Graf_Aviator

Basic Member-

Posts

26 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Store

Everything posted by Graf_Aviator

-

G1000 Engine Data logging in Ovation 2 ?

Graf_Aviator replied to N177MC's topic in Modern Mooney Discussion

Well, at a certain time in the life cycle of the Ovation I guess our birds came with 0401.34 installed right from the factory. And those who were built before .34 eventually (most) got upgraded. If your tech is not familiar with the software revision history I would dare to ask if he is familiar with this particular software at all. But that also might mean he is not from a MSC since they have access to all the firmware documentations as well. Ask him if he has the boot loader upgrade for the GMU44. It is not part of the .34 software package. And without that you will not have a functioning compass any more.... And in case something goes wrong with the upgrade, ask him if he has the Bootloader downgrade files for the GMU44 as well... Going up from .30 to .34 is a lot of fun... and going back down even more so... Installation is actually quite easy and straightforward. However there are some precautions necessary, e.g. you need to write down (or just make photos) from a few config items before you start or you might be SOL when the new software is installed and you try to figure out which config item goes where. (Ask me how I know LOL). I would suggest taking the Ovation to someone who is familiar with G1000 Mooney firmware updates. Two hours and it's done. Just my $0.02 And just in case, here are some instructions from Mooney.com: https://mooney.com/wp-content/uploads/2020/12/SBM20-305B.pdf Best of luck and happy landings Graf -

S-TEC 55x software / hardware mod for integration with G1000

Graf_Aviator replied to dvk's topic in Avionics/Panel Discussion

I do have an STEC 55x in my 2006 Ovation 2GX The AP was porpoising like crazy when I had more weight in the back with more backward CG. At that time I was flying full down trim in cruise and there was no room left for the STEC to really adjust properly. Like I said before now my trim is in the middle again as its supposed to be and the AP is doing a good job again. It’s easy to try out. Let us know what you were able to accomplish. Graf Sent from my iPhone using Tapatalk -

S-TEC 55x software / hardware mod for integration with G1000

Graf_Aviator replied to dvk's topic in Avionics/Panel Discussion

Same as it was with my plane. Just bend the trailing end of the control surface upwards a little bit. I used two screw clamps and some pieces of wood to not damage the trailing end of the control surface. Also I used a digital protractor. In my case it was something like 4 degrees, afterwards it was perfectly flat in level flight. Basically your plane is aiming upwards the entire time and the trim is counteracting this with a downward pitch. And since the Mooney moves the entire end of the tail cone up and down for trim your control surface is not straight. Happy to talk to you about this in detail. If you want you can PM me your number. Graf Sent from my iPhone using Tapatalk -

S-TEC 55x software / hardware mod for integration with G1000

Graf_Aviator replied to dvk's topic in Avionics/Panel Discussion

This is how it looked like during level flight. If you zoom in you see the weights at the front “hanging” down, control surface was up. Now it is perfectly straight. Sent from my iPhone using Tapatalk -

S-TEC 55x software / hardware mod for integration with G1000

Graf_Aviator replied to dvk's topic in Avionics/Panel Discussion

Hi! How is your elevator trim setting in cruise flight? I am asking because I had a similar problem. It was caused by an improperly rigged elevator. In level flight the rudder was actually pitching up so the trim had to compensate with a lot of down pitch. The trim gauge in the G1000 MFD was almost full down in level flight . It is solved now, no more porpoising with my Stec55x. Trim is in the middle - And it’s faster too. Graf Sent from my iPhone using Tapatalk -

@EarthX Inc Could you please share some insight on this ? Thank you Sent from my iPhone using Tapatalk

-

I would be interested to know how the EarthX battery is actually behaving during the charging process. What happens exactly when the battery is empty or close to empty ? Will the BMS limit the amount of amps which go to the battery for charging ? My understanding is, that an empty or close to empty LiPo or LiFe battery is pulling as many amps as it can get when it is charging back up from a well depleted state. So what happens when there is no limit ? Will the alternator run at full output for an extended time, possibly overheat and burn out ? I am not sure if our stone age alternators are designed to handle the demands of these new batteries... a burnt out alternator will be quite a few AMUs to replace or fix.... An AGM or wet cell battery also does pull a lot of amps when it is close to being depleted, but only for a very short time, then the drawn amps will get back down and so does the load level of the alternator. Thanks, Graf

