Fritz1

Basic Member-

Posts

626 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Fritz1

-

put a wrench on the waste gates shaft and make sure it moves freely, lube waste gate shaft with mouse milk at every oil change, find out what was done during annual that might have anything to do with what you are experiencing, and while you are at it inspect turbo transition weld in exhaust with mirror from backside

-

seasonal, I fly the Bravo to Montana of over X-mas, stop in Piere SD, they keep the lights on for us, heated hangar $50/night, very friendly family run FBO, Bozeman $300/night use one night before flying home, Jet Aviation, I am there 3x a year typically 100% personnel turnover per year, bottom line price for winter hangars can be all over the place, $200/night for ROA on Thanksgiving is not really terrible, but stiff, maybe ask how much they want for parking it outside with engine heater and a cabin heater plugged in, any frost wipes off easily with TKS fluid.

-

Water on floor on pilot's side? Need help

Fritz1 replied to Rick Junkin's topic in General Mooney Talk

sounds like something is going on around the left side of the windshield and the windshield retainer, but maybe also bottom edge of pilot window, if no water trails evident dust the suspect area with baby powder on the inside and spray with hose on the outside -

sounds like baffles, make sure they press against the cowl, don't count on ram air pressure to close the baffles, might as well swap CHT probes and clean probe connectors just to be sire they are reading right

-

New Paint any noticeable airspeed increase, weight saving?

Fritz1 replied to Brian2034's topic in General Mooney Talk

As A64 said the stripper is the problem, under no circumstances must that stuff be vaporized, applying by hand and staying away from seams and carefully removing by hand is extremely time consuming, at the MBB military aircraft shop in Manching Bavaria we had a CO2 blasting apparatus, worked very well but prohibitively expensive for small aircraft, when I had the Bravo painted I insisted that the stripper not be vaporized, hard to tell if they did or not, paint shop better be visited at least once a week to see what is going on, good paint work is hard to come by because it is hard and extremely labor intensive -

New Paint any noticeable airspeed increase, weight saving?

Fritz1 replied to Brian2034's topic in General Mooney Talk

no speed gain or weight savings, I had a G-model painted by now defunct Mod Works in 2000 and I had to twist their arm not to strip it, the paint was just worn, nothing was flaking, no adherence problem, that airplane still flies today with the same paint job and looks good, nothing coming off, you are limited to the original graphics though, when I had the Bravo painted in 2018 I did not have that option, paint was coming off in lots of places partially due the TKS fluid creeping under the paint, bottom line if your paint is not chipping off, not stripping is an option, why disturb primer that has been on there doing its job for 30 or 40 years -

Real world Ovation2 vs Acclaim vs AcclaimS Performance

Fritz1 replied to qwerty1's topic in Modern Mooney Discussion

lots of facets, a turbo with TKS is able to do things that the n/a aircraft without TKS is not able to do, i.e. climb over a lot of weather and in particular icing, the question then becomes how important is it to be able to do these kinds of things, best way to find out might be to talk to one of the dealers and test fly aircraft, Jimmy Garrison at GmaxAmerican, Richard Similie at Thunderbird and Mark Wood at Delta Aviation, as a serious and funded buyer you might just offer to pay for the test flight which they will most likely decline or credit to a purchase. Once you have experience the smooth and solid climb of a turbo going through 14,000 ft the risk is you might want one. Buyer beware! -

Sorry to see that much aggravation, airplane damaged, trip derailed, repair may take a while, I have bought two gear legs, one for my G-model way back when, my own FBO wrecked it and repaired it, the other one when I bought the Bravo 7 years ago, part of the pre purchase. A lot has been written about this, there is no easy way out. Line personnel especially at large FBOs often has a turnover of 100% per year. Therefore avoid towing with a tug whenever possible, especially pushing backward, park so that the airplane does not have to be moved if possible. If towing unavoidable, talk to the line service person, give him a tip, that makes you less of a moper, a make him touch the left gear leg tube and feel that there is no dent. Explain that the repair is somewhere between $4k and $5k and nobody wants to go there.

