All Activity

- Past hour

-

CO2 detectors the "Good The Bad and The Ugly

Paul Thomas replied to Jpravi8tor's topic in Vintage Mooneys (pre-J models)

What do you seal that with? -

Which is downright confusing to normal people and makes little sense. And will lead to issues with people flying aircraft they are not authorized to fly. Pilot A has a Sport Pilot certificate, so he can fly that M20J, but NOT that Model XYZ Light Sport airplane.

-

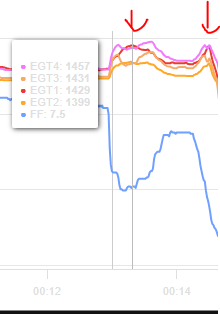

MAP would still be less than ambient pressure at sea level, no? Granted not by much, but 4" of pressure difference is enough perhaps for what he is seeing. No? This is curious: FF decreases while EGTs rise twice when I presume power was reduced. Classic induction leak? Also the small rises and drops in EGT could be going so lean that it's over the top and to the lean of peak side.

-

Lasar Aviation Mooney Assurance Program - Really?

Pinecone replied to PeteMc's topic in General Mooney Talk

As I understand it, they are buying all of Mooney. They need to keep the Mooney name and location to keep the legal ability to make the parts under the existing approvals. -

Bendix never made a dual mag with a lower lag angle for the impulse coupling, so if you set the timing to 20, it will fire 5 deg late during start.

-

You might check the Surefly timing. Sureflys are timed to 0 TDC on the engine and the advance is set with dip switches. There have been instances of mechanics timing them to 20. You might also try setting the Surefly to fixed timing as a test.

-

Lasar Aviation Mooney Assurance Program - Really?

Paul Thomas replied to PeteMc's topic in General Mooney Talk

Own all of Mooney or part of Mooney? It's hard to understand how the membership program will work. It seems if you're AOG, you could just pay the membership to jump ahead of the line of the non-members and cancel. You may as well call it a rush fee. -

OK, well the Surefly installation muddies the water a bit.

-

When you check the baffle seals, make sure that after flight they are curved inward. If not installed correctly, they can look fine when the cowling is installed but then blow back from air pressure causing a leak. Afterwards, they can appear to seal the cowling when the engine isn’t running. Another trick to check for air leaks is to put the airplane in a dark hangar and insert a light through the oil filler door and peer through the inlets by the spinner. A significant induction leak should cause a rough idle. For comparison, my IO-360-A3B6 in a 1994 J generally runs about 360 deg F CHT or less with cowl flaps open during a sea level climb at 105 KIAS with full rich mixture and about 18 gph fuel flow. It will get hotter on a warm day at lower IAS but never over 400. In cruise I usually see about 340 with the mixture leaned peak or LOP and the cowl flaps closed. If your left cowl flap is flat rather than curved like the right one, you might try rigging it to be open about half an inch when the cowl flaps are closed.

-

At closed throttle, high vacuum scenarios, yes. In climb at wide open throttle, an intake leak isn’t going to have much of an effect on mixture unless the leak is huge.

-

Whoops…misfire on my part. My apologies! I know that you’ve received a lot of Lycoming specific information from the factory over the years. I have never timed a dual mag. Do you have any insights as to why the optional 20° timing is prohibited with D suffix engines? Having flow behind my engine when times at both 20 and 25°, I prefer 25°.

-

Thanks so far, I will double check the rear baffling seal. The magneto is times to 20 degrees, though I also have a SureFly ignition on the left side that is set to the variable timing option. This is the flight in which I had some engine roughness and CHT #3 tended to have a mind of its own, pulled the cylinder after this flight: https://apps.savvyaviation.com/flights/shared/flight/9962458/5b23d3f3-71e9-4feb-ac34-01b25341f1dd This is a break-in flight where CHT 3 rapidly reaches 440: https://apps.savvyaviation.com/flights/shared/flight/10132193/0238ab27-4e50-41be-a418-cc720035a6eb I have not run a test profile yet, as I'm not able to climb about 1000' without the CHT continuing to rise. -Jared

-

OP said he has a A3B6.

-

mpilot changed their profile photo

- Today

-

An induction leak would present itself as overly lean condition. I just had all my induction gaskets and hoses replaced on a 18 year old engine and they were all brittle and destroyed. There was evidence of AVGAS on the induction pipes (with a turbo the leak happens both ways at different phases of flight). With your NA engine it would happen only to the lean direction, so you wouldn't see any traces of AVGAS.

-

Lasar Aviation Mooney Assurance Program - Really?

