-

Posts

775 -

Joined

-

Last visited

-

Days Won

6

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Z W

-

I've found Rustoleum high-gloss white paint, available at any hardware store, matches the white paint on my gear very well for touch-up purposes. I'd use a spray can for a larger surface like that. Multiple light coats. I wouldn't bother with more primer but maybe just a light scuff sanding on the green. Or, consider getting some paint stripper and removing the green primer, assuming the piece is aluminum and won't rust. You could use a magnet to check if you can't tell by its weight. A little polish would have a shiny wheel cover like you see on most Mooneys, if you don't want it white, or don't want paint that will get scratched and chipped. Those covers should come off pretty frequently to air up the tires and inspect the wheel bearings. A lot of wear and tear on a painted part.

-

Upper cowl machine screw issue on '83 J

Z W replied to 0TreeLemur's topic in Modern Mooney Discussion

I do the same but with Corrosion-X on most fasteners before they get re-installed somewhere exposed to the environment. Seems to give you a few more years before anything rusts or seizes in place. -

I believe removing the copilot seats, front and rear, might be easier than removing the right radio rack, depending on your panel setup. Makes it easy to lay on your back on the floor and reach the starter relay. Your legs can lay up into the rear of the plane where the rear seat goes. Not too bad under there that way.

-

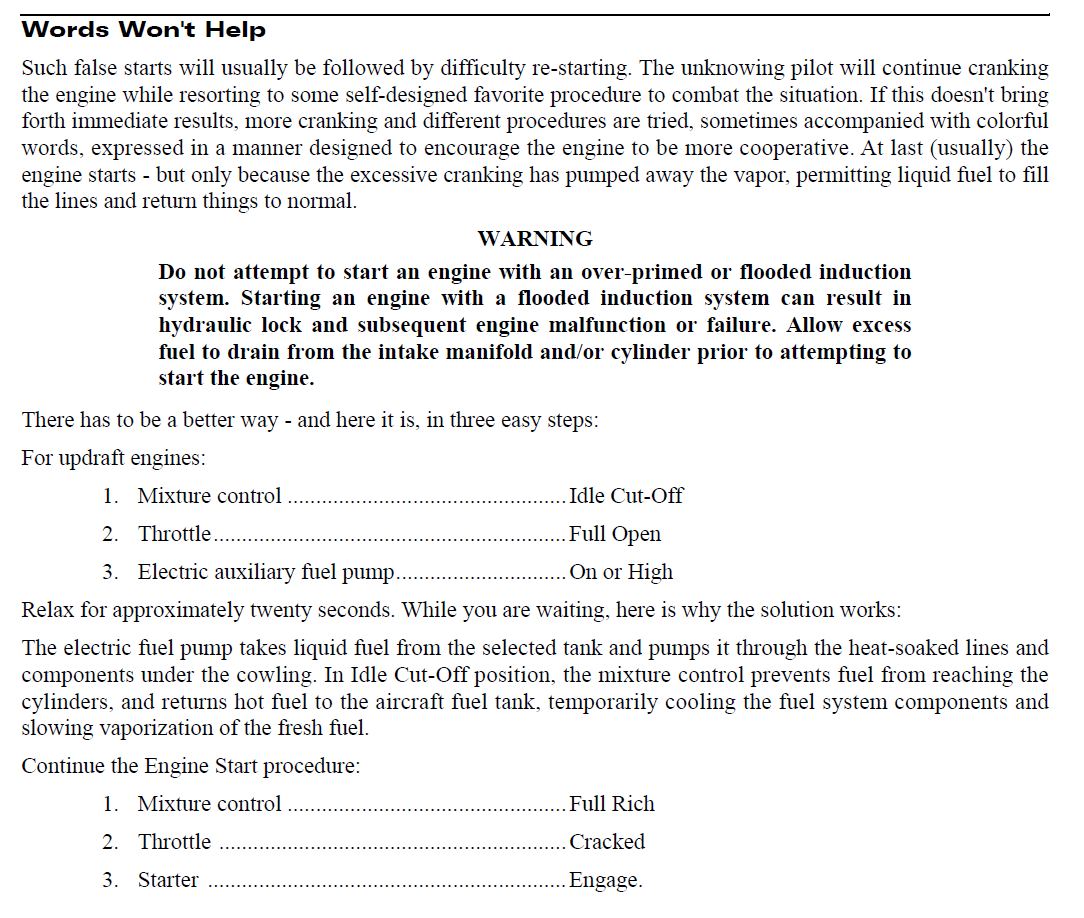

Here's how Continental says to do it, from their "Tips on Engine Care" publication. Works every time. Full documentation attached and worth the read. Lycoming people may have a different experience. Hot Start Procedures - Continental.pdf

-

In factory configuration, the avionics master is "on" by default meaning if its relay fails, the avionics stay on and won't turn off until the master goes off. When you flip the avionics master switch to off, the relay triggers and severs the connection to the avionics bus. You know the relay has failed when you try to power off the panel but it stays on until you turn the master off. If your avionics master relay in the tail fails, do your radios, flaps, lights, and gear continue to work? Or does your entire panel go dark? Where would you look to find the answer to the question, if you don't know?

-

If it were my plane, I would want that extra relay and 3-way avionics master switch removed and everything returned to stock configuration. There are reasons and failure mode considerations it's done the way it is, and what you are experiencing may be one of the reasons the factory didn't include the option to turn on the avionics with the master off in the first place.

-

Sounds like if your 3-way avionics master switch were to fail or have an internal short, it could be back-feeding power into your master relay or your panel, depending on how they wired it. You know something is back feeding power, and it would have to be either the fused line you sent a picture of, or your non-stock avionics master relay.

