-

Posts

9,934 -

Joined

-

Last visited

-

Days Won

222

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by PT20J

-

Based on the G100UL fuel leak thread what's your position?

PT20J replied to gabez's topic in General Mooney Talk

Maybe this will help explain things 34811808-North-American-P-51-Mustang-Pilot-Training-Manual.pdf -

Deployable spike strips at active runway entrances should do the trick

-

Making Sense of Best Glide and Glide Ratio

PT20J replied to Max Clark's topic in Modern Mooney Discussion

I did a lot of practicing the "impossible" turn in a sim and then verified my findings at the airport. With no wind, I can just barely make it back at 800' AGL using my normal takeoff sequence where I lift off at about 65 KIAS, pitch to 7 deg, raise the gear at positive rate, raise the flaps passing 80 KIAS. Wind is the biggest variable. 1000' is more comfortable. -

Garmin will play with others when there is a market demand. For instance, Garmin made its connext interface available to ForeFlight because a lot of Garmin customers use ForeFlight. But I suspect that more Aspens have been removed than newly installed (not talking about Max upgrades to existing installations) since the G3X became available for certified airplanes. Spending a lot of engineering resources to support a product with declining market share (not to mention the technical difficulty because of the GFC 500 architecture) would not appear to be a profitable venture. Aspens work great with legacy autopilots -- I flew with one for years with my KAP 150. But, if you want a GFC 500 you need a Garmin panel.

-

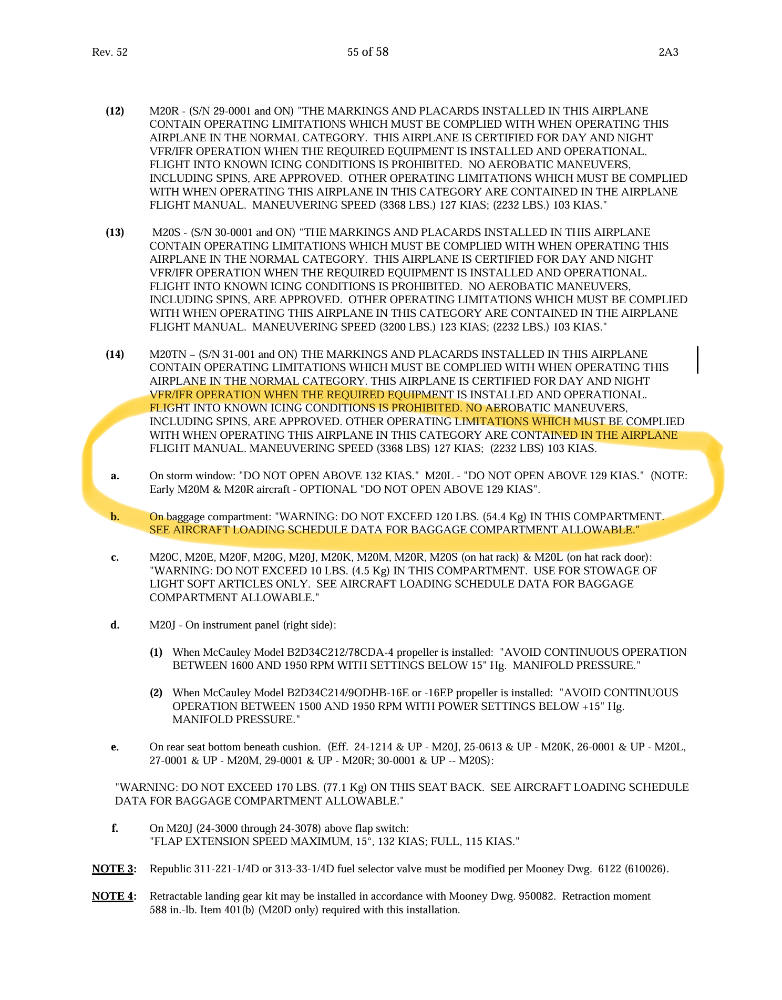

It should be listed in the Limitations Section of the POH where the required placards illustrated. From the TCDS:

-

It is important to understand that the GFC 500 architecture is different from other autopilots. Most autopilots have a computer that gets inputs from the the attitude gyro and the directional gyro or HSI and compute solutions to drive the servos. The GFC 500 is different. Most of the software is actually in the G3X or G5 or GI275 and some of it is in the "smart" servos. There is no separate computer. That's why the GFC 500 will not work with an Aspen.