-

tightening those connecting wires between the metal baffles will help, check the rubber baffling all around and don't count on ram air closing anything, the rubber has to press against the cowl, all small losses add up, check where the intercooler duct connects to the intercooler, lots of ram air leaks out, use hi temp RTV, seal any leaks around the oil cooler with hi temp RTV, factory baffling has large holes around the starter, step by step CHTs and oil temp will come down

-

figured it out and ordered the Honeywell 1SE1 with pigtails as a replacement for the obsolete throttle boost pump switch, $80 at Skygeek

-

Removed dead throttle boost pump switch yesterday, Honeywell ZS-1009 with pigtails which is obsolete and unavailable, have Honeywell 11SM244-T which I had bought according to the Bravo parts catalog a while ago, mounting holes fit, but does not have pigtails and is overall smaller in size and does not appear to be sealed as well as the old switch, What is the

-

Encore TKS FIKI performance in moderate icing?

Fritz1 replied to Beestforwardspeed's topic in Modern Mooney Discussion

-

Encore TKS FIKI performance in moderate icing?

Fritz1 replied to Beestforwardspeed's topic in Modern Mooney Discussion

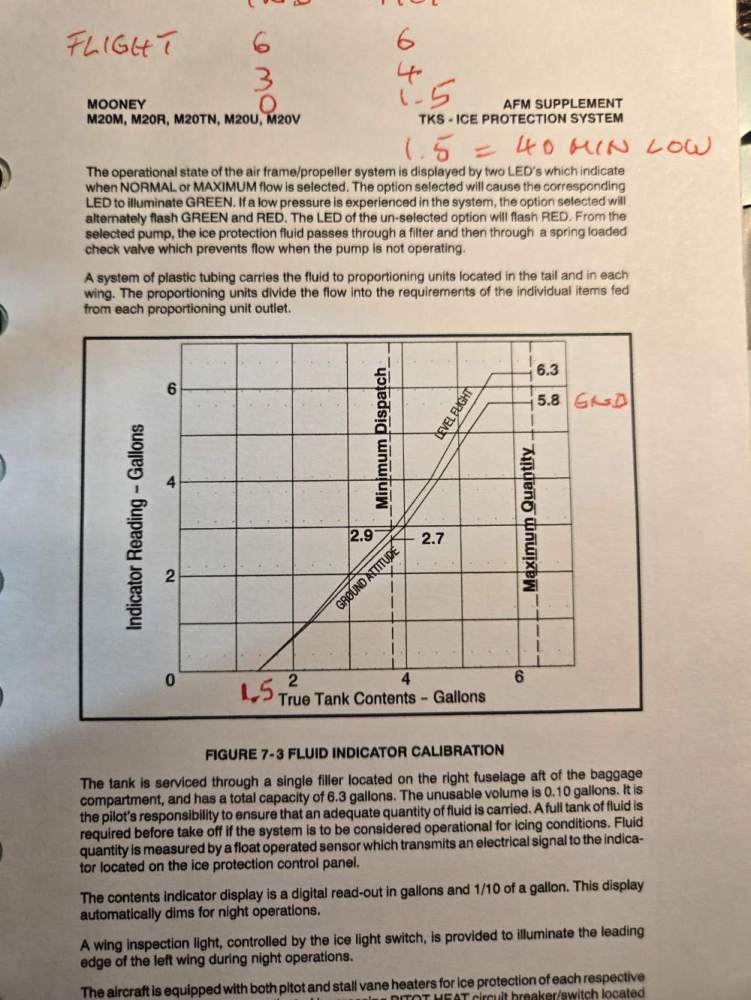

the sender float tends to get stuck when the engine is not running, however, when you look at the TKS fluid level chart in the POH supplement you also realize that that you have more in the tank than the display shows, display zero means that you still have about 1.5 gal, think this is a safety feature, display is zero in icing means you have to get out within this logical second because you have 45 min left at low flow at best, 20 min at high flow -

Encore TKS FIKI performance in moderate icing?