-

I have a similar inline fuse. In my plane, it connects directly to the main power line coming off the battery at the master relay, so it is always hot, and runs forward into the cabin. It therefore provides always-hot power to something in the cabin, though I never figured out exactly what, or if it's even still connected to anything. I would expect it to be something like a clock or cabin light that you would want powered with the master off. For what you describe, I am still suspicious of the mystery 3rd not-stock relay mounted to the aft of your battery without any terminal covers. Someone has done something non-standard with your wiring. Does that relay send any power thorough wires forward into the cockpit?

-

Every 10 minute job is one stripped screw or broken bolt away from becoming a 2-hour project.

-

My plane is sitting at KMKC right now. It's a great airport, easy access to downtown, Lyft and Uber work great. Easy to fly in under the Class B while VFR. The free transient parking is good as long as you have the time/desire to use the self-service fuel. You need the fuel receipt to get in and out of the city-owned terminal building and access the ramp. You have to self-fuel upon landing or you won't have the receipt to get back in, so leave extra time on your arrival. I've heard you can call the airport manager from a gate and get buzzed in, maybe, if you don't have the code, but I've never done that. Atlantic is very nice and accommodating next to the self-serve fuel, but they don't sell 100LL. They've let me walk through their lobby before and even arranged a rental car for me once. If you're short on time or prefer full service fuel, Signature is the only option. Their prices are usually high but the service is good and the people are nice.

-

When I went through this, the old original OEM part number relay was no longer available anywhere. There is some kind of advisory circular that allows A&Ps to install relays that don't match the part number, and arguably to install relays that are not TSO'd nor designed and intended for aircraft use. Someone in the distant past had used relays with NAPA auto parts stickers on them for my shore power, master, and starter relays. I discovered it when they started failing in interesting ways - the starter relay failed closed, resulting in the prop starting to move when you turned on the master. Modern TSO'd units should not fail like that. The answer is to use the TSO'd relays from Spruce. The mounting holes lined up just fine on mine, replacing an older style like the one in your photos. If not, you or your A&P might need to drill a couple new holes in your battery box, it just mounts with a couple of screws/bolts. Good time to order new mounting hardware while you're getting a shipment in from Spruce. Good luck.

