1980Mooney

Basic Member-

Posts

3,228 -

Joined

-

Last visited

-

Days Won

4

Everything posted by 1980Mooney

-

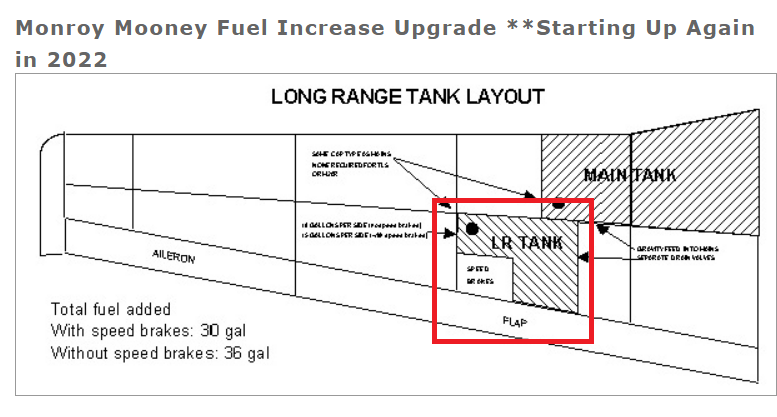

He has Monroy Long Range Tanks. The "long range" tank is a separate tank that gravity drains into the main tank. If you look at the parts list you will see that they use a straight 3/8 inch union fitting, AN832-6D, and a a 3/8 inch elbow, AN833-6D, to connect the 2 tanks and allow fuel to gravity flow between tanks depending on level in each tank as it is filled or the main tank is consumed. Since the connection between tanks is only 3/8 inch ID, that is why the tanks do not immediately equalize when fueling either the main tank or the long range tank fuller than the other.. https://skygeek.com/mil-standard-an832-6d-union-flared-tube.html https://www.aircraftspruce.com/catalog/hapages/an833.php Look at the 3rd pic in this topic - the OP included a copy of the parts list for an M20K installation.

-

"$19,000+ ... total outlay will probably be $25k" Unbelievable. What an escalating ripoff to seal Mooney tanks. I wonder how many Mooney owners realistically budget for that or honestly factor it into the true cost of "thrifty Mooney" ownership. And given the sad state of the paint in the pics you posted, I assume that you have seen the recent MS topics on repainting costing about $30K Last, pay close attention to the condition of engine mounting frame on the Rocket - especially close to hot spots. Rocket Engineering uses very thin wall tubulars with 3 different wall thicknesses getting progressively thinner. The slightest corrosion on the engine mounting frame can lead to airworthiness issues. Rocket Engineering still supports the Rocket and Missile. I had my Missile engine frame repaired by Rocket about 1 1/2 year ago (rewelded, oil filled tubulars, powder coated). The labor involved to remove and reinstall the engine mount really drives the cost up. There are some topics on MS regarding this - one owner welded the frame in place. I see you are in Rocket's backyard not far from Spokane which is good.

-

New upholstery and new windows/windscreen (1/4 in.) Paint looks good. Speed brakes and GAMI's. Panel not glass but has 530W, Flightstream, 330ES, STEC55X - so not terrible. Do you know what the price was before the price drop? Prices are starting to drop - this is just anectodical but it looks to me like I am seeing the same planes listed that are not moving. Keep in mind when using any backward looking price guide.

-

Except there is not. The only '80 J on Controller has 200 hours on engine and says "call for price". There is an '87 J with 1638 hours on the engine, steam gauges +GNS430, one pielce belly and speed brakes for $145K. Not sure what you are referring to - maybe I missed it. Also looked at Trade A Plane - The only '80 J is a Turo Bullet - 728 hours on the engine in 25 years.....

-

I know that I looked at this on Controller 2 days agon on April 10 - And I remember that it was priced at $175K But they just dropped the price to $124,900 on both Controller and Scott MacDonald Aircraft Sales. It says "Reduced for quick sale!" Personally, I would get on it and give it a hard look. Alternatively, perhaps this is a harbinger that the market for used GA aircraft is about to see the bottom drop out. I think a lot of people are sitting on planes that are not moving. And interest rates will be rising. 1978 MOONEY M20J 201 For Sale in Stuart, Florida | Controller.com 1978 MOONEY M20J 201 For Sale in Stuart, Florida | www.macdonaldaircraft.com

