-

Posts

9,508 -

Joined

-

Last visited

-

Days Won

206

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by PT20J

-

That’s true for all airplanes with a conventional tail because aft CG reduces the tail down force which reduces induced drag of the stabilizer and wing (because the wing has to support the aircraft weight AND the tail down force). So the aft CG limit should be the lowest drag.

-

NEED (good) ADVICE on Hard Trim Repair/Mechanic

PT20J replied to CMMPilot's topic in General Mooney Talk

On my J, one of the trim wheel chain sprockets is slightly eccentric and if the chain is too tight it binds at one spot every revolution of the trim wheel. Easy to check by removing the chain cover and observing the slack in the chain as the trim wheel is rotated. -

I probably wasn't clear: I meant only to suggest that you install Teflon hoses when you replace them. I have no way to know what kind of hoses are installed on your airplane.

-

There are lots of places that make hoses. Teflon hoses are an upgrade that don't have a stated service life and should be good to TBO. You can get them with molded-on fire sleeves. I got mine from Precision Hose Technology www.aircrafthose.com. Who knows about safety? You are assuming that the problem is the hoses because they are old, but you haven't verified that the hoses are actually the issue. SPD-PTFE_Hose124.pdf

-

The lines should have metal tags with date codes on them unless they were field built.

-

NEED (good) ADVICE on Hard Trim Repair/Mechanic

PT20J replied to CMMPilot's topic in General Mooney Talk

What's up with the reverse font? I'd suggest Don Maxwell https://www.donmaxwell.com/ or the Mooney Factory Service Center https://www.mooney.com/ -

I'm missing something. If the airplane was adequately insured, I would collect from the insurance company and let them try to recoup their loss from the other parties. But it wouldn't seem worth my time nor cost effective to sue anyone over this. Sure, I'd be pissed that my airplane was destroyed, but at the end of the day, the remedy for this is to recoup the hull value so as to be made financially whole.

-

The suggestion that such things are caused by air leaks in the fuel selector comes up here often. Has anyone actually solved such a problem by overhauling a fuel selector or is this just a theory that gets repeated but has no confirmation?

-

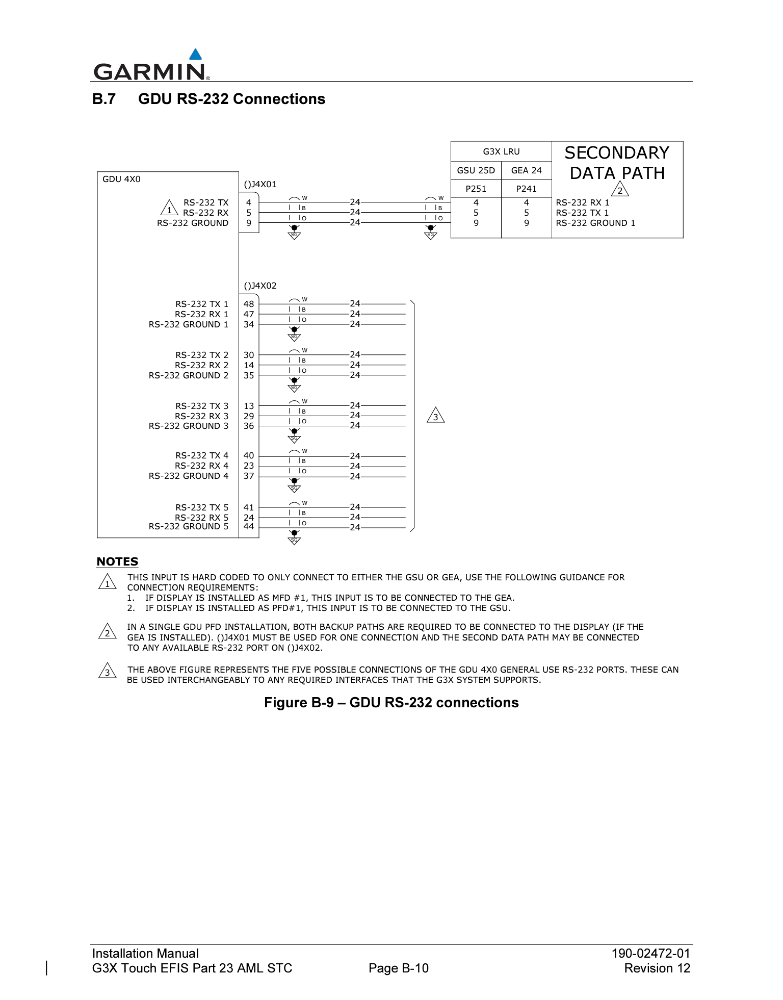

Actually, the more I look at this the more I think Garmin thought out the failure modes for the certified system pretty thoroughly. The G5 has its own ADAHRS, so it doesn’t need input over the CAN bus from the GSU 25D, and the G5 has an RS-232 MapMX connection to the GPS. So, if the CAN bus goes down, it will lose the GMU 11, but it should then revert from HDG to GPS TRK.