Brandt replied to PeteMc's topic in General Mooney Talk

Your point? -

Engine Overheating Help (High CHTs)

mike_elliott replied to Jarerh's topic in Modern Mooney Discussion

Check rear baffle seal about half way across the engine. They have a tendency to droop there and let air escape vs being forced down thru the cylinder cooling fins Look at the baffle seal for evidence of contact with the cowl and maybe use a light at night to check for fenstration -

I seriously doubt that this is a timing issue. I run maximum advance in my engine for the TCDS and it runs much cooler than yours. I would start by thoroughly inspecting all baffle material. Do not neglect to check the internal baffle seals in between the cylinders. With a relatively new installation, there can be multiple factors that are causing problems. Indeed, you could have a baffle seal issue and also if you flow issue. I’m of the opinion that 17.5 GPH is not adequate full rich fuel flow for an IO360 departing a sea level airport. Your fuel servo may need to be serviced.

-

Has the TCDS been changed? The copy thatI have does not authorize 20° timing. In fact, it specifically excludes setting an A3B6D to 20°.

-

Can you share a flight from your Savvy uploads so we can see the whole data set? Also, did you fly this?: https://www.savvyaviation.com/flight-test-profiles/

-

Assuming all baffling is good here are a couple of suggestions Remove and clean each injector. Do the baby food jar to confirm equal fuel flow, with the injector inserted installed. Check ignition timing. 25deg BTDC is allowed on my A3B6D but it runs hotter than 20deg.

-

Where is the timing set? It should be 20 deg BTDC for an -A3B6.

-

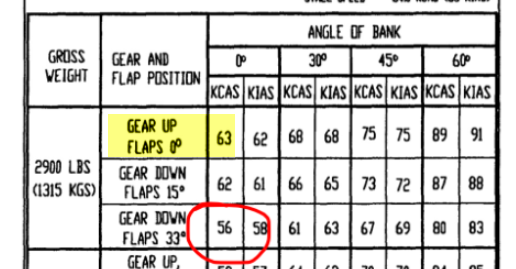

If you are asking whether you can fly it only exercising sport privileges, no. The relevant number is 63, not 56. Vs1, not Vs0.

-

One of the things I've seen confusion about is the difference between an LSA (an aircraft certification) and what those exercising sport pilot privileges (a pilot certification) are allowed to fly. One of the things MOSAIC did was to decouple them. The best illustration of this is that you will not find a reference to "light sport aircraft" anywhere in amended Part 61. They've been removed. The best practical illustration is, as you point out, a light sport aircraft can have a Vs0 of 61. IOW, there will be LSAs that sport pilots are not authorized to fly. Remember these ancient private pilot knowledge test questions? With respect to the certification of airmen, which are categories of aircraft? vs With respect to the certification of aircraft, which is a category of aircraft? That's what we are dealing with.

-

No. A plane can only be certified as Light Sport in new Type Certification. Existing planes cannot be recertified.

-

Hey everyone, Looking for some help troubleshooting overheating issues on my 1984 M20J IO-360-A3B6. I’ve owned the airplane for about 60 hours now. No major problems for the first 50 hours other than slightly higher CHTs, topping out at around 400 in climb and typically cruising with cowl flaps in trail and the hottest cylinders (#1 or #3) running around 380°F. However, over the last 10 hours, both the #1 and especially the #3 cylinders have been running significantly hotter. By about 1,000 ft AGL, both are over 400°F, and even climbing out at 120 KIAS, #3 stabilizes around 420°F before slowly dropping. A few weeks ago, I had an engine stumble on initial climb and #3’s CHT spiked rapidly to 435°F. After I landed we did a compression check and found Low compression on #3 (50psi). After pulling the cylinder, we discovered a broken piston ring and a bent exhaust pushrod. We don’t know the exact order of events, but they were likely related. The cylinder, rings, and pushrod were replaced, and I’m now in the break-in phase of the new cylinder. The problem is, I’m having a really hard time keeping temps under control. I know new cylinders tend to run hotter during break-in, but even climbing at 120–130 KIAS, #3 is hitting 440°F (the Lycoming-recommended max for break-in) by 800 ft at 120-130kts, and it keeps climbing if I don’t level off and reduce power significantly. #1 is also very hot, around 425–430°F by 800 ft. What we’ve checked so far: Baffling is in good condition with solid contact between gasket material and cowling. Inter-cylinder baffles are properly installed. During the cylinder replacement we noticed that all lower baffle springs had been removed at some point before me owning the plane; they’ve since been reinstalled (before the most recent flight with the highest of CHTs). Takeoff fuel flow is 17.5 GPH. At this point, I’m looking for ideas on what else to check to get these CHTs under control. I got a Savvy analysis trend report that puts my plane in the 94th percentile for climb and cruise CHTs, so I know I have a cooling issue. Any insight or experience with similar issues would be hugely appreciated. Thanks, Jared