wpbarnar

Verified Member-

Posts

127 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by wpbarnar

-

That power supply is for the two wing tip strobes only. The tail is powered by another power supply mounted in the tail. It is mounted on an inspection cover on the left side. If I read correctly, you have already, determined the bulb is OK. You can swap the left wing, right wing outputs from the power supply and determine if it is internal to the power spply or in the wiring. You can also move the inop left side over to the unused output. I have attached Whelen's install manual. The Mooney service manual also contain some information on testing the power supply output with a volt meter. If memory serves correctly, a good power supply output is 400-600 VDC Use caution when handling the output wiring when the power supply is powered up. There is enough energy there to give you more than a mild tingle. Bill HDACF install.pdf

-

Looking to Buy an Eagle or Early Ovation?

wpbarnar replied to Mike@Loves's topic in General Mooney Talk

I am biased, but think a 252 or Encore with Monroy tanks would suit you well. My Encore ( 105 gallons total useable ) flying between 15 & 20 K feet should be able to make that 1000 mile hop on 75 to 80 gallons in no wind. There are several very knowledgeable K model owners on this forum. @kortopates @gsxrpilot @Parker_Woodruff @jlunseth and others. They should have some real world examples. Bill -

The Aspen has a VSI tape that pops up in the HSI window when you are in a decent. 200k TAS is plausible in a 252 @ 25k ft. I think he is level flight. @gsxrpilot, Have you ever looked into why the JPI and Aspen OAT indications don't correlate closer. If the Aspen is reading low you are going a knot faster. Bill

-

Anyone with tail dragger experience- need opinions

wpbarnar replied to helitim's topic in Miscellaneous Aviation Talk

I like the Bogi-bar from Bogert Aviation. It locks solidly onto the axle of the tail wheel. I have used and owned others, but believe the Bogi-bar clamps on the best if properly sized for your particular tail wheel. Generally I only pull with a tow bar and push with my hands. I typically push most tail wheels at the attachment point on the rudder for the flying wires. Place the base of your thumbs on the attachment point and you can push without pushing on the wires or fabric surfaces. Bill -

Don't need to jack it up. Pull the airplane forward, lay out garbage bags behind the wheels and push it back on to the bags. Then pull them up. This is from experience as I used to reside in a crappy row of T hangars that were susceptible to minor flooding. Bill

-

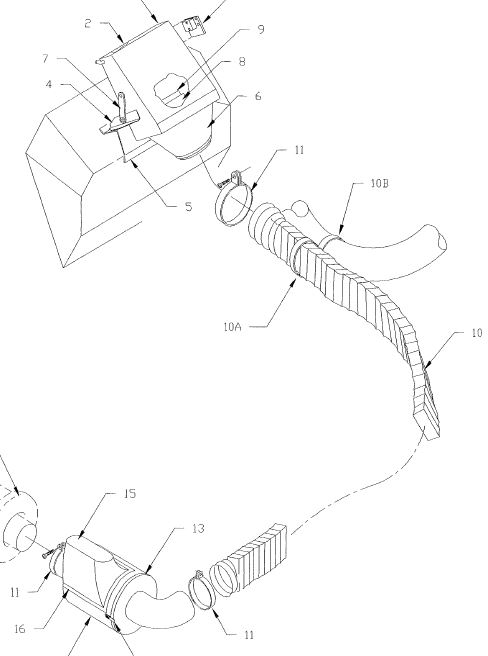

If I did it again, 3 to 4 hrs. Doing it for the first time 4+ hrs. Probably the most difficult part was removing the old hose from the manifold under the glare shield. It is difficult to reach and see. Practice on the spring clamp with your tool of choice on the standby vacuum pump end before tackling the hard to get to one. Remove the left rear seat back and screws holding the side panel so it can pulled away at its top and back edge. Remove the carpeted side panel in the baggage compartment. It comes out easy with the side panel loose. From that point I could kneel in the baggage area and reach and see the two difficult spots when pulling the new hose in place. There is a vertical piece of the fuselage tube frame located at the end of the passenger compartment and beginning of the baggage area. The hose is routed between that piece of tubing and fuselage skin which is a tight fit. The other tricky spot is just forward of that area. The hose transitions down and forward through a hole in a flange of the fuselage. As I feed the new hose through that hole, my helper pulled on the old hose over the top of the panel. That is a long pull, but we did not encounter any resistance from that point forward. Bill