-

-

By the way, Pilot's Operating Handbooks did not exist before GAMA issued it's specification 1 in 1975. Earlier documents were operating manuals, operating instructions, owner's manuals or whatever the manufacturer wanted to call them and varied in information content.

-

I did this on mine. The Shadin powers the transducer. You just need to parallel connect the transducer to both devices by connecting the EDM 700 transducer input and ground to the corresponding transducer connections on the Shadin connector. Pinouts are in the docs. Shadin Miniflo-L.pdf INST-103-RevE-10-09JFP-Checked-.pdf

-

The TCDS should be definitive. https://drs.faa.gov/browse/excelExternalWindow/6EA0F05ECCA8304486258305006833CF.0001?modalOpened=true

-

I sent the following to Garmin support: My G5 (v8.20) is about 2-1/2 years old with approximately 250 flight hours. My battery has been showing a decreasing percent charge on the battery status indicator and currently only shows 86% even after several hours charging on ship's power. However, the capacity test concludes with 4:14 time remaining indicating a healthy battery. I understand that the Aera 760 requires calibration by running the battery completely down and then recharging. Is this necessary for the G5? Should I try this? Support replied: They are currently looking into G5 batteries not displaying correct state of charge. With your battery still indicating healthy I would not recommend trying that. So, this sounds like a known problem being investigated by Engineering.

-

The most important thing about replacing the door seal is getting it placed properly on the door. It's not obvious and if it's not right it doesn't seal well or the door is too tight.

-

Interesting. I assume that this is done in the interface chips so that there is a minimum of circuitry involved. But in the reader’s description the GEA 24 apparently did take the bus down so maybe Garmin doesn’t support this.

-

Interesting idea. The Aera 760 manual suggests running the battery down the first time it's used and then recharging to get full capacity. There is no mention of this that I can find in the G5 documentation and I don't know that it works with a aged battery, but it's worth a try. From the Aera 760 manual: INITIAL BATTERY CHARGING After fully charging the battery for the first time, the aera 760 battery indicator may report significantly less than full charge. In this case, the battery will need to be conditioned to report the correct capacity. This can be accomplished by allowing the battery to discharge completely and then fully recharging the battery.

-

I was just perusing the letters to the editor in the June AOPA Pilot and saw one where a reader described a G3X failure where red X's started appearing on one after another G3X instrument until nothing was available. The problem turned out to be a bad GEA 24 (engine monitor) that swamped the CAN bus shutting down communications between the G3X and the LRUs. This was on a SLSA that didn't have a standby G5 or GI 275, but presumably those instruments might have been affected also. In my installation, I have a AV-20-S for a backup attitude indicator and it is not connected to anything common to the Garmin equipment except for pitot and static sources. I felt it important to have some non-Garmin technology onboard to keep me upright while I troubleshoot a catastrophic failure in the primary equipment. In this case, I would pull all the LRU circuit breakers and then bring them back on line one by one to isolate the bad LRU. It should be possible to get most everything working again.

-

Actually, I think this might be normal behavior for an aging battery. My G5 is 2-1/2 years old with about 250 flight hours. My SOP is to power up the G5 on it's battery during preflight to check the battery level. I look at the percent charged but don't often wait for the full capacity test to complete where it switches from percent to time. When new, it showed 98%. Lately it has been showing 93 - 95%. Today, I noticed that it showed 86%. I ran it on ship's power with the battery minder and it indicated charging (lightening bolt) and 100% during that time. After two hours, I shut off the master and powered up the G5 on battery for the capacity test. It still showed 86%. When it switched to time, it indicated 4:14.

-

This is normal behavior for mine. The battery status seems only to be accurate when the battery is not charging. When charging, it shows 100%. The only way to check the actual battery status is during a few seconds when first powered on ship's power, or to turn the G5 on without ship's power to cause it to run on the battery. I do the latter during preflight. It sounds like the battery is not charging for some reason. Does the lightning bolt symbol have a black dot in the center? According to the Pilot's Guide, this means that the unit is running on ship's power but not charging the battery. One thing you could try is swapping the batteries between the two G5s to see if the problem follows the battery or stays with the attitude indicator.

-

ALT, PITOT STATIC, TRANSPONDER, IFR CERT - COST ?

PT20J replied to DCarlton's topic in General Mooney Talk

$400 flat rate last October at Crown Avionics @ KPAE -

Do you see the yellow lightning bolt symbol on top of the battery symbol indicating that the battery is charging when the master and avionics switches are on? I'd double check the G5 by powering it up on it's battery with ship's power off by pressing the power button on the G5 to see if you get the same indication as when ship's power is on. If you have a battery minder, I would turn off everything except the G5 and turn on the master and avionics switches and let it sit for a few hours and see if the battery charges.

-

14v to 14.2v is optimum, but you shouldn’t be getting a discharge at 13.8v. It’s always a good idea to check the instrumentation accuracy before adjusting anything.

-

Does the needle show zero when the master is off? If not, some meters have a zero adjustment screw on the movement. You’d have to take the meter out of the cluster to check.