-

M20M TLS as first plane , family travel plane , weight and balance

1980Mooney replied to Raffi's topic in General Mooney Talk

With 4 adults you are right. But with 2 adults and two (2) 90+ lb. and growing children ( I will assume young teens) it can work for @Raffi for a window of time. I have done it successfully. However, the good news/bad news reality is that as they get into their older teens the odds become more likely that they will either want to bring a "friend" (which is a "no-go" 5th pax in a Mooney) or they will conjure up semi-legitimate reasons/obligations to opt out of the family trip and stay home. (The occurrence of the first situation will precipitate the second.) Even if you buy a bigger plane, eventually 4 will become 3 and 3 will become 2. Buy the plane (4 seat or 6, Mooney or Bonanza), and enjoy it while you can. -

M20M TLS as first plane , family travel plane , weight and balance

1980Mooney replied to Raffi's topic in General Mooney Talk

While you are thinking about family load hauling, don't forget that the "2 kids" will be growing probably rather rapidly - and the "adults" will also probably add lbs,, albeit more slowly, over time.. Maybe things are different in Europe but most teenagers I see nowadays, girls included, are bigger and heavier than I ever recall. Also, not sure who told you that "a F33 Bonanza, turns out that 2 adults , 2 kids and some luggage will ground you..". When you say "grounds you" that means Useful Load is consumed by PAX and junk - no weight left for fuel - right? 2 Adults + 2 Kids won't "ground" any Bonanza ever built. Someone must have mixed up Kg. for Lbs. Bonanza's will handily out-haul any Mooney built. F33 Bonanza was only built in 1970. Only 20-25 were built . It kept the old Debonair 225 hp. IO-470. Even so Useful Load was 1,065 lbs. F33A Bonanza built 1971-1990. Over 1,500 built. 285 hp. IO-520. Useful Load out of the factory up to 1,467 lbs. UL of 1,200 - 1,350 lbs is pretty common. Additionally many GAMI modifications include GW increases (different improvements with different combinations of improved baffles, injectors, tip tanks, IO-550). Turbo normalizing can take GW even higher. https://www.aopa.org/news-and-media/all-news/1998/september/pilot/bonanza-f33a https://gami.com/prgamitatgwi.pdf https://taturbo.com/gwipr.html -

Apples and Oranges. A shortage of A&P's is unrelated to expensive or hard to find parts. Sourcing a solenoid from NAPA vs. from Aircraft Spruce or Aviall is not going to change the population of A&P's. Are you suggesting that the FAA is going to open the floodgates to allow either Owners or "shade tree mechanics" to conduct and sign off on maintenance and repair of Certified Aircraft? It is not just A&P's that are in short supply - I would argue that there are very few true automotive mechanics left. Most are just "parts changers". The tests are automated, and they just replace parts when the computer tells them.

-

The FAA "VARMA" Document link posted by @hammdo seems to be from about 2008 and the FAA circular which governs this posted by @A64Pilot (as noted by him) is from 2009. I am struggling to find the "New" in any of this. Haven't we been living with this "program" as applied for the last 15 years? So what if a FAA Rep mentioned it in a seminar. What am I missing?

-

Yes Rocket Engineering added them on both the Missile and Rocket Conversions. STC-SA4443NM - Lasar - Paul Loewen. The STC also added wing tips on the Missile (early J’s) and the hinge cover in shown in your pic.

-

Hangar advice in the Austin area?

1980Mooney replied to northaustinmooneypilot's topic in Miscellaneous Aviation Talk

Many here seem to be under the delusion that municipalities actually want more General Aviation. Most GA airports are owned by municipalities. And most municipalities lose money on airport operations. - hangar, landing and fuel fees are hard pressed to cover expenses with massive amounts of land and perimeter to maintain. Security requirements since 9/11 are costly and difficult to manage. Most need Federal handouts for capital improvements. For instance, Texas receives the largest Block Grant of funds for GA airports - $27 million in 2022....(think of it as "airport welfare") Municipal airports are more likely to make money catering to business aircraft - higher fuel sales, more professional, less risk, large hangar rents, easier to manage security, etc. GA pilots are more of a headache- using their hangar for home storage, dumping leaded fuel on the ground, driving cars near aircraft and sometimes into, etc. Since they are owned by Municipalities, citizens have to vote for funding and bonds. We pilots forget that the general public think of us the most entitled special interest group on the world - a bunch a rich people making noise all times of the day. -