Fritz1 replied to Beestforwardspeed's topic in Modern Mooney Discussion

watching the drip profile on the ground you may realize that the tail gets much more fluid per foot than the wing, this is required due to the sharper radius, gut feel the horizontal tail gets about the same amount of fluid as the entire wing, I have never seen any ice accumulation on the horizontal stab with the system primed and running, occasional patches on the wings mostly around the stall triggers though, once the system is primed and running you can cycle between low and off to stretch the fluid and watch the accretion rate, those sports around the stall triggers are hard to get rid of, typically I run the system down in summer doing monthly priming runs, right now it sits at 2 gal, will top it off in the next week or so to start the season with mostly fresh fluid, I would not want to run the pumps dry, think the POH supplement for the TKS says not to do that -

Encore TKS FIKI performance in moderate icing?

Fritz1 replied to Beestforwardspeed's topic in Modern Mooney Discussion

watching the drip profile on the ground you may realize that the tail gets much more fluid per foot than the wing, this is required due to the sharper radius, gut feel the horizontal tail gets about the same amount of fluid as the entire wing, I have never seen any ice accumulation on the horizontal stab with the system primed and running, occasional patches on the wings mostly around the stall triggers though, once the system is primed and running you can cycle between low and off to stretch the fluid and watch the accretion rate, those sports around the stall triggers are hard to get rid of, typically I run the system down in summer doing monthly priming runs, right now it sits at 2 gal, will top it off in the next week or so to start the season with mostly fresh fluid, I would not want to run the pumps dry, think the POH supplement for the TKS says not to do that -

suspecting a fuel flow imbalance a GAMI type lean test might provide clues if not done already, they describe it on their website, in a nutshell go to a power setting that cannot damage anything, let's say below 60%, maybe 24" 2400 rpm start leaning in 0.5 gph increments and record fuel flow, TIT, EGTS, CHTs, find and record peak EGT for each cylinder, I did that with my wife before I installed the GAMIs, I said the numbers and she wrote them into a table, my EDM 700 did not have a data logger, this will tell you something, a good peak EGT spread is below 0.5 gph, .3 gph is about as good as it gets, chances are there are several things going on, TIT reading low is very likely unless you replaced the probe since you owned the airplane, I replaced mine with an Alcor probe last summer, only the Alcor was available, the burnt KS probe read about 100 degrees low, think the Alcor is right on. My CHTs typically range between 350 and 380 dF in cruise, for quite a while #4 was my hottest cylinder, spent quite some time replacing worn baffle pieces and squeezing RTV into the last nook and cranny, all the little gaps add up, the Bravo engine pushes the parallel valve design to the limit and has nothing in common with the 541s used in Aerostars, Dukes and Navajos, this is a much heavier engine with cross flow heads and angle valves, think that engine is at least 50 lb heavier, the Bravo is nose heavy as it is so the 541 was not an option, properly set up the AF1B turns the Bravo into a magic carpet, you will figure it out and you are getting close

-

Spruce sells the sound ex material in different thickness, approved for cert aircraft, maybe go for the thinnest one to save weight, there are pre-cut sets for many aircraft types, buying by the roll is typically less expensive, make card board templates first and then cut insulation material with heavy pair of scissors

-

there is more than one thing going on, call Brian Kendrick in San Marco TX, 830 370 1190 he tends to figure things out that nobody else does, TIT probe may be burnt and read low, fuel flow transducer may read high, unlikely though that both are off at the same time, the upper deck air lines blow air into the turbo injectors, helps atomizing fuel, cant figure how lack of that air would cause high CHTs, fuel would have to blow back and leak out somewhere

-

hmm, you have low TIT and lots of fuel flow, the Bravo engine is very sensitive to baffle leaks, as Lance said check the metal baffles between cylinders, maybe some are missing, also check mag timing for excessive advance

-

Encore TKS FIKI performance in moderate icing?

