Aerodon

Supporter-

Posts

1,288 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Aerodon

-

You are missing the cutout for the engine controls, but at least you are showing the bend at the lower edge. I don't like the Lemo and headset jacks on the panel, put them on a L-bracket attached to the horizontal bent portion. I prefer the 'recessed' position. but you van turn the L-bracket around and make it flush with the panel. While you are at it, seriously consider the dual MaxDim instead of the Mooney dimmer circuit - reduces CB count by 1, and much more compact. Put this and the USB symmetrically around the co pilot control column like the OEM. I like your vertical arrangement of the switches and annunciators. Put the smart glide at the top and the go around at the bottom? I don't like your C/B's on the LHS. Move the comas and CO2 mount, put the GMC507 at the top. Put the switches that you use in the traditional location so you can use your right hand to turn things on an off. I would stick with clock (MD93) and smaller CO2 monitor - located in CB panel? Can the GNC355 and GTX650 interface directly to the G5 indicator without the GAD29 box? I would seriously consider the GI-275 instead. Put the ELT switch where the GSB15 is. I think the WX8 is next to useless in real weather. I have a WX10A for you, and you can find a WX1000 quite easily. Maybe even a WX500. Modern 'data' allows you to stay well away from weather, so a Stormscope is less important. But put something nicer in if you know there are times you will want to fly closer to the weather. I like the way you have lined up the top of the radios with the GDU. If you can put the GMC507 at the top, maybe change to an SL30 or GTR215 to get the bottom to line up too? Aerodon

-

So my 1986 M20K has the RPM sensor on the left magneto, inboard side. Still installed, but I can remove it. Then the matching tachometer. No tacho-generator. Aerodon

-

The very early ones had a lever. And the experimental version ones had an electric motor in the centre of the fuselage to wind up the cable. I have a vacuum version and plan to keep it operational as long as possible. Aerodon

-

My electrical drawing shows a sensor attached to the left magneto (1986 M20K). I will go look today. Aerodon

-

I have a spare one out of a 252 with the same markings for you.....Should have the tach generator too, but will have to search. Aerodon

-

Do you remember what the tach generator looks like? And where it was attached? Don

-

I have all the components for a WX10A removed from my Mooney. Might be useful to someone trying to get their system going again. Could be reinstalled if you have panel space and space on your rear avionics tray. Aerodon

-

WX500 Stormscope System Complete $4950

Aerodon replied to Aerodon's topic in Avionics / Parts Classifieds

Updated, I have another system available. -

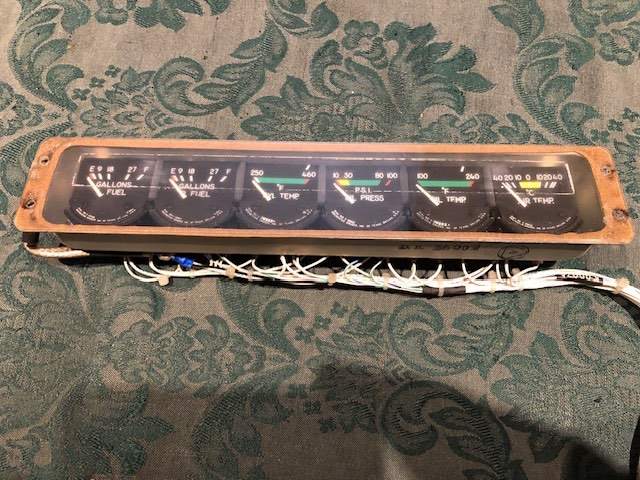

There are several flavours of these, this is out of a 1986 252 M20K and has the OAT instead of Ammeter seen in other models. I could be persuaded to disassemble and sell individual gauges. Don

-

Garmin GTN 750 to GTX 335R interface

Aerodon replied to Old Chub's topic in Avionics/Panel Discussion

All I can say is be meticulous: 1) be sur that wiring is correct and know which serial ports are actually in use 2) make sure software is up to date in both units 3) make sure serial port settings are correct. Every time I go through this trouble shooting exercise, we always find something wrong with one of the above. Aerodon -

