-

Posts

803 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by slowflyin

-

Holy Micro's Absolute AoA is Ready for Purchase

slowflyin replied to HolyMicro's topic in General Mooney Talk

Good Morning, Where can I find a copy of the installation manual. The website returned zero docs. Thanks. -

Scott Perdue did a review after six years of ownership. He's tried lots of different tugs and I find his reviews credible. I think it would be easier and safer for my hangar. I have multiple AC in my hangar and it would be nice to be able to check clearances without being tied to the front of the aircraft.

-

8K, 29/2400 or 30.5/2250, 172-174 TAS.

-

Yes, the KAS297. I also enter the desired altitude into the GI275 as it offer altitude call outs, alerts, TOD, BOD and what I call the banana on the map to show my both. My navigator is a GTN750. Works great but definitely no Alt. Select or ROC via the GI275.

-

I have a Pair of GI275s with a King KFC 150. Works well! My alt preselect functions are not available on the 275 but everything else works great. I’m not familiar with the KAP but the KFC has a flight director and it works well with the GI275s. No regrets.

-

I’ve flown about 5 hours since my last post. First crank the #1 jug lagged less than 5 seconds. I surmise the lifters had to pump back up. Next two, #1 came online in perfect sync. Ran for awhile LOP and performed an inflight mag check with satisfactory results. I have a flight Monday morning so I’m going to repeat and upload all the data to my Savy ticket. Feeling much better but still scratching my head. Thanks again.

-

I agree with the reamer suggestion as a matter of good practice and I may come back to it later. I could not give them a quick check because I don't have the correct size reamer. Mcfarland is out of stock of the guided reamers so I chose to put her back together. I'll have the correct reamer in a couple of weeks and after feeling the guides I'm confident they won't stick open or closed in the interim. Tried plug swapping. I did bench test all the plugs (fine wire) under pressure but I did not check resistance. Good suggestion, thanks! I'll be doing an inflight ignition test this afternoon.

-

I did, see my previous post.

-

Starting to feel like I'm hunting Zebras with regards to the valves. Both intake and exhaust are smooth with the appropriate wobble. I had another A&P take a look and I did not offer an opinion prior to his diagnosis. He concurred all is well. I also uploaded a video and pics for Savy to diagnose. Same. I bought these jugs new from Lycoming and sent them directly to Victor for valve work. I'm reluctant to ream just for the sake of reaming as I'm in the do no harm camp. I may come back to the valves but for now I'm starting to re-diagnose. Thanks again for weighing in!

-

Yes, but thanks for the advice.

-

Well, no joy. Pulled the valve springs and the valve stem is smooth as silk in the guide.

-

Thanks, I had read this. I'm ordering but preparing for plan B.

-

Thanks for the responses. I use 20/50 with camguard. Oil consumption is minimal. I believe reaming the guide is the solution but it's great to hear a consensus. I'm a Savy user and they offered the same response. To bad I don't have the appropriate size reamer in my box. Mcfarland is out of stock. I plan to back order and clean the valve stem up to buy myself some time. I don't want to waste time doing the job twice but without the reamer I don't see I have an option. They estimate 15 June but since COVID I've much more skeptical. Thanks again.

