Search the Community

Showing results for tags 'cylinder'.

-

I need to replace the pilot's brake master cylinders in my 1967 F model. Before I throw down for a set of 10-24D upgrades, does anyone have a set of Cleveland 10-49 master cylinders in good condition that I could buy off of you, or a good place to get them? It needs to be soon; I'll probably pull the trigger on buying the 10-24D's this afternoon. Thanks for any information. Sincerely, Craig Steffen

-

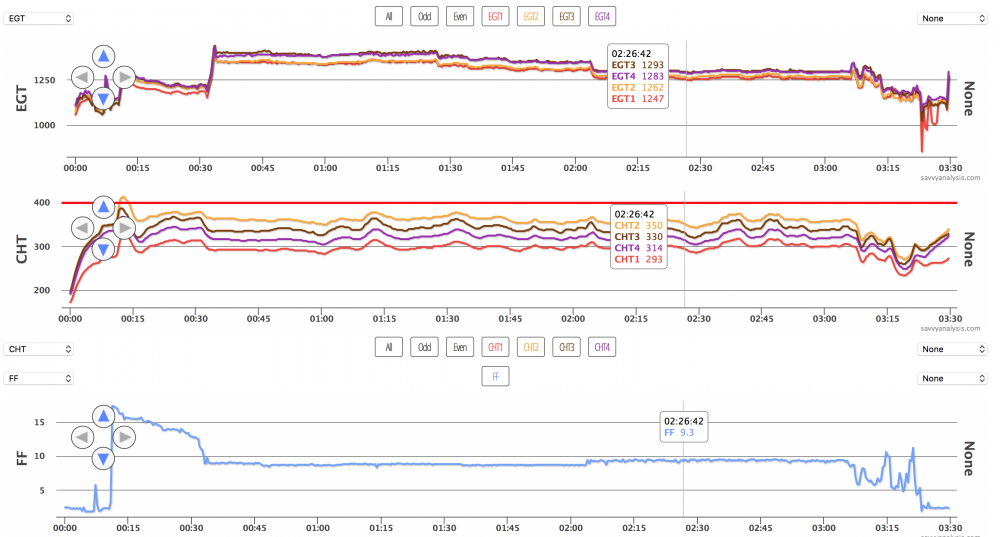

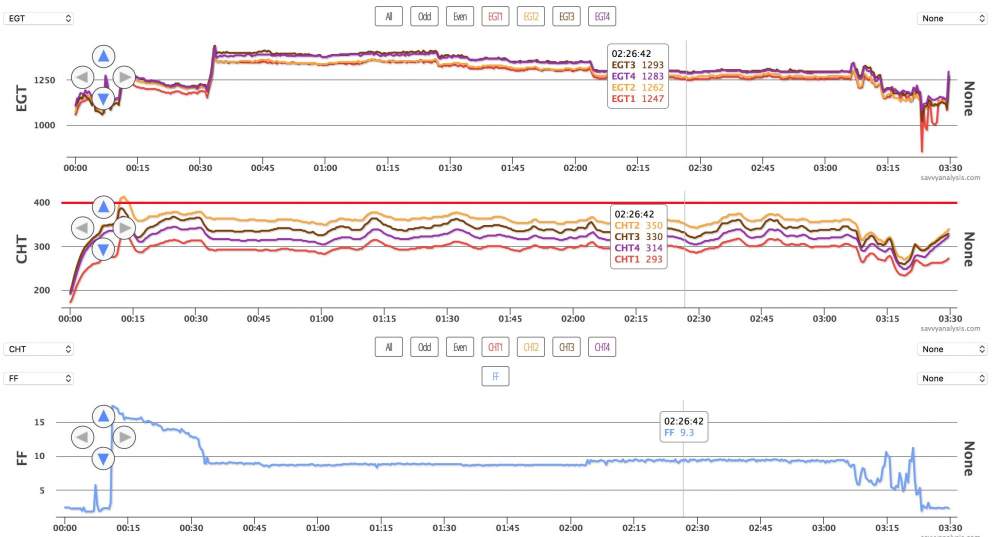

Quick question vintage Mooney officianado's, I've put roughly 35 hours on my new to me 67 M20F since taking ownership and finally was able to download the EDM 700 data. The engine is a Lyc remanufactured IO-360-A1A installed in Feb of this year by prior owners. Normal cowl but it does have the lower cowl cover. I'm seeing a consistent temp split between my #2 (hottest) and #1 (coolest) cylinder of ~70-80 deg F. (attached pic of data from one flight). Engine now running Aeroshell 100+...max fuel flow indicated during takeoff ~15-16 gph She runs smooth, during runup with the JPI Norm mode, all appears to respond as expected. Figured I'd ask if there is a 'normal' or expected temp differential between hottest and coldest cylinder...thoughts ?

