-

Posts

839 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by wombat

-

Got the plane back from annual, and the electric trim no longer works. The switch for electric trim is getting 14V, and when switched 'on' it has 14V on the downstream side too. (i.e. that switch is working properly) The autopilot self-test fails. The electric trim on the yoke fails to do anything. There is also no additional draw on the electrical system, so I don't suspect it's a problem with the servo. The manual trim wheel works fine. There was some minor work done behind the panel during this annual; adding two wires to the Garmin GPS and routing them to a new button on the yoke, as well as removing and re-installing the engine monitor and a slide-out/slide-in replacement of the GPS. I expect this activity dislodged some wire or connector behind the panel. The wire added to the yoke was on the right hand side, opposite the electric trim and AP disconnect and CWS buttons, so I expect those remained undisturbed. Any ideas on what I can look for before I just take it to a shop and start paying for someone to figure it out?

-

Tight Landings, Take Offs, and Close Calls!

wombat replied to Tim-37419's topic in General Mooney Talk

That first plane looks like Bryan Painter's plane. Don't know if he still owns it. Update: He doesn't, but I don't know when that video was from. I'm pretty sure he painted it (haha) so this would have to be after he bought it. But he was very much into doing this sort of thing, so I would be not at all surprised if he's the one that was flying it for this video. Survey (and FAA) says no: https://www.flightaware.com/resources/registration/N5842Q Date Owner Location 24-Jun-2019 BRADFORD MICHAEL SAN JOSE CA 28-Mar-2019 TAYLOR GAIL L RED BLUFF CA 14-Mar-2018 CARTER TERRANCE B SACRAMENTO CA 14-Feb-2018 PAINTER BRYAN J RENTON WA 07-Nov-2014 PAINTER BRYAN J AUBURN WA 10-Feb-2012 PAINTER BRYAN J FAIRFIELD CA 25-Jul-2008 PAINTER BRYAN J TACOMA WA 18-Jul-2008 REGISTRATION PENDING TACOMA WA 02-Jun-2006 ORR RONALD L BRYAN TX -

Want a Mooney M20 but no hangars available.

wombat replied to thevaliant's topic in General Mooney Talk

I recommend getting the plane whenever you want. They are airplanes, not marshmallow peeps. They won't melt in the rain or the heat. Sure, it's less good to leave them out, but you still have a plane you can fly, even if it sits outside. -

Sorry to hear about your fuel tank problems. I took my Rocket with Monroy long-range tanks to Wetwingologists last summer to have all of them resealed. He was on time and on budget. It's only been 6 months, but no leaks yet.

-

It's interesting how the climate that people live in seems to determine what they consider to be "too cold". My Midwest friends don't do anything special if it's above freezing. My Northern Midwest friends will preheat if it's below 10F, but still fly. My California friends will preheat below 60F, and won't even try to fly if it's below 40F because it's too cold and will 'damage' the plane regardless of preheat. Continental's recommendation (for a TSIO-520-BE) is to preheat for 30+ minutes if the engine has been below 20F for 2+ hours. But they also have procedures for starting if you do not preheat below 20F. For good engine longevity, follow the manufacturer's recommendations with a little extra leeway. (Don't run quite so hot, don't start it quite so cold.) For best engine longevity, submerge the engine in oil and never run it.

-

New Flying Club Forming at Auburn, WA S50

wombat replied to Steve Hughes's topic in Miscellaneous Aviation Talk

I had some extensive discussions with my insurance agent last year. For 1 to 5 people, from an insurance perspective it's just a co-ownership situation, regardless of how you have formed the group's finances. For 6 to 9 people, it's a 'club' and the rates are roughly 2X the rates for co-ownerships. For 10+ people, it's a 'rental' and rates are roughly 4X that for co-ownerships. This does not mean you can rent it, but that the rates are similar to what they would be if it was a rental aircraft. -

I've found that I can 'trim' the plane slightly by moving my body forward or back in the cabin. Even leaning forward or back can have an effect I can see. If the autopilot is on and in altitude hold mode it'll correct for it, but movement within the cabin can cause slight pitch and roll of the aircraft.

-

The only time I wish I had thinner shoes is when I'm providing instruction to PPL students or new tailwheel pilots. In those cases I want to feel what they are doing on the rudder without putting enough pressure on that they might feel what I'm doing which could cause them to change their behavior or think I'm trying to take over.

