1980Mooney

Verified Member-

Posts

3,720 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by 1980Mooney

-

FAA shows that the registration was "cancelled" in 2013. I bet it got scrapped. Sometimes the wrong N number gets attributed to a flight on FlightAware - especially in pre ADS-B aircraft.

-

FAA shows that this one was deregistered in 2018....

-

The registration is still current per the FAA. Hope springs eternal. This also highlights that the list of about 7,000 Mooney's registered world wide is not the number flying....

-

Any recent Smooth belly mod for m20e

1980Mooney replied to Hradec's topic in Vintage Mooneys (pre-J models)

But isn't that true of everything in General Aviation? I bet that the Mooney Factory could not put an Ovation back into production for less than $1.2 million.... -

Fuel Cap Strap...Should it be There?

1980Mooney replied to Lax291's topic in Modern Mooney Discussion

Pragmatically they are not very useful even if we ignore the problem of fouling the fuel float. Think about how you might lose a fuel cap. You or someone fuels the plane, puts the cap on but forgets to push the tab/lock down and you miss it in the preflight. You take off Your cap will come off as you roll down the runway with the air creating lift over the wing. If you have the original stainless steel chain (which is strong) your cap will be flopping around potentially beating the crap out of your wing until you land. However, if there is no lanyard, the cap will be right on the runway or next to it - Trust me - this personally happened to me (also another post below of same). The airport found my cap which was completely undamaged. Alternatively if the tab on the cap pops up in flight (note - I have never heard of this happening because the airflow naturally pushes it down) The cap may flop around chipping and denting your wing The lanyard will eventually break before you can land You will have a real lose-lose situation - potentially chipped wing and no cap $$ That plastic lanyard doesn't look like it will foul the fuel float. But it also doesn't look like it has much strength to hold the cap in airflow. I suspect that if you forget to lock the tab on take off that the plastic lanyard will allow it to bash the wing a few times and then break. The cap will likely be lost outside the runway Here is another one, without a lanyard that was found by the airport personel -

IO-550A Hot Cylinder Troubleshooting

1980Mooney replied to Ryan121b's topic in Modern Mooney Discussion

The baffling on the sides look fine (not sure about the "even side comment". You can put a dot of red RTV where the camloc's are wearing. Make sure that the shank on your camloc's are the right length. I can't see it in your pics but I always flip the front baffle up inside the lower cowl. If you don't flip it up before you install the lower cowl it can be a pain to reorient. It fits really tight The back baffle has a split seam in the middle - mine does not. I would put a doubler on inside. The pilot's side of the rear baffle is a bit weird on all Missiles because that is where the wide nearly rectangular tube for the ram-air is bonded into the top cowling. You will need a boroscope or something to see how it lays down then that flat tube pushes down. Also look at the top cowl to see the telltale marks where everything touches when it is bottoned up and pressing the baffling down Below is a pic (bottom) of another Missile from Missile Oil Drain Hose and fitting - Modern Mooney Discussion - Mooneyspace.com - A community for Mooney aircraft owners and enthusiasts Notice that the front baffle (right behind the bottom part of spinner) is flipped up. Also my pic: -

IO-550A Hot Cylinder Troubleshooting

1980Mooney replied to Ryan121b's topic in Modern Mooney Discussion

Rather than swap the probe position on #4, can you swap the probe to an adjacent cylinder in order to prove that your readings are accurate and not caused by a faulty probe? Second, since the IO-550A is unique to the Missile, I assume that your mechanic took pictures of all the baffling, cabling, hoses, etc before removing/tearing down your engine for the internal inspection. Do you have those pics to compare with your current baffling? -

You forgot to add about the current owners shopping the company around in late 2021 in what appeared to be a desperate attempt to flip it and get out. - only to have it show up on the "Craigs List" of Business Brokerage sites "Bizquest.com" with a cheesy "Legendary Aircraft Manufacturer" ad and a $15 million asking price tag. https://www.aero-news.net/ANNTicker.cfm?do=main.textpost&id=37B810E4-8C5F-4A32-9069-F9E524F2E459

-

This is a great point that seems to be completely sidetracked for now. One sad builder on VansAirForce forum commented that had have already built some major sections like the empennage and applied 2 coats of epoxy primer. It contains defective Laser Cut Parts. He commented that it will be easier to start over and build a new empennage than to tear the one he has apart in order to replace the parts.

-

Do You Leave Your Tow-Bar Connected While Parked?

