philiplane

Verified Member-

Posts

1,278 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by philiplane

-

Radiant Power charges $6k to repair the engine data computer for the early Cirrus EIS that displays on the Avidyne EX5000 MFD. The computer used to cost $1100 exchange from Cirrus, before RP took over the line.

-

The biggest downside to ripping out the original gauges, and going all EIS, is when the EIS fails. Then you have nothing, and you're grounded. The advisory monitors can give you all the information you need, without that risk. I have an Insight G4, and my original gauges. All of which have been overhauled, so they function perfectly. I've fixed four complete EIS failures so far this year in customer airplanes. Three were failures of the GEA71 engine computer, which grounds the plane. The fourth was a shorted power line to the 5 volt sensors, which takes out fuel flow, manifold pressure, and oil pressure, also grounding the plane. How often does this happen? Not often, so far, but these systems are already aging since they date back to 2004. But with legacy gauges there is no single point of failure that takes out everything.

-

Friends don't let friends buy MT props. Stick with a two blade for speed, light weight, and durability. Hartzell is best in that regard.

-

I've had no such problems. I apply it on a dry surface after washing, rather than the wet method that can also be used. I would guess that spotting might occur using the wet method, if the water has contaminates in it. Like chlorine, minerals, or salts, which is very common. But the instructions also direct the user to towel dry the vehicle after using the wet method. Which is where some people might get lazy, and end up with spots. I don't see any way that the product itself could cause the problems they're having. All sealants require a clean surface first. Good sealants will seal any contamination or stains in, just as well as they seal the paint. So of course, those defects would be "hard to remove". I've also used all those others, and the previous best paint sealant I liked was Rejex. The only downside to Rejex is that it takes more effort in application. I've been using hydrophobic coatings in my mining equipment applications for ten years. Those coatings are applied more like clear coat, and they are designed to prevent mud and calcium dust from sticking. They dull the paint, but they do have a life span of 5-6 years. It seems that MAXL has figured out how to combine hydrophobic properties with high gloss, which are normally mutually exclusive.

-

Forget the hassle and expense of "ceramic" coatings. You should try MAXL MAXEasy. It's easy to apply, repels everything, and lasts about year. It's not expensive either. It's a triphene coating with extreme hydrophobic qualities, so dirt and bugs don't stick, water slides right off, and the gloss is outstanding. I've been using on the plane and the cars for six months so far. Unbelievable product!

-

Half of that loss is due to forward CG alone. The three blade prop has more drag than a two blade, but worse, it's heavier. And that extra weight is all the way upfront, causing more load on the tail. Figure out how to get your CG further back. Push your seat back in cruise, add weight to the baggage, etc. Mooney, like all other manufacturers, got the book speeds with the plane loaded to gross weight, but also with the most favorable CG. But most pilots fly at or near the forward limit, which adds a lot of drag, slowing the plane down. Cooling drag is the next big item to tackle. If the engine baffles aren't perfect, a lot of air goes through the cowl, but in the wrong manner. You end up with higher CHT's, and can lose 2-4 knots depending on how bad the leaks are. External things like antennas and gear door rigging, and flight control rigging, are the smallest contributors to your problem.

-

oil starvation due to main bearing shift, or other blockage of the oil system. I personally know of two dozen ventilated Continental cases over the past 25 years. But zero Lycomings, even though I've seen more large Lycomings over the same span. Lycoming failures tend to come from broken exhaust valves, and that doesn't trash the whole engine. Also, since Continental camshafts are at the bottom of the case, all that extra oil just falls into the pan. The top mounted cam in a Lycoming spills its overflow oil onto the crankshaft.

-

It's yet another big Continental with a hole in the case. It seems to always be #2 or #6.

-

For those who have the SureFly

philiplane replied to Matthew P's topic in Vintage Mooneys (pre-J models)

