-

Posts

12,171 -

Joined

-

Last visited

-

Days Won

170

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Shadrach

-

I had my TC overhauled by AQI a month ago because I did not know about Kevin and Porter Straight. I certainly would have had him do it had I known. Nevertheless, it was returned with an 8130 labeled as overhauled.

-

Get voting for an alternative engine option!

Shadrach replied to FredG's topic in Modern Mooney Discussion

I remember the R10 Diesels of the mid to early aughts. Didn’t know they made a hybrid diesel race car. -

Get voting for an alternative engine option!

Shadrach replied to FredG's topic in Modern Mooney Discussion

Why has no one made a diesel hybrid. -

Get voting for an alternative engine option!

Shadrach replied to FredG's topic in Modern Mooney Discussion

I’ve never owned an SUV. This is a 5 series BMW. I’m not downing the ultima, that’s a great commuter. But for a family of four it’s small for a road trip. just took my family to Great Wolf lodge for two days. We did 412 highway miles RT plus driving around Williamsburg for a total of 460miles. We avg 35.5mpg and returned home with just about a quarter tank remaining. It is the best road car I’ve ever owned. What’s more remarkable is that it is still turning high 20s mpg Cherokee speeds. -

Get voting for an alternative engine option!

Shadrach replied to FredG's topic in Modern Mooney Discussion

Indeed. But I’d miss the sub 6 second 0-60 and the >400lbft on hand @ 1500rpm. I get the strangest looks when people see a trailer full of firewood behind a 5 series. -

Get voting for an alternative engine option!

Shadrach replied to FredG's topic in Modern Mooney Discussion

I estimate you’re making about 160hp at 11.5gph. Any one of these turbo diesels should do that at a lower fuel burn. I understand why most are skeptical. Having switched to a turbo diesel road car a few years back, I am a believer. The difference in fuel specifics are sort of mind boggling at first. Like anything you get used to it. I’m now disappointed if I average <36mpg on a road trip in large sport sedan loaded to well over 4K. 40mpg is the goal. -

Get voting for an alternative engine option!

Shadrach replied to FredG's topic in Modern Mooney Discussion

I think one of the biggest hurdles will be cowl design. It’s not a plug and play with cowls designed for opposed air cooled engines. -

Get voting for an alternative engine option!

Shadrach replied to FredG's topic in Modern Mooney Discussion

I do. Even so, I’m still puking fuel through the engine, just not as much as I would at full rich. -

Most shops can OH that turn coordinator. But it’s nice to have an ex Brittain guy doing the work.

-

Get voting for an alternative engine option!

Shadrach replied to FredG's topic in Modern Mooney Discussion

Fuel delta would be larger than that. You wouldn’t be puking fuel through the engine on the way to altitude. -

I just replaced all of the black silicone “surgical” tubing with Gates 27043 per the recommendation of a certain former Brittain tech. The install was pretty easy including filters. The only benefit to old surgical style tubing is that it has almost not rigidity. It’s like a well cooked piece of Bucatini and can make an almost infinite number of turns and curves in a tight panel space. The gates is somewhat rigid and one turn will affect a previous turn. Took a bit more tinkering with clamps and zip ties to ensure proper orientation than the old stuff.

-

Switch from key to switches?

Shadrach replied to Modify201's topic in Vintage Mooneys (pre-J models)

Many GA aircraft are delivered without a keyed ignition. Citabrias and Decathlons have toggles on the upper left side switch panel. I don’t believe I have ever been in a light twin with a keyed ignition. -

Get voting for an alternative engine option!

Shadrach replied to FredG's topic in Modern Mooney Discussion

6 quarts of 50-50 blend weighs 14lbs. An angle valve 360, Lycoming weighs about 350 pounds on the mount with accessories. Parallel valve Lycoming is about 40 pounds lighter than the angle valve. The weight penalty will be significant for C and models. For the Angle valve Birds, I think the Delta will be less than 40 pounds. The reduced fuel burn goes a long way towards diminishing that.. this is all pie in the sky kind of stuff, but in less complicated regulatory world, one could make a really efficient cross country airplane with diesel powered Mooney. -

Get voting for an alternative engine option!

Shadrach replied to FredG's topic in Modern Mooney Discussion

It would be an excellent retrofit to the 4 cylinder birds. And makes far more sense than something like an IO390. It’s true the market is shrinking. As a consequence values are increasing and the cost of a power plant is a smaller percentage of total aircraft value. I’ve seen people spend ridiculous amounts of money, trying to squeeze 5kts out of an airframe. Spending an extra 50-60k over a factory overhaul on an engine swap that gives any 4 cylinder Mooney performance that approaches a 231…with better fuel specifics and useful load in some cases, seems far more practical then some of the other rabbit holes I’ve seen people through money down. The real question is, can they price it to sell. I would pay a premium to have diesel power, but the number needs to be reasonable. -

Get voting for an alternative engine option!

