Tcraft938

Verified Member-

Posts

201 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Tcraft938

-

That's exactly what my AP/IA was saying and seriously contemplated doing. However, he wanted the adjustability so I could put them in a few positions and see what works best before pinning. "Before you spend $500 on a used cable that will likely break soon, lets see if having the thing really does much benefit, it must be Mooney found it didn't, or they made other changes to the cowl and/or doghouse to improve air flow". He feels the front cowl enclosure is probably better benefit for the $500. The other confusion I/we have is my Mooney is technically a D but was converted to retractable gear, it's basically a C. The manual says on the D to adjust the cowl flap opening almost 2x wider than on a C. When we had everything apart for the engine install, he put it to the D specification because that is what the plane is and paperwork does not say to change. Plus he was thinking new engine, hot cylinders, summer, climb, open more gives more cooling if needed. However the difference between the two settings is maybe 5 degrees if that. Where they REALLY help more is on the ground/taxi if ATC does not get you out right away. Fortunately most of the controllers at KROC are pretty good about it. Have two that on first flight with new engine, I asked ground to let me know when they thought I could taxi straight to runway and go, I would then start up. Those two controllers to this day remember that and usually try to not have me wait for anything and ask, "how's that new engine doing"? Of course reduced traffic of COVID helps.

-

It's a real old style cessna type cable/knob with no lock to it. However the cable/knob do not move from where I have it set in flight. In other words, the cowl flap is not pushing the knob out when it opens. I am able to push the knob in in flight pretty easily but the flaps are not moving while in flight. So I think the cable just bends or kinks. On the ground it does not take much force of the knob at all to smoothly move the flaps open/close. It's just that in the air, what I do with the knob/cable has no affect on the flaps, the stay open. The parts catalog does not show mutliple holes in the arm, just that the flap rods go at the very end, which is where mine are. The catalog does not show the spring I have either. The spring seems to hold tension in the up/flap closed position. Not the greatest pic, but if you look at bottom panel left and below throttle can see a little of the red knob that looks like a late 60's cessna 150 mixture. You don't twist it, nor does it have a lock button. When I get to the hangar I can try to take better pics of it and inside the engine compartment. Thanks for looking at it and comments

-

Thanks, but I checked that. I can move the plane a bit and they don't budge. Also the entire motor mount was blasted primed and painted last year for engine install and there is no signs of the cowl flap mechanism moving. I read on another thread that they all open in flight a little. But it's only going to get colder here in Western NY, and on a 48 degree day cruising with CHTs in the 260-275 range seems crazy low.

-

Plane is a little slower than this time last year and CHT's are running about 30-30 degrees lower. Used a friends GoPro Cam on the wing and saw that if I close them at top of climb, slow airspeed they close slightly but when get near cruise speed they open up the same or wider than when I put them in open position. It must be incredible pressure that builds in there because on the ground I would need to REALLY pull on the cowl flap to force them open when in close position.

-

I've seen a lot of write-ups on rigging the system, but I have a different twist. I noticed in flight my cowl flap doors open cruise and they open quite a bit. As a result CHTs are in the 270 range. We have insured they are rigged properly by the Service Manual and posts here. On the ground they open the prescribed mount and shut with a little snap. The handle/cable in the cockpit is not changing, so their opening up or not shutting is not changing that. However, I am question one or both of two items on the plane. First, the cowl flap push pull knob in the plane is not like what I see in pictures (silver knob with push button in the middle). What I have looks to me like someone put in a C-150 mixture pull knob/cable. So I'm wondering if as inside the cowl builds pressure that thin wire can't hold the actuating arm it connects to down and it just bends allowing everything to go to the open position. The other consideration is there is a long thin spring that runs from the right seat footwell to the pivot arm that connects to the cowl flap push rod. It appears the spring is there to provide tension to the arm to hold it in the flap closed position. Perhaps that spring over 57 years has become weak and not the tension it was designed to give? If you have time, what are your thoughts on my thinking, and any suggestions on a proper cowl flap pull cable? I'm not demanding the exact one that would have come with the plane, but even a correct size/strength replacement. Thank you

-

Houston we have a [dead cylinder].

