Search the Community

Showing results for 'Vernatherm'.

-

I’m interested in purchasing or borrowing a used assembly of oil filter adapter with Vernatherm properly seated. The adapter should be known to work and maintain oil temperature within the range of 180-190 degrees. Please let me know if you have one available! 66E IO-360-A1A. And I know, ebay… but hopefully someone here can help me Thank you and happy New Year

-

Please DM if you want to get rid of one, I pay shipping. Trying to make a seat cutting tool out of the old vernatherm

-

I have an IO-360-A3B6D that incurred a massive crankcase crack. It was disassembled and re assembled in a yellow tagged overhauled case and reinstalled into the airplane. Ever since, the oil temperature gauge “pegs” out on every flight. It starts and runs fine. The cylinders were sent off and “nuChromed” and have excellent compressions. I removed the Rochester temperature sensor and put it in hot oil with a thermometer. I have OEM analog gauges, but they appear to be reasonably accurate. I removed the vernatherm and placed it in hot water. It expanded accordingly and appears fine. I endoscoped the vernatherm housing and the seat looks good, no noticeable nicks or anomalies.I removed the oil cooler and sent it off and had it overhauled, and checked the oil lines for any obstructions or kinks. I have also reversed the oil lines to see if that made a difference. So far, nothing I have done has remedied the hot oil temperature. I am open to suggestions. Also, I know the vernatherm expands when hot, but how does that open the oil cooler lines? Does the seat move, and if so, could something be preventing it from opening up? All help appreciated!

-

How long from start up to take off? (Normally aspirated)

Pinecone replied to NotarPilot's topic in General Mooney Talk

My M20K POH says 100 min oil temp for take off. I normally wait for 100 before run up. But my engine warms pretty quickly. If yours is taking a while, you might want to check the operation of your Vernatherm. My CAP-10 (AEIO-360) says off the peg before run up. -

Mooney M20E 1975 CHT high but oil temp low

47U replied to ighazali's topic in Engine Monitor Discussion

Welcome… pretty E model you’ve got there. I’m a C owner, O-360, but my CHT doesn’t act that differently than yours. Of course, I have a doghouse, which presumably your ‘75 E doesn’t have. And you have an ARI or SWTA cowling mod? I’m not sure what affect that has on CHTs. At only 50 hrs SMOH you could still be breaking in the cylinders, especially if the overhaul shop didn’t run it on the test cell. Was the overall done with chrome cylinders? They might have a reputation for running hotter CHTs. So, start with standard troubleshooting the baffling. Good sealing against the cowling, the flexible pieces are bent the correct direction, gaps around the starter and alternator, inter-cylinder baffles on bottom of the cylinders are installed correctly. There’s many threads on lowering CHTs. As far as low oil temperature, I’d start with verifying the gauge is accurate. The sender can be put in boiling water to verify. It that’s good, then looking at the vernatherm to make sure it’s opening and closing properly. There’s threads on that, too. An engine monitor is a good thing… my factory CHT runs hotter on the scale than what is indicated on my UBG-16. Top picture is from the sales ad showing the gauge scales more clearly… -

I have a question regarding my oil temperature. Since my oil temp had been running high (around 200-205°F), I recently replaced my Vernatherm a few days ago. However, during my first flight after the replacement, the oil temperature climbed to 225°F and was still rising, so I immediately returned to the airport. I wanted to ask what could cause a new Vernatherm to result in even higher oil temperatures. I also compared the new and old Vernatherm valves at the same temperature, and I noticed that the new one expands significantly more than the old one. I would appreciate your insights. Thanks! 1968 Mooney m20f, 201 cowl, overhauled oil cooler

-

Ok, this might be a little long, but it is kicking my backside. Last Oct, my engine crankcase (IO-360-A3B6D) had a massive crack under #1 cyl near Waco. I was able to make it to Waco and land safely. My A&P/IA and I removed the engine and brought it home where it was disassembled. There was no metal found and oil pressure never dropped. The engine had under 500 SMOH. We obtained a yellow tagged case and reassembled the engine. It now starts right up and runs great. However, the oil temperature gauge (OEM analog) will slowly climb in the pattern past the red line (245f) and will slowly drop to just under redline on descent to land at low power settings. Shortly after landing I can hit the oil filter with a laser temp finder and it will read 185-190f. I added a second temp probe on the front of the engine with a digital gauge. It too will get up to 230 or so. I have since tried two different vernatherms, replaced the factory temp sensor and flushed out the oil cooler. The original vernatherm end looked great. I flushed out the vernatherm cavity and reached in and felt with my fingertip and could not detect any burrs or imperfections. I’m still not convinced if I actually have high oil temperature, or if the gauge has gone wonky. I’m at a loss what to try next.