Shadrach replied to FredG's topic in Modern Mooney Discussion

The engine is being developed for the SR20. So 25 year old airframes not 50… -

Get voting for an alternative engine option!

Shadrach replied to FredG's topic in Modern Mooney Discussion

What is it that makes you skeptical of the fuel burn? Given that it’s a turbo diesel with a compression ratio of 20:1, the fuel specifics look very believable, if not conservative. -

Freshly overhauled IO-360-A3B6 - max fuel flow too high?

Shadrach replied to Ryan ORL's topic in General Mooney Talk

It’s true that probe placement affects raw EGT numbers. It’s also true that the peak EGT number for a cylinder has little variation between cruise and max power settings. It would be pretty easy to ballpark how far ROP each cylinder is at full rich. I would bet that all cylinders are between 250° and 300° ROP. If any cylinder is richer than that, I’d consider having the servo adjusted. I’ve flown several Lycoming’s that have cylinders in the 200ROP range at full rich. That’s ok, but I prefer a bit more fuel flow. -

Lycoming Part Number Needed - IO-360-A1A

Shadrach replied to MrRodgers's topic in Vintage Mooneys (pre-J models)

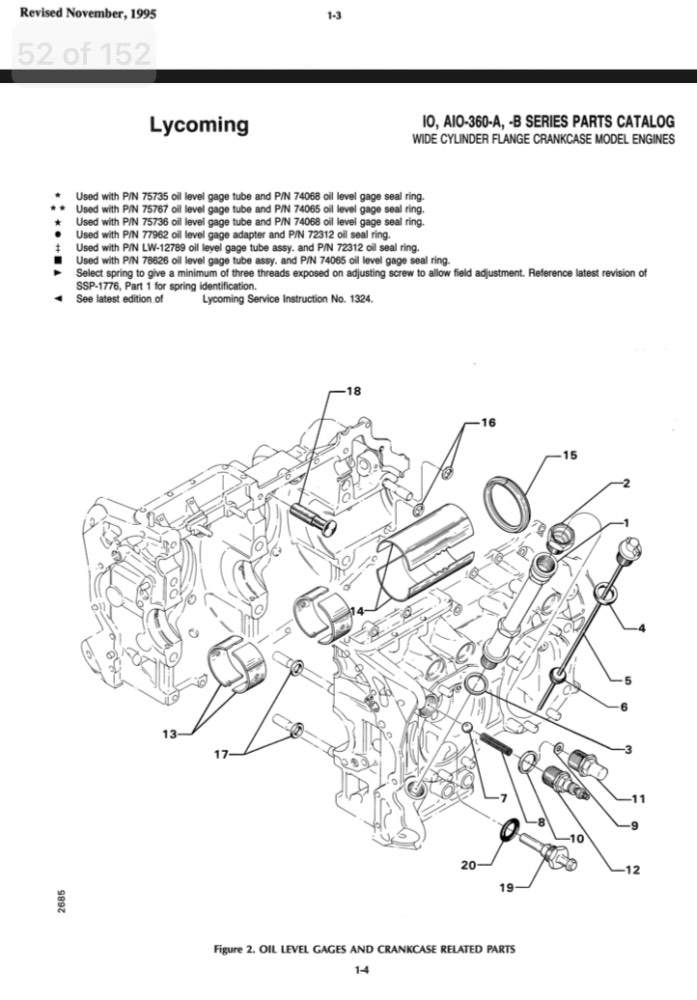

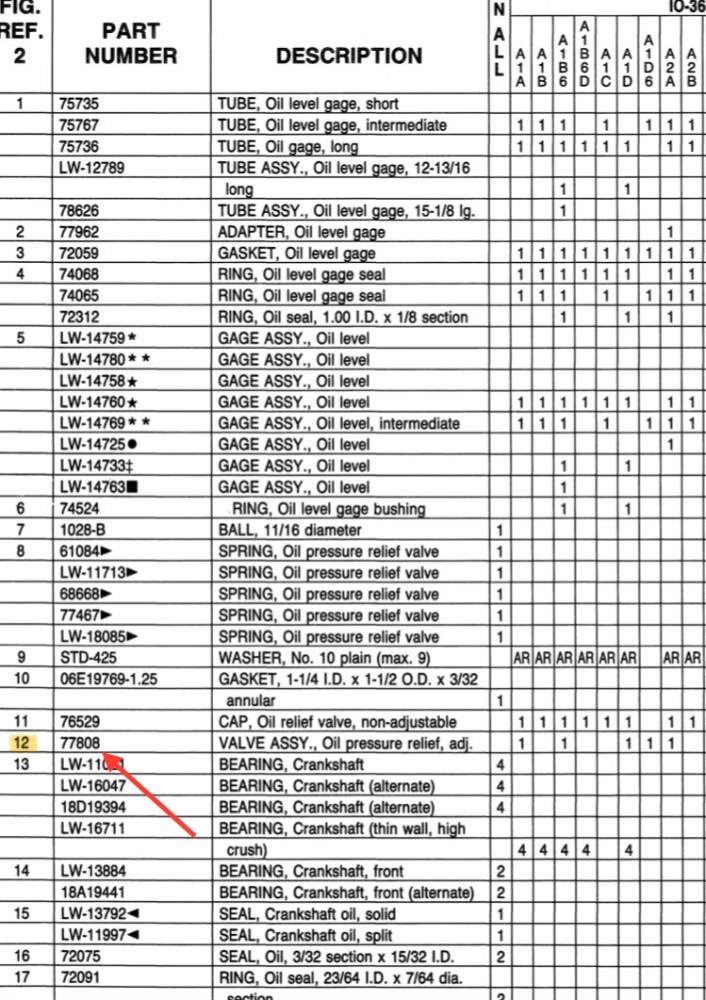

So weird. This morning I posted the IPC pages with diagrams but it’s gone… 77808 is indeed the Lycoming part number. -

Get voting for an alternative engine option!

Shadrach replied to FredG's topic in Modern Mooney Discussion

Where are you getting your numbers? Per Lycoming TCDS: The following tabulations show std. dry weight (less) (alternator and starter), C.G.’s, fuel injectors, fuel pumps and magnetos for these model. Lycoming IO360A1A - Dry weight 293lbs Delta Hawk- Dry Weight 357 lbs/157 kg (includes starter, turbo, exhaust, alternator) So it looks to me like a 64lb delta per the published numbers except that the Lycoming number is sans starter and alternator. Once those are added to IO360, the difference is a wash. The Deltahawk is likely lighter than a TN’d IO360 dry but more once fluids are added. -

Seems like an odd part to replace. Was it physically damaged? The ball and spring are available individually. complete assembly pn - 77808

-

Freshly overhauled IO-360-A3B6 - max fuel flow too high?

Shadrach replied to Ryan ORL's topic in General Mooney Talk

