-

Posts

139 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by FlySafe

-

Straight Valve Stem Tubes or Angled Stem Tubes

FlySafe replied to ELT's topic in Vintage Mooneys (pre-J models)

@Pinecone You can use the same pipe as on the nose gear through the similar hollow tube on the main gear above the wheel. Only other requirement is that your jack with the Bogert cradle on top is high enough and has enough lift to get the wheel off the ground. I'm not recommending this method over a wing jack but it has worked well for me and its quick and easy and i feel a little safer. It's easier if you loosen the lower attachments on the gear door arms to give you room for the jack on the outboard side of the wheel, this also give you room to get to the brake which has to come off to slide the wheel off the axel....not an A&P so i try and have someone look over everything before return to service. Don't forget your gear safety stand or safety blocks whenever you have the wheel off https://bogertaviation.com/products/landing-gear-safety-stand-9-base-7-25-to-10-25 k -

Straight Valve Stem Tubes or Angled Stem Tubes

FlySafe replied to ELT's topic in Vintage Mooneys (pre-J models)

yes @Pasturepilot has the ID spot on. its very handy, can use on any standard bottle jack for tire changes on main or nose; I have only used for lifting of 1 wheel at a time for wheel maintenance tasks and found stability as being very good and very quick setup. Just watch winds and make sure clam/mild if working on a ramp and have the other wheels chocked. Be safe. k -

Straight Valve Stem Tubes or Angled Stem Tubes

FlySafe replied to ELT's topic in Vintage Mooneys (pre-J models)

Hi All, I have a pilot report on valve stems. Recently had a slow leak on my 5x5, 6 ply nose tire on a M20C. It has a wheel cover and has had bent tubes installed in the past. Tube removed was an aero classic leakguard (GL-5076B) with a 90 degree bent stem. I was replacing with a Michelin airstop (097-908-0, TR67-A) also a bent stem. Funny thing was when all back together, the valve stem with its cap sticks out too far and prevents the wheel cover from being reinstalled. I was able to remove the vale stem cap and get the cover back on as a temporary solution until I can get a replacement aero classic tube (knowing it will fit). Must be some small difference in the Michelin stem design. oh well, more owner basic maintenance tire change practice. -

Landing gear indicator (on the floor) 78' M20J

FlySafe replied to Mooney13's topic in Modern Mooney Discussion

Affirmative on the part above, alternative style also from aero-lites (2 pack) https://www.amazon.com/GE330-Replacement-Bulb-12VDC-BULBS/dp/B01N1UPFF6/ref=psdc_2314207011_t5_B08GKY8S7L -

How many pilots does it take to unscrew a lightbulb

FlySafe replied to FlySafe's topic in Vintage Mooneys (pre-J models)

thank you -

Landing gear indicator (on the floor) 78' M20J

FlySafe replied to Mooney13's topic in Modern Mooney Discussion

@EricJ Do you know how this pic from earlier in the thread relates to the schematic. Assuming my C is similar would i need to remove all the labeled screws for access? k -

Landing gear indicator (on the floor) 78' M20J

FlySafe replied to Mooney13's topic in Modern Mooney Discussion

Thanks EricJ, I have another go at it from the top side this time. I had the same impression with the current light, only time i can even tell its even there is at night. -

Hi, This is a self-incrimination post in that I have to confess I'm mechanically challenged on what should be a simple task: change a lightbulb in the floor visual gear position window on my 74C. I posted a similar question yesterday and realized it's on an older J model thread, so I apologize for repeating it. I have the belly skin off, I can see the light bracket holder with a small locknut on the ground side, but when I loosened it, I still could not figure out how to get at the bulb as I could only push upward in the holder about 1/4 of an inch. pic below. Feeling embarrassed to be asking this simple maintenance question and once again humbled. Thank you k

-

Landing gear indicator (on the floor) 78' M20J

FlySafe replied to Mooney13's topic in Modern Mooney Discussion

Good evening, my floor visual gear position light is very hard to see so thought I would try and change it out for a 12v style as suggested. I removed the forward belly skin and could see the light bracket holder. It has a retaining nut on the down side with the ground wire. However, I can not get to the top side of the bracket to remove the upper retaining nut to pull bulb out through mounting bracket.This is on a 74 C. Any ideas, not a mechanic, stuck. Thank you. k -

gear push to test lights not working...