First Post and Several Questions

1980Mooney replied to PrairieFlyer's topic in Modern Mooney Discussion

In a fleet in which no new Mooney’s will ever be added, it is just a matter of time before some degree of damage history becomes the norm. 4 Mooney’s in the last 10 days were damaged. Look at ASIAS. And there are plenty that get damaged and don’t come to the attention of the FAA (like the Minnesota Bravo that fatally crashed - the Docket showed that the insurance company revealed that he botched a landing in 2017 which took out runway lights and tore up both wings. No FAA history of the incident.). -

First Post and Several Questions

1980Mooney replied to PrairieFlyer's topic in Modern Mooney Discussion

In General Aviation, no purchase is as cut and dry as you hope. Everything is a compromise. There will always be surprises and unknowns especially with older aircraft. -

First Post and Several Questions

1980Mooney replied to PrairieFlyer's topic in Modern Mooney Discussion

The flip side is 20 years and 10 owners after a repair - it has been reviewed and looked at so many times - it has stood “the test of time”. It becomes less and less relevant as a purchase or sale issue. -

Garmin 750 and 650 upgrade to the Xi Versions.

1980Mooney replied to Little Dipper's topic in Modern Mooney Discussion

Sarasota Avionics is now advertising that cost to upgrade the GTN750 is about $6,100. I would not be surprised if there are some additional or hidden costs when it is actually installed. And probably about another $400 in sales tax. I wouldn't be surprised if the total cost starts with a "7". -

First Post and Several Questions

1980Mooney replied to PrairieFlyer's topic in Modern Mooney Discussion

You do know that Useful Load is not a Mooney strength. My M20J came from the factory with 943 lbs UL. Later J's had a GW increase of 160 lbs. (from 2740 lb GW to 2900 lb GW) Regarding filling 4 seats - it depends on who is in those seats. The average US male now weighs about 200 lb and the average female is about 170 lbs. Canadians are probably more fit. If you have 4 adults you could easily be at 720 lbs. Add 50 lbs of luggage and crap and you are at 770 lbs. That leaves you 170 lbs. for fuel, some extra quarts of oil, whatever junk you have on the hatrack, flight bag, etc. That means you can only put on about 27 gallons. Assume that 7 gallons is reserve so that give you about 2 hours flight time. #1 - I can't give you a fair answer - my J was converted to a "Missile" long ago which includes a much heavier IO-550 and full feathing prop - i.e. lots of weight on the nose gear and any bumps with those spongy donuts is usually a problem for me. But it may not be an issue for regular J owners. #2 - This has been a topic several times previously. See comments from @M20Doc in first topic. He owns the MSC (Mooney Service Center) in Ontario. He is also the Diamond and Cirrus Authorized Service Center and is importing planes into Canada all the time. Tri-City Aero Maintenance Inc Company Profile | Breslau, ON, Canada | Competitors, Financials & Contacts - Dun & Bradstreet (dnb.com) #3 - As you may have seen, Mooney's land gear up with great frequency. Mooney's survive gear up landings better than most single engine retractable. They are generally easily reparable by knowledgeable shops. I know a Mooney owner who landed the same J gear up twice. And he still owns and flies that plane. If a Mooney has been repaired properly it should not be an issue. If the incident were repaired a long time ago it becomes basically a non-issue. Recent repairs may bring a bigger discount #4 - You will appreciate the convenience and utility of an autopilot with GPSS steering coupled to your WAAS navigator that can do LPV approaches. Ask @M20Doc about the Canadian Mooney market - he is the most knowable here on MS about Mooney's in Canada - and he is here frequently. -

So are you concerned about potential liability if you sell a plane in which the engine is making metal and you failed to disclose it? I wonder how many people asked to see the latest oil analysis during a pre-buy? If a potential buyer asked to see your last 3-4 oil analysis along with all the other logs, would you provide them?

-

FLYING announced that it acquired Plane & Pilot Magazine. Plane & Pilot will dumb down and focus only on Piston GA. https://www.flyingmag.com/flying-acquires-plane-pilot-magazine/ As you might expect they try to put a positive spin on it. - They are claiming that piston GA is making a "robust comeback". The production numbers compared to fleet attrition are flat-line at best. There is no subscription support for competing stories or competing reviews of GA products. GA advertisers are not going to support both. It is also a function of the reduced popularity of publications that are also struggling with higher costs. IFR Magazine acquired IFR Refresher in 2021 and combined the two which IFR Refresher ceasing to exist Textron (Cessna) acquiring Beechcraft has not breathed any new life into Beech GA pistons - their production continues to shrink. MAPA is trying to stumble back into publication but most seem skeptical It is probably only a matter of time for Plane & Pilot to be combined into Flying. "FLYING and Plane & Pilot have been the top two independent aviation magazines for decades. While the brands have been viewed as competitive at times, the focus of the two magazines has also differed. FLYING is an aspirational brand, featuring the latest and greatest in general aviation, spanning the most advanced light sport models to the fastest business jets. Plane & Pilot, on the other hand, has had deeper coverage of the piston community and the world of recreational and private pilots."

