-

Posts

606 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by bob865

-

I'll chime in as a long time tier downer. -Covers- I use one. It's a Bruce's cover I bought from a fellow MooneySpacer. It is a long one that covers the main part of the cabin and the engine. I do recommend covering the whole cowl if you do. It eliminates the need for cowling covers and covers the avionics bays so no water can seep in. It also protects the interior and the glass from UV which is a big issue for tied down planes. -Tie Downs- The problem with cheap screw in tie downs is where they crimp the metal. This reduces the effective size of the metal rod to less than half in most cases, plus creates a stress point where it can fracture. I bought these for when I was going to fly to Oshkosh before weather kept me at home. They looked to be much better because they were welded instead of crimped. I do have to say I've never used them, so I can only describe why I chose them. (https://smile.amazon.com/Gray-Bunny-GB-6873A4-Trampoline-Powder-Coated/dp/B07H2QF7L2/ref=pd_ybh_a_2?_encoding=UTF8&psc=1&refRID=SFT8PGQ5NMWA6VG7QAXV) -Control Locks- I've never used them on my plane. I probably should, but with the pushrod controls and the PC system, they have always seemed to have enough resistance to wind. The only time I did anything different was when the hurricane was forecast to make it's way through upstate, SC. -Fuel system Protection- Keep your caps maintained. Enough said. Beyond that, learn to identify when the caps aren't installed correctly and don't let it happen. One more thing on fuel systems, unless you have bladders, keep your tanks full at all times. The fuel will prevent the sealant from drying out and cracking. My tanks started leaking because it sat around with half tanks. From then on, you could only fill it half full before it would leak. Also keep your gear donuts maintained. If they get hard, you're absorbing the shock load of that hard landing in all the structure of the fuel tank. It can cause seals to fail prematurely. Or at least it's a good story and reason to maintain something you should maintain anyway. -Paint Protection- Keep a good coat of wax on it. Let the wax become the sacrificial layer for when you wash/buff/polish so you aren't taking off too much paint. It will also help reduce how much the paint oxidizes leading to the need to wash/buff/polish.

-

413HM gets a much needed face lift

bob865 replied to bob865's topic in Vintage Mooneys (pre-J models)