-

The iPad gets it's data from the GTX 345.

-

I have a mini mounted on the yoke. I don't usually bother with it for local VFR flights -- everything I need is on the G3X and GTN. When flying VFR, I keep the GTN on the traffic display and when flying IFR I keep it on the Flight Plan page. I use the iPad with ForeFlight for longer flights and for IFR flights. 1. I can do the flight planning on it, file the flight plan with it and upload the flight plan to the panel via Bluetooth. 2. It provides a larger display for the approach plates than the G3X split screen. 3. I find it easier to maneuver around ForeFlight to check on weather and also do what if planning. 4. I like the weather overlays on the ForeFlight map and especially the ability to increase the transparency so that the radar doesn't obliterate the other map features. 5. It provides instant redundancy should the G3X fail. I tried using the iPad on my lap, but I have a tendency to rest my hands there and I was always touching the screen and causing the display to change to something other than how I left it.

-

For your second question, it will be dictated by what the STCs for the Aspen and G5 allow. I don’t know if Aspen will allow a G5 to replace any backup instruments. The G5 STC only allows it to replace an AI, HSI or turn coord. And you’re going to have to ditch the Aspen if you install a GFC 500 because the autopilot needs a Garmin display to drive it and that display must be primary.

-

Making Sense of Best Glide and Glide Ratio

PT20J replied to Max Clark's topic in Modern Mooney Discussion

Deakin’s take on climb speeds. https://www.advancedpilot.com/articles.php?action=article&articleid=1842 Airspeed and altitude are both forms of energy — airspeed being kinetic and altitude being potential — and are thus interchangeable (neglecting losses due to drag). But, conversion requires acceleration which has a time element. If you are close to the ground and descending, you don’t have a lot of time. -

Making Sense of Best Glide and Glide Ratio

PT20J replied to Max Clark's topic in Modern Mooney Discussion

Vx should increase with altitude and Vy should decrease with altitude and they converge to the same speed at the absolute altitude. The chart shows Vy decreasing with altitude but doesn’t show Vx increasing. Looks like Mooney just picked one number and stuck with it. -

Making Sense of Best Glide and Glide Ratio

PT20J replied to Max Clark's topic in Modern Mooney Discussion

200. Thrust required = drag, so lower drag will also reduce Vx. 94 mph seems way too high for Vx. Especially when Hank’s C is 80. -

Making Sense of Best Glide and Glide Ratio

PT20J replied to Max Clark's topic in Modern Mooney Discussion

According to my 1994 M20J POH, clean, power off, gross weight, level flight stall speed is 62 KIAS and Vx at sea level is 66 KIAS. Best angle of climb is the speed where there is the maximum difference between thrust available and thrust required. The bigger the engine, the lower Vx. The F-15 supposedly has a thrust/weight ratio of 1.17:1, so it's Vx is zero. -

The exhaust cavities are supposed two be sealed to the firewall, so you should reapply sealant when you reinstall them. My airplane doesn't have any parts requiring service in there. I loosen enough screws to insert a borescope in the area from the aft end to look around and check for any issues with the boost pump or brake master cylinders.

-

It looks pretty noisy even when it’s working. I’d first check all the connections carefully. O