-

Alt Field On or Off during engine start and shutdown

1980Mooney replied to bucko's topic in General Mooney Talk

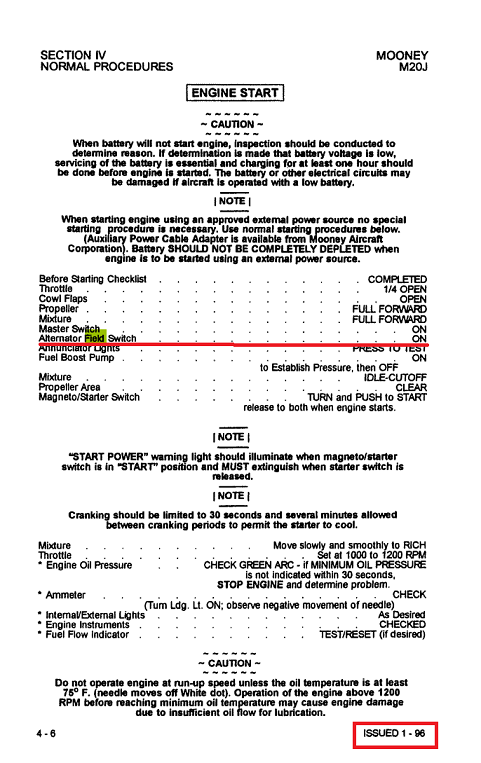

Most J's do not have an Alt. Field switch. The Service Manual with Electrical only shows Alt. Field switch starting with 28 volt system and Serial Number 3000 and up. As noted in the Service Manual, for the 2,999 M20J's without an Alt Field switch, the only way to diagnose the charging system per @M20Doc 's explanation above is to pull the Alt. Field CB. The POH for Serial Numbers below 3,000 notes "The master switch operates the battery relay which controls battery power to the main ship bus bar. This switch also cuts the alternator field power - from main bus to the alternator." The "Normal Procedures - Starting" for those M20J's does not say anything about the Alt. Field. It does not say to pull the CB. The POH for Serial Numbers 3,000 and above (28 volt systems) says to leave the Alt Field "On" when starting. As noted by @jkgyr52 and others, Mooney has been inconsistent in providing an Alt Field switch and in the instructions for its use across models. But in 40 years, starting the 3,400+ J's with the Alt Field "on" has not been an issue for old or new avionics. This seems to be a non-issue. As @ArtVandelay said "Frankly I would be more worried about a lightning strike frying the electronics...." -

Are pilots going to be replaced by AI?

1980Mooney replied to ilovecornfields's topic in Miscellaneous Aviation Talk

As said many times the airbus stalled because the human at the controls manually pulled 1.6 G's upward at 35,000 ft. without full power on the engines. If the pilot would have maintained attitude and power while the pitot tube thawed and reengaged the autopilot all would be well. It is no different than if you are at altitude in cruise and your pitot tube freezes. Do you panic and pull the yoke back? Or do you keep it straight and level while you figure out what is going on? -

Are pilots going to be replaced by AI?

1980Mooney replied to ilovecornfields's topic in Miscellaneous Aviation Talk

I never meant to imply that the pilot monitoring could not take over. Who gets to choose with 2 pilots up front? The PF at the controls is flying. The other pilot is monitoring. Fight /force between 2 pilots? - that is a sure way to crash. That CRM went out years ago. AF447 - the 2 pilots were both acting PF fighting each other on the controls with opposite inputs. One has to hand off to the other. If the AI Autopilot goes down the pilot takes over. How does 2 pilots help that situation? -

Are pilots going to be replaced by AI?