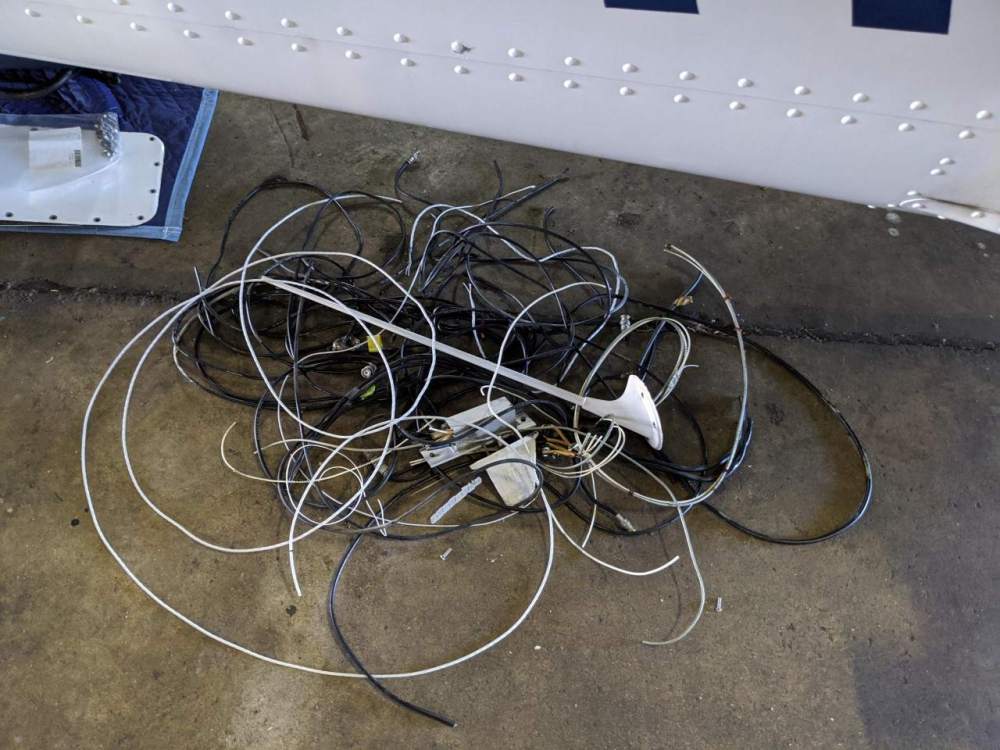

She's in work. Stopped by the airport yesterday and checked on the progress and to put the EDC that was back from Electronics International back into the plane. All new cables for the antennas were pulled, the new transponder antenna was installed, the old loran antenna was removed, and he was starting to pull the cables and jacks for the audio panel. Hopefully they'll finish up next week if the holiday doesn't cause too much of a delay. Electronics International didn't find anything wrong in the EDC. The RPM inputs checked fine on the bench. This means I have something wrong in the wiring. I'm guessing we are on the wrong terminals on the switch, but I can't really troubleshoot right now. I've asked the AVI shop to check it when they put her back together. This did get me to thinking about odd things I did see when we started the engine. We didn't do a full run up since we didn't have any RPM feedback, but did run it long enough to check for leaks etc. We ran the governor and saw that it would adjust the prop, and checked the mag hookups to make sure they would ground and shutdown the engine, i.e. no hot mags. There were a few odd things that I did notice during the short run that I haven't really looked into yet because I haven't really had time, but with her getting close to coming out of the shop I'm starting to contemplate. The first is the engine appears to run massively rich at idle. With the mix set to full rich the engine stutters and gasps. If I pull the mix back to about half way, it smooths out and runs like a champ. Unfortunately I can't answer if it runs smooth at higher RPMs at full rich or not right now. The second things that I noticed is the oil pressure is at the bottom of green arc at idle, but it increased with RPM. Again, I don't know what the RPM was, but as the RPM increased it drifted into the upper yellow arc. I brought it back down to idle before I went any higher. Do these sound like normal new engine startup issues? -

One thing I noticed that would likely help some with this specific screw. It looks in the picture like it was painted over. You should try cutting the paint around it before trying to easy out, slot, or anything else.

-

413HM gets a much needed face lift

bob865 replied to bob865's topic in Vintage Mooneys (pre-J models)

Thanks @Bartman. I don't know how I would have gotten through some of this without mooneyspace. It has saved us a huge amount of time at the least. I ended up having to pull the EDC for the engine monitor and send to EI for repair. Their support felt that the problem was in the inputs. So that's where she sits today. The AVI shop is supposedly going to pick her up today to start the GPS, G5, transponder, and audio panel install. Getting closer everyday. Now if Garmin would just certify the GFC500 for the E models -

We started with the 79k and after advice from support we switched to the 47k. Still no indication from either mag at 47k. It was never run without isolators. I was the guy with the key on the first start and watched the mechanic remove the 79k when asked to switch to 47k so I know it was never run without the isolators. I spoke with Surefly also and they suggested 8-18k for their mag. I spoke with EI support and they suggested trying 23k and said 8k-18k would probably work too with the surefly. They were at a loss why the slick wasn't working at 47k. They said their mag puts out a 60V pulse with a 10v offset, 2 pulses per revolution for four cylinder engines, in case that helps you guys in the future. Support did recommend we try the 23k with the slick also to try to get a response, but to not go any lower to prevent any damage. I am going to give the other resistors a try tomorrow morning. I was able to locate a spread of values in my old electronics stash, but I have a suspicion I'm going to be packing it up and sending it in this weekend.