Tcraft938 replied to the_elkhartian's topic in Vintage Mooneys (pre-J models)

What causes the cam pitting? Is it lack of engine use? Improper oil? Combination? I should have asked that question at OH when I was told/showed pitting on my cam, so new was installed. Thanks -

Carusoam, I'm honored. A little over a year ago I did not know much more about Mooney's other than I wanted one that would fit my budget. In a year of Annual, Maintenance and Engine overhaul I have learned a lot thanks to MS, Don Maxwell and my A&P teaching me along the way. The greatest thing I've learned, is there is MUCH more to learn and I don't know what I don't know and that will likely be what bites me. I'm glad I could finally contribute back to the MS community. Trust me, if I can change the oil and filter carefully and methodically in a about an 90 minutes someone with skills could likely train their dog to do it in 20 minutes. :- ) To make sure I don't flub something up, I take pictures on my phone of several angles, then when done, I compare what I see to the pics. That usually means I end up doing the safety wire a 4th or more time. I know my AP will ras me about a sloppy looking wire job.

-

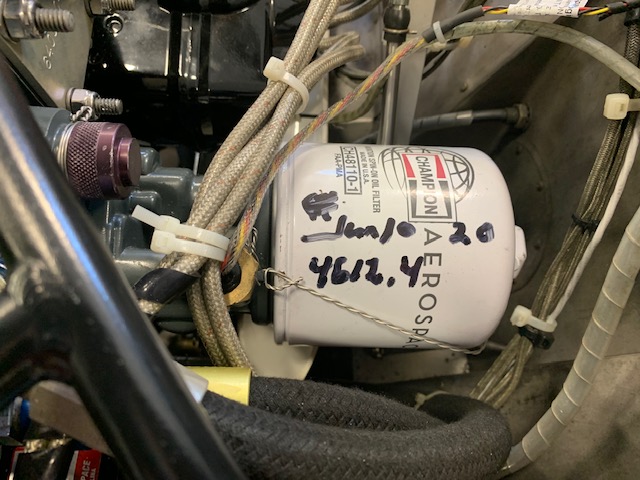

Here's a better pic of filter. about 3" of room to the firewall. Get a 2" by 3' section of PVC pipe, cut in half and bevel one end about 30 degrees, carefully slice through the hoses and wires so it's wedged under the filter and you won't spill a drop in the engine compartment. My A&P has a flexible setup that he can get under the battery box and he just opens the pilot side cowl. He amazes me what he can work on without seeing it. Yes he uses mirrors and scopes to visually look at things and inspect his work. Fortunately, he enjoys the challenge and design of the Mooney so doesn't get frustrated easily or take the frustration out on my wallet.

-

Here's a better pic of filter. about 3" of room to the firewall. Get a 2" by 3' section of PVC pipe, cut in half and bevel one end about 30 degrees, carefully slice through the hoses and wires so it's wedged under the filter and you won't spill a drop in the engine compartment. My A&P has a flexible setup that he can get under the battery box and he just opens the pilot side cowl. He amazes me what he can work on without seeing it. Yes he uses mirrors and scopes to visually look at things and inspect his work. Fortunately, he enjoys the challenge and design of the Mooney so doesn't get frustrated easily or take the frustration out on my wallet.

-

Here's a better shot of the filter. Bet a 2" or 1 1/2" by 3' section of PVC pipe, cut it in half and bevel one end about 30 degrees. Carefully slide between wires and hoses so it's directly under the filter and you won't get a drop inside the engine compartment. If the batter box was not on the pilot side, then you could get away just taking one cheek cowl off and do everything from there. My A&P has a flexible tube device that he uses from just the pilot side and he does the process that way. He amazes me what he can not see, but feel and get it done, or uses a combination of mirrors and scopes to see what he wants to see.