-

After determining the degrading Tygon tubing in my standby vacuum system was the problem, I replaced it with Aeroquip 306 (MIL-H-5593) due to concerns of damaging another vacuum pump. Now I am really glad that I did. The old tubing showed evidence of its oil or plasticiser attacking other plastic pieces that it was in contact with. Surely the long term effects of being in contact with wiring insulation would not be healthy. See the attached photo with the imprint of a tyrap on the Tygon hose. I have learned a lot since my first post. IMHO, Tygon tubing in this service should be inspected on a regular basis and replaced at the first sign of degradation. The replacement wasn't as difficult as I originally thought. I removed the pilot's seat , glare shield, baggage compartment side panel, and all the lower side panels. I joined the hoses together with a short piece of 1/2" wood dowel and a couple of screws. Pulled the old hose from the front and feed the new hose in from the rear. Snaking the new hose in place was the easiest part of the job. I spent more time removing and installing panels. If I had to do it again, the pilot's seat and lower side panels would stay in place. The two tricky spots for snaking the hose in place can be accessed from the baggage area. Bill

-

Have you removed the glare shield on top of your panel? Access to where it connected to the manifold was from the top on my K model. It is behind the attitude indicator on the fire wall. I was tempted to remove the AI for better visibility but managed without doing so. Bill

-

Lycoming factory lead times for overhaul?

wpbarnar replied to FloridaMan's topic in General Mooney Talk

I purchased a factory reman from Lycoming in Nov '14. The actual delivery time was 11 weeks vs the 6 weeks quoted. Based on the date on the test run sheet, the engine was assembled in 4 weeks. Apparently it took another 6 weeks for them to paint and prepare it for shipping. Bill -

What position are you flaps in? The flap toggle switch in your photo looks like it is in the take off position. Bill

-

Mark89114 Based on the N# your O is a 2000 model. Is the tubing to the vacuum pump similar in appearance? Bill

-

Could that be a slurry like mixture of graphite from the vanes and the oil? The clear oil I saw was just prior to the pump inlet. Internally in the pump it was dark and dirty. I also had some of that paste like material in the ports. Your hose is identical in appearance. I wonder if they are that same color when new? Bill

-

I believe the source of the oil is the hose itself. The hose from the manifold under the glare shield to the standby vacuum pump is made of some type of vinyl. I think it is slowly breaking down due to its age. Over time, a small quantity of oil accumulates in the hose and migrates toward the standby pump. Key findings that lead to my belief: The vinyl hose feels oily or greasy to the touch. The oil in the pump suction was clear, not engine oil. I have thoroughly inspected all the other vacuum system components. The only place I found evidence of oil contamination was in the vinyl hose and S/B vacuum pump. There is no plausible method for oil to enter system. Both "Mooney time" and "Greg_D" experienced a similar problem. All three aircraft are roughly the same age. The problem occurs about +20 years in service. Either it is the vinyl material used in that era or the vinyl hose starts breaking down after a period of time. If it can be done as a minor modification, I plan on installing a CV1J4 filter which is identical to the filter that protects the primary vacuum pump. This is only a stop gap measure until there is a suitable time to replace the hose. Bill

-

Greg_D What year model is your aircraft and approximately when did you have your problem? Bill

-

'97 Encore with electric standby vacuum pump located in the avionics bay. The standby pump recently failed during preflight run up checks. Disassembled the pump and found oil in the pump which had caused stuck vanes in the rotor. The inside of the pump was oil wet. Where did the oil come from? The primary engine driven is a dry vacuum pump. Apparently there is enough oil in the line from the manifold where the two pumps connect to the standby pump to cause problems. Any ideas on the source of the oil? I typically only operate the standby pump during preflight run up checks only. How could engine oil get past the primary pump, not foul it and contaminate the standby vacuum system? Bill

