-

Posts

6,339 -

Joined

-

Last visited

-

Days Won

33

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Ragsf15e

-

EarthX Batteries STC Approval for 150+ 12V Aircraft

Ragsf15e replied to EarthX Inc's topic in Miscellaneous Aviation Talk

Hopefully ours will be less than that one since it’s for Turbine/turboprops and actually has more amps than our current model. Even at $3000, it’s like $2k more than our current battery and ~20lb improved UL. Won’t find that in avionics or a new prop. -

EarthX Batteries STC Approval for 150+ 12V Aircraft

Ragsf15e replied to EarthX Inc's topic in Miscellaneous Aviation Talk

And, i just looked, my rga-24 battery weighs in at 29.9 lbs and costs $962! The Earthx experimental 24v is 9lbs. I wonder what the certified one will cost? -

Ill be interested in what you get. I suspect there’s some measuring issues depending on exactly what probe you have. The probe is immediately after the cooler. My oil rarely goes above 140. I know that’s not good, right? Cirrus had this problem on turbocharged models as well and “fixed” it by using a slightly longer probe to measure further into the oil stream where it’s bypassing the cooler. I’ve become comfortable seeing 135-140 and it sure seems warmer when I open the cap after flight. Oil analysis has been fine too.

-

I flew Strike Eagles with 2 x 25,000lb thrust PW-220 engines and I swear the F-35s are noticeably louder.

-

EarthX Batteries STC Approval for 150+ 12V Aircraft

Ragsf15e replied to EarthX Inc's topic in Miscellaneous Aviation Talk

This is actually a lot more lbs/$$ UL increase than putting on an MT prop or doing an avionics upgrade. -

EarthX Batteries STC Approval for 150+ 12V Aircraft

Ragsf15e replied to EarthX Inc's topic in Miscellaneous Aviation Talk

In my F that I used ifr with one alternator and one battery, probably I’m with you. With a dual battery and/or dual alternator setup (or maybe even both) maybe it’s a different story. I can also see the vfr only argument. My current airplane with two alternators and pretty new avionics draws about 6 amps/24 volts (~12amps with pitot heat and landing/taxi leds on). I’m thinking this battery provides a pretty good backup. If I was looking to add UL, I’d consider it. In fact, I have two growing 10 year olds, so maybe I should! -

Airport choices in Seattle area Redux

Ragsf15e replied to dkkim73's topic in Miscellaneous Aviation Talk

Honestly, it’s a nothing-burger. Choose whatever cruise altitude you like over the cascades (maybe 14000’ or higher?) and expect them to have you cross Skyko at 10,000. I would just file GEG, Skyko, Skyko1, so you don’t have to start the arrival earlier. Right about Skyko you will be handed to Approach, so get atis as you cross the mtns. Sometimes you have to make the turn at skyko to stay on the arrival, sometimes they give you vectors before. They actually get you low pretty quickly to get out of the jet traffic, so I’ve never been slam dunked. Speed, just fly casual and let them tell you if they need something, they are use to pistons going into bfi. -

I had same experience with the trim torque tube. Got grooved where it passes through a bulkhead. Had to get a new one through Mooney. Wasn’t cheap, took a couple months. I would find a way to protect it. Some of the pass through holes have sacrificial “plastic” blocks for it to rub on.

-

Airport choices in Seattle area Redux

Ragsf15e replied to dkkim73's topic in Miscellaneous Aviation Talk

They will want you filing to Skyko on the Skyko arrival if possible. It’s right next to the Glasr. I usually file from Spokane direct to Skyko and that works well. If you go in IFR it’s real easy. Vectors from just past Skyko. If the weather is nice, right next to the space needle. Yep, they tore down the old fbo that was there and operated out of a large mobile home “complex” for a while and now have a real nice (and huge) fbo/hangar facility. Same general manager throughout and a lot of the same line/csr folks. The parking area is just south of their facility, ground knows it as the Southeast tie downs. They are tight, so be careful but I usually just pull right up there to avoid the fbo needing to tow the airplane. -