-

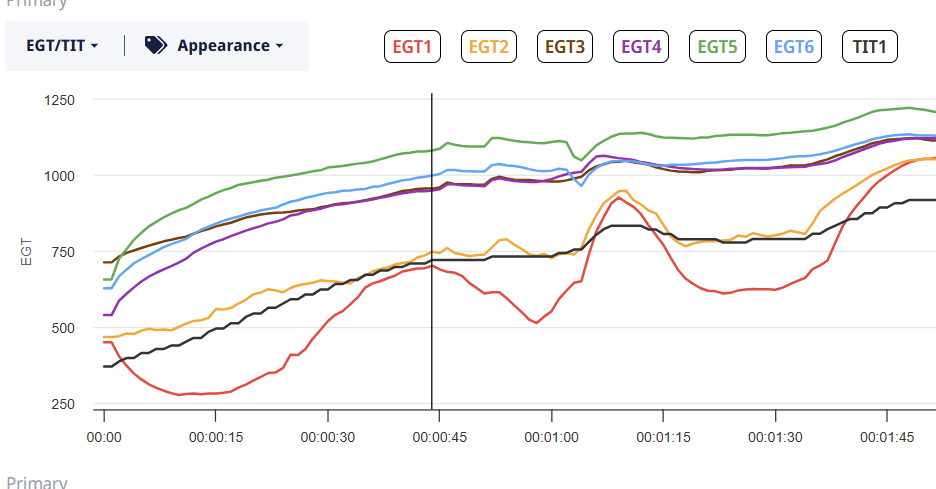

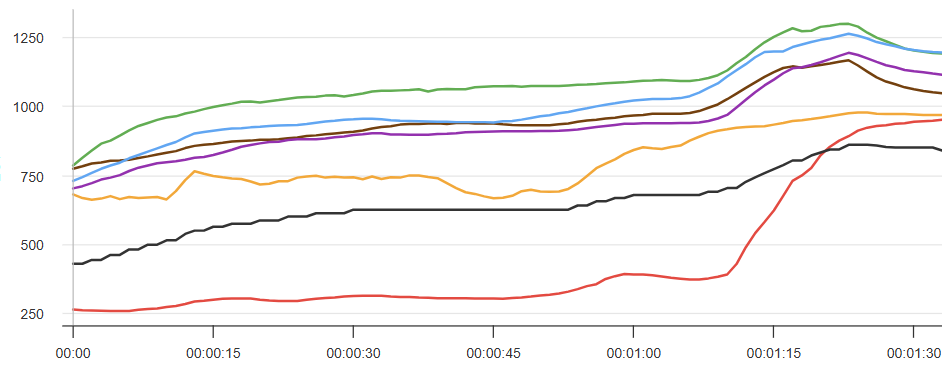

Good afternoon, I've been working an issue with my Bravo and as always, I'm reaching out to the group for advice. M20M TIO540AF1B 300 hours SMOH (Victor Aviation) On 4/18 I experience a rough running engine after start up. After 30-45 seconds it cleared up. The remainder of the flight was ops normal. Next two flights were normal as well. As my annual is coming due I performed a 100 hour on the engine. This included plug cleaning, testing, and rotating-timing check-and borescope. Post maintenance I started the engine to check for leaks and experienced the same roughness for roughly twice as long. My Son observed rhythmic puffs of black smoke and the data shows #1 and #2 EGTs slow to rise. After the roughness cleared up the engine ran normally. #1 Valve

-

IFR avionics panel planning - need for VOR /LOC/GS?

slowflyin replied to AJ88V's topic in Miscellaneous Aviation Talk

I have GPS and VOR, ILS, loc capability. I prefer having non-GPS options. That being said, it's more of a feel good thing as so many of the VORs are OTS. -

I've had a couple and by far my favorite is the Alpha systems with the HUD display mounted on the glare shield. I fly a Bravo. The other unit I had was mounted on the panel and I found it much less useful. For me, having the indicator in my field of view to the runway makes a significant difference.

-

Looks like it was pried up. Not sure what could have caused it but I can't imagine you wouldn't have noticed it while getting in or out of the AC. As it's pried outwards it seems unlikely it was an inflight event.

-

Based on the G100UL fuel leak thread what's your position?

slowflyin replied to gabez's topic in General Mooney Talk

It seems reasonable to hypothesize a more aggressive fuel may be fine for freshly sealed tanks but would cause old, weak sealant to fail. MY Bravo never leaked a drop until I had the paint stripped. After inspection, Eddy advised the sealant was susceptible due to it's age. I'm more concerned about the paint damage. Most AC will leak sometime. Big difference in resealing a 30 year old tank with unknown life expectancy prior to G100UL and resealing and repainting. Alibi, I'm not wading off into the "drop in replacement" waters. I understand the position. -

850 with no wind is doable. Westbound typically means significant headwind up high or slower down low. Either way, 850 Westbound isn't something I'd plan on ROP. LOP helps dramatically but not all Bravos care for it.

-

Thanks to all for responding!

-

I'm planning on taking the IA exam in May and I'm looking for advice regarding preparation. I used Baker's years ago for my A&P. I tend to do well with written test and have had success with self study aides such as King Schools so I'm wondering if time at Bakers is wise. Thanks in advance.

-

Alpha Systems AOA: flaps or no flaps?

slowflyin replied to DC_Brasil's topic in Avionics/Panel Discussion

I have it and love it! For me, the heads up display mounted on the glare shield is a must. During the landing phase it's just where it needs to be. Fly the blue doughnut with a cross reference to the airspeed indicator for on-speed landings regardless of weight. Extended, aircraft in the landing configuration. No. For me, the AOA is useful for landing at different weights. By myself with 45 minutes of fuel is a much slower approach than landing with folks and baggage at maximum landing weight. No buyers remorse!- 4 replies

-

- aoa

- angle of attack

-

(and 1 more)

Tagged with: