-

Posts

167 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by CharlesHuddleston

-

I am assuming that it either fell out or broke and then fell out. I believe once it was out and lost, it allowed the stress to break the steering pin. Ugh... the joys of plane ownership!

-

In the first picture, with the red circle, the stub is what I believe is left. Tried to use pictures from the illustrated parts catalog to compare.

-

Ok, so after a recent landing, had a horrible shimmy in the nose wheel, that settled once we slowed way down. Taxied on in, at first afraid of a flat tire. Noticed I had lost rudder input for steering so had to use differential braking to park. On exam, the steering horn was dangling free, and it appears that the bolt between it and the nose-gear frame was gone, and it had snapped off the lug coming from the tubular cross-beam in the top/front of the nose wheel well. My A&P is going to look at it, but as they have a Mooney as well, he recommended reaching out to the community to see if anyone could add some guidance. Going to put it on the Mooney FB page as well. Wondering if the lug can be re-welded on the cross-member. Tried to include some pics, and circled the lug location. Thanks for any input!

-

Secure your aircraft at all times.

CharlesHuddleston replied to 0TreeLemur's topic in Miscellaneous Aviation Talk

That's an expensive mess! Wonder who will foot the bill for that one? FBO? Owner? You know a 17 yr old is not going to be able to pay for the repairs... I'm constantly reminded at how frighteningly stupid at the actions of others can be. -

I have thought seriously about trying to use this Harbor Freight dolly as nose-wheel towing apparatus. Just have had so many other projects that I have never gotten around to it, but it might work. You slide it in from the side, and it closes in and lifts up the wheel. All 4 corners are casters. I've seen a video of someone using one under each tire to basically roll a car around a garage. https://www.harborfreight.com/1250-lbs-capacity-vehicle-positioning-wheel-dolly-61917.html

-

How hard would it be to get 350hp?

CharlesHuddleston replied to Niko182's topic in General Mooney Talk

I have seriously pondered this exact question. You could put a 300-500hp turboprop up front! Fit shouldn't be a problem, but you might have to re-work the weight and balance/CG. Then your only worry would be how much fuel you could carry! Can't you convert a certified aircraft to an experimental? For "testing" purposes, of course. If anyone wants to poney up for the equipment, I will volunteer my airframe! -

So my M20K has Lemo powered plugs in the front panel, and these, mounted overhead. I have tried everything short of calling Bose to inquire about them. Best I can ascertain, this is an Airbus style connector, but for what purpose? How could I tell if they still work? Appreciate any information you might have!

-

I would offer up a guest room and the bunk beds in our bonus room if anyone needs lodging. Both spaces come with a full bathroom. We are in middle Tennessee, a quick car ride from a KSRB. I will ask our airport manager tomorrow morning about the available hangar space. I could probable also get a couple Mooney's parked in a big hangar at KCSV next to a Legacy 650 that my best friend flies. Their company has a couple big hangars that swallow their Legacy, Pilatus, and 182. I remember when Maria hit Puerto Rico last year, Kenny Chesney (the country singer) flew some folks to KSRB on his jet to escape the storm. More than happy to help. If interested, send me a PM.

-

Panel Maintenance Question

CharlesHuddleston replied to CharlesHuddleston's topic in Modern Mooney Discussion

I do not want it to appear that I am bragging about anything that has been done. The original post was asking about the panel removal. Yes, I am fully aware of what can and cannot be done by a pilot/owner. I also have a good relationship with my mechanic that has helped/supervised the entire process. For me, understanding what is working behind the scenes (and why) to allow me to fly is almost as import as knowing how to take off and land. I enjoy learning. Some people would rather take their car/airplane/etc to the shop and let someone else perform the maintenance. I would rather be involved as much as possible. Just my personality. On the other hand, I also realize limitations, and would not do anything to jeopardize anyone’s safety. But I do appreciate your point, as it is well taken. -CTH -

Panel Maintenance Question

CharlesHuddleston replied to CharlesHuddleston's topic in Modern Mooney Discussion

I do not want it to appear that I am bragging about anything that has been done. The original post was asking about the panel removal. Yes, I am fully aware of what can and cannot be done by a pilot/owner. I also have a good relationship with my mechanic that has helped/supervised the entire process. For me, understanding what is working behind the scenes (and why) to allow me to fly is almost as import as knowing how to take off and land. I enjoy learning. Some people would rather take their car/airplane/etc to the shop and let someone else perform the maintenance. I would rather be involved as much as possible. Just my personality. On the other hand, I also realize limitations, and would not do anything to jeopardize anyone’s safety. But I do appreciate your point, as it is well taken. -CTH -

Panel Maintenance Question

CharlesHuddleston replied to CharlesHuddleston's topic in Modern Mooney Discussion