-

Making Sense of Best Glide and Glide Ratio

PT20J replied to Max Clark's topic in Modern Mooney Discussion

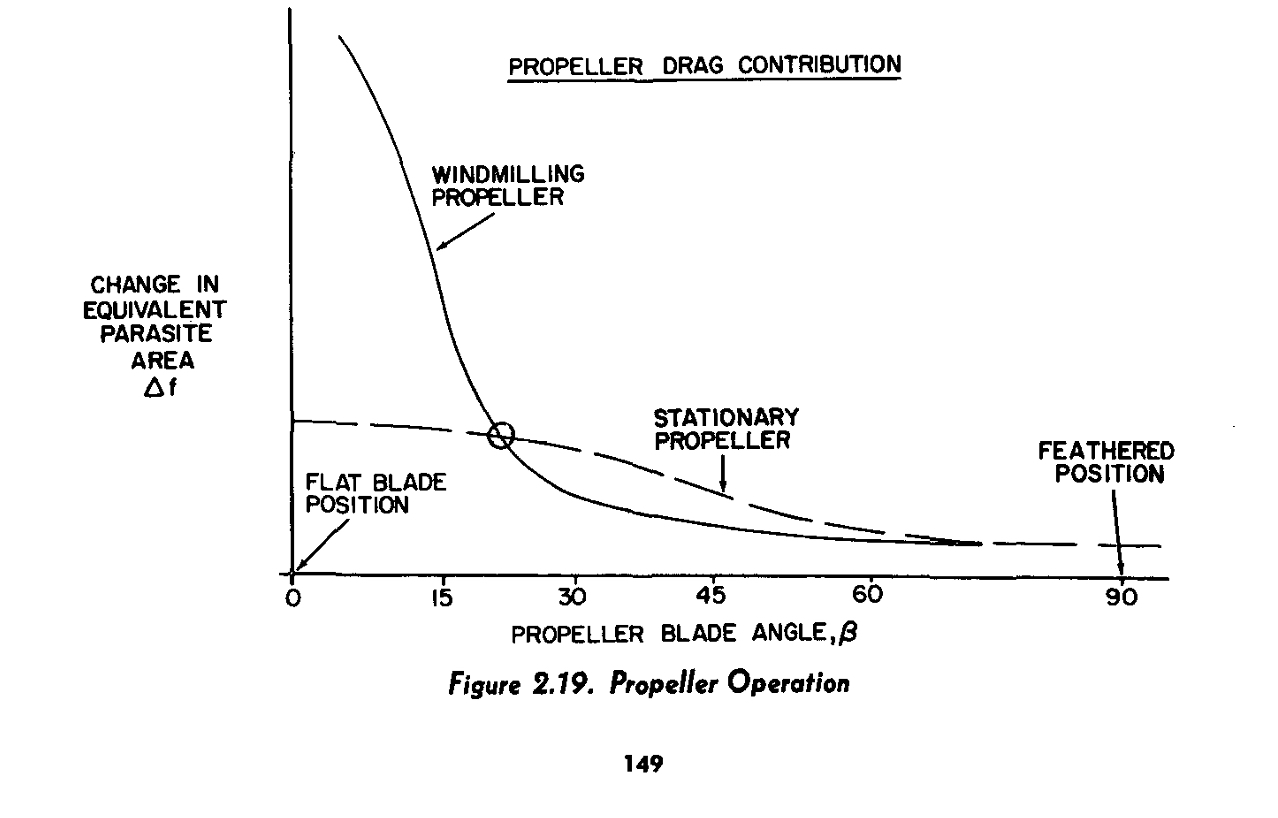

That surprises me, also. Best glide occurs at the max L/D speed. In fact, the glide ratio is simply the ratio of lift to drag. Since lift = weight, it's also the minimum total drag speed. Total drag is comprised of induced drag (which decreases with airspeed) and parasitic drag (which increases with airspeed.) The minimum total drag occurs when each drag component is contributing half of the total. Since stopping the prop reduces parasitic drag, it should cause the minimum drag to shift to a higher airspeed, but the chart shows lower. -