-

My typical rocket weight in flight is about 3,000#

-

Then my 75% LOP power fuel flow is 16.697 GPH. The ROP numbers in the POH for 75% power are for 20 to 21 GPH. Quite a difference.

-

Please don't mis-understand my position here. I'm not planning on taking any blanket statements and going out and operating my engine this way. I am gaining academic knowledge which I can perhaps use in a thoughtful manner to expand my engine operations envelope. But in the continuation of this pursuit.... If we take 305 HP as my 'max', and then anything less than 228.5 HP is < 75%. So 228.75 HP / 14.9 gives me 15.39 GPH; therefore any time I'm at 15.39, if I can get the engine to run smooth (and the temperatures to be OK, and the MAP & RPM combo is OK) then I'm not hurting the engine, regardless of what position. the levers are in. @Fly Boomer Continental says 470 is OK. Nobody here seems to believe it, and I'm not getting anywhere near that temperature on my engine. But that's why I picked 390 as an "OK" temperature.

-

Looking for PIREP on Wet-Wingologist East

wombat replied to FLYFST's topic in Modern Mooney Discussion

I had Edison at Wet Wingologists seal my tanks (4 tanks total, since I have the long-range Monroy tanks) in June of 2023. No leaks so far. He was accurate in terms of budget and time. I'm a satisfied customer. -

So if my full power fuel flow is 33 GPH, then anything less than 24.75 GPH is less than 75% power. So is it impossible to hurt my engine (regarding LOP operations, assuming the MAP and RPM are acceptable values) if my fuel flow is less than 24.75 GPH?

-

My personal opinion is that the FAA's real purpose is... To keep the innocent, unsuspecting public safe. And with that in mind, they've done a great job. We had a 10 year stretch with 0 airline fatalities. Amazing. Do they want to get rid of GA? Well, probably. Unfortunately, all of the pilots of these airlines happen to be... Umm.. Pilots. And they all learned in GA aircraft. We keep training them in GA aircraft, then the senior pilots all want to keep having the new pilots trained in GA aircraft too. It's a vicious cycle. I think we *could* do all airline training in simulators and classrooms and eliminate GA entirely. Airline operation is 99.999% systems management and procedure following. No need to learn how to run a piston engine in order to run an Airbus. It would make things easier for administrators and ATC, and cheaper and safer for the public. Get rid of all these little airports all over the place. Get rid of all of these complaints about little planes buzzing people's neighborhoods. Get rid of those 66+ year old crazies that are out there in their bugsmashers and are too old and incompetent to hear "Turn to heading 080" and are tying up the airspace while they lumber around the sky. Get rid of all of these 'airplane accidents' that make people drink before getting on their airline flight because they are so scared. Get rid of all of the planes falling out of the sky onto people's houses. Get rid of anything that isn't fully approved by the FAA first with a multi-million dollar budget. But all those pesky pilots that think you need to learn how to fly a little airplane first.... Ugh.

-

I'll assume that for the purposes of this conversation, you want an airplane that is 'experimental' like all of those cool Van's RVs flying around. Then you can just go fly it whenever and wherever you want and modify it with parts from the Aviation isle at Home Depot. That means experimental amateur-built. While there are some limitations on what you can do with it, all of the other experimental varieties have a lot more restrictions. And the rule is that the builder must have built 51% or more of the aircraft. As of 2020, according to Ron Wanttaja (another member of my local EAA Chapter, that I've been participating in for about 10 years now) the FAA's stance on the use of certified aircraft assemblies has varied over the years, and they are currently doing this by task. Read a little more here: https://www.pilotsofamerica.com/community/threads/certificated-parts-on-amateur-built-question.127940/ Also, read more here: https://www.faa.gov/documentLibrary/media/Advisory_Circular/AC_20-27G.pdf Could you put a turbine on an M22 and fly it under experimental R&D? Sure. But you can't take your family. Could you put a turbine on an M22 and fly it under experimental AB? Nope. Could you take apart an M22, and use some portion (less than 50%!!!) to create your own experimental amateur built aircraft that has a turbine? Sure. It's a LOT of work. Good luck, have fun! I'd love to read about it.