That was exactly the plan! That happens next week. -

Panel Maintenance Question

CharlesHuddleston replied to CharlesHuddleston's topic in Modern Mooney Discussion

Also read and learned about calibrating your altimeter using your current airfield elevation and pressure settings. Was surprised to find that mine had actually been off a bit. http://www.mrkent.com/flying/altimeter/ -

Panel Maintenance Question

CharlesHuddleston replied to CharlesHuddleston's topic in Modern Mooney Discussion

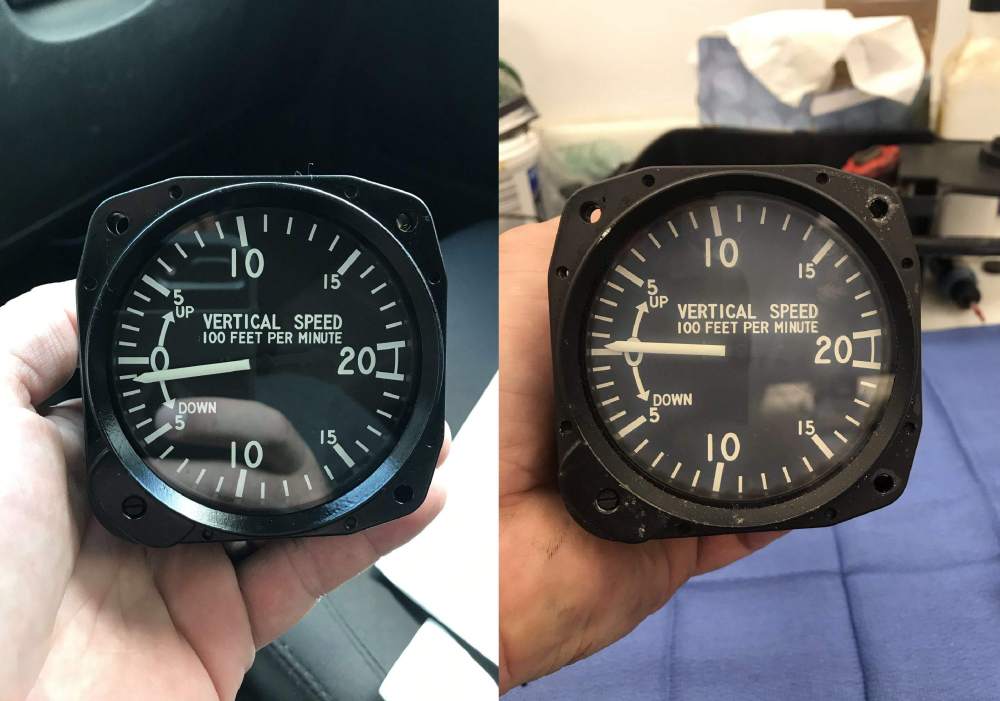

The biggest difference was in the ASI and altimeter faces. Reference the above before pic. Alas, I did nothing, but my hanger elf removed the small flat-head machine screws on the back side of the face. They hold the face-plate on. They have gaskets between the instrument body, glass, and the face. A new microfiber cloth to wipe it all down, and then reverse. Be careful to seal everything up well when reconnecting, don’t want any leaks in your pitot system. -

Ok, my hanger elf has been cleaning up my instrument faces, and I wondered if there was an easier way to access them. For example, wondered about replacing the analog clock with digital. Also need to replace a Grimes light connector. If I remove the capped bolts, will the panel move foreword a little bit (with any slack in wiring and plumbing)? You can only reach so far and do so much from above or below! BTW, I have to echo that this group is a wealth of information! Love reading through the new and the old posts. -Charlie

-

After researching and reading about this on an older thread, I had to re-ask this question. The boost pump on my ‘82 K has a very slow, but noticeable drip. Just noted over the past week or so. Pulled the cover and panels to look everything over, and filmed this video. When operating the boost, the drip increases noticeable. In an old thread, someone had mentioned that this is ‘normal’ or ‘expected’ but I find that hard to believe. Thinking that I would need to follow advice in the other thread, and send out for overhaul, but want to hear some confirmation! Thanks to all! A0B8FCF5-9F47-4854-AC3F-B365512B278F.MOV

-

Old thread, revisited. I just got my K back from a full overhaul. Everything is running great, including the temps.... until I fully close the cowl flaps. When fully closed, the #6 CHT will begin a stead climb to over 425 while the rest of them remain in the 360-380 range. I understand there are a lot of variables involved (RPM, fuel flow, mix, MP), but I’ve experimented with all of the above. The one consistent is the the #6 will begin an immediate climb. I would have thought with it being in front, that it would stay coolest. My first thought after reading and researching goes back to the baffles. They were not replaced. While they don’t look to be in bad shape, they are a little wavy. Also wondered if there could be an outflow issue with the flaps closed? But it seems if this were the case, the rest of the cylinders on that side would climb as well. Appreciate any and all thoughts and input. Going to call Gee-Bee on Monday and price a new set of seals. Also, have about 15-20 hrs since the overhaul. ‘82 K model, LB engine, intercooler and Merlin wastegate. JPI 800. Fixing to download the JPI data and review that as well.

