-

Posts

85 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by N204TA

-

I don’t know, but it seems to me that you have a math problem. The G5 in the first photo shows speeds in knots. I can’t read the OAT but it looks like 56F. 119 KIAS at 3,000 feet, 30.04 altimeter setting, 56 degrees, computes to 126 KTAS. The G5 in the second photo shows speeds in MPH. Assuming that was the same flight, I estimate the OAT around 37F. 133 MPH at 9,500 feet, 30.08 altimeter setting, 37 degrees, computes to 155 MPH TAS. 155 MPH = 135 Knots which seems about right for our M20Fs.

-

The fuel pickups should be 610150-001 (Left) and 610150-002 (Right) The drain valves are F-391-53-S Wetwingologist has done my tanks twice and I trust Edison not to take advantage of you on the cost of parts.

-

Lycoming Connecting Rod Bushing AD 2024-21-02

N204TA replied to MikeOH's topic in General Mooney Talk

“This AD applies to Lycoming Engines (Lycoming) model engines that have an affected part and part number (P/N) installed and are assembled within the ship date range, as specified in Table 1 to paragraph (c) of this AD.” It sounds like the ship date is for the assembled engine, not just the connecting rods. -

For what it’s worth, you have a 1968 M20F built and certified in 1967. My ‘68 F was born N3460N, S/N 680059. Coincidentally, I saw the F between ours, N3461N, S/N 680060, in Kerrville last month. Small world.

-

Interesting installation in front of AOPA headquarters

N204TA replied to Shadrach's topic in Miscellaneous Aviation Talk

Probably belongs to Signature https://www.ainonline.com/aviation-news/business-aviation/2024-03-07/signature-installs-betas-electric-charging-stations-fbos -

I have a ‘68 F and visit family in COS a few times a year. I feel the density altitude but I’ve never had trouble getting off the ground and climbing out. I typically cruise at 11,000/12,000 and plan on 140 Kts TAS and 10 GPH. I am comfortable saying that the airplane has a 6-hour endurance but I usually limit my legs to four hours or less. I recently went to Phoenix and back, stopping south of Albuquerque for fuel. The longest leg was 537 NM which I did at 11,500 in 3+45 and burned about 9 GPH. By comparison, I heard an M20K pick up a clearance west of OKC and he made it non-stop to Tucson at FL200 in the same amount of time.

-

It depends on your engine. According to the McCauley website, that prop is approved for your airplane if you have the IO-360-A3B6 engine.

-

Help Me With My Hot Start Technique (or Lack Thereof)

N204TA replied to bigmo's topic in Vintage Mooneys (pre-J models)

It’s worked for me for 30 years and over 3,000 hours. -

Help Me With My Hot Start Technique (or Lack Thereof)

N204TA replied to bigmo's topic in Vintage Mooneys (pre-J models)

No pump on a hot start, correct. I only leave the mixture full rich for just a couple of seconds…usually not much longer than it takes to move the throttle to full. My theory is that it helps break any vapor lock as I usually see the fuel pressure gauge fluctuate as I bring the throttle in and the mixture out. -

Happy Birthday to ‘The Mistress’ N5976Q

N204TA replied to HRM's topic in Vintage Mooneys (pre-J models)

I love the bubble canopy and tail wheel mods in the second photo. -

Help Me With My Hot Start Technique (or Lack Thereof)

N204TA replied to bigmo's topic in Vintage Mooneys (pre-J models)

My hot start procedure for my’68 F is this: 1. Mixture full rich 2. Full Throttle 3. Mixture idle-cutoff 4. Master On 5. Engage starter 6. When the engine catches, reduce throttle with one hand and slowly increase the mixture with the other. It takes a few seconds of finesse to get the perfect combination of throttle and mixture to get the engine running smoothly then I pull the throttle to idle and set the mixture as needed. -

1963 M20D/C Nose Gear Truss Dents

N204TA replied to BrettC113's topic in Vintage Mooneys (pre-J models)

There is no AD, it’s covered in service instruction SIM20-137. https://www.mooney.com/wp-content/uploads/2020/12/SIM20-137.pdf -

I pretended that I was in a Cirrus or Airbus and just flew side stick. I was pretty close to home so it looks worse than it was. Like a good owner, I was more upset by the looming repair cost.