-

Garmin Yaw Damper - Weight & CG Implications

Z W replied to oisiaa's topic in Vintage Mooneys (pre-J models)

The yaw damper is nice. I'd put it in again. Maybe double-check your weight and balance? Was the plane weighed, or is it the product of 40 years of + and - by well-meaning A&P's? My former C model was almost impossible to load out of CG, from my memory. Where is your trim on a normal landing? If it's not nose-up and you find it very easy to flare, that's a sign you are running aft CG. If you are lots of nose up trim and still have to pull back hard to flare, that's a sign your W&B numbers might be wrong. -

The new solenoid in your pictures on the crossmember next to the inline fuse is not powering the main bus, I don't think. It would need to have the big 2 gauge wires going to it. It's powering something else, and I can't tell what.

-

For clarity, if your F is wired like my K, and it looks like it is, this one is your master relay/solenoid, mounted on the rear of the battery box where you have to lean way into the tailcone to see / work on it:

-

@eman1200 My parts catalog calls it a relay. It could also be called a solenoid. Pretty much the same thing. The solenoid with the arrow pointing to it in your photos does not look less than a year old. There is another one mounted on the crossmember that is not present in my plane that looks new, and also like it should have some protection over the terminals to prevent accidental arcing. I suspect someone has done something non-standard with your wiring that may be contributing to your situation.

-

That's your master relay. It could be bad, or you could have a wiring problem between it and your master switch. I believe a short to ground between the master switch and the relay could cause what you're seeing, in most installations. Don't let the A&P go down to the local auto parts store for a replacement. Spruce sells good FAA/PMA ones. https://www.aircraftspruce.com/catalog/elpages/solenoidx610028.php

-

+1 for Peerco 321. It was a little slow acting but did not eat or damage any paint and mostly smelled like oranges and I felt no need for a respirator or filtering mask.

-

@WilliamR Before you go adjusting too much, add some grease to your door pins. Mine were bone dry. The new seal made it concerningly hard to close /open the door until I added the grease.

-

@Marc_B Thank you for the write-up. Looks like a very clean install.

-

No, most would not run that turbocharged engine wide open throttle in cruise. Most people seem to cruise at 2300-2500 RPM. Flightaware is showing you ground speed, not true airspeed. The plane may have had bad luck with headwinds. Or the owner is running low power settings for some reason. In most real world conditions it will get 150-170 KTAS, varying with altitude and your choice of power settings.

-

I applied masking tape to the outside of the door to protect the paint, mixed up the glue that Guy sent, brushed it liberally on the door seal surface, put the seal in place using a few clamps, added some more blue masking tape over the seal to hold it, let it tack up, wiped away any excess glue, removed the clamps, and closed the door. Crawled inside and verified it looked good from that angle. You can see the seal from the inside on the lower part of the door. Came back the next day and removed all the tape. Seems to have worked OK. The seal hasn't moved. The glue is invisible once dried, I like how it looks a lot better than the old yellow stuff I had to strip off before this job. I am not a professional and would recommend you follow Guy's instructions, which is what I'll do if I ever do it again. The same silicone glue Guy sends with the seal is available on Aircraft Spruce in case you need more. Comes with one of his cards in the package. https://www.aircraftspruce.com/catalog/cspages/siliconecatalyst05-13310.php

-

As an update on this post, I had planned to get a second cylinder at some point to either cascade or just dual-stage fill the O2 in the plane. However, with the Mountain High 02D2 system I added about the same time, I go through the oxygen so slowly, I've found it unnecessary. I just refilled the supply cylinder for the first time. It still had 700 PSI left in it, but I wanted the plane topped up more for a long cross-country with 2 on board. So, if you're considering doing this, maybe start with one cylinder and see how long it lasts you before you invest in a second one. I have found having the setup in the hangar has greatly increased the percent of the time I fly on oxygen, and has also increased the average altitude I fly at. I'm in clear smooth air more often and feeling better and less fatigued when I land. All around worth it.