-

I have a 1963 C. The direct mount is a bit of a pain taking off both sides of the cowl. You can do it with out taking the top cowl off, just remove the aft screws and prop it open a bit, but I don't like bending the metal, even slightly. Here's a pic of what you have to work with. As far as overhaul shops, I highly recommend Penn Yan. Did mine last September, done on time, under price quote and they keep good track of how things have been since.

-

Fat Albert , is ready to be my runner

Tcraft938 replied to Alan Fox's topic in Vintage Mooneys (pre-J models)

Which conversion are you doing first to the Mooney, four blade prop or turbine? I was going to ask about a rear cargo door, but that would sacrifice speed. So un-mooney like. :-) -

Did my OH exactly a year ago. New mounts, bolts, etc. When got done it looked like yours. I read somewhere should by 1/2" top of spinner to that curved piece of upper cowl. I had a bit less. After 70 hours of break in, it has moved to the 1/2" mark and points to the right a bit more, so the mounts do break in as well, I guess. My A&P said he would check it more thoroughly and shim it at annual in May. "Might as well, we have to take the engine out anyway". I said WHAT?!!!! "Oh yeah every 100 hours, just like tire rotation on your car, you have to pull them and rotate 180 degrees and mount them, otherwise the bottom of cylinder wall wears more than the top, now if the plane were certified to fly inverted, we wouldn't have to do all that. Relax, my point is shimming it is not as bad as you think, it's a well engineered Mooney everything is fixable and when you do it only makes it better". At the time he was installing new control cables (AD) in a T tail Piper Arrow and lets say he wasn't enjoying having access panels well below the connection points. "Parts of your Mooney are hard to work on, but I'll do it anytime because they are that way for good reasons and well built, these things..... well anyone who uses a machine oil can as a brake reservoir, you know sacrificing quality and workmanship to save a dime was not a big worry on their mind".

-

The way I look at it, too much (within reason) is better than not enough. I can by a lot of quarts of oil for the price of overhaul. Also my AP jokes, it's good anticorrosive treatment for the belly. "Have you ever heard of corrosion on the belly of a plane that flies fairly regularly?"

-

Great ideas. The access door seems like it's not lined up well, just enough to make the quart bottle not want to sit there.

-

I would like to tie into this with a similar question on the topic. I now have almost 70 hours on the overhauled engine. Even prior to overhaul, putting 8 quarts in after oil change was futile, I would get the same result putting 7 quarts in and the 8th just open the bottle and throw it down the belly. If I put 7 quarts in, within an hour or so it is slightly above 6 quarts and it doesn't budge for at least 10 hours then slightly below 6. The OH shop and AP told me if doing short flights to leave it there, keep an eye on it, they wanted to see what it did and to increase my oil change interval from 25hrs to 30-35. At 29 hours it dropped slightly to exactly 5.5 on the stick, so rather than add and throw off the sample, just did the oil change there. Is this pretty normal for the rest of you, that your O360 seems to not like much more than 6 quarts and it kind of finds it's happy level and hangs out there for awhile? It just seems unsettling to have an 8 qt system and to know it's going to settle at 5.5 to 6. I'm glad I can get 25+ hours there, but it just seems if something starts to change, that's not much buffer. Penn Yan is happy with it, "said, oil consumption definitely stabilized, you're broke in" and everyone saying the oil samples are real good. Thanks

-

I made a checklist in foreflight that I physically touch/check each item. Also scanned into foreflight cruise and other performance data and W&B cert. That way when in an FBO waiting for weather to pass don’t have to run out in the rain to get POH. I was ramp checked and told them I had the info on iPad but would grab the POH from seat pocket. He wanted to see the iPad and said “your cool, safe flying and take time to enjoy it”.

-

Huge job. No turning back now. Anyone know if the 63 year had arm rests?

