All Activity

- Past hour

-

- 1 reply

-

- 1

-

-

jamesyql started following Mooney Mustang project on YouTube

-

Just popped up on my feed (not my channel). Check out this Mooney Mustang project. He has also made a website mooneymustang.com. Great to see an iconic plane getting some love.

-

Lasar Aviation Mooney Assurance Program - Really?

Tom F replied to PeteMc's topic in General Mooney Talk

That assumes they have successfully purchased Mooney. Not what I’d call the spirit of the deal however. I’m sure the Lasar guys will take your shortcut into consideration. Good luck with that. -

Lasar Aviation Mooney Assurance Program - Really?

Tom F replied to PeteMc's topic in General Mooney Talk

While I do not have firsthand knowledge of the agreement between Lasar and Mooney, I believe you are correct with regard to the name and the PC, TC, PMA’s STC’s etc. -

Lasar Aviation Mooney Assurance Program - Really?

Tom F replied to PeteMc's topic in General Mooney Talk

I would assume you may be correct on Mooney being broke. Please provide some information to back your claim of Lasar’s financial condition. I’ll monitor and wait for factual information to back your claim. -

Lasar Aviation Mooney Assurance Program - Really?

Tom F replied to PeteMc's topic in General Mooney Talk

You may very well be correct. Unfortunately that’s not where we find ourselves today. -

Lasar Aviation Mooney Assurance Program - Really?

Aerodon replied to PeteMc's topic in General Mooney Talk

Companies like Univair and McFarlane are much better setup to look after type certifies, PMA etc. and support owners. -

Lasar Aviation Mooney Assurance Program - Really?

Tom F replied to PeteMc's topic in General Mooney Talk

Nothing, except it’s not for sale for a $1.00. Business go out of business everyday without filing bankruptcy. You’ve made an assumption without any knowledge of the actual facts. -

The leak may only appear when the metal is hot.

-

Lasar Aviation Mooney Assurance Program - Really?

GeeBee replied to PeteMc's topic in General Mooney Talk

In finance, words and terms are important. It avoids misunderstandings, disappointments, lawsuits and the tax audits. -

Lasar Aviation Mooney Assurance Program - Really?

GeeBee replied to PeteMc's topic in General Mooney Talk

Nothing prevents the existing owners from selling Mooney to LASAR for $1.00 if they want to avoid bankruptcy court. -

Ragsf15e started following Engine Overheating Help (High CHTs)

-

Can you tell from your past engine data that it was colder at some point? Especially before some specific maintenance?? Like maybe before the Surefly was installed? I had one on my F and I really liked it. Never had heat issues, but as @PT20J said, it times a little different than a mag, so could be installed wrong. Or the dip switches set wrong, or maybe even the MP tube not rigged right allowing it to advance earlier than it should? I’m just spitballing here, but I might look back at the data and see if you can tell when it started getting hot. And how long has the SF been on there? Just for clarity, installed properly, the Surefly has a pretty good history of working fine and didn’t cause any heat issues in my F. It should not be advancing at all below about 5,000’ anyway.

- Today

-

One you get that LSA certification has exactly nothing to do with sport privileges, the problem goes away. But I've seen more than enough confusion on it that the FAA probably should have come up with a new category name and tossed "LSA" out altogether. The other one I've seen several times is, you can't fly that Cessna 172/M20J, whatever unless it gets recertified as an LSA.

-

Wow. I think I paid $499 for mine.

-

Fuel flow isn't field adjustable on an RSA injector. I've never been able to find a spec for full power fuel flow on a Lycoming IO-360-A. I have test cell data from Lycoming for my rebuilt, but they only measured airflow at full power, not fuel flow. However fuel flow was measured at three lower airflows (500, 900 and 1000 pph) and extrapolating shows that fuel flow would come out to about 17 gph at 1118.5 pph measured full throttle airflow. I got the bench test specs from Precision Airmotive for the fuel servo. Pertinent test points are at 600 and 1400 pph airflows and that works out to about 16.2 gph 1118.5 pph airflow. The Lycoming Operator's Manual shows a best power fuel flow of 15.7 gph at full power. Full rich would be greater. If I recall correctly from past posts over time, it seems most people are getting around 18 gph at full power at sea level. But I am doubtful that 1/2 a gph would account for the high CHTs.