Airport choices in Seattle area Redux

Ragsf15e replied to dkkim73's topic in Miscellaneous Aviation Talk

Good to know it’s fixed now. It was probably 3 years ago when I saw that. Ive been flying to bfi for work ~8 years now, so sometimes it blends together. -

Airport choices in Seattle area Redux

Ragsf15e replied to dkkim73's topic in Miscellaneous Aviation Talk

If you ignore the line of derelict motorhomes parked along the road, security is great! There’s a person gate there with a porta potty inside the airport fence. I was jogging up that way a while back while sitting at bfi and saw people from the motorhomes punching in the code and using the restroom. Not sure if that’s any better… -

Airport choices in Seattle area Redux

Ragsf15e replied to dkkim73's topic in Miscellaneous Aviation Talk

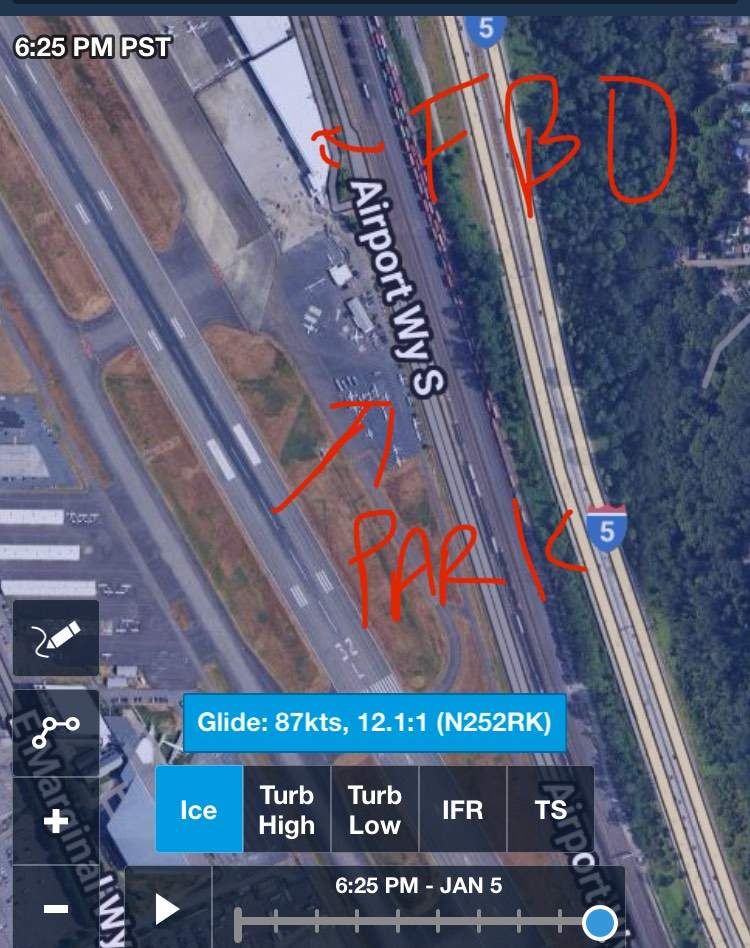

Here’s where I tiedown, South end, east side, usually against the airport fence or across from that, facing the airport fence. Ask skyservice fbo for pricing… -

Airport choices in Seattle area Redux

Ragsf15e replied to dkkim73's topic in Miscellaneous Aviation Talk

Davenport is actually a good idea for a stop! Good gas prices too (at least better than Felts). I travel to Seattle for work a lot and would not use ksea. I personally use KBFI because the services are good and I know exactly where to tiedown. But I would call and talk real nicely to the ladies at the front desk of Sky Service fbo. Tell them you’re just a little mooney and you would like to use their south tiedown for a couple nights. They seem to change prices abruptly, but 10-15$ a night has been my recent experience. With that you get excellent service At the biggest, newest fbo. I can send a picture of where to tiedown so you pull right in there and they never tow your plane. They will bring your rental car over and gas it there too. Kpae is good and Ive been there but I wasn’t completely happy with the tiedown plan as it was near where big jets were taxiing in and they wanted to tow the plane around as required. Pt townsend is great but no rental car is a problem. If you want to go over that way, pt angeles is a bit bigger and the fbo can get you (sometimes $$) rentals. I would 100% go into bfi ifr even on a nice day. It’s busy and complicated airspace. Arlington is also good and you can tiedown by the excellent restaurant, but I have been unsuccessful getting a rental car there on the weekends. I also have been to ktiw and had great service if you need to be south. Friday Harbor is also really cool, you can just walk into town from the parking. After all my flying around Seattle, I go back to kbfi, skyservice south when I go there. -