FlySafe replied to funvee's topic in Vintage Mooneys (pre-J models)

Fantastic, I love the mooneyspace community, thank you all! k -

gear push to test lights not working...

FlySafe replied to funvee's topic in Vintage Mooneys (pre-J models)

thanks Rich that is helpful. Would you or anyone @Hankhappen to have the electrical schematics for this circuit (serial number 20-0016) and knowledge on best route of access for inspection (glare shield, exterior cowl avionics panel etc). thanks in advance. k -

gear push to test lights not working...

FlySafe replied to funvee's topic in Vintage Mooneys (pre-J models)

Good morning All. I'm seeking advice on my gear-up panel light before starting the gremlin hunt. This question relates to a 74 m20c ranger with electric gear. As a reminder to others not as familiar with this model, two lights: amber gear up, green gear down, off in transit, and a gear position indicator window on the floor with a dim backlight when the gear is down. In addition, there is a separate push-to-test button on the panel for the various annunciator lights. My issue occurred on the preflight yesterday. When I pushed the annunciator test button, there was no gear-up light. However, in the following inflight test, the up indicator illuminated as expected on gear retraction. Likewise, the green gear-down light illuminated when pressing the test button inflight with the gear retracted. I'm pretty sure the gear-up light should, and in the past, illuminated with the push to test on preflight but now I'm questioning myself, and the POH is less than adequate. My post-flight investigation showed that the bulb tested ok on a multimeter. However, when I pushed the test button, there was no indicated power to the socket. Two questions: 1. I would like your help verifying that the gear-up bulb should illuminate with the push-to-test button in a 74 M20C (i saw in another thread, valid for mid-body models). 2. If true for my C, suggestions on the next step to debug Thank you for your collective wisdom; not a EE, plain speak appreciated k -

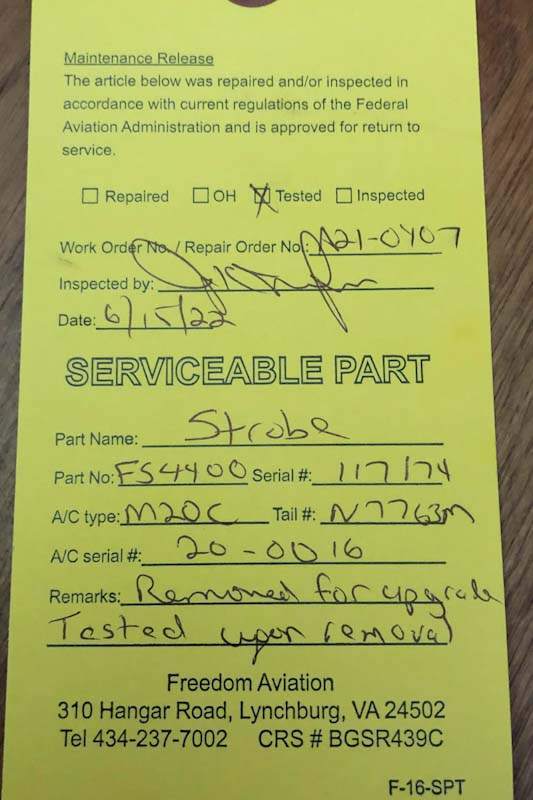

Anyone need a yellow tagged, Universal FS-440 Flight Strobe off my 1974 M20C? $100, 90-day warranty. Here are the specs and new price from aircraft spruce: https://www.aircraftspruce.com/catalog/elpages/fs4400.php. PM me if any questions or interest. Thanks.

