Fritz1

Supporter-

Posts

742 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Fritz1

-

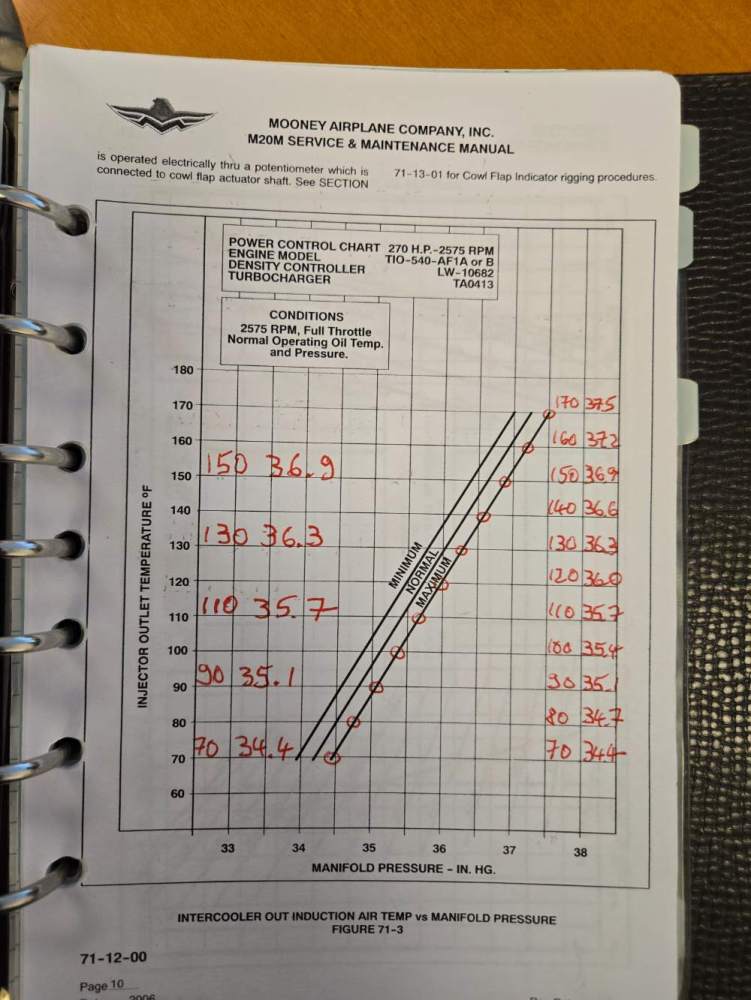

Turbocharged engine takeoff ground roll checks - tips?

Fritz1 replied to hazek's topic in General Mooney Talk

For the density controller to work correctly you need about 180 dF oil temp, I turn the boost pump on manually when I enter the runway just in case the throttle switch fails, line up, check cowl flaps open, push mixture rich, if enough runway slowly turn in boost, watch RPM rise to 2575, check oil pressure, check fuel flow 29-30, check boost, minimum 35, maximum 37" as a function of induction air temperature, which is typically between 90 and 150 dF, watch airspeed, rotate between 70 and 75 kt depending on weight, positive rate, no runway remaining gear up, flaps up check boost below 37 with intercooler full flow, 1000 ft reduce power 34" 2400, boost pump off, fuel flow around 23, lean for 1580 TIT, cruise climb about 120KT, keep CHTs below 400 dF. Depending on weight the Bravo will climb at around 600 fpm through 18000 ft, when altitude captured close cowl flaps, let speed build up, reduce boost to 30", reduce rpm to 2300, fuel flow about 18.5 gph, produces about 1580 TIT, 350-380 CHT and about 185 KT TAS in my TKS Bravo, others may be 5KT faster, power is about 78%, reducing power I take out 2" per minute, keep TIT between 1550 and 1580, CHT reduction not more than 15 dF per minute, Lycoming says 50 dF per minute is permississible, descent 750 fpm, don't go below 18" at that descent rate, engine starts driving propeller and rings may start fluttering, with gear down power can go below 18", don't push mixture rich for landing, just fouls plugs, keep mixture where you had it during descent -

As stated before your cigarette lighter may be 12V, you have two 24V batteries, not sure if you can backfeed though the step down transformer, standard solution is an Anderson connector on each battery, if no tks door, Anderson connectors are typically mounted on hat rack or on left cabin panel in luggage compartment, think battery minder sells Anderson connector kit with fuse

-

Test fly all of them, talk to the owners, get an idea for an annual operating budget, the journey is the destination!

-

there is an idler arm in the nose gear steering mechanism, that arm pivots on a #10 bolt, that bolt may be loose, if so tightening it will take some of the slop out, thread locking compound on that bolt thread cannot hurt, bolt is vertical, your A&P will know where to find it, as stated before, jack it up, wiggle it in all directions and see and feel what moves

-

looks like an awesome paint job, Hawk aircraft in Florida does a fair amount of Mooney work and did the Eagle of a friend of mine with good results, he typically replaces windows with a paint job, in order to have a flawless match you may have to paint the non-white color on the top cowl, he is typically boked 9-12 months out but may be able to squeeze a side job in

-

Need a Landing Light Split Rocker Switch

Fritz1 replied to Raptortail's topic in Mooney Bravo Owners

That is aggravating, simplest stuff cannot be found, call Maxwell, he may know something, after that maybe find generic switch that carries the amperage, have engraved and fill the engraved letters with black epoxy, sand and clear coat -

