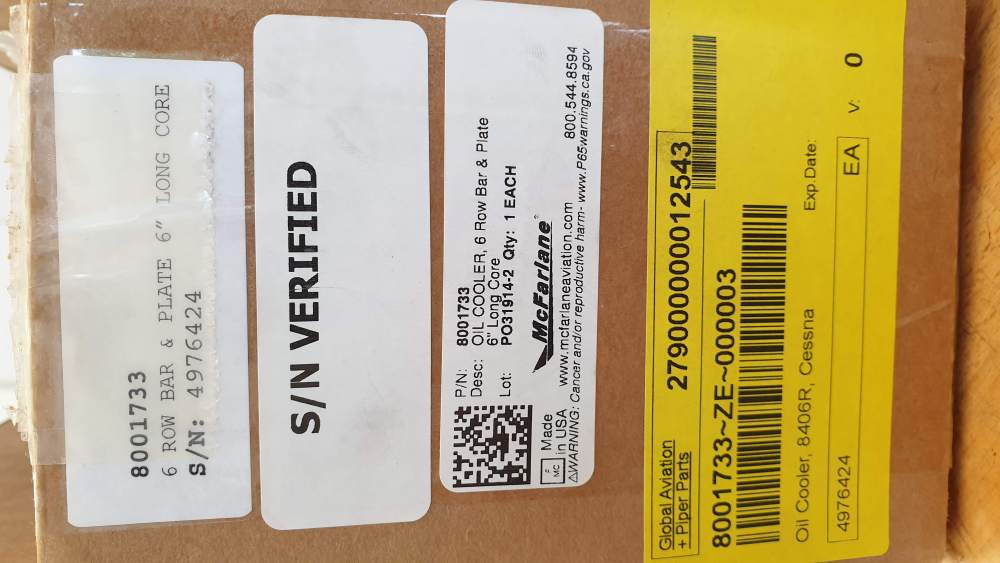

My 43 years old & new oil cooler. P.s. even with old one I did not have a high oil temp. Issue. (1977 M20C). Lg, m

-

+20 year old donuts (1966 M20E)

brndiar replied to Matt Ward's topic in Vintage Mooneys (pre-J models)

Not so bad, younger than me!!!! -

+20 year old donuts (1966 M20E)

brndiar replied to Matt Ward's topic in Vintage Mooneys (pre-J models)

I was under my 77 C, took these pictures. It is possible (on the basis of code) to say the year of production? Thanks, M -

Noise Certificate M20C with 3 Blade Hartzell Prop

brndiar replied to brndiar's topic in Vintage Mooneys (pre-J models)

74 " in Diameter= 187,96 cm in Diameter. At 2700 RPM speed tip is: 3,14*1,8796*2700/60= 265,59 m/s. Sound travels at 343 m/s in air. lg, M -

Noise Certificate M20C with 3 Blade Hartzell Prop

brndiar replied to brndiar's topic in Vintage Mooneys (pre-J models)

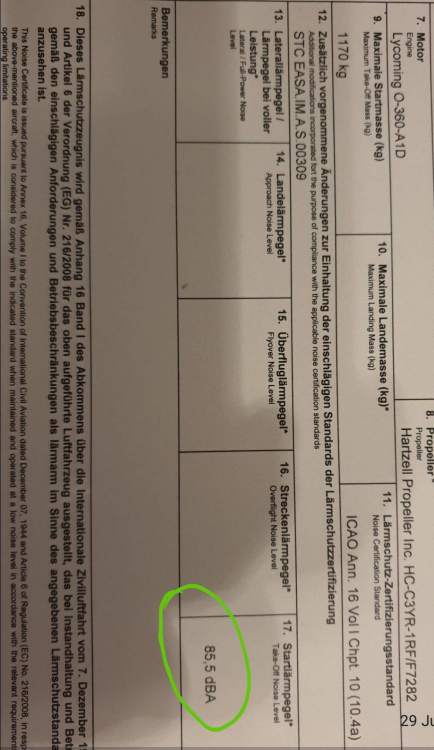

Hi, From Hartzell I got a link to EASA database https://www.easa.europa.eu/domains/environment/easa-certification-noise-levels and explanation: "Whatever the reason, for the listings in the EASA noise level archives, you can bet that we had nothing to do with it. Here’s what I can tell you about it Prior to 1988 noise was measured at 1000’ AGL (overflight). In FAA speak, this was FAR 36, Appendix G. EASA, or more specifically the Authorities that preceded EASA called in ICAO Annex 16, Chapter 6. After 1988 both organizations changed to a noise measuring system that took take-off and climb performance into account. The better a plane climbed, the higher it would be at 8200’ from where the airplane started rolling, and the microphone is set up. This Take-off method is called FAR 36, appendix G, or ICAO Annex 16, Chapter 10. I can tell you that Hartzell never tested a M20C with any prop on it for the FAA or EASA. Both of these prop TC/STC’s were validated in Europe well before EASA was established. Hence they were grand-fathered in without any noise testing on our part. The note that EASA has pertaining to the three blade entry is “”9/24/201 Engine designation revised”. Looking at the numbers themselves, the Chapter 6 numbers are on props that were TC’ed. Maybe these numbers came from Mooney from the TC process? I can only guess. The 7282 three blade is approved on an older STC. In 2010 we added eligibility for the Powerflow exhaust to the STC. The only thing I can think of is that when Powerflow applied to validate their STC it must have initiated some noise discussion. If you will note, 85.5 dB(a) is the maximum allowable under Chapter 10. That seems like allot for un untested unit that is the same diameter as the two blade?? So, to get to the bottom of your questions, The props are the same diameter. They should be about the same noise-wise, except the 3 blade climbs better (CHAPTER 10). The numbers in the archive compare two 74” props at the same RPM, using two different methods, one of which may be considerably closer to the mic, and the Chapter 10 listing is as high as it can be to pass. It seems almost arbitrary?? The three blade certainly is not 10 dB(a) louder than the two blade." lg, m -

Hi, Please, what should be a Take -Off Noise Level for M20C with Lycoming O 360A1D and new 3 Bladed Hartzell (HC-C3YR-1RF/F7282) Prop? I replaced the original, old 2 bladed Hartzell HC-C2YK-1BF/F7666A-2 with the new 3 blade Prop. Unpleasant surprise for me is a new Noise Certificate (Foto) with 85,5 dBA, while in the old one there was 75 dBA. According the Hartzell Page new prop. should dramatically decrease noise. lg,m.

-

Hi, Unfortunately during engine overhaul (Lycoming O360 A1D) the old (I think) Prestolite starter motor was not overhauled. Last time worked at "second attempt" and now is not working any more. Please advice regarding replacement. Thanks, M.

-

AOA is difference between where the plane points and were it flyes. Just a battle of the words. For me, the biggest problem is, that people take their two dimensional 1 G world in air and consider the turn as a a change in heading over the ground. Something like to drive a car, they want to fly "level". For a plane a turn is any change in the velocity vector of the airplane. When we pull up the nose, that is a turn because the airplane is now flying in a different direction. When we push, that s also a turn. A turn is always accomplished by changing the lift being produced by the wing. And here is, where problem arises. lg,m,

-

Hi, when you are in descent, relative wind is from below, AOA rise. lg,m

-

Good analysis of one accident from AvWeb. m