-

My Ovation spits out oil via the crankcase breather tube when I pour it too fast. So now I give the oil a little time to flow down, I no more put the bottles into the oil filler neck top down. Problem solved. Also with the IO550 it takes time for all the oil to get down into the oil pan after running the engine. My plane sometimes needs almost 2 days till everything is back in the pan and the dipstick shows the right amount of oil. When I refill before that, my engine just blows out anything above 6 quarts and I have it on the belly of the plane. So maybe just give it some time ? Cheers TC Sent from my iPhone using Tapatalk

-

Thanks for clarifying! Was not aware of that! However, that is quite scary actually… Sent from my iPhone using Tapatalk

-

With the emergency release you can still open a locked cargo door from the inside… Sent from my iPhone using Tapatalk

-

Dan, could you please share a picture of this trickle charger breaker? Would love to find it but did not see it in my 06 Ovation 2GX. Thanks Sent from my iPhone using Tapatalk

-

Thanks all for the great feedback ! Mooneyspace is awesome !! I have looked further into the matter taking all of the recommendations into account and I will move forward with Sheppard. @Brandt I have subscribed to the Flying like the Pros YT channel. Looks awesome. Thanks for pointing that out ! Happy landings, Graf

-

Just recently got my EASA instrument rating, yeah. Have my FAA license based on my EASA PPL, now I need to do the FAA theoretical exam in the US to legally be able to fly my N-reg Ovation outside my home country. Any recommendation for an Instrument rating prep software I should/could use ? Heard of GLEIM or ASA, found some info on the web about DAUNTLESS and SHEPPARD but obviously have no clue which vendor I should use. Any experience or recommendation ? Thanks Graf

-

Chris, I really like your videos and I have subscribed already to your channel on YT quite some time ago. Very informative [emoji106] Thank you for taking the time to create all these great Mooney videos… Sent from my iPhone using Tapatalk

- 40 replies

-

- 1

-

-

Mooney Ovation 2 GX - IO550 - Muffler shroud source

Graf_Aviator replied to Graf_Aviator's topic in General Mooney Talk

Hi ! I have sourced a company now that will renew the muffler for me. It is Acorn Welding in Alberta, Canada. I actually did get an alarm from my CO monitor, the highest I have seen was around 70ppm. Quite happy that I had invested in the CO monitor on the first day I owned the Mooney and I don't have to rely on a stupid paper card... The muffler now has been used about 1400 hours since it was installed in the factory in 2006. Not sure if that is a good service time or not - what is your experience ? Best regards, Graf -

Mooney Ovation 2 GX - IO550 - Muffler shroud source

Graf_Aviator replied to Graf_Aviator's topic in General Mooney Talk

Niko, I had high levels of CO displayed on my CO monitor, mostly during take-off and landing. I suppose this was due to the fact that I fly LOP most of the time... hence no CO to be measured during cruise. However there was a constant flow of fumes entering the cockpit. After landing I smelled like a BBQ pit.... I will replace the muffler and have the shop re-seal the cabin as much as possible. -

Found the culprit of high CO levels and horrible exhaust smell in my cockpit today... Several welding lines on the muffler / shroud seem to be torn apart... the vibrations have taken their toll I guess... For the time being I had the local shop re-weld the muffler - it kind of works for now - but for sure this is not a long term solution. I am expecting it to break again sometime in the not so distant future. So I am looking for a reliable source for such a muffler and shroud. Any tips on where to buy one ? Are there quality differences between different aftermarket manufacturers ? What about OEM ? Thanks upfront, best regards, Graf