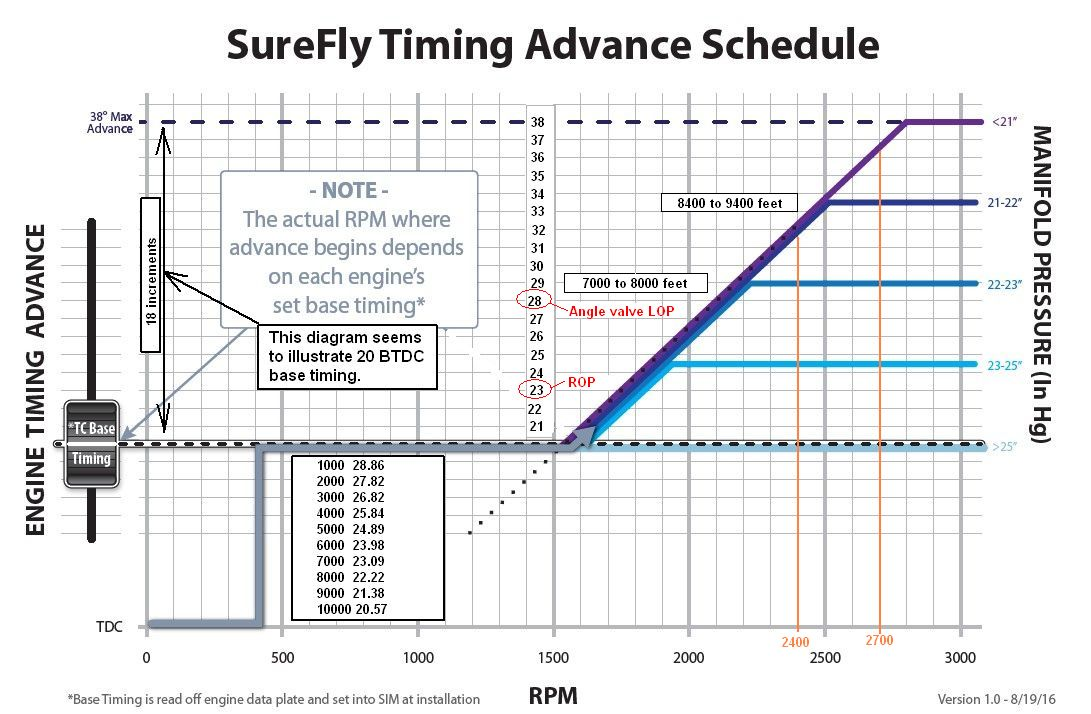

Surefly has timing advance based on MP and RPM. The Electroair only uses MP, and only advances below 25" MP. -

For those who have the SureFly

philiplane replied to Matthew P's topic in Vintage Mooneys (pre-J models)

A Surefly is even better than an impulse coupling, because it has full voltage available the moment the engine turns. It doesn't even need a half turn or more like an impulse coupling or shower of sparks. I had impulse coupled mags, and no starting issues hot or cold, but with the Surefly, the starts are exceptionally fast. As soon as the prop turns, it's running. -

It has no effect. Any Continental engine, large or small, in any airframe, suffers the same short cylinder life.

-

I personally fly a pair of 540 Lycomings in my Aztec. Best engines ever built. Strong, reliable, low maintenance. Continentals have a reputation for weak cylinders. The folks on the Beech and Cirrus forums list cylinders as their biggest problem. And it is a design problem. There's nothing you can do but spend extra money to head off problems that do not occur in Lycomings. Sodium filled exhaust valve stems have been a solution that extends the life of any engine. Ford used them in their industrial and heavy truck gas engines starting in the 1960's. It's a proven technology. Continental would be wise to adopt this simple tech to help extend the life of their cylinders. The associated problem is harder to fix. Continental put the cam below the crank, which also means the pushrods are at the bottom of the cylinders. But the cooling oil that travels through those pushrods does not defy gravity, and flow freely upwards onto the valve stems. This is where the Lycoming design, with the cam above the crankshaft, is superior. All that cooling oil flows downward over the valve stems in a Lycoming. Much more cooling oil flows down and over the valves, than is splashed upward on a Continental. So Lycoming has a cooler exhaust valve, due to the sodium filled stem, and more oil to carry that heat away. Continental has neither. Continental relies only upon a rotocoil to rotate the exhaust valve, to help distribute the heat evenly. The low expectations of Continental cylinder life are something that people live with in return for a slightly more efficient engine. But the gas money you might save, is given back many times over, in maintenance costs and shorter service life. So why do some OEM's use Continentals instead of Lycomings? Years back, it was a combination of price per HP, and fuel efficiency. Longevity is not a concern for an airframe manufacturer, because weak cylinders and other problems don't come up until well after the airframe warranty has expired. One great example of change is the Cirrus SR20. Introduced with six cylinder a Continental IO-360-ES in 1999. But when flight schools demanded better, Cirrus switched to the four cylinder Lycoming IO-390 in 2017. Because it's a better engine, with greater longevity and lower maintenance costs.

