Leaderboard

Popular Content

Showing content with the highest reputation on 11/23/2025 in all areas

-

Just an update for everyone - it looks like after a few days of working with my hosting company they FINALLY a) admitted this was a problem with their top level DNS servers and b) they managed to fix the issues. I am not sure what exactly was wrong but it was something with the SOA (start of authority) DNS records for the domain and something that is outside of my control. So users that were not able to access the site with certain ISPs (Verizon and CenturyLink are ones I am aware of) should now be able to find our site again. This also fixed the email delivery issues we were having with Yahoo (and their subsidiaries like AOL and SBCGlobal) and Apple as far as I can tell looking at logs over the past 12 hours the emails seem to be going through now. If you do have any issues I would appreciate you letting me know by shooting me a message here at @mooniac58 Thank you for your patience! Craig4 points

-

3 points

-

You cannot use just any old POH. You need the POH/AFM that goes with your specific airplane serial number. Mooney can supply that if you don't have the correct one. However, since your airplane has been modified, any change in limitations caused by the modifications need to be taken into account. If the mods were done by STC, the documentation would have a AFMS that would list any changes to the limitations. It becomes tricky when multiple modifications are applied because of the potential for interactions between them.2 points

-

It's not quite that simple. If Bendix King still makes theses servos they are North of $5000 each, maybe closer to $10,000, and that may or may not correct the problem. You need someone other than just an avionics shop's opinion - someone that deals with autopilots every day. Talk to @Jake@BevanAviation2 points

-

Most likely running down from above. There is no oil behind the O-rings.2 points

-

Knowing the target approach speed provides a crosscheck for your AOA indications. And of course the elephant in this room is, not everyone has an AOA display.2 points

-

Before going down, I digitized and cataloged every record for this airplane (bookmarked PDF of each log). I had the AD research for the last annual and the pre-purchase that was done in April. There aren't that many issued against the J. I tried to make it as easy as possible to point to the records to reduce time spent in the research. 3 results: 1. This isn't applicable- NA. I didn't make that call, the last two shops did (and the prepurchase was done at a MSS) 2. This is applicable and due at this time/date. Some were deferred, others accomplished 3. Here is your fresh printout for your logs as to what is left to do1 point

-

I can always tell the chocks are there when I can't taxi away. Once I stopped briefly at an FBO to drop off a friend, and visited the men's room. Didn't chock the plane, started up and couldn't taxi. Shut down, got out and removed a mystery set of chocks, and not knowing where they came from, I just moved them out of the way, cranked up and taxied away. Have only missed the pitot cover one time, knew something wasn't right when the Airspeed needle didn't come alive on takeoff. The runway was long enough to stop and taxi back; my wife volunteered to get out, circle behind the plane and remove it without shutting down since temps were around freezing. Sure is nice to have a supportive, understanding spoise!1 point

-

The manufacturer needs to do the testing and I can't see Mooney doing it; maybe they'll be willing to outsource it to you.1 point

-

I hate oil leaks! I want my engine to rust away from the outside not be preserved in a bath of oil! :-) My guess is the rocker cover drain tubes hose couplings above. Just found my prop governor cap leaking on last trip so off it comes next week in annual. Antique airplanes take constant maintenance just like old Rolls Royces !! :-) Don't fall behind on the job.1 point

-

Probably the smartest move but be aware you may know more about the subject than the one you talk to so YOU may be doing the educating at first1 point

-

So to “Carusum” (summarize), 1 qt in 7 hours is just fine but you should look into it because something isn’t right and it won’t get better by itself. It’s probably not urgent.1 point

-

The intermittent alternator over voltage light came on a couple of times for no apparent reason. Not wanting to be stranded, I took the precaution of buying a solid state VR and stored it in my baggage compartment. The light never came on again. I have since sold the plane, but still have the VR. As far as I know the "fix" is still working. Anyone need a spare "over-voltage preventer" for their baggage compartment?1 point

-

Lycoming says allowable oil consumption is up to about .65qt per hour for your motor. So you are far from that.1 point

-

Probably more likely or just as likely to cause an accident as to prevent one which is why this isn’t common practice.1 point

-

It doesn’t sound like you are going to run out of oil, but it should be fixed, if for no other reason, so your airplane doesn’t look too ghetto.1 point