-

Quote: „The surest way to tell if if a G1000 Mooney is WAAS is to remove the avionics bay panel on the pilot’s side of the fuselage and look at the part number of of the GIA units; the GIA 63 (non-WAAS) is p/n 011-00781-00 and the WAAS GIA 63W is p/n 011-01105-00 or -20.“ As a reference for other people please let me correct the GIA product numbers: 011-01105-00 will NOT work in a Mooney using the .34 WAAS Software. It is either the -20 or (if must be) the -01 version of the GIA 63W. Ask me how I know [emoji52] TC Sent from my iPhone using Tapatalk

-

Carusoam, could you elaborate a little bit on the ice cream pumps that you have mentioned ? Not sure if this is a joke or indeed a possible alternative... Just heard about the immense cost of TKS replacement pumps. Thank you !

-

Clarence, the turntable is driven by two motors with a friction wheel pressing on to the outside steel frame of the turntable. Takes about 1:30 min to turn 360 degrees. There are 7 planes max on the turntable, the 8th "pizza slice" is being kept empty and serves as a shunting yard. A plane is pulled from the outside onto the platform in that space and then unloaded accordingly after turning towards the taxi way. In order to use the space properly on the platform, a low wing plane parks next to a high wing plane and so on. My direct neighbor is a Tecnam high wing P2012 SMP - that grey massive thing almost looks like a Transall C-160 So the less frequently used planes are parked outside of the platform. Works quite well. This type of A/C storage is quite common here in Europe. Normally there is not enough space on our airfields so they have to come up with some storage solutions. Just found this web site with further information on this type of system: Aero Disc Parking System Merry xmas,

-

Yes, it is. I have found a home for my Ovation in this beautiful hangar, it is the home base for a total of 13 planes. 7 of them are parked on a turntable with wooden planks, the rest on the sides. It's a really nice place. Could not have found a better spot. And I have 3 Mooneys as direct neighbors, an Acclaim, a 231 and this beautiful Porsche Mooney.

