-

Posts

794 -

Joined

-

Last visited

-

Days Won

6

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Z W

-

-

Yes, related to a poor repair of the air filter housing, which had cracked.

-

Most 252's do 160-165 KTAS and 11-13 GPH at 12,000. Pinecone's seems to run 15 knots faster on 20% less fuel than everyone else's.

-

I believe this is the standard practice, using a shop vac to pressurize. At one point chasing a low MP issue we did this and the A&P said he found several leaks around the intake. We replaced all the intake connecting rubber hoses at a reasonable cost. It made no difference. All of yours should have been replaced 200 hours ago at overhaul though.

-

Does the 310 HP require excessive right rudder on takeoff, such that it feels unstable or dangerous on takeoff? Sometimes I like the idea of an extra 100HP over what I've got in a 262. But I've wondered how that really feels on essentially the same airframe. And at 38 GPH take off / climb and 20GPH in cruise I feel like I would often be flying around with range anxiety, or be effectively limited to 2-hour legs unless flying solo and light.

-

Need some paint and possibly some interior recommendations

Z W replied to Schllc's topic in Acclaim Owners

At this point, I'm just happy when any shop will agree to work on the plane. Currently been down three months getting a turbo rebuilt and then chasing oil leaks on reinstall. Last year, after waiting a year for a 430W to GTN650 install slot, that took about 2 months too. I redid the carpet myself after that just because I didn't want the plane to disappear into a shop again for a month for it. It's not pro level but good enough for who it's for and I got it done in a weekend. The maintenance situation is getting very bad and I think it will get worse before it gets better. Seems like every time I get the plane back, it's almost time for another annual which also somehow takes a month or more. The shops all are doing their best and have always had good reasons. They can't get enough good labor and it takes forever to get the parts they need. I've never complained about a single bill and bring the checkbook when I come to pick up the plane. Sorry that doesn't help you but thought I'd let you know you're not alone. -

First thing I would do is apply Mouse Milk to the wastegate linkages. A sticking wastegate can cause lots of issues. I Mouse Milk mine every 25 hours at oil change time. While the lower cowl is off to do that, maybe also remove the air filter, reach in, and spin the turbo by hand, checking for abnormal axial and radial play and making sure it's not contacting the housing. Wouldn't expect that at 200 hours since overhaul, but it's a quick check. Looking for intake and exhaust leaks is a good idea. I'll also add - make sure your alternate air is not coming on, as it can cause this problem. Check for intake obstructions, which can cause the alternate air to come on. Make sure your intake plenum boot is fully drawn up onto the cowl flange and not bunched up and partially obstructing your intake. This is an important step every time the lower cowl goes back on that is sometimes missed, and as far as I know, unique to the 252 engines. You can quickly check that by removing the access door on the copilot side of the lower cowling. After that, if you're still having the problem, I would have the fuel system setup checked in accordance with SID97-3G (attached), now a part of Continental's M0 maintenance manual, by a Mooney-specific shop. I've had multiple non-Mooney shops fail to get this right. Maxwell is really good at it. What were your fuel pressure and fuel flow showing while you observed the decrease in MP? The fuel pump has an altitude compensating function that has to be set up correctly. I think of it this way - to make maximum power, your engine needs sufficient air, fuel, and spark. Taking spark out of the equation, you're missing either some fuel or some air. SID97-3G - Continuous Flow Fuel Injection Systems Adjustment Specs and Instructions.pdf

-

Making Sense of Best Glide and Glide Ratio

Z W replied to Max Clark's topic in Modern Mooney Discussion

To clarify - the full nose up trim I described above is for an engine out situation. I do not use it for regular landings. I don't want it in that configuration if a go-around may be required. -

Making Sense of Best Glide and Glide Ratio

Z W replied to Max Clark's topic in Modern Mooney Discussion

I was also taught full nose up as a way to approximate best glide in the 172 trainer I learned in. It works pretty good in the Mooney too. Maybe a little slow, so slightly less than full nose up trim is ideal, but full nose up gets you close and then you can trim after that to exactly where you want it. The idea is the plane will naturally want to hold proper speed that way while you're looking out the window to pick your landing spot, running the engine restart checklist, making your mayday call, turning on your ELT, securing the cabin, and otherwise preparing for an emergency landing. So step 1 is full (or nearly full) nose up trim. It does however make it to where it requires less backpressure to stall the aircraft on short final, so you still have to watch your airspeed and not try to stretch your glide. -

How does it attach to the oil cooler? Do you tape it in place? A picture would be great if you have one.