1980Mooney replied to ilovecornfields's topic in Miscellaneous Aviation Talk

I think the basic problem with question #1 and #2 is that I believe you are assuming that the pilot will actually be flying the plane. A more sophisticated "AI" autopilot will be flying the plane in the future. The "pilot" will be monitoring. I hope you don't think it is actually pilots today that keep planes from flying into mountains at night these days - the route is set in the FMS. Same goes with a pilot falling asleep. As far as runway incursions go, one set of eyes should be adequate. On the GermanWIngs 9525 disaster, there were two (2) pilots on board - That didn't stop a determined pilot. Are you suggesting that planes need to go to 3 pilots so that one single pilot is never alone? Lastly what today keeps a hostile actor from hacking our spy satellites and drones and redirecting or crashing them? Encryption and security. -

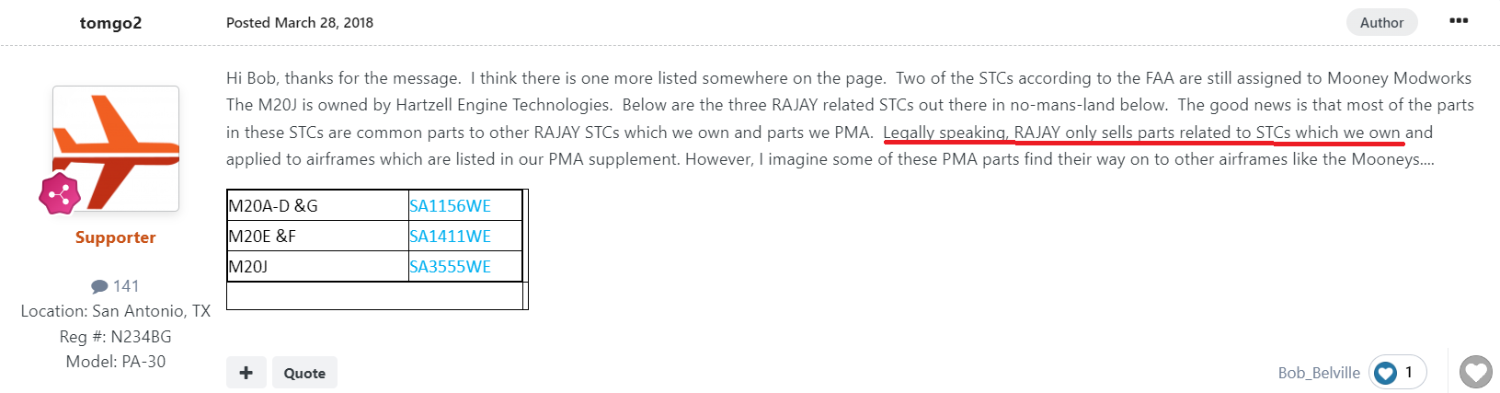

@KSMooniac is right - If you want a add a turbo (normalized or boost) to a 4 cylinder Lycoming powered Mooney, the only way you will get one is by trading planes with someone that already has one. The companies that offered STC's in the past are gone - M20Turbos, ModWorks and Turbo Bullet (an early Darwin Conrad company before he started Rocket Engineering). Rajay Turbos has been resurrected in North Houston at Kestral Airpark but they don't own the STC's for Mooney applications - not clear that they will even sell parts to those that already have a ModWorks STC based upon the Rajay turbo. See comment from "tomgo2" who is Rayjay. Note that they ref the Mooney STC's as being in "no man's land". https://rajay.aero/pages/list-of-stcs (Mooney applications via ModWorks listed in the detail at the bottom of page) The Turbo Bullet installation required the pistons converted to lower compression. The turbo originally boosted to 38" but because it produced more than 200 hp and broke crankshafts, the FAA reduced the allowed boost. It effectively had to be flown like TN.

-

Are pilots going to be replaced by AI?

1980Mooney replied to ilovecornfields's topic in Miscellaneous Aviation Talk

Headline: Pilot Unions Form Coalition to Oppose Single-Pilot Operations, Citing Safety Concerns and Profit-Driven Motives The only reason that 3 competing pilot unions would form a coalition to try to stop single pilot operations is because they know it is a imminent real threat to their employment. Notice that it is 3 international pilot unions (not the APLA) banding together - no wonder the concept that airlines have "profit-driven motives" is foreign and confusing to them. I am sure their strategy will be brilliant - go on strike while being made redundant. The same fight is going on with rail - in North America and Europe. The industry is pushing for single man rail crews in the cab. The UK rail unions continue to strike for 2- man crews. However apparently the European unions have already given up on freight trains and are operating those with single man crews. Maybe the logical progression in aviation will be that freight flights, FedEx, UPS, etc will be the first to go to single pilot ops.