-

Inspect the ball and seat of the oil pressure regulator. A very small piece of trash between the ball and seat can cause a large drop in oil pressure. If no trash is found rotate the ball 180 degrees as it will wear slightly where it contacts the seat. Bill

-

M20K 252 with "black" instrument panel?

wpbarnar replied to MRussell's topic in Modern Mooney Discussion

Paul- Mystery solved! After looking closer at the split alternator switch, it is labeled "left and right" not "1 & 2". I knew which switch physically controlled which alternator but never had looked at the split switch label closely until yesterday. I was positive the switch on the left contolled the belt driven driven generator, just did not realize or remember it said "left" not "1". Also I do not have the dual load meter. According to the service manual that stopped with S/N 25-1224. Maybe that is when they changed nomenclature. They did not update the POH with the change to left and right nomenclature. Mine has the exact verbiage you quoted in your earlier post. Thanks for prompting me to go look at my airplane with a more critical eye. Bill -

M20K 252 with "black" instrument panel?

wpbarnar replied to MRussell's topic in Modern Mooney Discussion

My Encore has two alternators but the arrangement is reversed. #1 is belt driven and #2 is the engine driven one. Odd that the arrangement is reversed on basically the same airplane. Bill -

Since the airplane is new to you, when was the fuel injection system last adjusted? TCM has a specific procedure for this (SB97-3) and it should be noted in the log book. Your stated stated full rich fuel burn (13-14 gph) seems low so I suspect your full power fuel flow is low too. Making sure your fuel injection is set up properly is good starting point on a TSIO 360 before attempting to trouble shoot other issues. Bill

-

Not in a Mooney, I play in another airplane. What is your definition of a Falling Leaf? In the aerobatic community, a Falling Leaf is performed by stalling and intentionally inducing rotation with rudder. As rotation develops in one direction it is stopped and started in the opposite direction with opposite rudder. This is repeated to over and over. Basically an oscillating spin with rotation limited to 1/8- 1/4 turns. Depending on the aircraft a fair amount of roll is induced every time the rotation is stopped and direction changed. Bill

-

Contact a MSC. I obtained a duplicate Medeco key through Don Maxwell. Mooney is the registered owner of the key according to Medeco and will only release keys to them. I spent a lot of time talking to locksmiths and eventually Medeco before contacting D Max. I had a key from them in a few days. A lot of locksmiths are capable of cutting the key, the problem is obtaining the blank from Medeco. Bill

-

On the back wall of the luggage compartment, just below the hat rack. Bill

-

turbo broken after 200 hours Mooney 231Turbo Problem

wpbarnar replied to Taborsky's topic in General Mooney Talk

I recently experienced a turbo failure when the gasket between the bearing section and turbine housing disintegrated or broke down. This made the connection between the bearing section and exhaust or turbine housing not rigid. The compressor and bearing section would move relative to the exhaust section resulting in turbine blade rub. The failure was gradual. Thought I had a sticking waste gate. Pulled the cowling off to investigate and found I could wiggle the compressor section and the exhaust section would not move. 650 hrs since new but 19 calendar years old. Mine required the rule of 700s to repair. Bill -

I have a TSIO 360 SB. The scat tubing for the alternate air is an unique piece. It is rectangular in shape for most of its length. My assumption is that it was made specifically to provide clearance. If yours has normal round scat tubing, I don't think you can not make it chafe against the cowling. I will take some photos the next time the cowling is off. Bill

-

SMART CHARGER ALWAYS PLUGGED IN THE HANGAR?

wpbarnar replied to N400YS's topic in General Mooney Talk

I think the vast majority of battery charger fires are related to Li-ion or Ni-MH batteries found in our portable devices not lead acid type batteries in our aircraft. However at a minimum I would only use a charger that was UL approved or used UL specifications for it's materials. I could not tell if the charger you referenced is UL approved or not. I have a friend that lost a airplane due to a hangar fire. The origin was traced back to the wooden workbench on which his cordless drill battery charger sat. His misfortune prompted me to relocate the battery chargers for my portable radios and drill to a safer area and not leave them plugged in continuously. Bill