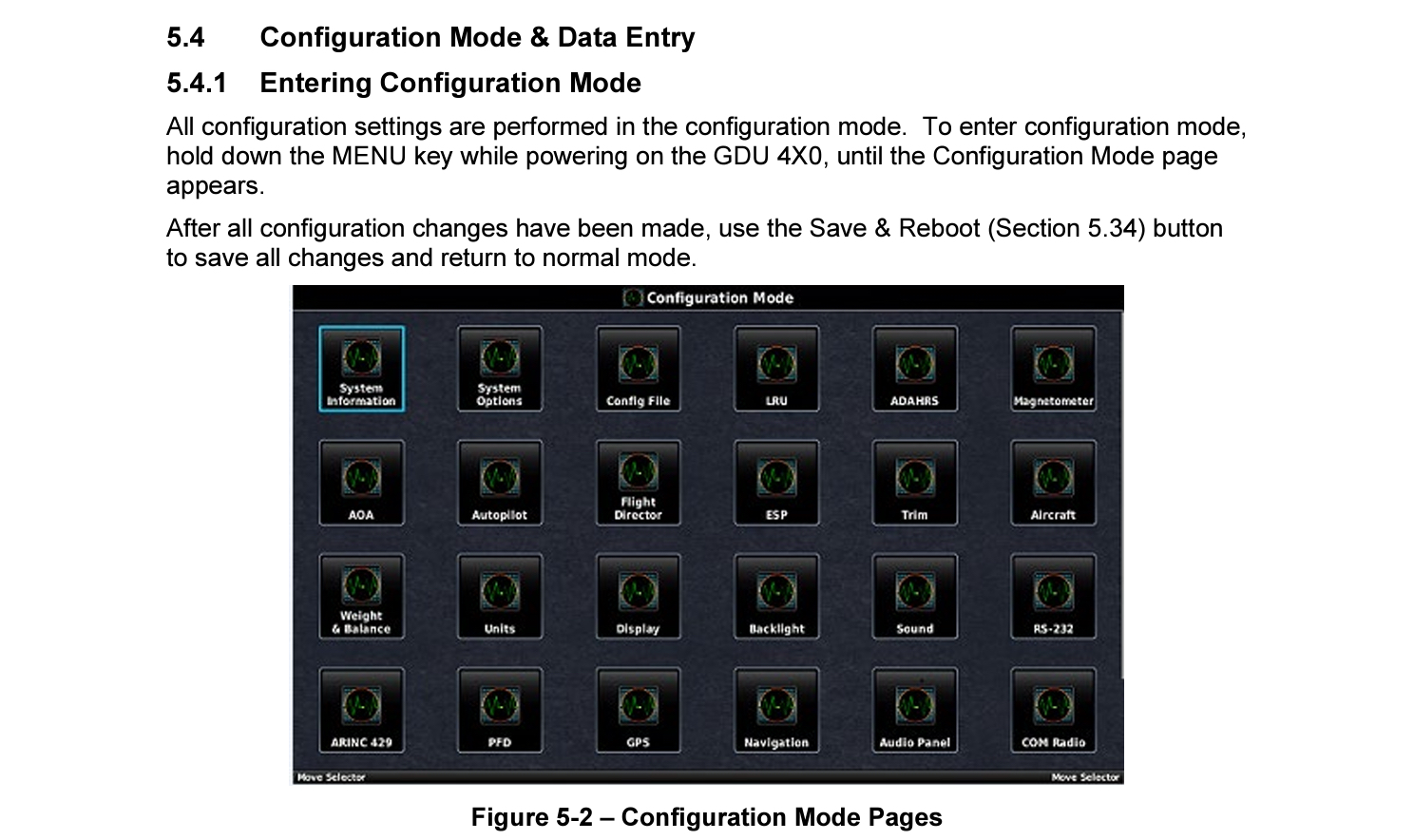

It took a lot of sleuthing and phone calls to Mooney to figure it out. The installations can be confusing because the installer has to read the installation manuals for each piece of equipment in the right order as some equipment installations require changes to wiring or configurations of other equipment.

-

Making Sense of Best Glide and Glide Ratio

PT20J replied to Max Clark's topic in Modern Mooney Discussion

I’ve heard lots of discussion about which is the lowest drag: windmilling vs stopped prop. According to this graph from Aerodynamics for Naval Aviators, it depends on blade angle. This agrees with data from an old NACA report I looked up once. What is apparent (and easily verifiable if you try it) is that pulling the prop control all the way back greatly improves glide. In my J, the rpm is in the yellow arc at best glide with the engine at idle and the prop set for 2500 rpm. The vibration reminds me to pull the prop control back. -

In a G3X installation, all the audio is routed through the G3X GDU and the G3X installation manual calls for only the G3X to be connected to the audio panel. If the GTN is also connected, you will likely get an echo when engaging Smart Glide (that’s how I found out that both of mine were connected.