-

Just musing out loud here... You have a TSIO-360-MB (or GB or LB). You're flying it in cruise at 75% power of your 210 rated HP. Say 28"/2500RPM/13.5 GPH, just for a rough example. At 75% power, no matter how you get there, you're putting out 157.5 horsepower. You take that same engine and reconfigure it to a TSIO-360-SB. The engine internals, to include crankshaft, pistons, connecting rods, and compression ratios, have not changed. But now your takeoff power settings are 39" and 2600 RPM which generates 220 HP. You take off again, and set your engine the same to 28"/2500RPM/13.5 GPH, putting out 157.5 horsepower. You are now at 72% power, with the engine performing exactly the same as before the conversion. Are you taking it any easier on your engine than before? All that to say - why do we focus on % of horsepower for cruise power settings? Wouldn't it be better to choose settings that produce ideal temperatures for CHT, EGT, and TIT? How are you even "taking it easy" on the engine by running it at reduced horsepower? % power isn't even a very good rule of thumb. I didn't do the math to verify what I posted above is 75%, I think it's actually a little less, but it requires a mathematical formula to know, it depends on whether you're ROP or LOP, and the number your engine monitor displays for it can even be wrong. Rules of thumb are supposed to be quick and easy and this is not. What the guys at GAMI say always sticks with me: "It's not how hard you run the engine - It's how you run the engine hard."

-

Unable to make maximum RPM a few hours post overhaul...

Z W replied to Tito22's topic in Modern Mooney Discussion

When I was looking into this, there was no real way for the propellor blade angle to "get out of whack". It's all bolted together. If your engine just didn't sound good, but you didn't push it to full power, you might want to just do some more testing on the ground. Run it up to full power. Report back on maximum MP, RPM, and fuel flow while at full throttle. Do some high speed taxis down the runway, pulling power before rotation speed, and let us know what it's doing. Bonus if you can download the data from an engine monitor and post it here. You have a fuel flow instrument in the panel. Let us know what it says during full power run up and high speed taxi down the runway. We'll be able to check it against your factory service manual for your engine and let you know if it's correct. At 1200' density altitude you should be making full power, no question. Make sure you sump your tanks well so you can rule out something like water in the fuel, which can cause stumbling and momentary loss of power on the takeoff roll. -

TSIO-360-MB. 27-28" MP, 2500 RPM. Leaned to just under 1600 TIT, usually 12.5-13 GPH. Gives about 155 KTAS at 10,000, up to 175 KTAS at 17,500. CHTs vary greatly with density altitude and OAT, but range from 320's to 370's. I can maintain under 380 degree CHTs easily at all altitudes and temps by opening the cowl flaps which is my practice. I do have the infinitely adjustable electronic motor cowl flap. ROP because my engine goes rough LOP. I've tried all kinds of power settings, still rough LOP. I do not have GAMI injectors. Under 1600 TIT to take it a little easier on the turbo and exhaust, and because this setting is a nice balance of fuel flow, power, and all engine temps. Sometimes I can get 28" MP and stay under 1600, sometimes I have to walk it back to 27" MP. Peak TIT is somewhere near the 1650 redline at these power settings. I've taken GAMI's online engine management seminar. I understand the "red box" and internal cylinder head pressures, and that what I do is not optimal for them. My take away is while that might be a good rule of thumb, the purpose of all of that is to keep your engine temperatures in proper operating ranges, which I do through a full engine monitor. I could run more efficient on fuel, but at the cost of either power (speed) or higher turbo and cylinder head temps. So I think this is a nice balance. I've considered getting the GAMIs and trying to save another gallon or two per hour running LOP. My engine is getting to be higher time, and I unfortunately don't have a good local mechanic to work with on it, so I haven't done it. If I overhaul the engine I'd plan to start out with a fresh set of GAMIs.