-

break in - expect higher temps oil level low Bad sensor bad gauge Oil cooler fins, flush, etc vernatherm Outside air temp baffles and seals cowl flaps

-

Hey guys, I have a low oil temp issue (engine is not running cold, like 380F) and OAT is 26C (hot Houston summer). Oil temp at cruise is 140F (at 25in/2500RPM). I want to take out the vernatherm to see if it is stuck open. I've read the maintenance manual for Lycoming IO 360, and I think everything is pretty straightforward. My only doubt is, do I need to drain the oil? When I removed the pressure relief valve, I did not and everything was fine. But the Vernatherm is closer to the oil filter and I'm not sure if I'm going to get a bunch of oil when I remove it.

-

I think there’s more to the story then… if the oil is only ~150 degrees before going through the cooler, then the vernatherm shouldnt be letting any (or very little) into the cooler at all which means a winterization plate wouldn’t make much difference. The vernatherms open ~160ish depending on the part number.

-

From everything I’ve heard here, the difference between what is described here as an IRAN and an overhaul is maybe a few hundred dollars. The only things that are on the mandatory replacement list they may have overlooked are the Vernatherm and the fuel pump push rod.

-

Hi, After annual with combined avionics install, I have noticed higher than previous oil temp. Its over 200 where previously I would expect between 180-200. It came a bit down with cown flaps. I have noticed they didn't reseal around the cooler. Would this be likely to cause it? I have occasionally seen higher than expected temps before but they normally aren't sustained. That has me thinking maybe the vernatherm is getting sticky? But I'd like to first eliminate anything simple. Also, the guage equals the OAT on start up. Although it could still be an issue because I'd expect the oil a bit cooler inside the cowling with no reflected heat.

-

Simple things first, reseal whatever gaps you find, clean electrical connectors in oil temp circuit, if vernatherm was not taken out chances are slim that there is anything wrong with it, think of things that were changed or disassembled during annual

-

Observed oil temp difference based on probe location

pkellercfii replied to shawnd's topic in General Mooney Talk

I used to get uptight about my TSIO-360 engine oil temps being too low at around 160-170 F. After hearing at an IA renewal seminar that peak oil temps will typically reach ~50 F above the supply temperature for NA engines and ~75 F above supply temp for turbos, I’m not concerned about 160-170 F oil supply temps anymore. In fact, that IA renewal seminar makes it sound like Continental’s vernatherm spec of 170 F for the TSIO-360-MB is about right. —Paul Keller -

Observed oil temp difference based on probe location

pkellercfii replied to shawnd's topic in General Mooney Talk

I made the switch from a JPI EDM 800 to an EDM 900 for my TSIO-360-MB just over a year ago. With my case as well, that changed the location of the oil temp probe from the supplemental position in the crankcase nose to the engine type certificated location at the base of the oil cooler. I'd say that my average measured oil temps haven't changed much as a result of the probe location change, but I do see much faster variation in oil temperature from the new location. That observation is pretty much entirely the result of inspecting the logged engine data after flights. Your reported oil temp of around 160 F with OAT around 60 F sounds is very similar to what I'm seeing. On a recent flight from PGD to my home base of TTA, just after top of climb over S. Florida in January I was seeing an oil temp just over 160 F with the OAT at 50 F. The OAT fell to around 15 F near the end of that flight, resulting in the oil temp dropping to around 140 F or less. I can't provide any advice regarding the Garmin EIS. I've never dealt with any Garmin EIS. Keep in mind that the engine service manual specifies that the vernatherm is supposed to close completely at oil temps between 168 and 172 degrees F, so we really shouldn't be seeing oil temps very much higher than 170 F from certified primary oil temp instruments on TSIO-360-MBs. The highest oil temp I recall seeing from my EDM-900 was about 195 F, just after landing on a hot summer day. --Paul Keller -

Even higher oil temp after new Vernatherm valve

A64Pilot replied to AaronJr's topic in Vintage Mooneys (pre-J models)

A vernatherm of course works by expanding when hot and closing off the cooler bypass. There is always some oil flow through the cooler. I would bond a thermocouple to the tank part of the cooler and go fly and see what your temp is, it should be somewhat close to the indicated temp. Have you verified your temp indicating system is accurate? -

Even higher oil temp after new Vernatherm valve

MikeOH replied to AaronJr's topic in Vintage Mooneys (pre-J models)