1980Mooney replied to PeteMc's topic in Miscellaneous Aviation Talk

The J POH only says in PREFLIGHT: "10. Baggage Door Area Baggage Door ........ VERIFY SECURED , (VERIFY inside handle is properly secured) . (CHECK outside handle operation)" Later POH's like R say same thing. -

Regarding rudder - does your plane fly straight and level when in cruise with power settings and speed stabilized? - meaning hands off with minimal adjustment? If so it is properly rigged. The torque steer on full power (and rudder to counteract) is normal.

-

Great questions. The RPM restriction has been discussed many times. The consensus is "the main concern is not for short term usage but for continuous operation in the limited range" - meaning in a cruise. And "there is no way I can fly an approach without being in the limited zone. I have always taken this restriction to mean not to fly a long flight sitting in the restricted zone."

-

Correct. In 2020, multiple sources announced that Meijing Group sold 80% of Mooney to U.S. Financial (a Wyoming financial entity that remains hidden behind Wyoming's corporate laws) with Meijing keeping 20%. https://www.aopa.org/news-and-media/all-news/2020/september/03/pilots-aircraft-owners-buy-mooney-international https://www.australianflying.com.au/latest/pilots-and-owners-buy-out-mooney-international https://themooneyflyer.com/issues/2020-OctTMF.pdf See page 3 In November 2019, after the factory shut down, AVweb published "We don’t know the terms of the Meijing deal, but the company has admitted to at least a $150 million capital infusion. That’s not trivial. " https://www.avweb.com/insider/mooneys-last-act/ I doubt that Meijing made all their entire "capital infusion" in the form of equity in Mooney. More likely they did much of it in the form of debt - a crushing debt which Mooney Int'l has on the Corporate balance sheet and owes to Meijing today. That would explain why Jonny and US Financial were out marketing the company in late 2021 attempting to flip it (with the debt) to a new owner.