-

CO2 detectors the "Good The Bad and The Ugly

Ragsf15e replied to Jpravi8tor's topic in Vintage Mooneys (pre-J models)

Excellent question. I’ve read lots of different solutions. I think I used some closed cell foam (think pipe insulation) around the wire bundle on my F. Your mechanic might have different ideas. For me, closing that space changed the temperature a lot, but I wasn’t getting CO in through there. I haven’t looked there on my K yet to see what is insulating that hole, but the cockpit is definitely warmer at cold OATs than my F was, so I’m sure something is there. -

CO2 detectors the "Good The Bad and The Ugly

Pinecone replied to Jpravi8tor's topic in Vintage Mooneys (pre-J models)

It is not saying 0 PPM in the exhaust, but 0 PPM in the cabin. And running LOP you can be close to 0 PPM due to near complete combustion of the fuel, as you are running with excess O2 available. -

Lasar Aviation Mooney Assurance Program - Really?

Echo replied to PeteMc's topic in General Mooney Talk

Ahhhhh. O.K. NOW I better understand. Mooney is broke and Lasar as well as being cash challenged does not want/can't go through part approval process so needs owners to pony up cash to allow that to happen or Mooney goes bankrupt and existing owners lose equity and the liklihood of someone coming in buying Mooney and jacking up prices (more than current out of this world price) will happen...OR an existing specialist in aviation parts buys Mooney and organizes as a PARTS supplier vs. trying to build and sell airplanes under current type certificate (that is unprofitable) as shown by bankruptcy after bankruptcy. -

I have heard of oil coolers being hooked up backwards and causing issues.

-

I certainly wont rule out an induction leak, however I always thought that an induction leak would lead to a rough running idle? This engine runs as smoothly at idle as any IO-360 I've ever flow, for what its worth. My left cowl flap is flat, I will double check the rigging. I know the right side is about 1/2" open when close, but I don't remember if the left one is as well.

-

Lasar Aviation Mooney Assurance Program - Really?

toto replied to PeteMc's topic in General Mooney Talk

I think this was mentioned earlier in the thread, but does anyone know how the Assurance program would affect the MSC network? I'd prefer more, not fewer, MSCs, and the Assurance parts priority thing is a little bit hard for me to get my head around. When I'm placing an order for a factory part but the order is submitted from my mx shop, I assume that Mooney has no idea who the ultimate buyer is. -

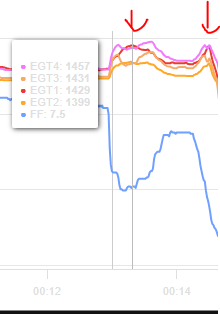

Fuel flow looks a bit low. Rule of thumb is WOT, full right, 1 GPH per 10 HP. So 200 HP engine should be 20 GPH or higher.

-

CO2 detectors the "Good The Bad and The Ugly

Paul Thomas replied to Jpravi8tor's topic in Vintage Mooneys (pre-J models)

What do you seal that with? -

Which is downright confusing to normal people and makes little sense. And will lead to issues with people flying aircraft they are not authorized to fly. Pilot A has a Sport Pilot certificate, so he can fly that M20J, but NOT that Model XYZ Light Sport airplane.

-

MAP would still be less than ambient pressure at sea level, no? Granted not by much, but 4" of pressure difference is enough perhaps for what he is seeing. No? This is curious: FF decreases while EGTs rise twice when I presume power was reduced. Classic induction leak? Also the small rises and drops in EGT could be going so lean that it's over the top and to the lean of peak side.