nels

Basic Member-

Posts

848 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by nels

-

Parking Brake Locked Up in Flight??

nels replied to Skates97's topic in Vintage Mooneys (pre-J models)

I do notice you have a rigid pipe going to the reservoir and what looks like a soft line going to the pressure side and not even a hose clamp. I would think that side sees all the brake pressure and would be rigid or at least a flexible brake hose? Maybe Im seeing the wrong thing and what appears to be a rubber hose is just a covered pipe? If it’s a hose made of fuel or vacuum line it can’t be right and brake fluid may have collapsed that hose locking the brakes by not allowing fluid to return to the reservoir? If it’s a fuel line or vacuum line it isnt compatible with brake fluid. If it is an old flexible brake line it also may have swelled up and closed off not allowing fluid to return? Are you using the proper brake fluid? And, one more possibility, residual pressure from the system may be holding the valve in place not allowing fluid to escape back to the reservoir. This would probably be caused by a lose cable casing at the clamp.. -

Anybody have an original photo of a Crosley powered Mite?

-

Parking Brake Locked Up in Flight??

nels replied to Skates97's topic in Vintage Mooneys (pre-J models)

Was your wife with you? If so, will she ever fly with you again? on subject: the vent hole plugged sure sounds plausible. -

Sorry, Paul. I was trying to post the fuel tank inspection panel post but it ended up reposting my post from several weeks ago. I had to finally erase the old post before I was able to repost...if that makes any sense.

-

Got it. Thanks!!!

-

I’ve actually separated the wing skin from the access panel using a skin wedge. The wing skin appears to move but the panel almost appears to still be attached somewhere? I can move the skin wedge all the way around the panel seam which tells me the panel is free from the skin but the panel won’t drop into the tank.

-

I have a minor leak at the bottom of the inboard chamber on the door side. In an effort to save some labor dollars I am taking the panel off myself. I have all the screws around the perifey removed and the panel is free from the skin but it does not want to drop Into the wing. I noticed other Phillips head screws in the area and I am now guessing there might be some sort of reinforcement attached to the inspection panel keeping the panel in place? Am I correct on this or is there just residual sealant around the edge that is holding it in place?