-

Seat pocket fire extinguisher.

CharlesHuddleston replied to RobertGary1's topic in General Mooney Talk

Just watched the Jay Leno info-mercial about the Element. Per the product guy, it can be used in a confined space about 1.5 cubic meters. The fumes it produces are apparently non-toxic. No shelf life or expiration. I think they just sold one to me! -

Have been searching though old threads, and came across a link to RadioRax. www.radiorax.com Looks like an awesome idea, but was wondering if anyone has any experience using them in a Mooney? I know it would require removing and re-installing the trays, but this looks like great product, and would be able to avoid using/removing rivets... TIA, Charlie

-

KAP 150/ GDC31 and a New Alarm

CharlesHuddleston replied to CharlesHuddleston's topic in General Mooney Talk

I used Air Services, Inc in Carrollton, Ga. Sammy Baraznack (owner) was great to work with. I had knocked over a taxiway sign, so had to have part of a skin replaced. They were great to work with start to finish. The back story on my plane includes a purchase from the US Marshal’s service sans log books. It had sat for over a year as well. Despite the fact that she ran great, the guts of the engine looked like trash. Cam and all 6 cylinders were condemned and replaced. Turbo overhaul cost twice what he usually expects. But I now have a great flying, zero time engine. Just have to figure out the alarm and how it’s tied to the autopilot breaker. Wondering if the GDC31has some sort of alarm that is sounding off. Reading up on that now. -

So I just got N1157L back from some repairs and a full overhaul. Also installed ADSB transponder and had them install a GDC31 roll steering converter. Have flow a few times now, but this week, on our way to the beach, there was an alarm (constant) sounding off through the cabin speaker. Finally was able to turn it off when I pulled the autopilot breaker. While en route, I pushed the breaker back in and alarm continued. I was able to test the autopilot, and it went through it’s self-test with the normal 6 beeps, and worked great. Tracked heading/Nav/gps, etc... It even followed an RNAV approach and picked up the GS and everything. Alarm would still sound, even with the trim switch turned off. Called the shop, and they thought it sounded like something in the trim system, so will need to look at it again. Wondered if anyone had any thoughts or recommendations. Happy to be back in the air! Appreciate the wealth of knowledge from this site.

-

G5 HSI and KFC150 Autopilot

CharlesHuddleston replied to Diesel 10's topic in Avionics/Panel Discussion

So I have been reading about the dual G5’s and the Aspen. Am I reading this correctly that a dual G5 install will NOT run a KFC-150 but that an Aspen will? If I am correct, then I will be going the Aspen route (with the adapter). -

OK, so I'm saddened to report that I grounded my plane last week. Landing in the rain, at night, I feel like i carried too much speed into the landing, and after touching down a little long, tried to brake to slow down. My assumption is that the left brake either caught or locked, but the right didn't brake well or at all, and I yawed off the runway and hit a taxiway sign. Got a couple small dents in the leading edge of the left wing, the biggest one right on the stall warning vane. FAA paperwork, insurance adjuster, etc has been a little bit of a headache, but doesn't hurt near as bad as not being able to fly. Mechanic has it in the shop now, and is giving it a very thorough eval. His first reply was that it might be cheaper/easier to simply replace the whole wing with a salvage wing rather than re-skinning. I get his point, but at the same time, I have long-range tanks, and electric speed brakes that would have to be transferred. As long as all the measurements are square (no wing warping, etc), can you not simply pull the dent out and replace the stall warning system? I have read through the Service Maintenance Manual and it describes the structure of the wing and all the components, but I could find any recommendations regarding repairs. Appreciate any thought or guidance.

-

Touch and Go in a fire breathing turbo... 252

CharlesHuddleston replied to gsxrpilot's topic in Videos

I thought it was cool to be able to look back and watch the shadow gear retract! Definitely checking out the tech... -

My mistake. Yes the floor indicator was DARK, as it was supposed to be. It turned GREEN when I cycled the gear down.

-

Yes, both annunciater light was off, and floor mounted indicator was green and lined up. And, this happened about 30-45 mins after take-off.

.thumb.jpg.f27f6acf472c65c841a515ea794d3009.jpg)