-

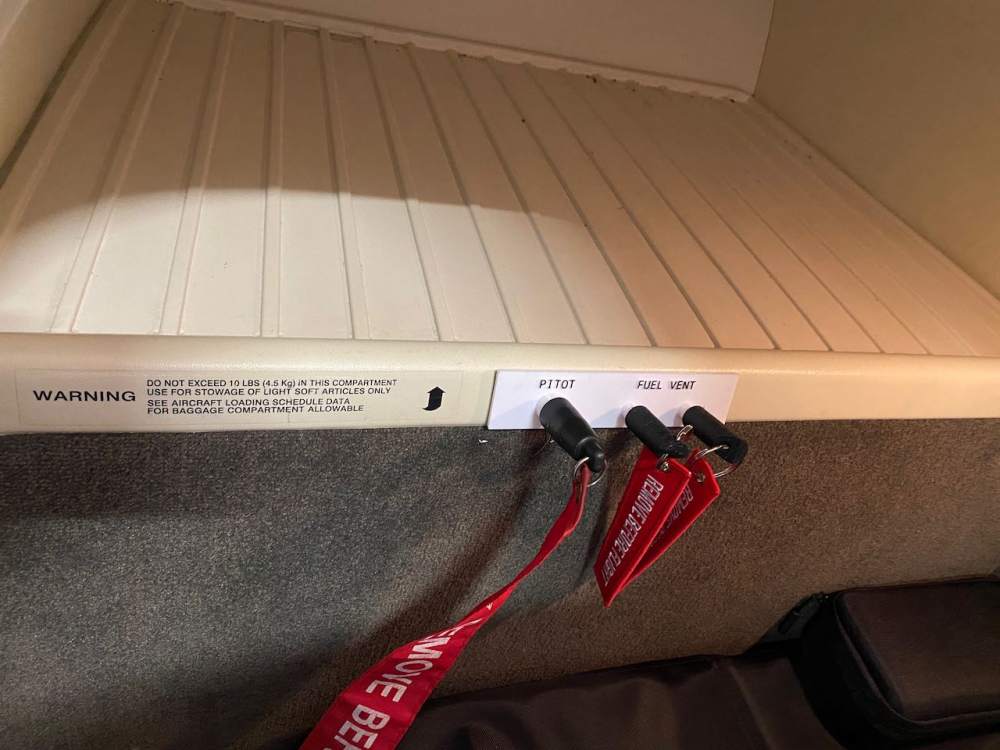

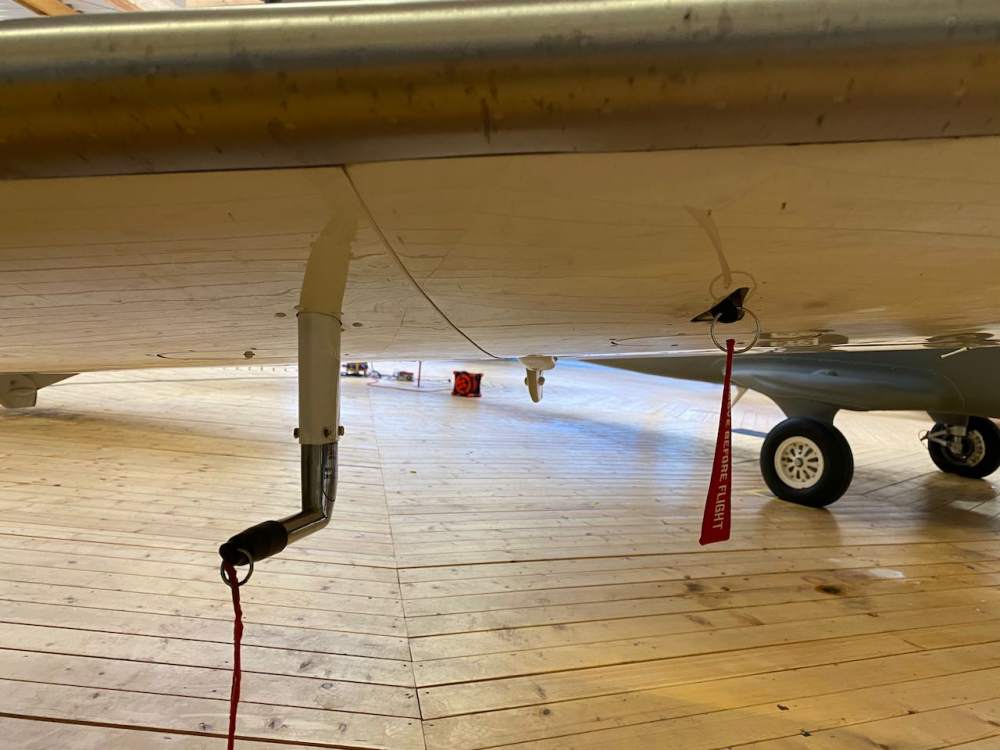

I have 3D-printed fuel vent covers using flex material, they perfectly fit on my Ovation. I have designed the cover with a small breather hole, about 2mm, maybe 1/16" in size. That allows some air exchange but it is definitely not enough for flight operations with the cover on. So, I have printed a small storage board also which is glued to the back wall of my luggage compartment. It holds both fuel vent covers and the pitot heat cover... In order to not forget to remove these covers I have added a line to both the outside- and regular check list. Just before starting the engine I turn my head and look to the back. If I see 3 red tags, all of the covers are removed. In case anyone is interested and wants to print it, I have posted the parts on thingiverse. Thingiverse Download Or if you are in my neck of the woods, come by my house in Munich for a chat and I'll print them for you. (After Covid19 has eased of...) Happy landings !

- 65 replies

-

- 12

-

-

-

Send me a PM with your email and I’ll send it to you. Along with my checklist file for my O 2GX Sent from my iPhone using Tapatalk

-

Thanks Danb! I am living in Europe, have to find someone over here to sign off on it. Maybe the MSC can do it when the bird is in for the next annual. Sent from my iPhone using Tapatalk

-

Unfortunately this door seal is not available for M20Rs ... Any hints on a vendor that supplies such a door seal suitable for newer Mooneys? Sent from my iPhone using Tapatalk