Fuel tank leak with odd stain

Ragsf15e replied to Officer25's topic in Vintage Mooneys (pre-J models)

It’s just gravity and surface tension as mentioned. I have a similar one at a different drain hole. I was able to use a patch to fix it, then 100ll on a rag to clean your mess. As it sits, it drips down and then spreads out leaving the circle until you fly, then it blows back. -

Ive been contemplating doing this as well. Lots of threads on this, here’s one…

-

Fuel tank leak with odd stain

Ragsf15e replied to Officer25's topic in Vintage Mooneys (pre-J models)

Open the one next to it, don’t open the X one. You should be able to see the leak, however, that’s not going to help much. It needs fixed from inside the tank. You need a patch at a minimum. Where are you based?? -

Need advice for fuel control in climbing to higher altitudes

Ragsf15e replied to Jer's topic in Modern Mooney Discussion

Yeah, the sweet spot for ktas is lower. If you’re up at 15k+, you might be more efficient, but likely not faster. ~140kias is 175ktas up there, so I think he was saying he’s getting 145ktas… -

Need advice for fuel control in climbing to higher altitudes

Ragsf15e replied to Jer's topic in Modern Mooney Discussion

Nope, it had flexible baffles, the cowl design isn’t quite as good as the J though, so I believe you when you say you can keep them half open, but if your engine is warm in the climb and they’re half open, id definitely open more. Obviously airspeed, oat and mixture will play a part too. (And baffle quality). -

Need advice for fuel control in climbing to higher altitudes

Ragsf15e replied to Jer's topic in Modern Mooney Discussion

I had an F until recently, maybe the cooling is a lot better on the J, but my F needed the cowl flaps open during climb. Once in cruise closed was good. Leaning to SL target egt should be fine in climb, and Id say if it’s hot and the cowl flaps aren’t all the way open, then open them, that’s what they’re for? -

Need advice for fuel control in climbing to higher altitudes

Ragsf15e replied to Jer's topic in Modern Mooney Discussion

Weren’t you just talking about flying at -30c though? That makes a big difference. Generally these things need cowl flaps open in climb. -

Need advice for fuel control in climbing to higher altitudes

Ragsf15e replied to Jer's topic in Modern Mooney Discussion

In climb, your cowl flaps should be full open. Especially if your engine is getting warm. That’s what they’re for. -

That is a gutsy route in the winter! Beautiful, but gutsy. You don’t want to land out somewhere just north of the border, very pretty, very desolate, very cold!

-

Fair enough. That’s a good technique a lot of places back east. Once you cross the Mississippi (or thereabouts), you’ll likely see less ifr weather, less good ifr routing (because they have to keep you high above the mountains or well away, and better results from flight following. The atc is a little more relaxed out this way too, so ff isn’t really ever a problem and you can generally get a popup ifr if you need it (California might be different).

-

They said the 252 to Encore doesn’t need them. They did a few airplanes that way when they didn’t have access to the brakes/gear doors and signed them off as “Single puck conversion”. They said “Mooney approved it”. However that feels a bit shady considering there’s no documentation…

-

Depending on time of year, it should be totally vfr. If it’s not, 90% of the time you don’t want to be imc in whatever is there anyway. Flight following should be fine. If you don’t like a route change or shortcut when you’re ifr, feel free to tell them youd prefer your original route and they will normally comply. watch out for los alamos r area nw of santa fe.