-

Flap Retract on Takeoff

Tcraft938 replied to moontownMooney's topic in Vintage Mooneys (pre-J models)

Not the latest engine monitor but I do have the data. I have a sheet where I record the various parameters for each phase of flight. 384 in the climb is highest CHT I have seen. Cylinder 3 is consistently the warmest in climb by about 25 degrees. Cruise everything settles to around 310 to 330. TAS is at book or better at 75% any altitude. Climb is better. However it is new scimitar prop so that could change things some. Fuel burn climb and cruise data indicate it is making the power or more. So far very happy with Penn Yan Aero and the support they provide. -

Prist Acrylic, Plastic and Glass Cleaner

Tcraft938 replied to PTK's topic in Bug Reports & Suggestions

Spray lemon pledge works well at fraction of cost and slicks up the plastic so many bugs don’t stick and easy to wipe with microfiber towel and water another trick is bugs are water soluble. Wet a towel with hot water or put in microwave and put hot soaking wet towel on windscreen. Let it sit for ten minutes. All gone in one wipe. Easy and cheap -

Flap Retract on Takeoff

Tcraft938 replied to moontownMooney's topic in Vintage Mooneys (pre-J models)

Very interesting post. My checkout in the C last year I was told if no significant obstacles get positive climb and under control out manual gear up and that 85mph or a little less is optimum speed to do that with least effort. If ready with trim the pitch change not bad and you will be accelerating through 90-95 mph by then and put the flaps up pitch to hold that speed until 500’ AGL so can return if needed and then let it accelerated to 110 to 120 mph for cooling (I’m breaking in a new engine so cool is the focus). Climb rate is very good at that speed. I recently did a couple of takeoffs with flaps up. I did not notice any real change in the amount of runway used. I got to a higher altitude by the end of the runway than with using flaps and it rotated and lifts off the runway much smoother than with flaps. I’m sure flaps are better if heavy and/or hot or obstacles, but at our low level 4000’ paved runway and just me and one other I will likely keep the flaps stowed much if the time. The only thing I don’t like about that is it changes a routine and easy to forget them some day when I use them -

Excellent advise, and potentially save one $ on a pre-buy. My AP/IA allowed me to be there and assist in certain things on the two prebuys I did. The first plane came in the shop and he had me take pictures of data plates on engine, governor, mags, etc. "One of the best ways to find out up front if we are dealing with someone reputable and cares, or cut corners, or is playing silly games, is to check this stuff out. Why rip this thing open to find out 4 hours later parts are not legal? It's a 50+ year old airplane, there may be some checkered past, but hopefully the last 5-10 years someone has sorted that out and kept it good, otherwise YOU'RE going to have to spending $ fixing the sins of others". We found undocumented parts, signs that maybe not even AP/IA installed and some pencil whipping in the logs and strong indication of corrosion. Rather than opening more stuff up to confirm the extent of corrosion, I weighed all the factors and very early in prebuy process cam to a No Thank you. The AP/IA said, "wise choice you saved me time and that saves you $ the $600 pre-buy became $75 and you now know much better what to look for when you look at your next one before a prebuy". The second Mooney prospect was the opposite experience, him smiling and saying, "I have a feeling you're going to buy this one, if not, you don't really want a vintage Mooney, go find something else". This post got me thinking. My M20 has a two blade Hartzell Scimitar on it and the manual says no restrictions "except for E and F no continuous above 24" between 2350-2550 rpm". I have a digital tach and on short final or approaches the red light will come on around 2000 rpm, always getting my attention, so I don't fully trust I'm not doing something wrong. It appears I should either learn to ignore it, and/or get the tach reprogrammed to not give me that red indication.