Fritz1 replied to Beestforwardspeed's topic in Modern Mooney Discussion

judgement call, hard where to draw the line, the system is very powerful, once you have figured out that it really works run time becomes the limiting factor, 150 min low, 75 min high, figure a blended max run time of 90 min or 1.5h, you want to land with a reasonable reserve that gives you 0.5h blended run time and 1h reserve, 45 min blended run time is already stretching it, the end of the icing better be close. You can gain some by cycling the system on and off on low and watch the accretion rate, most icing is slow and benign until it it not. Fly safe! -

you might consider hiring somebody who has done this a lot, maybe do the 201 windshield swap

-

Encore TKS FIKI performance in moderate icing?

Fritz1 replied to Beestforwardspeed's topic in Modern Mooney Discussion

Congratulations on the FIKI Encore, probably only two or three of those. The TKS works as advertized, run system on the ground once a month, 5 min on each main pump, 10 shots out of each windshield pump, watch the drip pattern on the ground, massage fluid into the dead spots with a sponge, prime system on the ground before you take off for an icing flight and top off again after priming until fluid runs out of overflow drain, use the high setting for priming before you enter an icing cloud, 2-3 min should do if system has been primed on the ground, leave yourself space below to drop out in case the system gets overwhelmed, runtime on high is 75 min which can go by quickly, set yourself an icing limit for each approach, when in doubt stay out of icing, study all icing forecasts, you will learn that they typically paint a worst case scenario, icing is everywhere, once airborne pireps on XM weather are extremely helpful, most of the time you only need the system for 5 min on the climb or 5 min on descent, learn the correlation between radar echos on nexrad and actual icing, with the system working properly some horns will form around the landing light lenses and around the stall strips, turn the system off when you exit the clouds and watch how long it takes for the horns to go away through sublimation. I have seen the worst icing around freezing in the tops of Cus, speed loss of 15KT, I have seen icing down to -30C. When in icing ask yourself every couple of minutes, what do I do right now if system fails. After using system lube all heim links in flight controls and landing gear with triflo, at annual watch where TKS fluid goes in tail and lube anything that moves. Washing the airplane thoroughly after TKS use cannot hurt. A well primed airplane will drip in hangar when pressure drops, once airplane stops dripping it is time to re-prime. When you fly in winter call ahead and make sure your destination has TKS. You may be amazed, I landed in Juneau AK, no TKS fluid, cannot be shipped by air, when in doubt keep a jug in the trunk, maybe even T connect the jug into the filler tube with a cutoff valve so you can add it in flight. Fly safe! -

interesting question, some of these rod ends are Mooney parts, I had a slightly bent landing gear retraction rod with one slipping rod end in the fuselage of the Bravo a couple of years ago caused by mis-rigging, tried to get the whole rod including ends from Mooney, no joy, just got the tube, eventually straightened the bent tube and replaced the roll pins with monel rivets which is a legal replacement, used in helicopters a lot, if I could get the rod ends I would put the new tube in, drilling the new tube for the old rod ends is doable but the benefit is marginal, bottom line: some of these rod ends are Mooney parts and they source them from a vendor that custom makes them for Mooney, they can only be had from Mooney, there are rod ends that are standard parts. Give Lasar and Maxwell a call and find out what it might take to have a batch of rod ends made.

-

welcome aboard, the FIKI Bravo shines in mountain flying, typical cruise at FL190 30" 2300 RPM is 185 KT TAS at about 18.5 GPH, at climb power 34" 2400 RPM the Bravo will hold 600 ft/min at 120KT up to FL210, I typically do not go higher unless there is a need to climb above icing clouds, the critical altitude on the turbo is around 21,000 ft, key to longevity is CHT below 400, TIT below 1600, power reductions not more than 2"/min with synchronous fuel flow reduction to keep TIT in the mid 1500s, this engine really runs better with Tempest fine wire plugs and needs 25h oil changes, run conservatively the engine will make TBO, maybe needs a cylinder or two overhauled, turbo and wastegate tend to need an overhaul around 1200h. Overall about as good as it gets in a piston single, the Acclaim is faster due to its better cowl and propeller, the engine though has very different characteristics compared to the Bravo engine