-

413HM gets a much needed face lift

bob865 replied to bob865's topic in Vintage Mooneys (pre-J models)

She's alive! We fired her up for the first time today with huge success! However we have a few small issues we found too. I have to say, the Surefly ignition module made her start crazy easy! Hot? Cold? It didn't matter. Key in, engine fire. And no leaks on the first try. A big success. Even all the temp probes and pressures registered perfectly on the new EI CGR-30s the first try. The problem? No RPM! None at all. I spoke with EI a few times today trying to get it figured out. The kit came with two isolaters, which are just a 79k and a 47k resistor. We installed it with the 79k initially. After speaking with support, they suggested we try the 47k. Still no luck. We shot the wires back all the way to the mags and to the pins on the EDC to verify that there wasn't an issue in the harness and found none. After speaking with support again they suggested I send the config files for review for errors in the configuration. They did find one and said they would send an updated config to correct, but felt sure it wouldn't solve my problem and that we would need to continue to try smaller resistors. Has anyone else installed a CGR-30? Or other EI unit? Did you have any trouble with the RPM readout? What resistor did you end up using to get it to work? -

This thread may help.

-

I sure hope not. I didn't order one.

-

Yes, Remove the SOS - you won’t need it. Depends on which mag you are replacing. If it has an impulse coupler then use SIM4P Correct. You do not have an impulse coupling. You need the SIM4N. That's what I'm installing on mine anyway.

-

413HM gets a much needed face lift

bob865 replied to bob865's topic in Vintage Mooneys (pre-J models)

Hadn't thought about it. I'm going to ask my buddy what the size limits are on his engraver. If he can fit a hub cap, I might do just that. -

413HM gets a much needed face lift

bob865 replied to bob865's topic in Vintage Mooneys (pre-J models)

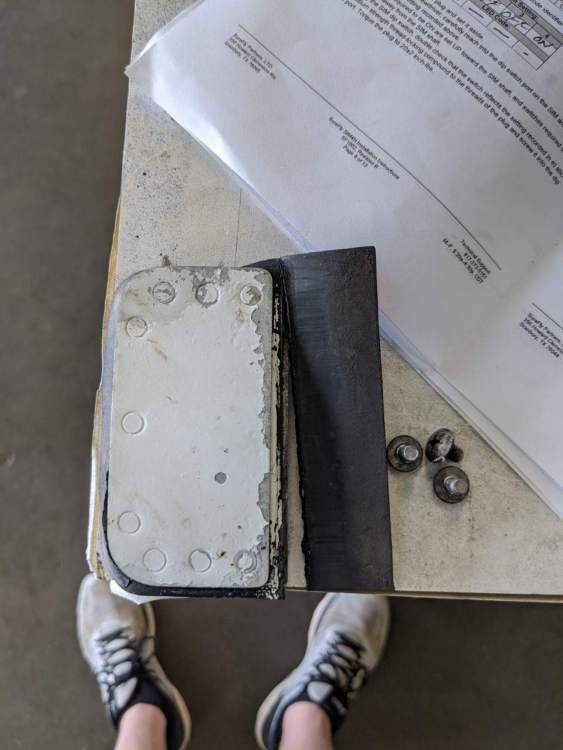

Time for an update. Finally making some good progress. Engine is almost ready for a test run and panels have been pulled for the annual. Spent some time with them today getting caught up on the progress. Several Shout outs to follow. MooneySpace has been a part of this upgrade whether you know it or not. We replaced the main shock discs last year when we resealed the tanks. We bought the discs but have been sitting on them because we didn't have the tool to do the nose wheel. While she was down we made sure to get it done. While they were working on the nose I saw the cowling and remembered the story of @chrixxer losing power and having an emergency and finding a piece of the ram air door seal had broken off. Guess what I found?? Yep. Mine was one operation or less from failing. Pulled it from the cowl and talked to my mechanic and he is going get get some new material cut and get the door repaired. Checked on a few other upgrades we did while it was down. @OSUAV8TER helped me out with a new belly strobe replacing the old one. And @khedrei helped me out a while back with a replacement LED tail light too when he removed it during his upgrade. The engine monitor if finally all in. We still need to mount the tray holding the data receiver box. Once we finish with the annual and do the shakedown flight on the engine, she'll go to the avionics shop for a new transponder, GPS, and second G5. The tow holes on the right that held the tach, manifold pressure, and fuel pressure are going to get plugged. I have a friend with a laser engraver and he made some plates for me. She's getting close. Not too much longer. She's been down since November. Will be glad to finally have her back. -

For me, it was not just a general upgrade for the sake of it. My plane didn't start well at all. Everything functioned properly, the necessary spark energy just wasn't there I assume due to worn or out of adjusted points. I needed to replace or rebuild the SOS box. A new one was ~$600. If I was going to replace it, I was going to replace it with a high power capacitive discharge slick start for the extra spark energy which jumps the cost to ~$1000. By the time I was at $1000, the extra ~$300 wasn't a big jump for the full electronic mag which doesn't have a 500 hr life, and has spark advance. Whether the spark advance is useful or not is yet to be seen; by me at least. So I agree with your statement, but when I'm putting the money in already, a few hundred extra dollars was an easy justification. Replacing just because, not so much.