In my now over 7 year saga to determine why my oil temp is high, like the OP, I tried this. By the time I taxi back to my hangar and have someone point an IR thermometer at my oil cooler the oil temps have already dropped. I also tried to instrument the oil cooler inlet and outlet fittings with thermocouples but the temps were too low to be believable unless there is no flow through the cooler...but, I had the oil cooler overhauled and new lines installed, along with a new vernatherm! Looking at engine monitor data the vernatherm opens and oil temp stabilizes at 180 degrees after 5-10 minutes at idle, so the vernatherm must be opening. Once I go to take-off power the temp climbs to as much as 230 during climb on a hot day, then decreases and stabilizes at around 200-220 depending upon OAT and power setting once in cruise. Now that I've overhauled cylinder #2 oil consumption has gone down to 7-8 hours/quart, so I don't think it's blow-by. Very frustrating, but I just continue to live with it -

Even higher oil temp after new Vernatherm valve

Utah20Gflyer replied to AaronJr's topic in Vintage Mooneys (pre-J models)

The new vernatherm could be defective. You could remove it and test it to verify it opens at the right temperature. I believe there also might be two different versions that open at different temperatures, you might check which one was installed, neither should run at 225 degrees though. -

Even higher oil temp after new Vernatherm valve

N201MKTurbo replied to AaronJr's topic in Vintage Mooneys (pre-J models)

It is possible your Vernatherm seat needs to be cleaned up. The old one could have warn into the warn seat. I did mine once on my old M20F and it improved the oil temp. I knew the owner of the local engine shop and he loaned me the tool. It took about two minutes to do it after the Vernatherm was out. Like most Lycoming tools, If you go to buy one, it will cost like $5000. https://www.lycoming.com/sites/default/files/attachments/SI1316A%20Bypass%20Valve%20Seat%2C%20Oil%20Cooler%2C%20Repair%20of.pdf https://www.aircraftspruce.com/catalog/eppages/lycomingtools_07-17473.php -

Extreme cold temperature winterization

Shiroyuki replied to Shiroyuki's topic in General Mooney Talk

That's a really good analysis of what I should expect for oil temeperature! Good to know. By any chance would you have any idea at what temperature should I expect the vernatherm to open up? 200? I do have a Reiff XP system which including a 200 watt oil pan heater, and four cylinder head heater at 100 watt each. That's the most powerful installed heater I can find. I do have a engine blanket as well. Beside all the, I have a 1500w car heater that can be tucked inside the cowl intake to provide more heat, or used to heat the cabin. I suppose there is really nothing I can do about those grease in the gear or other places, but if someone is flying in -30c, regardless if it previously parked inside a heated hangar or not, these unheated part will become freezing cold real quick. -

Extreme cold temperature winterization

Slick Nick replied to Shiroyuki's topic in General Mooney Talk

I guess in that case, you’ll need to do a really thorough preheat on the engine, ideally starting the night before. Have you got cowl blankets and stuff? Also try to preheat the interior to protect your avionics, plastics, etc. Ground lean the engine out after start and get it as hot as you possibly can before run up and subsequent application of takeoff power. You should see an initial rise in oil temp, then a drop as the vernatherm opens and allows cold oil to circulate back into the engine and through the cooler, then another rise in temperature which would indicate all of the oil is now flowing properly through the engine. Once the oil is hot cycle the prop a few times and observe the oil pressure drop and rise, too high of oil pressure is just as bad as not enough. You can blow out your oil filter and engine seals. If the battery is in good condition, it should be able to start the engine no problem, maybe give it an 8-10 second prime. Oil pressure with that thick of oil may be very slow to rise on startup, so keep an eye on it. If you don’t see any within 15-20 seconds, shut it down. The book says 30, but I always thought that was way too long. Once she’s hotted up and you’re airborne, you’ll want to lean in the climb and aggressively in cruise to keep the temps up. Running too rich in the winter keeps the engine too cold and can lead to a lot of corrosion inside. Enjoy the crisp, cold air! -

I suspect that the vernatherm is headed south. They don’t always open correctly when they start to fail.

-

My temps have always run low. CHTs on the above trip were something like 280F max (in cruise). My oil was running around 155F in cruise. Evidently the baffling and sealing are excellent, and all that without cowl flaps on the O. The oil temp is too low (I have installed a non-factory small oil cooler plate). I need to install the large (standard) plate, but even then, oil won't get much over 170 in cruise. We've checked the sensor accuracy and vernatherm. Highest I ever see is 200F right after runup. I have 250 hours on an overhauled engine. Even in summer, most I've ever seen is 380F max in climb out and that was only because I forgot to put the mixture all the way in prior to takeoff (grumble). Usually, this engine is maxing out in the mid-300s during summer climb (full rich on takeoff, followed by leaning to the white bar on the G1000 engine page, as I pass 1,000 AGL). That's a good point about % power and running a bit more fuel through the engine. I would definitely pick up a few knots. I, too, notice a noticeable surge of power when advancing the mixture from 50 LOP. So far, this engine seems to be a textbook example of George Braly's and Mike Busch's applied engine theory. Ed

-

If it is in the green arc on your oil temp gauge then you're fine. The indicated temp is the temperature coming out of the cooler or the bypass from the vernatherm. It's much hotter returning to the sump.