-

1 point

-

New engine? I guess those are Teflon hoses (replace on condition), otherwise they look kind of oldish. Sources of oil from 'up above' include the rocker box gaskets, rocker box drain B nut connections, intake manifold gaskets, push-rod tube seals, and even exhaust flanges. Engines that 'pool oil' in the cylinder at shutdown can leak it at the intake and exhaust stack connections. One mode of this is oil coming down the valve stems. The #2 intake runner is most susceptible to chewing it's gasket due to it's length. If it doesn't leak out the flange it will likely end up in the induction chamber where the four intake runner connect. The next time you flood the engine some oil will wash out the sniffle valve. But....what you're seeing is a relatively small amount of oil compared to a quart. IMHO.1 point

-

Also the fact that that it can’t be coming from the intake doesn’t mean “nothing to be concerned about” you need to find where it’s coming g from to make that determination.1 point

-

In regards to your glideslope issue, have your avionics guy use a signal generator to determine if it’s the instrument or the antenna. Your post above mentioned that on an ILS your other instrument didn’t show glideslope until close to the station. This could also be an issue with your antenna diplexer.1 point

-

I think you may be confused on how the HSI works. It is two separate systems, integrated into one instrument. There is a heading component, and a navigation component. Other than being displayed on the same instrument, the two have nothing to do with one another. You could remove your GPS from the airplane entirely, and the directional gyro component would still work normally. A compass swing is a deviation check. 5-7 degrees is within limits, but I wouldn’t fly IFR if I was off by that much on the HSI. You can correct for this by having your KA-51 adjusted, which is what I suggested originally. Even the super old units with no internal adjustment, the Bendix King procedure was to actually clock the magnetometer in the wing accordingly to compensate.1 point

-

Just an update for everyone - it looks like after a few days of working with my hosting company they FINALLY a) admitted this was a problem with their top level DNS servers and b) they managed to fix the issues. I am not sure what exactly was wrong but it was something with the SOA (start of authority) DNS records for the domain and something that is outside of my control. So users that were not able to access the site with certain ISPs (Verizon and CenturyLink are ones I am aware of) should now be able to find our site again. This also fixed the email delivery issues we were having with Yahoo (and their subsidiaries like AOL and SBCGlobal) and Apple as far as I can tell looking at logs over the past 12 hours the emails seem to be going through now. If you do have any issues I would appreciate you letting me know by shooting me a message here at @mooniac58 Thank you for your patience! Craig1 point

-

On my last 1994 MSE I completely refurbished the plastic interior parts. Removed all panels, fiberglassed the back side of all cracks, filled front side discrepancies and painted all of them using SEM products sprayed with a small HVLP gun. I reinstalled them using new stainless hardware and they looked absolutely brand new. SEM makes one type of paint for the plastic and a different type for the upholstered parts. You get a very, very durable finish and whatever colors you want. It’s a lot of work but it can certainly be done DIY for very little money.1 point

-

1 point

-

Starlink allows me to refresh my Foreflight in flight at flight levels. I can also use live satellite data feeds, and other data feeds like live webcams via the Windy app for my destination. Can also make WiFi calls, etc from flight levels. I don't mind it on my dash, Bravos don't have much visibility anyway1 point

-

LASAR quit producing this part long before the move to Oregon. I inquired about it six or seven years ago because I thought I might need a new steering horn at some point. Corrine Boatright told me at the time that many of the PMA parts had been made by a local machinist that retired, and since they weren't selling many of these anyway, they decided not to look for another machine shop.1 point

-

1 point

-

Poor man’s aoa just do a power off stall with gear and flaps out. Note speed at stall and multiply by 1.3. After you do that at various weights you will have a good set of numbers for your plane with all its individual quirks rigging issues etc. having said all that the range for mine was about 7 knots and realistically about 5 knots as i will probably never be landing right at gross weight and never empty weight unless i ran out of fuel and being a few knots fast will assure i do not stall it in. Besides with my ol steam gauges my airspeed needle is at least 3 knots fat and only having 5 knot markings it’s really more like closer to one side or the other of 55kts. You young guys with eagle eyes and digital numbers, need to get out of the digital world and flow back to the analog land. Measuring with microscope and cutting with a chainsaw is overkill.1 point

-

For reference, here's a pic of my original '67 fuel vents. For the experts; any reason to not stick a pipe cleaner in there from time to time just to make sure they're clean and clear? Yes you could push something into the tank but what are the options? Haven't looked but I'm guessing you can't go at it easily from the inside.1 point