-

Found it! Called Surefly and he offered 3 part numbers. He couldn't tell me which one was right, except that the longer part number is the dual keyway part. I did some googling and found webpage which explains what is going on. The webpage is talking specifically about the robinson helicopter, but the gears are the same. https://www.aircraftmagnetoservice.net/magneto-coupling For reference in case someone needs it in the future, the dual keyway part number is 68C19622

-

What is the part number you ended up with? I'm having the same issue right now. I have the mag I can't get to properly install and I'm struggling to find a part number.

-

I'm in the process of installing the Surefly right now. WE just overhauled the engine and installing it during the engine install to try to make it easier. But my mechanic spent hours yesterday trying to get it to install and couldn't get it. He mentioned what you guys said above that the slick gear only has the one keyway and doesn't let you turn it around. He had mentioned we may have to get a Bendix gear that has two keyways. Have you guys found a solution for this?

-

Digital Copies of Old Electrical Prints

bob865 replied to bob865's topic in Vintage Mooneys (pre-J models)

Somehow the prints for my 75 E have gone missing. I have the J model prints and I have the 74 and earlier prints, but the 75 E/F prints are gone. On a side note, I think I have a line on a good digital copy. A 50+MB scan of original prints. I'll probably still create a visio copy so I can edit them instead of making a literal redline. I like the idea of a clean set of prints. -

I'm in the middle of a big upgrade on my plane. This means cutting a lot of wires and I hate to do it without being able to redline prints and know what I did for posterity and future troubleshooting. I've started drawing the prints for my plane in Visio. Before I keep going, I thought I would check and see if anyone has done this already. I'm betting no one has. I'm working on drawing up the 1975 E model prints for my plane using the pictures @Guitarmaster shared of his prints. It's a challenge tracing wires across multiple pictures so it's really slow work. It's not perfect. I'm not a CAD guy by any definition of the word. Just a plane owner that wants to do it right and be able to keep track of changes. In the meantime, I'd like to ask those of you who do have good prints to check my work. If you can redline my work, I'll make the corrections and them share them with the community. I'd like to get them right and then I'm happy to share for everyone to use. Attached is what I have drawn so far. Mooney Electrical Prints.pdf

-

Wanted: 62C Manifold Pressure / Fuel Pressure Gauge Combo

bob865 replied to FlyRye's topic in Vintage Mooneys (pre-J models)

I have one I just took out of my '75 E model. What is the pressure range you need for the fuel pressure? I think the fuel injected and carbureted ranges are different. -

413HM gets a much needed face lift

bob865 replied to bob865's topic in Vintage Mooneys (pre-J models)

Is that a standard Lycoming part? I'm guessing not since you said Tanis. Or is that something that would have been added by another owner and returned because I did an overhaul and it was there when it was sent off? -

413HM gets a much needed face lift

bob865 replied to bob865's topic in Vintage Mooneys (pre-J models)

Starting to make some progress. Engine is hung and the mechanic is starting to do all the accessory installation and control hookups. I was there getting ready to install the new CiES senders and they are weird! So the bolt pattern means that the senders would be mounted upside down, or at least the stickers on the senders will be upside down. Who else has done the CiES installation? Are yours installed upside down? -

I have a 75 E model that I'm replacing with CiES senders this next week. Can't speak to how well they work. Replacing them because the gauges didn't work right and I'm putting in an engine monitor. Not sure if it was wiring, senders, or gauges.

-

Yep. I had the identifier wrong. That's the one. That's the short field landing practice destination airport for this area. I've seen a pilatus go in and out of there!

-

Is that 26A along I-26? My instructor took me up there during my private training to get some "experience" on short fields.