- 13 replies

-

Departed NYC metro area at gross weight last week. OAT was about 90 and hit red-line cylinder head temp in climb to 8,500 for about 10 min. Wondering what type of engine issues may arise.

-

This is my first time using the forum. Last week, after doing several practice Instrument approaches each ending with missed approaches, with the two other partners in our 1979 M20J, we noticed the engine running rough when we were taxing back to the hanger. It didn’t seem too bad so we figured we would diagnose prior to the next flight. Also, we didn’t notice it when we were flying After a week of rainy weather, I pulled her out of the hanger, performed a preflight and fired her up. It was running super rough. When I throttled up the electronic rpm gauge would go crazy (running all the way up and then all the way down, even cutting out). Clearly I wasn’t going to fly it. When the mechanic on the field checked it out, he found the plugs were fine and so were the mags. What wasn’t fine was that 6 of the 8 bolts on cylinder two were missing and/or sheared off. Of the remaining, one was tight and the other finger loose. We bought the plane 18 months ago with an overhauled engine that only had 100 hours on it. We also had an annual done in August 2018 at a Mooney service center. The engine now has about 250 hours on it Any ideas how this happened? Did the overhaul guys mess up? Do the cylinder head bolts get checked on the annual? Is it possible that we have been doing something wrong with engine management that would have contributed to this? And most importantly, how do we make sure this doesn’t happen again? It could have been catastrophic if the remaking bolts would have left loose in flight.

- 18 replies

-

- 1

-

-

- cylinder

- engine problems

-

(and 1 more)

Tagged with:

-

Mooney M20F, Lycoming IO360-A1A I thought would put this out there for some advice & feedback. Recently I had my mechanic examine my engine and he mentioned pooling of oil and possible cylinder glazing. Cylinder glazing is a condition that occurs where oil film left on the bore "glazes" to a hard coating and can prevent optimal sealing of ring to bore. The oil here is the result of cylinder head temperatures, CHT'S, not getting hot enough to burn this oil film and. thus prevent the glazing. Optimally, he says, the CHT'S should run about 360-380 F. My engine is seeing a range of 300-320 deg F with an OAT of around 34 F. This is with cowl flaps completely closed all the way, they are closed and flush with the rest of the cowling. All cylinders are running about within 10-15 degrees of each other & measured by JPI930 engine monitor. Of course, my goal is to get these temps into the suggested range. Just wondering if anyone is running into the same issue? what temps do you typically see? Has anyone found a way for the cowl flaps to create more flow restriction? has anyone done anything with engine baffling as to affect the cooling of the engine? Thanks for any feedback. 04/19/2018 -- ADDITIONAL INFORMATION: Thanks for everyone's feedback! what a great resource! I thought I would share what led to the inspection of the cylinders and a give a clarification of the above statements. On a couple of occasions, a ramp guy took notice of a puff of white smoke when taxiing up the ramp. Curiously, I mounted a go pro camera and focused it on the exhaust to try and observe it myself and of course, it never showed up. Recently, I pulled the cowl to check a few items and noticed oil coming out between the exhaust manifold and tube flange at cylinder#4. I immediately sent it in for service and it ended up being a bad valve guide. With all that said, cylinder#4 has undergone a rebuild and will require break-in, hence, the recommended higher CHT's. After clarification and reading all the great comments, this is why he mentioned the glazing and the importance of running higher CHT's. My fault on the interpretation. Fortunately, I do not have any cylinder glazing as all cylinders. were checked at this time. For those that asked, oil consumption has been in the normal range. I have 2 years of history (about 400hrs worth) and it ranges from 0.10 to 0.15 qt/hr. This looks to be well below even what Lycoming says is normal. I found this formula in their manual Normal Oil Consumption (Qt/hr) =(0.006 * BHP * 4) / 7.4. At a BHP of 0.59, this equates to 0.19 qt / hr. Compressions are all good ranging from 77 to 80. One question I do have for all of you, When do you typically add oil? Do you wait til it gets down below the 6qt mark, or, do you add it when it is hovering just above around the 6qt mark? I have been doing to latter. I have heard that these engines typically find their happy spot and then do not vary much. I may be adding too early as it may stabilize at 6qt. Any thoughts here appreciated.