-

I change at least 80 rotocoils each year as preventative maintenance on 550 Continentals. And do exhaust valve lapping. Otherwise, these engines will not make TBO without cylinder replacement, turbo or non-turbo. The Lycoming engine does not suffer from this problem. Nor does it have starter adapter failures. I would choose a Bravo over an Acclaim if you are concerned about reliability, or choose the Acclaim if you really need the last few knots it will give over the Bravo. But remember that the Acclaim needs to be faster while in flight, because it will spend more time in the shop. There's no getting around that. Continental has a weak cylinder design, with the rocker arms at the bottom of the cylinder where they don't get much oil onto the valves. And lacking the sodium-filled exhaust valve stems that Lycoming has, the Acclaim exhaust valves will NEVER last as long. I'm drawing on tens of thousands of hours of customer's airplanes flights over the past three decades. It is extremely rare for a Continental engine, let alone a turbo Continental, to make TBO without cylinder changes. And there is also the bearing shift problem after cylinder maintenance. There are hundreds of Continental engines that have thrown rods through the case with no prior warning. Lycomings can do the same, but it is extremely rare.

-

Anyone Running a GNS480 w/ GMX200 MFD Combination?

philiplane replied to bigmo's topic in Avionics/Panel Discussion

there is a GNS480 owners group: https://gns480-users.groups.io/g/main -

Here's a fresh data point to consider. Cirrus has adopted the Earth-X battery in the 2024 models. I have a client with a six-month old SR22, and his Earth-X battery just failed. Probably due to my main complaint, which is the small reserve time compared to conventional batteries. The newer Cirrus have an app just like newer cars do. (Cirrus IQ)You can check the status of the plane from your phone. The problem is, planes usually reside in hangars, where there may be limited or no cell network. The plane's IQ unit tries to connect with the network, and will continue until the battery is dead. Like any cell phone will do under the same conditions. But with half the reserve capacity of a conventional battery, well, you get the idea. Dead battery, quickly. It also appears that the Earth-X battery does not come back quickly after using ground power to charge, and then start, the plane. They tried, and had to ferry the plane over to a Service Center to sort out the cascade of failures resulting from the dead battery. I think they'll be replacing it with a good old Concorde RG24-11M. Unfortunately, Cirrus changed the battery tray when adopting the Earth-X. So if your lithium battery dies on the road, you are stuck until a new one can be delivered. Like anything new, getting replacement parts can add to the downtime.

-

How Many Hours is Too Little Hours

philiplane replied to bigmo's topic in Miscellaneous Aviation Talk

Borescope the cylinders, and pull the pushrods & tubes out on one side, to remove lifters and inspect the camshaft. This would only take half a day to do. And it will reveal any possible corrosion that could shorten the life of the engine. In the event you find any minor pitting on the lifters, they can be replaced easily. So long as the camshaft itself passes Continental's Service Bulletin specs. -

The contract towers in Florida seem to work better than FAA staffed towers. The worst tower is at Fort Lauderdale Executive. It's not only an FAA tower, it's s training tower to boot. Super inefficient.

-

That's odd because Lycoming has been shipping ahead of schedule on many engines. Previous 10-12 month wait times have been reduced. The last IO-360-M1A engine I ordered was quoted at 11 months, revised to 8 months shortly after, and was delivered in 6 months. And a turbo Aztec engine (close relative of the Bravo engine) came in 8 months rather than the 15 months first quoted.

-

Having dealt with six different FDSO and two different ACO offices, I can tell tell you that the problem is definitely a government issue. They all use the same book of rules, but no two will "interpret" them the same. Even though they go to classes specifically designed to identify and prohibit "inspector's personal preferences". And over the past decade, it's increasingly difficult to get any inspector to sign off on anything new. Want a Field Approval? No, spend $$$$ and get a DER to draw up an 8110 instead. And check rides for an initial CFI was the sole province of the FSDO. Now, they're being done by DPE's. They're getting paid more and more, and putting out less than ever. Doling out what used to be FSDO core functions, to designees. I sympathize with the employees though, they waste huge amounts of time on non-productive bureaucratic chores that Washington thinks are needed. Oklahoma City has no say in the matter. This has led to FSDO shopping, which the FAA is trying to stamp out. There are a few FSDO's that are still operating like they were 30 years ago. That will change as the oldest inspectors retire.

-

Therein lies the problem. Why is moving a shop from one FSDO to another such a difficulty? The FAA exists to ensure that safety is assured. But it often results in completely unreasonable costs and delays, without ensuring or improving safety. This has to change.

-

Ovations are nice planes overall. To keep it running well, replace the exhaust valve rotocoils every 800 hours. And use oil analysis to track nickel trends, which will tell you well in advance if an exhaust valve guide is wearing. In combination, these items can help extend the cylinder life dramatically.

-

3AA standard steel cylinders have no life limit 3HT lightweight steel cylinders have a 24 year life limit Composite cylinders usually have a 15 year life limit.

.jpeg.9e0eca0f584aeebe8af53bf1ef9feb69.jpeg)

.jpeg.8a1b6f6fe56bbc93aaba7caedb619c7e.jpeg)