-

-

The diameter of the shaft itself isn’t the problem, it’s how it’s attached to the bracket for the linkages. The old one was welded into a cradle leaving a hollow shaft with lots of space between the end of the shaft and the vertical bracket to feed the wires. With the new one, the shaft is inserted into a sleeve not only leaving very little room at the end to get wires in there, but then you have to squeeze around the two crossing rivets.

-

Dugosh started doing flat-rate annuals a couple of years ago. Current prices range between $2,080 and $2,890, depending on the model. The price includes everything but parts, oil, and additional repairs.

-

That sounds like an electric gear issue. I take it yours is manual? As @Ragsf15e mentioned, it’s probably the switch on the throttle sticking so it thinks that the throttle is at idle even when it’s not.

-

I’m a little conservative when it comes to fuel so I would consider 500 NM “doable” but not “comfortable.” I try to limit my legs to 400 NM just in case I’m not getting the ground speed the math said that I would. Plus, my backside gets sore when I sit more than three hours, so I’m happy to get out and stretch at least before four.

-

Some days, I absolutely agree with you as there are members who seem to think that they are a cross between Chuck Yeager and Charles Taylor who feel an overwhelming sense of duty to respond to every thread. Still, that doesn’t diminish the fact that you came here for advice and have provided little information and now you’re getting frustrated by what you feel are a lack of “helpful” responses. In two threads, you state that your engine will not start but you won’t elaborate. I think most of us assume that this is a new, sudden problem so we are focusing on the obvious solutions. Despite decades of technological advancement, aircraft engines are still remarkably primitive and an engine that cranks but won’t fire either isn’t getting fuel or the plugs aren’t sparking. Now, however, you are bringing up flooding, boost pumps, mixture settings, etc. That sounds like you aren’t having a “won’t start” issue but, rather, want tips on making starting easier. “My engine won’t start…period” is different from “My engine won’t start right away and there must be better way of doing it.” The latter statement will probably get you all kinds of suggestions, tips, tricks of the trade, etc., but you need to ask that question if that’s what you’re seeking.

-

I feel your frustration but, as others have said, “engine will not start” is about as vague as it gets and nearly impossible to diagnose on a message board. At least, we need to know the circumstances, the symptoms, what you’ve tried, etc. If your mechanic right there can’t figure it out, the armchair quarterbacks here probably can’t either. FWIW, I have been in the Mooney game for 30 years and only two things have ever caused my engine to mysteriously “not start.” The first was a broken wire on the left mag. It broke right at the ring terminal and wasn’t immediately noticeable. The second was a failure of the flow divider, a.k.a. “The Spider” on top of the engine. Everything looked normal in the cockpit, but fuel was not getting to the cylinders. We discovered that by disconnecting one of the injector lines and turning on the boost pump. When fuel didn’t squirt out, we knew where the problem was. Sure enough, an overhauled flow divider fixed the problem.

-

Ouch! At my home base in the Oklahoma City area, the current price is $5.10 a gallon. I can hop over to a small airport about 20 NM away and get it for $4.75.

-

I’ve been to DC a few times and always flew into Manassas (HEF). It’s just inside the SFRA so you do have to complete the training online but ATC is very helpful so getting in and out is easy. The FBOs at HEF have rental cars available and it’s a short drive into the city. Stay in Alexandria and ride the subway into town. Most of the sights are a short walk from a subway station or its really not that bad to just walk everywhere.