-

My oil temp also reads low, usually in the 140's. I've never blocked the oil cooler. When it's very cold outside, I run with the cowl flaps fully closed which helps keep the oil temp up. I read somewhere on here that if it's indicating 140 at the probe, it's still likely hot enough to vaporize moisture elsewhere in the engine, so not to worry. But I'm just repeating something I read on the internet there. You're running a lower power setting than I usually do - I go closer to 75%. Nothing wrong with your setting but you might try running more power for a while and see what it does to your oil temp. I think I'd be concerned at 109 degrees. The turbocharger needs 100 degrees minimum to function properly, according to its documentation, and you may be getting too close to that.

-

Thanks for the tip. I have one on order and will see how it does, with some padding and/or moving blankets. This is the one I ordered: https://www.harborfreight.com/automotive/lifts-cranes-stands/hydraulic-lifts-carts/500-lb-capacity-hydraulic-table-cart-70726.html

-

This would be a good use case for the FS510 I had not considered. I don't travel often enough or for long enough to find much use for this, but others might. And I may someday hop in the plane to come home and be glad I have the option to tap "Yes" for updates and update the plane running on the ramp.

-

I have a 500TXi, G5, GTN650, GNC355, GFC500, GTX345. Database sync works very well. The installer said with that configuration he had to make the GTN650 "Primary" for databases and so the database card goes in it. You can make just one card and it pushes out to all the other devices. We added a Flightstream 510 to use Database Concierge and update wirelessly though Garmin Pilot. It didn't work at all at first. Then, I think after a Garmin Pilot update for my Android phone, I was able to get it working. But, it's so slow I don't like to use it. You power up, it prompts whether you want to update the databases through Concierge, and if you hit yes, sometimes you have to sit there for 15 minutes while it wirelessly transfers the databases and updates, then you have to shut the radios off and back on again, then sometimes they update again. I don't want to run the panel that long on battery power so the plane either needs to be running or plugged in to a ground power unit. And if I'm trying to go somewhere, it adds 15+ minutes to the preflight process. I wouldn't spend the money again on the Flightstream. I prefer to just make a SD card. Pop it in where the Flightstream goes in the GTN and everything updates in just a couple of minutes.

-

The dash gauges on my G500TXi are very accurate once you get below about 25 gallons total on that side. It's just when you are over 25 gallons and some of that fuel is out in the Monroy extended tank, the gauge is still going to read 25 gallons, even though you have more. The wing gauge will do the same. If starting out after a fuel stop where the inboard tanks were topped (37.5 gallons per side in theory), the gauges will read full, then quickly drop to about 25 gallons as the fuel flows out into the outboards, then stay at 25 gallons until you get below that, then become accurate again until 0. If starting out quickly after fully topping both inboard and outboard tanks (52.5 gallons per side, rarely done), the gauges will sit pegged at full until you reach somewhere around 37 gallons of actual fuel, then the gauges will quickly drop to about 25 (inaccurate) and stay there until you reach 25 gallons of actual fuel, then be accurate again until 0. The gauge system is reliable but inaccurate and can be confusing. You have to think about it and understand how it works. If you don't, you may be alarmed as the gauges quickly drop and think you have a fuel leak somewhere, or that they're frozen in place when they stop moving. And, as I said before, my wing gauges quickly drop from 10 to 0 as well and are not reliable at those levels. If the plane were not so efficient, making it easy to just carry extra fuel, I think this would be more of a problem than it really is.

-

The green arrow markers at the top of the arc show bank angle required for a standard-rate turn. The slip ball is at the bottom. Always visible, just combines a classic turn coordinator with an attitude indicator, flight director, and artificial horizon.