-

The FAA has been pretty clear that it has to be CAS and CAS since original certifications. For aircraft that do not have CAS, manufacturer need to go out and do the testing. During the process, there was push to allow modification to bring under the 59 knots or IAS to be used; the FAA said no to both.1 point

-

"A smoking hole is a small price to pay for a sh!t-hot approach"1 point

-

Same FSDO or a different one? They each run like separate kingdoms, with different rules and interpretations of the regulations. The FAA should operate the same all over the country, not with ten or twelve or ever-how-many sets of not-quite-the-same rules.1 point

-

1 point

-

AOA indicator. Why go through all the guess work and math when this measures the very thing you are trying to guesstimate using airspeed, weight, and load factor? My 201 takes a 100 gallons so I’m used to flying at all kinds of weights. It is a pretty substantial difference in speed between empty and heavy. I don’t pay attention too much to the speed cause AOA indicator gives me consistent results.1 point

-

I wondered the same thing. In fact, it sounded plausible enough that I made some fuel vent covers in response with "Remove Before Flight" tags to use next dirt dauber season.1 point

-

Two days is not a problem on a J with owner-assisted, i.e., two people working for two days. This assumes that there is no deferred maintenance and no big issues found. Did this many times with my old IA before I started doing them myself.1 point

-

Since I just bought one last week, that's almost a guarantee that a new model is imminent . . . lol.1 point

-

I just put my XM on a 6 month pause and am anxious to try out my Starlink. For the last couple of years if it had been awhile since I flew I made sure I did a refresh signal on the XM before take-off. I kept the info on my phone so I could quickly to a copy and paste the Radio ID into the link for each weather and music and always ended up with good coverage right after take-off. (https://care.siriusxm.com/subscribe/refresh-signal/unauthenticated-landing-page?intcmp=OTHER_NA_www:Home_RequestRadioSignal) Unfortunately our airplanes still have the legacy XM rather than that faster SiriusXM (SXM). Garmin sells a newer box, but it is cost-prohibitive, especially now with Starlink. https://www.garmin.com/en-US/p/228/pn/010-01294-16/1 point

-

Parts like this are more easily made than found. Take your could part and use it as a mold. Hand layup a new part. By rights, you should use antimony trioxide into the resin as a flame retardant. Use mold release. Sand and fit appropriately. John Breda1 point

-

Yes, somewhere around there, 20-30 psi or whatever it winds up being depending on settings. So an actual clog won't come out super easy, but if somebody just puts 90 psi of shop air into a line it's likely just going to just blow everything out. If you creep the pressure up it's pretty easy to tell whether a line/nozzle is actually clogged or not, and then try to catch the material that's clogging it.1 point

-

Typically you blow it out with low pressure over a catch cloth and see what comes out. If only oil splatter comes out, then there probably wasn't anything in it. If it was really clogged it'll hold several psi, because the fuel pressure is higher than that when it's making power.1 point