-

So funny, I know people that fly at towered airports only and will refuse to go anywhere without a tower, and those that fly at untowered airports only and will refuse to go anywhere with a tower. Remember: All of the 'traffic procedures' and radio calls are there to prevent mid-air collisions. There are not all that many midair collisions to start with. Looking at the most recent ones listed here: https://en.wikipedia.org/wiki/Mid-air_collision l Out of these 3 out of 8 might have been prevented if the pilots had and used ADS-B in and out or their radios. The other 5 out of 8 would not. In the Winterhaven one, the cub didn't have a radio and having the cub on the radio could have prevented it, as could have ADS-B in on either plane if both had ADS-B out. In the Dallas one both aircraft had and were using radios, but they were doing a bunch of close proximity maneuvering due to the airshow. I doubt ADS-B would have helped, due to the update frequency and known close proximity they were flying. So this would not have been saved by radio or ADS-B. In the Longmont one, it looks like the Sonex didn't have operating ADS-B out but since there are RADAR tracks (according to the article on cpr.org), and while they both had radios, they were not in a location where we would expect them to be on the same frequency. The Sonex did have a working transponder and was visible on RADAR, so if either plane had ADS-B in, both planes would have been visible. According to some comments on the avweb article about this accident, the Cessna did have ADS-B in. But despite having it and having both planes be visible to the ADS-B in aircraft, they failed to see and avoid. This was not prevented by having radios and ADS-B. In the Malibu/Cessna midair in Vegas in 2022, and regardless of ADS-B status, both aircraft had and were using radios. But since they were operating in known close proximity, ADS-B would not have helped. So this was not prevented despite having radios and ADS-B. The Key Lime & Cirrus mid-air in Arapahoe County in May 2021 is extremely similar. Such close proximity that ADS-B would not have helped, and both were on the radio, just that one wasn't flying what they were supposed to. In the Soldotna accident, one had ADS-B -out and the other did not. I didn't find anything to say if the ADS-B out equipped plane also had ADS-B in, but if it did (and the pilot had used it, AND the other plane had ADS-B out) that likely would have prevented the accident. The George Inlet midair in 2019 could have been prevented by having and using ADS-B in and out, but it doesn't seem like it would be reasonable to expect even above average radio use to have prevented this. Just out in the middle of nowhere, I don't make regular position calls on 122.75 (Air-to-air frequency) The F-16 & Cessna 150 was also not preventable by ADS-B or radios; the F-16 pilot was provided plenty of advance warning about the 150 and chose not to change their course.

-

@A64Pilot Let's say these are steady state temperatures and I achieve these temperatures by slowly approaching them from the 'cold' side of the curve, regardless of which side I'm on. (if I'm LOP, I approach it slowly from being too lean, and if I'm ROP I approach it slowly from being too rich) So there is no risk of anything from the lag between the actual in-cylinder or in-exhaust temperature and the measured temperature from the probe. If I do this, am I potentially damaging my engine despite the RPM& MP combo being an approved one and the CHTs and TIT are 'OK'?

-

Here is a question for folks about running a turbocharged engine.... If Cylinder temps are "OK" (Let's say 390, and redline is 470 on a Continental TSIO-520-NB) AND Turbine inlet temperature is "OK" (Let's say 1,600, and redline is 1,700 for 1 minute max, 1,650 max continuous) AND The manifold pressure and engine RPM combination is found as an acceptable power setting in the manual. (Let's say 32" and 2,400 RPM) Then: Am I running my engine safely regardless of where I am in relation to peak EGT or 'the red box', and what manifold pressure, RPM, and fuel flow I'm using? Asked another way, are the absolute value of those temperatures the sole measure I need to determine if I'm running my engine in an 'healthy' way? (TIT in order to make sure the turbine is safe, and CHT to make sure the rest of the engine is safe)

-

I took a look at the web page for this plane. A few things make me question the accuracy of much of the data. I am skeptical that this plane flies at 201 KIAS. Maybe 201 KTAS, but my Rocket only flies at about 165 KIAS at high power settings. But then they compare it to 178 KIAS from the Cirrus SR22T, that doesn't match any airspeed Cirrus claims. Umm.... What? Also, the useful load listed by Cirrus for the SR22T is 892 but n252q.com lists it at 820. The 'best range' listed for the Cirrus is 947NM, but Cirrus claims over 1,000NM. So......