-

This is, in my opinion, one of the weaknesses of the 252, or likely any Mooney with long range tanks. It's very difficult to know with precision how much fuel you have on board unless you always do the fueling yourself, which I have not found to be practical. I usually fly around knowing within 10 gallons +/- what is in the tanks. I compensate by planning to land with 2+ hours of fuel on board, which is easy to do because of the plane's efficiency. The problem is - you ask the FBO to "top the inboard tanks" which should be 75 gallons on board. In reality, they sometimes short you by as much as 5 gallons per side, depending on how patient the line guy is in topping you up. And you can't tell how much you were shorted by looking in the tanks, because by the time you get back to the plane, the fuel has flowed out into the outboard tanks and you can see those are 1/3 full and the mains are 2/3 full. You get in the plane, and set the fuel totalizer to 75 gallons, because that's a pretty good guess, but often you're really at 65-75. Sometimes I adjust the totalizer setting based on the fuel receipt or by what I see on the visual check. Then you fly for 3 hours, or about 36 gallons, land, and ask the FBO to "top the mains" again. Same problem repeats. You will rarely fully top both the inboards and outboards, because if you do, most planes are over gross or near it with just the pilot and a small bag. So you're always doing the dance between fuel orders, looking in the tank, fuel totalizer, and looking at the fuel receipts. Looking at the wing gauges can kind of help but not really. It's not really a problem because 75 gallons in the inboards is about 5.5 hours of endurance which is way longer than I like to fly. But on one or two occasions, I've ended up fighting headwinds, extending my planned flight to 4.25 hours, and worrying about the fuel levels because the FBO only filled me with 30 gallons when it should have been more like 40. If I know I'm doing a 4-hour leg, I will put 10 gallons or so into the long range tanks if possible and try to take off with 85 gallons on board. Even better yet, if I fuel myself at a self-serve pump, I can make sure I get a good top off and it's much less of an issue, but the way I fly that's not always an option. The only other solution is to do like @Pinecone has done and create a custom spreadsheet with dipstick measurements for each tank. To truly maximize your range I think that's required. But I don't like pushing range or staring at empty fuel gauges, so I just land with 25+ gallons on board. If I ever have to have 4 adults on board, which is rare, I try to take off with 50 gallons and limit my flight to 2.5 hours max.

-

They're kind of nice to have, but I wouldn't say "necessary." Mine are pretty accurate until they get below about 12 gallons, then they suddenly start reading zero. Really bothered me at first. Still bothers me a little bit, even though I know. Useful mostly for seeing if the fuel guy got to you without having to power on the plane and check the dash gauges or physically look in the tank. I don't find them reliable as an in-flight cross-check when it matters. Your experience may vary.

-

I didn't know you could do that without going through the full PMA process. If so I'd think it might be a good solution.

-

Looks like the FAA office that issued the AD has to approve an AMOC. I've looked over the clamp and turbo recently and can't immediately think of how it would be done reasonably. Eliminating the V-band clamp from the design would require major changes to the turbo and tailpipe not consistent with certified airplanes. Maybe we need to be asking the FAA to extend the deadline for compliance until the manufacturers of the new riveted clamps can catch up. Or to put pressure on the manufacturers to make them. V-band clamps are a standard part in the automotive world and high quality ones are available for less than $50. This should be a solvable problem and an opportunity for someone with a manufacturing facility to make a good amount of money. https://www.faa.gov/aircraft/air_cert/continued_operation/ad/alt_moc#:~:text=An AMOC provides an acceptable,an acceptable level of safety.

-

Turbocharged engine takeoff ground roll checks - tips?