-

Hi tcal78, similar to KSMooniac's experience, the male end looked fine. And, as carusoam, mentioned, the fist step in my checklist upon entering the cabin is now to check the emergency extension handle position. I'm teachable especially when $$$ associated with the event

-

I second @KSMooniaccheck the rigging on the manual extension; it has to be exact. I have seen a few instances after annuals when it's been inspected/adjust, while dealing with the 2 reoccuring gear ADs, subsequent failures of the spline gear socket to engage. Have inspected by your A&P asap, as it can be only partially engaged and simply rotating on the gear engagement shaft when the gear cycles causing damage ....personal experience, see pics (1st bad, 2nd good), LASAR has or did have part, good luck. k

-

And verify units kts vs mph… i know silly but it has happened;)

-

Danb, almost no back energy required with sidewinder once you learn how to attach / detach to nose gear. Walk up to side of plane behind prop, Sidewinder in unfolded config carried with both hands, kneel down and insert in tow bar hole with drive knuckle resting on tire, back around prop to the drive drill, lean down on assembly slightly, squeeze the trigger, up the incline, over the hangar bump, perfect alignment in the space, smile...leave it attached until you are ready to bring the plane out. just don’t forget to open the hangar door pricy but you will love it. k

-

Hi willerjim273, Hope you can get this all sorted with the FAA with minimal time and pain. AOPA legal PPS is a great resource and well worth the added cost for the peace of mind in my opinion. Also, while too late in this current situation, I have found, if in doubt, for almost any flight anomaly when interacting with ATC, file a NASA report early and often. Usually not need but nice to have as a safety net in cases when questions do arise. Good luck, I’m remined of the Dragnet line when you reply to your friendly FSDO ASI, “All we want are the facts.” By the way, does anyone know if a 74 C is supposed to have a light in the floor gear position indicator window? If mine is supposed to have one, it’s been unairworthy for 4 yrs non k

-

Interesting article in May IFR Magazine related to instrument currency. In the study cited, only 20% of instrument pilots complete 6 or more approaches in 6 months for currency in the air (I’m assuming they did the hold, tracks and intercepts as well Have a look and see where you fall in comparison and on use of an ATD in your flying. fly safe k

-

Bendix S20/200 magneto 500hr maintenance

FlySafe replied to FlyingDude's topic in Vintage Mooneys (pre-J models)

FlyingDude, you might give some of the mag shops you’re considering a direct call as you are deciding your next steps. I recently spoke with the helpful folks at aircraft magneto as my 500hrs. IRAN is approaching. They currently are running about 18-21 days shop time for service on Bendix S20/S200 style mags. Kelly stated they are averaging ~5 days but it varies. Both have a reputation for doing good work. Unrelated, any realtionship to the Big Lebowski? take care k -

Dukes Gear Actuator - Gear Replacement

FlySafe replied to tcal780's topic in Vintage Mooneys (pre-J models)

Hi, as I recall last summer LASAR warned me when mine was sent in for inspection, if needed, the new gears and labor would be ~1800. Maybe check with them on parts/ overhaul options. I had an earlier thread on this with the details. Good luck. -

Help me decide - Manual vs Electric Gear

FlySafe replied to gwav8or's topic in Vintage Mooneys (pre-J models)

gwav8or, sorry for thread drift but related to my above comment on parts, another name to add to your speed dial, msm, @Alan Fox for misc and hard to source parts after you aquire your mooney. -

Help me decide - Manual vs Electric Gear

FlySafe replied to gwav8or's topic in Vintage Mooneys (pre-J models)

and it can also varry based on condition of your electric motor, guess how i know i have the lower gear ratio set in mine and noticed cycle time starting to increase from ~2 -> 4 secs, was not long after that it became intermittent. motor needed new windings and brushes. It was speaking to me but i did not understand what it was trying to say. Regardless of electric or manual, bookmark LASAR for hard to find Mooney parts and overhaul needs. -

Rear position light replacement on 1976 M20C

FlySafe replied to BillYesIAm's topic in Vintage Mooneys (pre-J models)

https://www.aero-lites.com/web-store scroll down the page, one of the cheapest part you can buy for a plane