I had my servo overhauled in the mid aughts by a local fuel system specialty shop. I asked the mechanic to request that the tech set my servo at the max permissible fuel flow for the application. Prior to overhaul my egts were in the mid to low 1200 range. Upon reinstalling the newly overhauled servo egts dropped about 50° into the low 1200/high1100 range. Which made for very cool CHTs at cruise climb (typically 310° to 330°) even in summer. My airplane never ran hot for sale, but since the servo rebuild, I’ve never found myself wanting for more fuel flow to aid cooling. I wish I could tell you our take off fuel flow, but I am just getting around to installing a fuel totalizer. All the above being said, I would definitely make sure the reading is dead on before pulling the servo. The mag drop is odd, are you seeing issues with specific cylinders when running single mag? -

I’m not. I’m the guy that annoys the alignment tech by asking questions like an 8 year old.

-

Since adding polished wheel covers, I eyeball the tires rather than put a gauge on them. Prior to the wheel covers, I away gauged the tires during preflight.

-

Freshly overhauled IO-360-A3B6 - max fuel flow too high?

Shadrach replied to Ryan ORL's topic in General Mooney Talk

The servo was likely set on the high side of or out of spec when overhauled. Curious what your take off EGT numbers look like (I’m betting low 1100s). That FF would not concern me on a 15° morning in the mid-Atlantic…but in Orlando, it’s a little too much of a good thing. That being said, if I were the only one flying the plane, I’m not sure I’d pull the servo off over it if a turn or so on the mixture knob will bring things in line. -

It is different. 8 second ride is a caster angle issue. Positive caster angle is more stable in a straight line and self centering. Negative caster angle makes for faster turn in but is less stable. The Mooney is spec’d for positive caster angle but only just. If it’s out of adjustment enough to go negative, the 8 second ride becomes a possibility. If the steering linkage is worn, the 8 second ride is going to be that much worse. I get a noticeable shimmy at taxi speed if the nose tire is 5psi low. I theorize that even the slight change in geometry caused by a low nose tire shifts caster angle aft and causes the shimmy.