-

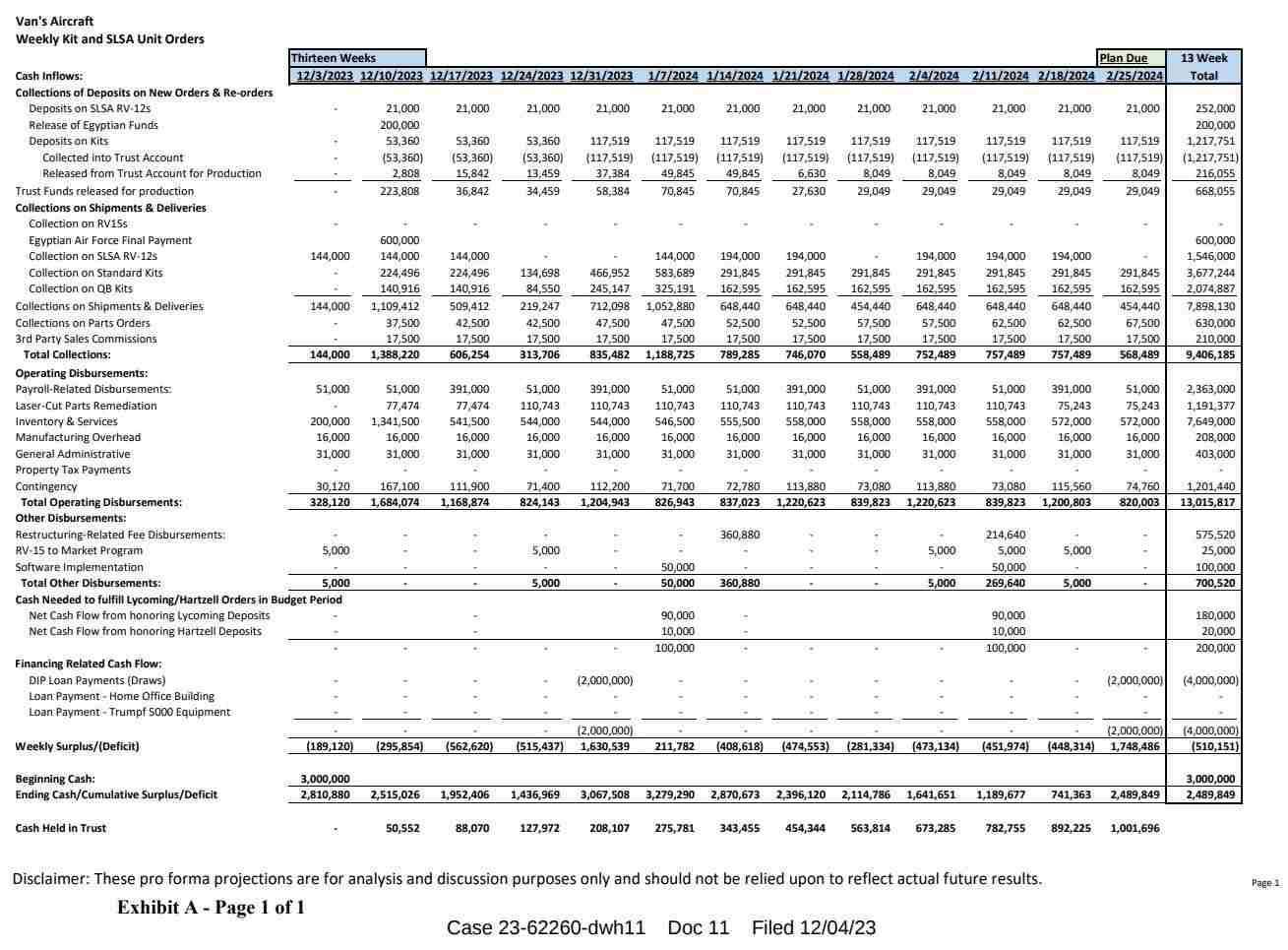

This will be tricky Don't forget that the employees are shareholders - not just just the old man. They will be wiped out. The bankruptcy filing shows that they are losing (negative cashflow) about ($500,000) per week. The negative cashflow is projected to continue at over ($400,000) per week through February (and that is with new orders and payments coming in) Their plan of negative cashflow depends upon builders sending Vans a new/fresh $9 million in cash over the next 90 days. Even with the $9 million they will still be short about $4 million and will draw upon most of the VanGrunsven's loan commitment. Without the fresh $9 million in cash payments by builders they will burn through $1 million per week and VanGrunsven's loan will be gone mid January.

-

Van's filed Chapter 11 Bankruptcy today. This should be no surprise. In October, Dick VanGrunsven said that he had been loaning the company money. That means that they have been negative cash flowing. With the October announcements and the retention of outside advisors (more negative cash outflow to their pockets) I am sure it only got worse. VanGrunsven and his wife have offered the company a $6M debtor in possession revolving line of credit to support operations during reorganization. They said they will start contacting customers with outstanding orders and offer them new higher prices. Van's Aircraft Announces Chapter 11 Reorganization - Van's Aircraft Total Performance RV Kit Planes (vansaircraft.com)

-

In the not too distant future AI Chatbots will do this for all of us - and you will not need a lawyer.

-

@PeteMc For reference hangar-planning.pdf (aopa.org) untitled (aopa.org) For the record: Ground control - AOPA UNDERSTAND YOUR GROUND LEASE

-

@PeteMc This one too into Word when downloaded TEMPLATE-Hangar-Rental-Agreement.docx (live.com)

-

@PeteMc This one downloads into Word model_lease_agreement.doc (live.com)

-

@PeteMc airplane hangar rental agreement - Google Search Literally every municipal airport Hangar Agreement in the US will appear. Here is one from EAA chapters.eaa.org/eaa55/-/media/5a6f918190404eb19ea7117e6eaf8450.ashx

-

attached now

-

The first article highlights some of the issues. https://shackelford.law/news-aviation/aircraft-hangar-lease-what-can-a-tenant-expect/ Here are some templates - they are customizable with a PDF app. There are some free ones online like Candy PDF to Word. The ones for Georgetown, Spanish Fork and Sweetwater have a lot more boilerplate. https://crp.trb.org/acrpwebresource6/wp-content/uploads/sites/13/2018/02/TEMPLATE-Hangar-Rental-Agreement.docx https://www.dot.ga.gov/InvestSmart/Aviation/Forms/SampleLandLeaseforHanger.pdf https://ftp.txdot.gov/pub/txdot-info/avn/model_lease_agreement.doc T-Hangar-Lease-Agreement.pdf (flywenatchee.com) Microsoft Word - Updated Privately Owned Hangar Lease Agreement (ventura.org) 3.7.14-City-of-Georgetown-Airport-Ground-Lease.pdf Hangar Ground Lease Agreement (spanishfork.org) https://sweetwaterfbo.com/wp-content/uploads/2020/02/Aeronautical-Use-Hangar-Lease-2019-Form-Fill-REVISED.pdf

-

Really? I just came up with 24 different leases on the first page of the search.

-

Here is a 2017-2023 "SuperCub.org" thread on problems with Sky Tech starters in Lycoming installations. Apparently, the legacy starters had lots of problems - they were basically crap. Owners with fleet visibility witnessed multiple failures. Things have gotten better apparently. But rather than argue with every pissed off owner, regardless of legacy or more recent purchase, they just give buyers their money back - like you. disappointed in Skytec starters (supercub.org)

-

Which model? year?