-

1 point

-

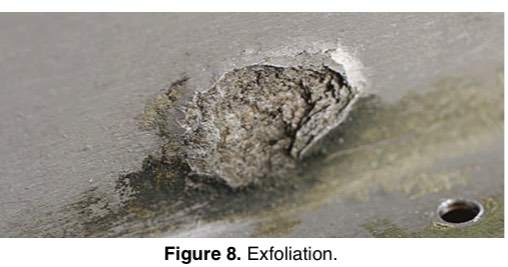

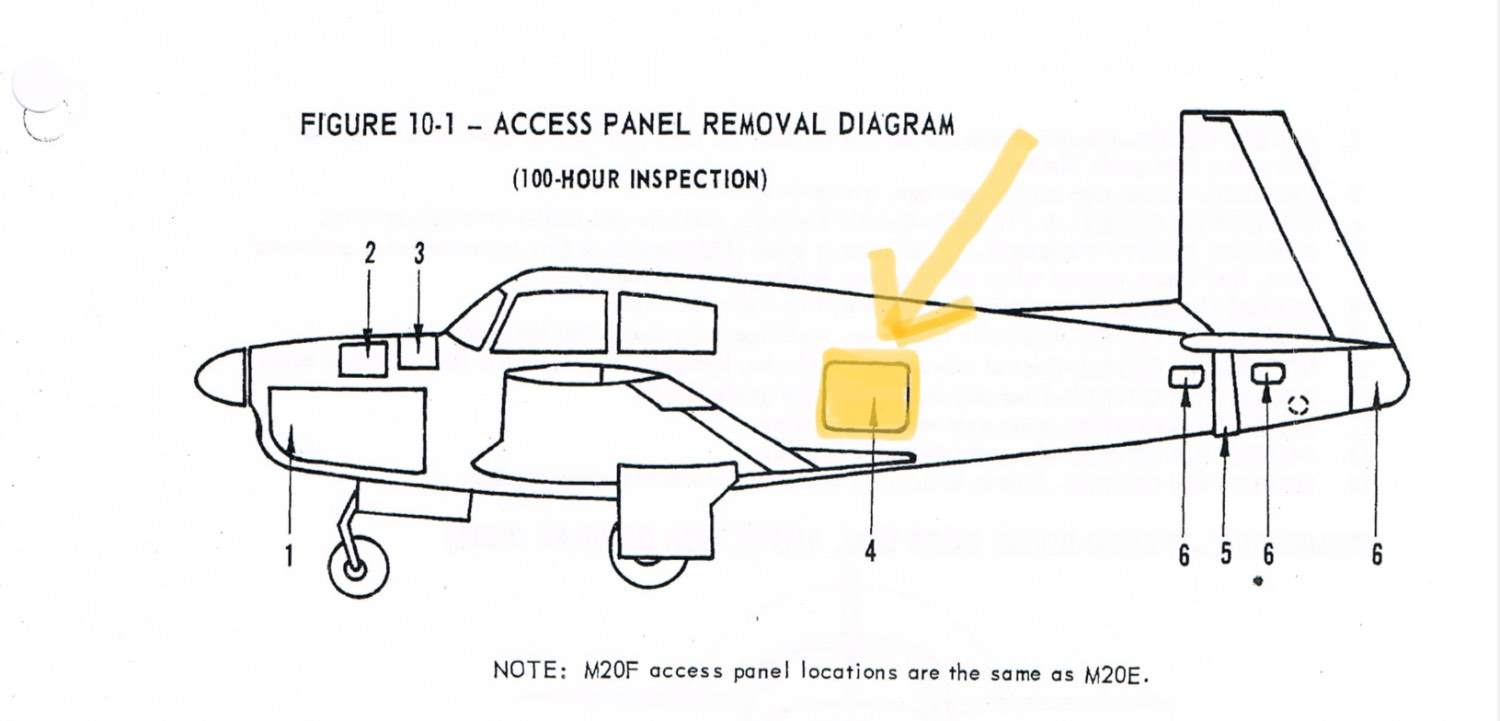

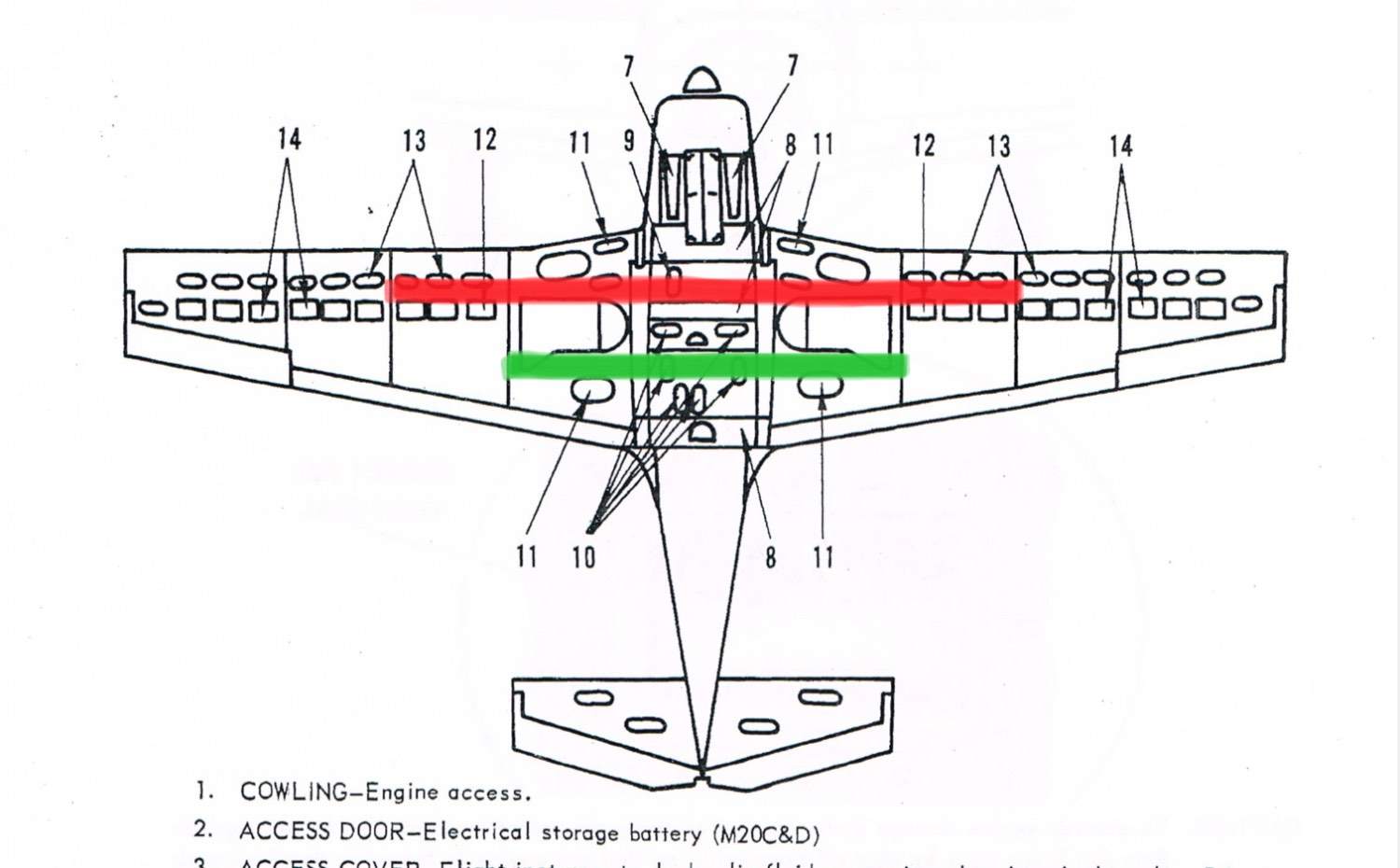

I’ll break my recommendation down into how much time it takes to perform. In general, you need to look at the main spar, the stub spar, the tubular steel frame (covered in SB M20-208), and then general surface corrosion on the skins and corrosion on the angle aluminum pieces. Phase 1 (about 30 minutes: You can see a good bit of the main spar and stub spar in the wheel wells. The main spar is the heavy frame work where the forward landing gear pivot point is. The stub spar is the rear pivot point. Look at as much of those as you can in the wheel wells. You can google search for “aluminum corrosion” and see some good pictures. Surface corrosion isn’t as important as intergranular corrosion, which leads to exfoliation (picture below). Next, look inside the tail cone (see below, marked in yellow with arrow). That panel comes out in less than a minute with 1/4 turn fasteners. Look for exfoliation on the angle aluminum pieces and surface corrosion on the inside skins. While you’re there, look at the pushrods- they are steel and often rust. That isn’t terrible, but does need to be addressed. Phase 2 (about 1 hour): If that initial look is acceptable, then you should dig deeper into the wings. Open up some of the inspection panels and you’ll see more and more of the main spar (red highlight). Look inside inspection panels #11 (see picture below) and you’ll be able to see a good bit more of the stub spar (green highlight). The main spar actually runs wingtip to wingtip, but I’ve noted the location of the extruded angle aluminum pieces that can corrode badly. Phase 3 (about 2 hours): If that seems acceptable, you’ll want to take a look inside the cabin. If possible, remove the back seat and pilot side wall. There are square panels under the back seat- remove one and you can see the inside view of the main spar (red arrow on picture below). Inside the pilot side wall, you’ll see the tubular steel structure that is the subject of SB M20-208. You’re looking for regular rust, particularly below the window frames. On the picture below, the steel tubes are painted green with zinc chromate paint- but you can see at least one tube with a lot of rust on it. That tube will have to be replaced. I’m sure others will chime in with additional suggestions. Good luck! I’m keeping my fingers crossed for you!1 point

-

Or just remove all that linkage and pretend you have Cirrus with caster nose steering.1 point