-

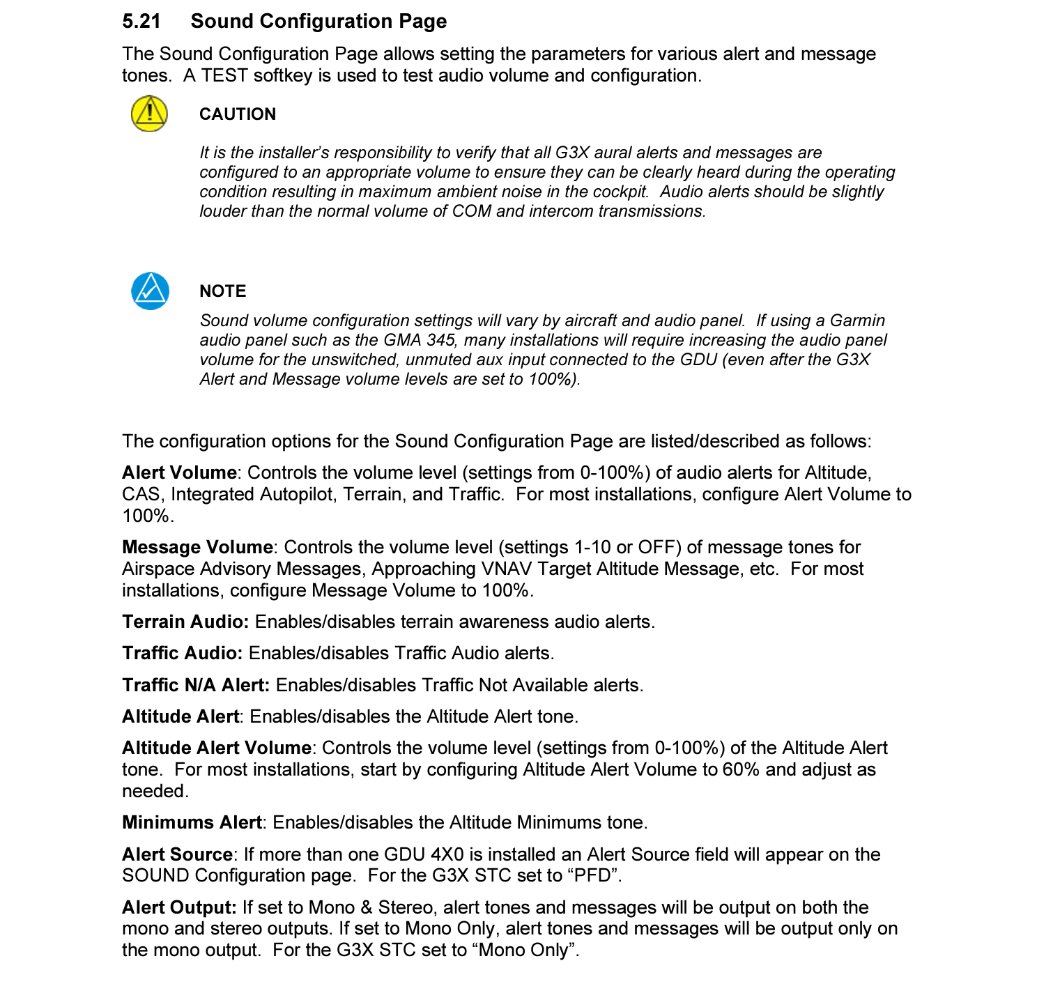

Sorry, but your installer doesn’t seem to know what he’s doing. The alerts should have been configured during installation. Assuming everything is wired correctly, enter configuration mode, go to the sound configuration page and set up the alerts.

-

Yes, the lift force can be derived as either a change in momentum or a change in pressure because the two are two sides of the same coin.

-

That's because that is a Mooney part number. If you want to order it from Mooney, call a MSC for price and delivery. But, McFarlane will almost certainly be cheaper.

-

That's a cool simulation. I did not see where it showed that there is a net downward momentum. I believe that Doug McLean addressed that fallacy at the end of his lecture and in more detail in his book. Both McLean's analysis and Lissaman's paper show that there is an updraft before the airfoil and a corresponding downdraft behind the airfoil and each accounts for 1/2 of the lift force. It occurs to me that there can be confusion with the term downdraft. There is downdraft behind even an infinitely long wing just as there will be an updraft ahead of the wing. But that's not the downdraft that people generally refer to when invoking Newton's third law to explain lift. The "Newton explanation" downdraft is the one that is not balanced by the updraft ahead of the wing and it is the source of induced drag, not lift. It is caused by a vortex sheet shed by a finite span wing. Details can be found in any aerodynamics textbook where induced drag is introduced.