Fuel Pressure is not an option available on an EDM830. Time to upgrade to an EDM900. Aerodon

-

And here's a thread with good installation pictures:

-

Always a good idea to know exactly which circuit breaker to pull if you get unexpected behaviour. I flew a C172 that had the aileron programmed the wrong way and it was interesting. Easy enough to change in the setup. Aerodon

-

N38RK Mooney 252 down near Oakdale CA 3/16/2024

Aerodon replied to LANCECASPER's topic in Mooney Safety & Accident Discussion

I think the 2.5G warning in the 252 is next to useless. A 9 or 10G warning would be much safer, much like the Bonanzas that state no takeoff with less than 1/4 tanks. Don -

This will work, google the usual suppliers. LONE STAR STEP UP 12V TO 24V CONVERTER I have a new one for you at a discount to the best price. Aerodon

-

Something is not making sense. I'm familiar with the K model, but the M cannot be much different? The trim servo should be the easiest to replace - it's a sprocket and chain arrangement, accessible through the avionics door. Easy. The pitch and yaw dampers are next easiest. cable attached to the fore and aft end of the pushrods. Inspection doors at the back, through the avionics bay at the front. Cable tension needs to be adjusted, and three different bridle cable lengths are available. But the servo mounts are so exact, I can't believe it will take long. The aileron servo is most tedious to install, but one the cable routing and alignment are sorted, replacement can't be too long. I think you are paying for someone else's learning experience. I have seen techs spend hours reading through installation or service manuals before starting, and others that can open the book at the page that is needed. Aerodon

-

I have a few new old stock GEM probes - CHT gasket style, CHT Bayonet, CHT 'adaptor, style. Also a couple of Alcor CHT probes. Someone must need these as 'standy' spares? GEM 2853 CHT Sparkplug x 4 GEM 2855 CHT 'adaptor' probe. This is the one that allows the OEM bayonet probe to remain in service ALCOR 86251 CHT Bayonet x 4 ALCOR CHT and EGT wires Aerodon

-

I have on for you, PM to follow. Aerodon

-

Are you talking about the shelf above the passenger's left knee? Mine was starting to look like swiss cheese because of all the different antenna splitters that had been mounted on the forward side. So I drew it and cut a new one on my CNC machine. This is an easy enough part to make by hand, but if you want something that looks like it came from the factory I can cut one for you. Aerodon

-

Hank It would appear the engine had about 2700 hours and about 230 SMOH. And it was either a 1600 or 1800 TBO to start with (depends on serial numbers). A factory overhaul would have replaced the gear. A field overhaul should NDT all the gears and make a decision. Not compulsory I would imagine, but apparently not wise in this case. So it was 'engineered' well enough to get to TBO, but I think major components should get at least 2 overhauls? Aerodon

-

Erik, the gear is not visible, its one of the gears in the accessory case, that why it is so difficult to change. Aerodon

-

Yes, I don't know how you could overhaul an engine and not replace this gear without worrying about the liability..... "To eliminate the possibility of camshaft gear tooth fracture, resulting in power loss or in-flight shutdown, and to inspect and remove from service P/Ns 631845, 655430, 655516, or 656031 and replace with camshaft gear, P/N 656818. This Service Document initially announced the release of improved camshaft gear P/N 656818 in 2005. It now clarifies part number superseding action and amplifies camshaft gear replacement instructions."

-

As far as I can see this could have been a 1600 or 1800 TBO engine with 2000 hours. We had an O360 (TBO 2000) that was running fine at 2900 hours. We made a decision to overhaul at 3000 hours because we did not want to put ourselves in the position of trying to answer that question. This was not such an easy CSB to comply with and I may not have complied with it. But this report is making me more conservative, so I think this should be one of the issues to take into account when stretching your TBO. Aerodon

-

This one is sold, but I have put together a newer and nicer system. Contact me.

-

Is There Sales Tax On Buying A Used Aircraft?

Aerodon replied to GeneralT001's topic in General Mooney Talk

Yes, even if you buy it privately from out of province, the PST guys will eventually track you down and ask for 12%. If you buy from a dealer they are supposed to collect GST/HST/PST. Aerodon (BC)