-

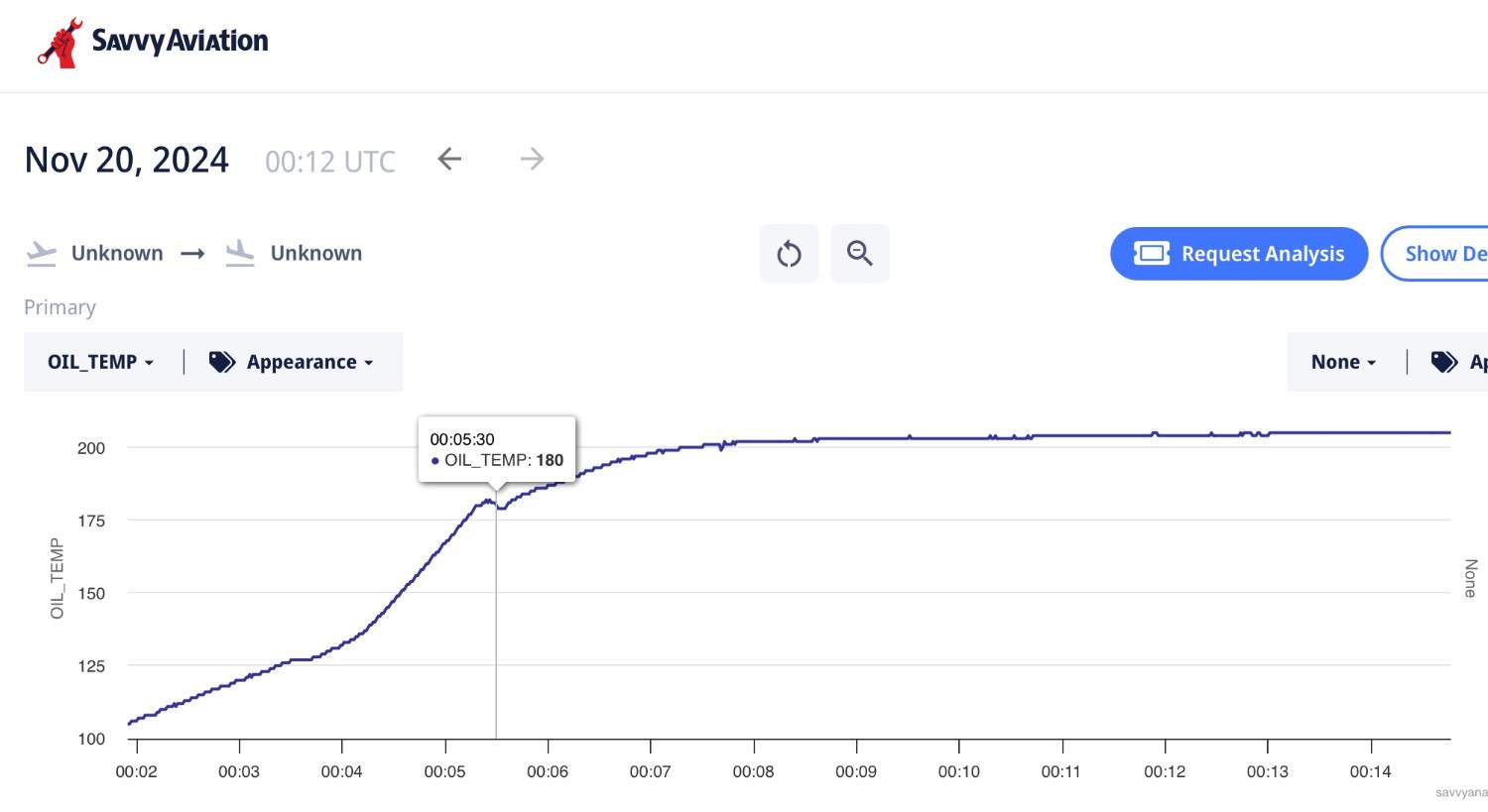

I've had my '70F for over 7 years and the oil temp has always run hot. 220-230 in the summer and 200-210 in the winter. Below is from a flight a few days ago and you can see it 'stabilizes' at 208. Over the years I've replaced baffles, overhauled the oil cooler, replaced the oil cooler lines, and the vernatherm. ALL to NO avail You can see the vernatherm actuate at right around 180, like it should. But the temp then just keeps right on increasing! Any ideas on how to determine if any oil is actually FLOWING through the cooler? I'm beginning to wonder if that is the problem.