-

looking for Continental IO550G cylinder needed for replacement.

-

Wondering what suggestions I can get on this. A little back ground first. '78 M20J 201 IO-360 ~1500 hours SMHO fly ROP per POH cylinder #3 plug fowled out a week ago (see picture) all new plugs and now I am seeing Cylinder 3 EGT highest and CHT lowest (see pictures) in all phases of flight. Oil consumption, maybe a quart every 6-8 hours and all oil analysis come back with excellent results. I am thinking bad injector and going to Gami. Thoughts and comments much appreciated.

-

Calling all Mooniacs with millennium cylinders, I conducted an oil analysis recently and was told millennium cylinders always have a high chrome content even with steel cylinders. Me and my customer would like to know if you experience the same and if you would screen shot your report so we can see your averages. It would be greatly appreciated.

-

Hi all, After several busy weeks I was finally able to fly last week and run a GAMI spread to diagnose the overheating issue of cylinder 1 on takeoff/climb. Not a massive overheating mind you (~390-400 deg) but still much higher than normal. Below are the screenshots from May this year (poor data rate but it gets the point across) and the one I took last week. You can see that the May spread was very good (about 0.2 gph). The one from last week however shows the cylinder 1 peak occurring roughly 1 gph higher than the rest of the cylinders; the other cylinders all look the same as before. To me this indicates a partial fuel blockage in either the injector itself or the feed line/distributor. I removed the injector before the flight (since I suspected this might be the issue) and everything looked clean and free. Reinstalled and flew the plane. Do y'all agree with my diagnosis? What other parts are susceptible to plugging? Since it's only this cylinder and total flow rates are normal on takeoff and cruise, I'd think it would be something downstream of (or in) the fuel distributor/spider. Should I send the injector back to GAMI to get it flow tested first before I do anything else? -Don

-

So we’re into this year’s annual, and I have a cylinder (4) with a leaking at the exhaust valve 60/80 and it’s opposing partner (3) leaking at the intake valve 72/80. From my logs, these same two problem children were replaced in 2001 and 2000 respectively, so it seems they haven’t done too bad to make it nearly 13 years and 750hrs. (although 1 and 2 are mid 70s and haven’t been touched since shortly after last major in ’89). My IA and I are discussing the options, but basically at 1500hrs and 25yrs, I’m weighing my decision pretty heavily. Oil consumption Is pretty low – 1qt every 6-7 hours. That being said, topping the engine is a thought I’m having, but I’m curious to know if anyone can offer any insight with regard to the “Overhauled” cylinders I’m finding around the internet for around $350-$800each vs the “New” cylinders at $2300 each. The OH’ed cylinders come with 8130, so I don’t think we’re talking about buying some grey market garbage. My thought process would lead me to believe that if I had any thoughts of getting the latter cylinders, I would likely end up better getting one jug for now and a factory overhauled engine in the not so distant future. This is new territory to me, so I thought I’d solicit input accordingly . Any thoughts , constructive input, or things otherwise to be aware of? Thanks! ~Abe

-

This is a little follow up from my other post.http://mooneyspace.com/topic/10331-making-aluminum/?hl=%2Bmaking+%2Baluminum My overhauled cylinders from Ly-Con showed up and I thought a few of you would be interested in seeing them. Ly-con claims 4 to 5 additional HP per cylinder with their porting and flow balancing so I thought I would give it a shot. If you look at the intake and exhaust ports you can see the work is amazing. In the photo above you can also see the dental camera that I bought on Ebay to take the following pictures. This is a close up of intake port you can see the nice smooth surface. This is the cylinder wall and top of the piston. The cylinders where not installed so the piston is all the way to the base of the cylinder or you would see more of it. These are a couple of shots of the valves and seats. I was very impressed with the little $79 camera! It fits in pretty tight but I was able to get all the critical views I would want. After I get it all together I will give you all an update on the performance! Karson

-

I know I should know this, and searching the forums didn't find me an immediate answer... What are the possible reasons for a cylinder running hot (CHT) on an IO550? What I can tell you is that it is the hottest both LOP and ROP (so it isn't a clogged injector?) meaning I have to go either extra lean or rich to keep that cylinder from getting out of my sub 400 degree comfort zone in cruise. This just started - coincidentally after an oil change. It also seems to have the lowest EGT of all the cylinders... Where should I start? thanks! Greg

- 10 replies

-

- io550

- continental

-

(and 2 more)

Tagged with:

.thumb.jpg.ed6aafa91f819cec0d83fd72d0471094.jpg)