-

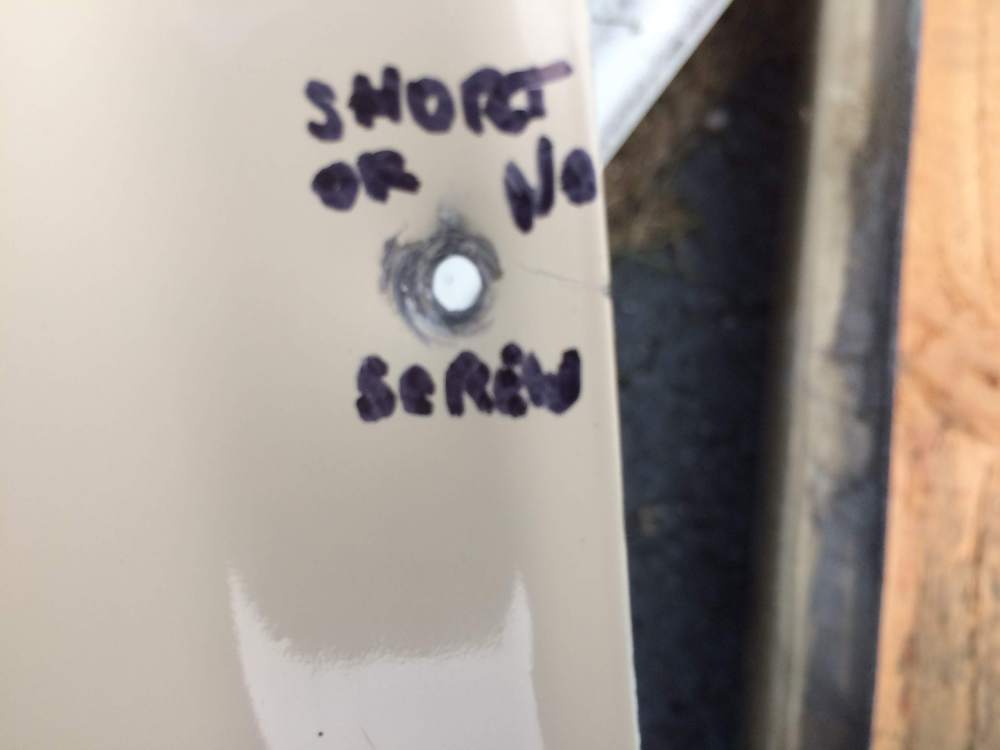

i Thought this might be something everyone here might want to check out? Yesterday, while playing around with my airplane, I noticed the aileron on the right side would not travel very far towards the up position when moving it at the wing by hand. It was obviously hitting a stop of some sort. I got in the plane and tried using the controls. I was able to get it to move but heard a loud pop and then things seemed ok except I could hear metal on metal under the wing near the fuselage. I had my cousin get in the plane and work the yoke right to left while I was under the plane. I quickly found the problem. One screw in the leading wing to fuselage filler panel was rubbing the aileron control rod. So much so that it had fatigue cracked the panel next to the screw. I removed that screw and no more rubbing noise. That screw had been replaced by a larger one (see photo) and I assume it needed replacing because the original smaller screw was also hitting the rod until that threaded hole was worn out. I then removed the filler panel to get a better look. There is a thick piece of felt that is probably supposed to keep the control rod away from the sheet metal and possibly if the screw is short enough the tip may not protrude through and touch the rod. Although in my case it did. Actually that screw is located in precisely the wrong spot. Moving it an inch either forward or back looks like it would have resolved the problem. I could see someone chasing the continual lose screw with a larger one and finally create a potential real problem. From what I could see from the underside with the filler removed, the control rod has a change in section or a weld joint that catches the screw. This may not be a problem on your plane but if you have a stripped or missing screw in this location I would think this might be the reason. I’m just going to leave that screw out for now. I did note it with a marker so next annual it doesn’t get replaced with a new even larger one. Pictures show original and replacement larger screw, location of screw in filler panel and crack in panel next to screw.

-

What is involved in pulling the screen?

-

I think the problem existed before the long screw. I think it started when the felt pad moved out from underneath the control rod as I could hear it dragging along the skin after I removed the screw. I think that hole got enlarged by the small screw getting bumped by the rod and it fell out. A number 6 was substituted to pick up the larger diameter hole.

-

Probably easily overcome at the yoke. I found it playing around with the aeleron by hand. It must have been going on for some time as there is a crack at the screw. Hopefully others will check to see if they have a similar situation. It would be interesting to know if it’s more common than most suspect.

-

Yetti, Shadrach and bradp, now I understand...a flat tinnerman. No wonder they go to larger screws once that panel is removed, nothing to keep the tinnerman in position. Looks like I have something to do next spring.

-

Thalnks, Clarence, your explanation makes sense. I really can’t see any damage to the tube so I am lucky. What I failed to mention is the felt pad that bushed the rod off the lower wing skin was no longer in the correct position and allowed the rod to drop down and contact the skin and brush up against the screw. I would think moving that fastener fore or aft would put the potential problem to bed?

-

My plane is a 1978 J model. Has a ttaf of about 1200 hrs. Original paint and interior. Never on it’s belly or repaired. I really don’t think there were ever tinneman nuts behind the skin. I’d check it out tomorrow and verify but my wife and I are headed to Mexico for my son’s wedding. Tinnerman or no tinnerman, my intent was to inform that the screw no matter what size, can interfere with the aileron rod. The location just wasn’t ideal on my plane and probably on others. Probably not a particular hazard but a good thing to check out. Maybe mine was a freak?