-

Please don't take any of this too seriously, but.... I already know both tanks worked before taking off, because they worked last flight. What happened while the plane was on the ground that would have caused it to work the previous time but not this time? If the answer is 'nothing' then you gain nothing. If the answer is 'something', then... What the heck are you doing to your plane? The thing is, there will be a first time that it fails. If we assume that there is a 0.0001% chance of failure any given time you use it, it's just as likely to fail in flight regardless of if you tested it before. If testing it before is good, why not test it twice? (Left, Right, then back to left)... You only tested it one direction if you just swap the one time! If testing it once is good, I should probably test it twice. If twice is good, more is better. To be extra safe, I should sit on the taxiway and swap fuel tanks until I run out of gas. If the selector valves have an average lifespan of 10,000 movements, and an average flight has 2 changes in flight, then by doing a fuel tank swap before each flight reduces the life span of your valve by 33%. If I landed and dropped off a passenger, should I test again before taking off again? What if I just did a stop-n-go? What if I stopped for lunch? What if I stopped, took a nap in the hangar and then took off again? What if I went home in the meantime to nap? How does the selector valve know if I went home or not? Seriously, I don't think there is single perfect answer here. Follow the regulations, evaluate the risks, and mitigate them until your mitigation costs and risk acceptance level are good for you.

-

I actually do like how you did that, a LOT. Do it within easy gliding distance of a long runway, at significant altitude. If you someone is uncomfortable with this, they should probably practice their engine failure procedures until such time as they are comfortable.

-

I would prefer an airport with a car available than one with a hotel nearby. I should really get an electric bike or some sort of 'better/faster than a folding bike' transportation I can put in my plane. Currently I have a couple of super old and cranky folding bikes. While they are way better than walking for any distance of more than about 1 mile, they are quite unpleasant to use for anything more than 5 miles or on hills. Electric scooters are quite small, don't have a steep learning curve, and are very affordable. Best Buy is offering a 20MPH one with 31 miles of range for $559. Their biggest downfalls for me are: The size of the tires and their inability to handle rough terrain, rocks, pavement cracks, and soft surfaces like sand. The weight (40# or so) The industry is full of cheap knock-off brands and the price premium for well established brands doesn't seem to come with a quality premium.

-

Can you take a handheld transceiver on a commercial flight?

wombat replied to Yariv's topic in General Mooney Talk

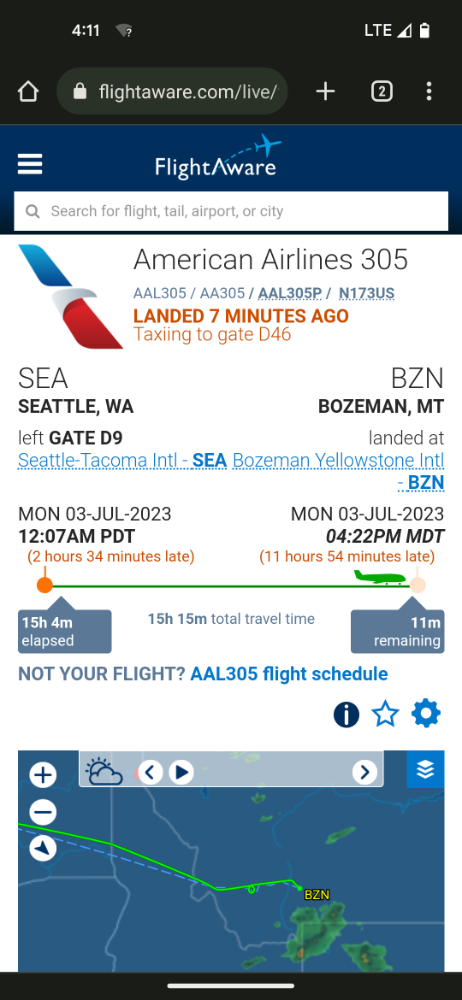

Thread drift to a funny story.... I was flying down to Miami from Seattle this summer on an airline and one of the FAs had a medical emergency (She ended up being fine) so we diverted. Sudden descent and loud noise in the cabin as they started dumping fuel. One of the pilots gets on the radio and says we are diverting to Boise. I get on my iPad and watch our progress as we approach and land at Bozeman. As soon as we are on the ground, everybody gets on their cell phones and starts making phone calls to loved ones, telling them we are at Boise. I corrected a few of them, but quickly gave up. It was pretty funny. -

Or flying an instrument approach or any of the visual approach indicator systems on final approach.... If your engine quits, you will not be landing on the runway this time. But it's all about the different risk profile that different people are willing to accept. Some people are confident that their engine will not quit in cruise flight, therefore their assessment of the risk of night flight over mountains is low. Some people have low confidence in their GPS hardware, so a second GPS makes them feel safer. Probably worthwhile to look at what the causes of actual accidents are and mitigate those rather than perceived risks that have negligible actual accidents.