-

I'm finding the exact same thing in 63C, depending on density altitude. I would say 7000-8000'msl is best speed, higher than that, speed will slowly start to drop off, but fuel burn also does at greater rate, so I call that the peak efficiency range. Last week I took it on my first trip, very warm day 90+ on the ground. Went to 9,500 msl to get above most of clouds and to see the building cumulous and was still in the mid 50's up there. Density altitude calculated to be 11,400. At WOT and pull back to just as the MP needle moved, was running 20" MP and 2500 rpm with indicated and true airspeed respectively being 145mph / 173mph or for those in knots 126/150, fuel burn was 9.1 gph. I experimented with reducing prop RPM to 2400 and the MP went up about 0.5" so speeds were 143/171mph or 125/149kts, but fuel burn dropped to 8.4gph. I'm new enough to not know how that compares to other stock 63C with only mod being one piece (not 201) windshield, but I was amazed at getting 19 to 20 miles to the gallon. Also taught me, if willing to go 2 mph slower (which meant about 3 minutes) on this trip, the efficiency increased 7.5%. So if weather or something requires you to extend things and you're up high, sacrificing a little speed can pay big dividends. We did the return in a friend's Beechcraft Sierra. Nice plane, roomy, but let's just say it was not as happy to go to 9500' as the little C was. The same trip adjusting for wind conditions took 15% longer in the Sierra and he burned 38% more fuel. Also interesting was he has a lot more room but less useful load than the C. He has 842lbs, vs me at 1,020, so his range is further hurt by offloading fuel to carry passengers. We joked, he can make it fit, he just can't lift it, I can lift whatever I can get in it.

-

First I'm not a Mooney expert or A&P. What I am, is a 1 year owner of a C model an in the process of breaking in a overhauled to new specs engine and my A&P likes to include me in the work "you learn your airplane and keep me honest". Based on the strong recommendation of Pen Yann Aero and my A&P I would recommend you shallow your climb to a cruise climb. While higher oil temps are normal during break-in, getting too hot is really bad. I was told, first 30 hours takeoff, clean up as soon as possible, climb at 85 mph to safe altitude (about 400'), lower nose to get the 105 mph Vy for another 1000' and then lower the nose and pitch to maintain a cruise climb of around 120 mph or more. All of this was to be done at full power and full prop rpm, the engine likes that better and gets more cooling air. Albeit I have a carb engine you have fuel injection. When get to 120-125mph I find my rate of climb is very similar to holding 105mph. The only thing I'm giving up is I'm going a little farther over the ground for every foot I climb. I was also told to run it hard once in cruise, nothing less than 75% power until oil consumption stabilizes, "if you fly and weather permits, don't fly for less than an hour, set the power and go and for God Sake, NO touch and goes!!".Yesterday I took off on a 92 degree day 670' msl, climbed to 6,500' for cool smooth air. Hottest cylinder (assuming accurate instruments) was 368 and oil temp was 194. During cruise climb hottest cylinder 344 and oil stayed at 184. If you're dialing back the power and prop while pitching for slower airspeed you're really diminishing cooling air to the oil cooler and cylinders, for a longer period of time and not good for engine break in (what I've been told/taught). Are you still using mineral oil for your break-in? None of what I said, is enough to "solve" your problem, but it can help a bit especially once you get things sorted out. When we installed the engine he flushed the oil lines and cooler and some junk came out, not much. His point was, "you paid big buck for a nice OH, do you want to potentially pump junk we don't know about through the new engine?" Oregon Oil cooler had one on the shelf for $240 and we got new oil lines, the others were 23 years old and could squeeze them a bit. The other consideration I just thought of, are you on the ground much with the engine running or long taxi? I was also told to minimize that. Being at a non-towered airport that's easy. First several flights did much of the checklist items while taxi, runup at end of runway with exercise the prop the last item. If it's good, full prop, release the brakes, full power and go. I hope it all works out well for you. I will be curious to read the result after the new cooler and hoses.

-

N6535U , 63 C model , parting out...

Tcraft938 replied to Alan Fox's topic in Avionics / Parts Classifieds

Cabin door hold open rod/track and dorsal fin? Possibly nose gear doors. Thanks