-

That’s original paint on the screw. Plane has never been painted.

-

I was thinking the large one was a 6 and the correct is a number 4 as you mention. They do appear larger in the photo than I remember? Pretty certain there are no tinnerman nuts on any of the screws.

-

i Thought this might be something everyone here might want to check out? Yesterday, while playing around with my airplane, I noticed the aileron on the right side would not travel very far towards the up position when moving it at the wing by hand. It was obviously hitting a stop of some sort. I got in the plane and tried using the controls. I was able to get it to move but heard a loud pop and then things seemed ok except I could hear metal on metal under the wing near the fuselage. I had my cousin get in the plane and work the yoke right to left while I was under the plane. I quickly found the problem. One screw in the leading wing to fuselage filler panel was rubbing the aileron control rod. So much so that it had fatigue cracked the panel next to the screw. I removed that screw and no more rubbing noise. That screw had been replaced by a larger one (see photo) and I assume it needed replacing because the original smaller screw was also hitting the rod until that threaded hole was worn out. I then removed the filler panel to get a better look. There is a thick piece of felt that is probably supposed to keep the control rod away from the sheet metal and possibly if the screw is short enough the tip may not protrude through and touch the rod. Although in my case it did. Actually that screw is located in precisely the wrong spot. Moving it an inch either forward or back looks like it would have resolved the problem. I could see someone chasing the continual lose screw with a larger one and finally create a potential real problem. From what I could see from the underside with the filler removed, the control rod has a change in section or a weld joint that catches the screw. This may not be a problem on your plane but if you have a stripped or missing screw in this location I would think this might be the reason. I’m just going to leave that screw out for now. I did note it with a marker so next annual it doesn’t get replaced with a new even larger one. Pictures show original and replacement larger screw, location of screw in filler panel and crack in panel next to screw.

-

Just wondering how bad it is down there in the south after Michael went through. Hopefully he didn’t have his way with any members.

-

Owner assisted annuals should really drop the cost. Removing and reinstalling all inspection panels, cowling, nose cone and belly pans takes about six to eight hours. Probably 800 or so screws. No mechanic in his right mind should complain if you volunteer that service.

-

Stuck for 2 days in Cedar City, Utah

nels replied to ragedracer1977's topic in Miscellaneous Aviation Talk

Great report! Just got back from a three week trip out west. Two of the three weeks were spent in southern Utah. What a beautiful area to visit. No Mooneybut rather a 1958 vintage camper. Still a lot of fun. -

Fly to Mexico or Tucson?......Recommendations?

nels replied to AaronDC8402's topic in Miscellaneous Aviation Talk

This is the first time I was asked the question.. I have Traverse Insurance and they shopped rates and found the least expensive one. This question was posed on my current application and I’m fairly certain is now in my contract. I had no interest in out of country travel so I paid little attention. Maybe Travers was just sharpening the pencil. Either way, I was happy with my premium. -

Fly to Mexico or Tucson?......Recommendations?

nels replied to AaronDC8402's topic in Miscellaneous Aviation Talk

You might be right on the cost. However, my insurance company specifically asked if I would fly out of the country, Mexico/Canada. I said no so I don’t have coverage to fly anywhere but USA. So, probably a good thing to check before you do it. -

Signature publishes fees for piston airplanes - AOPA

nels replied to FlyWalt's topic in Miscellaneous Aviation Talk

In general Signature Really Overcharges for fuel (typically 50% or more than any nearby competitor) and services. I would love to see Signature called out as to location on FLYQ for instance just to know to avoid that airport and it’s pick pocket mentality’s. I just looked up Signature locations in the USA and I can see there are plenty of them to avoid! http://www.signatureflight.com/sitemap -

Fly to Mexico or Tucson?......Recommendations?

nels replied to AaronDC8402's topic in Miscellaneous Aviation Talk

My insurance does not cover my plane outside the US.