Pic might help

-

CAV aerospace about $400

-

baffles are the easiest fix on the Bravo, the right rubber material, a couple of pop rivets and RTV, the smallest leak and associated loss of ram air makes a big difference, there are typically big gaps in the factory baffling around the starter and around the alternators, fine wire plugs also appear to go well in the Bravo engine, I daresay they dropped the TIT by 15 degrees in my engine, feels like more complete combustion in the cylinder and less post-combustion in the exhaust

-

Looking for a shop that has good turbo experience

Fritz1 replied to skyfarer's topic in Mooney Bravo Owners

Maxwell will set it perfectly if needed, you want to see at least 34.5" pretty much under all normal circumstances, you will have alt least 70 dF IAT even when it is very cold, lets say ambient below -20C, the defining moment comes when there is a hot and high takeoff your IAT may go to 140 dF at slow speed before the intercooler start pushing, you want all the power you can get and may need 37" boost, you can adjust the density controller by turning the square piece after removing the safety wire, if memory serves me 11 degrees clockwise increases max boost by 1", very sensitive, be very careful, in order to be able to go to the upper limit when you need it you may have to back off manually at low ambient temp, in order to do that you need an IAT probe installed, JPI makes them, the JPI700 and probably all other monitors are set up to receive the input from that probe, with that probe you can monitor the function of the density controller -

Thank you Brian, that makes it clearer already, my thinking was that the JPI was the more established unit, but the MVP 50 has more programming options, I have a JPI 700, only downside of the JPI was that the alarms are fixed, so you cannot get rid of any, the only limit that I might be bumping against is the rpm limit of 2575 now and then, maybe irrelevant, will talk to my installer, see what he thinks. -Fritz

-

Monitor is in my future, how did you decide between the MVP and the large JPI, think the large one is called the 930

-

Did the Lakeland class twice, excellent course, excellent instructors!

-

If you hang around Hilton Garden Inn is about 10 min from airport, Black's Barbecue is awesome, rental cars are typically better priced in town, 7 min Uber ride

-

Second Brian Kendrick, known him for almost 30 years, he ran the factory service center for a while and also was a company test pilot, he can test fly Mooneys to trouble shoot what few shops can do, did prepurchase on my airplane and 3 annuals thereafter, he test flew the airplane, figured stall warning was not coming on because mounted too low from factory, had to redrill TKS panel for new rivnuts to move stall warning up, he will find stuff that other people don't, airplane had 190h on factory reman, still spent at least $50k on repairs not counting upgrades in the first two years, biggest line item tanks, think 11k at the time, Brian replaced stuff in a preventive manner like flap limit switches because he knew they were going to fail rather sooner than later, re-glued TKS stall triggers because he knew they were about to come off soon, doing an annual with him and dropping the bird off for let's say at least 4 weeks will make most of your trouble go away, whatever he does not have time to fix he will explain to you so you can get it done locally

-

As stated supra, the FIKI stall warner and the panel are different, I would not want to cut and drill into a titanium TKS panel, the FIKI stall warner is a shaky contraption

-

Crudest way to check fuel flow is take injectors out stick each into measuring cup, run boost pump with full throttle mixture rich for let's say 1 min and compare cups, if this does not show anything do lean test at 24" record fuel flow for each cylinder egt to peak, make sure mags are wired correctly, one mag fires bottom plugs on one side, top plugs on the other side, persistence wil get you a perfect running engine

-

Looking for a shop that has good turbo experience

Fritz1 replied to skyfarer's topic in Mooney Bravo Owners

second the mouse milk, causes reproductive harm in California though, preheating helps a lot, Reiff heater gets engine to 120 dF, running 1500W cabin heater in hangar prevents windows from freezing over during taxi, Phillips XC 20W50 appears to do well in the Bravo engine -

Looking for a shop that has good turbo experience

Fritz1 replied to skyfarer's topic in Mooney Bravo Owners

Don is probably your best bet, end of Feb is just around the corner, to work correctly the controllers need about 180 dF oil temp, are you sure it is not just the gauge that is erratic? my density controller was not kicking in enough boost at high IAT and overboosting at low IAT, instead of trying to fix it I installed an IAT probe that feeds to the EDM700. There is a table in the service manual, typically you want at least 35" at low temp and at the most 37" at high ambient temp, the IAT probe is easy to install, intake plenum has a thread for it, with that probe you can fine tune takeoff power boost, I have never seen boost over 37" in my engine though, that is how I have set my density controller after a fair amount of tweaking -

ball swivels in instrument panel

-

Check the ball that swivels in the instrument with the steering joke shaft, make sure it moves freely and does not wedge the shaft in any position, clean as needed, trim to landing position, move the elevator by hand about the position where it is during landing, it should drop under its own weight and not bind in any position, trace the elevator linkage from the elevator to the joke, see if anything is binding or broken, lube everything according to service manual, do not lube the ball or the joke shaft, just catches dirt

-

patched my wing walk with Randolph grit brush on material and then spray painted with truck bed liner stuff from auto store to have uniform surface color

-

Why is my right magneto 'eating' condensers?

Fritz1 replied to Ryan ORL's topic in General Mooney Talk

as stated supra, install new condenser and see what happens, during COVID I had two dud mag overhauls from QAA, may have been a coincidence, use Aircraft Accessories of Oklahoma now with good success -

Annual recommendation (mid-west or ability to get home commercial)

Fritz1 replied to fmg85's topic in General Mooney Talk

Second Oasis in Wilmar -

concur, the Bravo engine also appears to like lower RPM, I am running 30 " 2300 and TIT is about 15 dF lower for the same TAS and fuel flow compared to 29" 2400, feels like more complete combustion in the cylinder, the Bravo exhaust and intake are not well tuned, the slower it runs, the better, minimum is 2200 RPM.