Z W replied to hazek's topic in General Mooney Talk

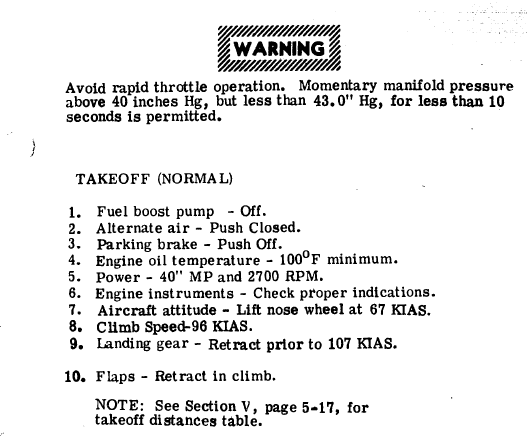

Item 6 - Engine Instruments - Check proper indications. Verify expected MP, RPM, and fuel flow once you've set full throttle. If your MP is a little high, reduce throttle until it's not. If any of them are unexpectedly low, abort takeoff and figure out why on the ground. Note - it's not uncommon for RPM to be about 50 below maximum until your airspeed comes up and reduces the load on the prop. Mine goes from 2650 while starting the roll to 2700 around 40-50 KIAS. With a turbo, you have the benefit of the fact that it should always make full power at any airport, so this is even simpler than a naturally aspirated plane and is the same every time. -

Turbocharged engine takeoff ground roll checks - tips?

Z W replied to hazek's topic in General Mooney Talk

Yes, I agree, that is what I was trying to say. But if you are trying to spin the throttle in from idle all the way to full forward, while rolling down the runway, it's hard to tell when you're getting past the fully forward position. -

Turbocharged engine takeoff ground roll checks - tips?

Z W replied to hazek's topic in General Mooney Talk

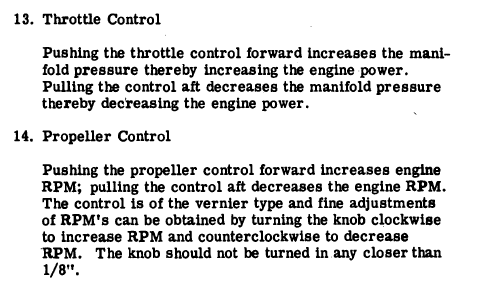

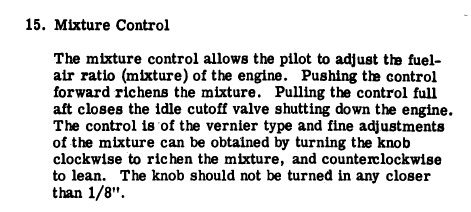

It's hard to feel because turning the vernier lets you really crank and put some pressure on the cable against its stop in the engine compartment, which you don't want to do, if you keep turning it in past full throttle. You are not supposed to use the verniers to advance the controls too close to the dash. My POH has warnings not to turn the prop or mixture closer than 1/8" using the vernier, though oddly enough, not the throttle, I just noticed: You can feel it hit the stop if you slowly advance the vernier in, like during cruise, but I find it hard to do while spinning it in relatively quickly and also rolling down the runway for takeoff. I find it easier to feel when you have reached full throttle if you just push the button and slowly, steadily, but firmly advance the control in. Your experience may vary, this is just what I do. My TSIO-360-MB engine has an automatic wastegate that under normal circumstances prevents overboosting, so full throttle is proper for takeoff. Under certain temperatures and density altitudes, it may overboost by 1-1.5 inches, which is allowable for a short time, and if it does, I just dial out a little throttle with the vernier. I was under the impression the Bravos also have an automatic wastegate and do not overboost normally, but I have never flown a Bravo. My takeoff practice is consistent with my POH, shown below. I do use 36" instead of 40" because my engine was changed to a MB series as part of the 262 conversion. -

Turbocharged engine takeoff ground roll checks - tips?

Z W replied to hazek's topic in General Mooney Talk

I don't use the vernier throttle to dial in on the takeoff roll - I push the button and slowly but firmly advance to full throttle. The vernier is too slow and it's hard to feel when you're at full throttle. Confirm turbo operation by verifying manifold pressure - you can also hear and feel it kick in passing 28-30" MP. Verify power set - MP, RPM, and fuel flow as expected (36" MP, 2700 RPM, 22-23GPH for me, your numbers will vary). After that, eyes on the airspeed indicator and out the window. You'll be flying too soon to look at much else. Scan for warning lights and to confirm power set as time allows. Be ready if anything is off to pull the throttle and stop on the runway or land straight ahead. -

@anthonydesmet You may want to verify the status of your V-band clamp before you remove that exhaust pipe. See AD_2023-09-09. If you need a new one, part numbers are 670105 (new) or 653337 (superseded) and they are currently hard or impossible to get.