-

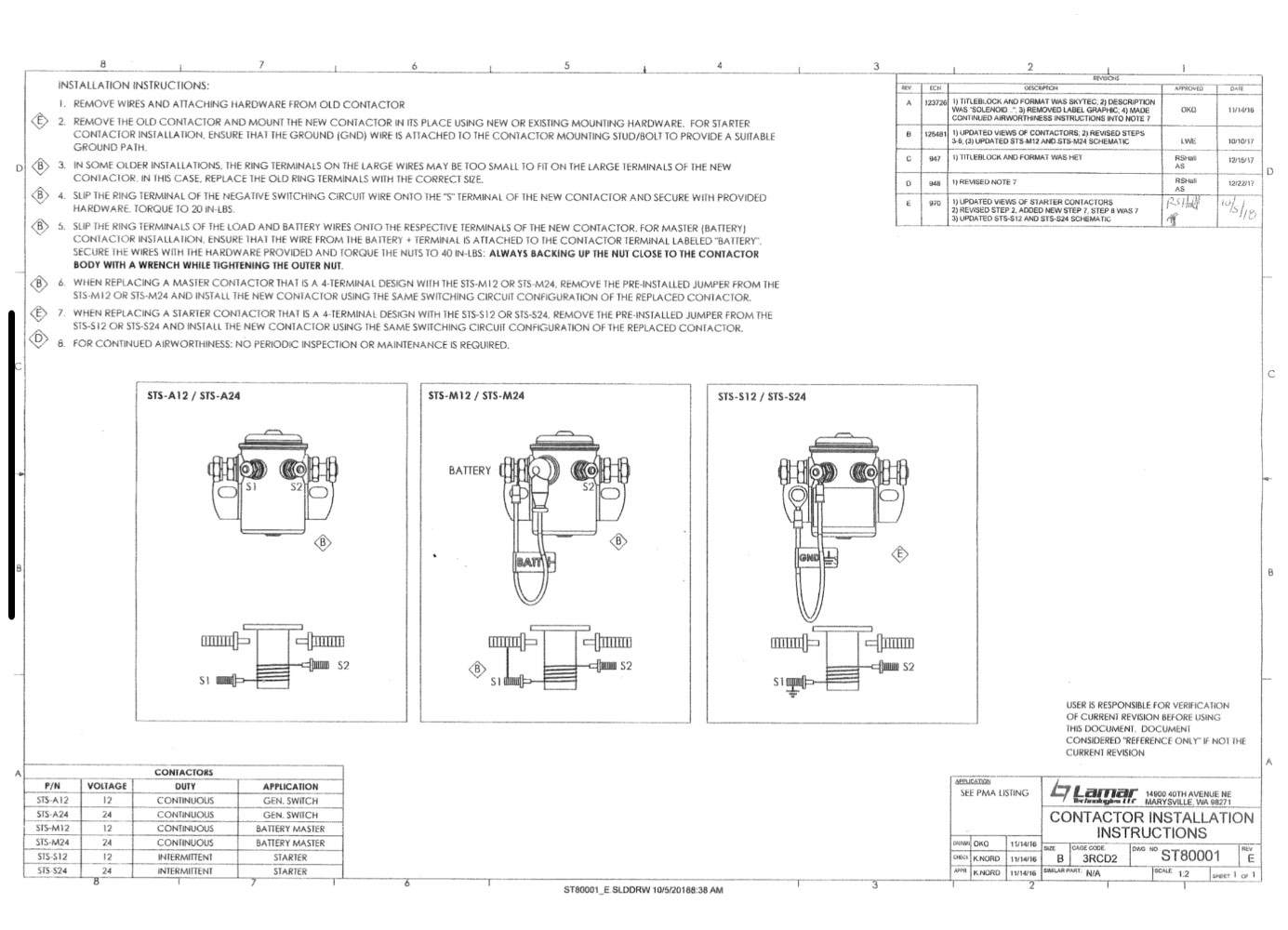

Here are the whole installation instructions: It says in Step 6 that if the old contactor has four wires, remove the jumper wire from the new one and then attach the wires in the same place as the old one.