-

Posts

1,657 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by exM20K

-

Congratulations, Mike. CFI & CFII are licenses I’ve never even contemplated earning for fear of learning what a lousy pilot I am. I’ll hit you up for sure when BFR comes around. -dan

-

For the TN, the STC comes from Bob Minnis, Minnis aviation. Highly recommended for t/o and climb performance. -Dan

-

Flew in and used Flightline in early March 2020, right before the world went kray-kray. Was outstanding then. -dan

-

-

Yah, best bet is to come for as many days as possible to maximize the likelihood of seeing the balloons fly. The show boss has some tough calls to make often. We left Saturday mid day as it was obvious that Sunday would be good for kite flying only.

-

That's a pretty reliable block fuel flow for the TN running LOP after a climb to mid-high teens.

-

Just back from the 49th Balloon Fiesta in Albuquerque. Great time and an amazing display of grass roots aviation. The precision with which the competition pilots fly these aircraft is astounding. Being among tens of thousands of smiling people during a mass assentation of 500 balloons is memorable to say the least. Mooney content: Interesting comparison of travel modes / efficiency. Chicago -> ABQ -> Chicago is approx 180 gallons and 10 hours. We drove a 40' motorhome instead, and the round trip stats for comparison: 260 gallons and 43.5 hours. Fuel cost is approximately the same, and the Mooney does the trip in 1/4 the time with maybe a little less useful load. Apples and oranges, of course, but interesting that it takes a similar dollar amount of fuel to move a 3200# aircraft that distance as a 35,000# RV at a quarter the speed. -dan

-

Minimum Safe Altitude for Engine Out Turn Back To Airport

exM20K replied to alextstone's topic in Mooney Bravo Owners

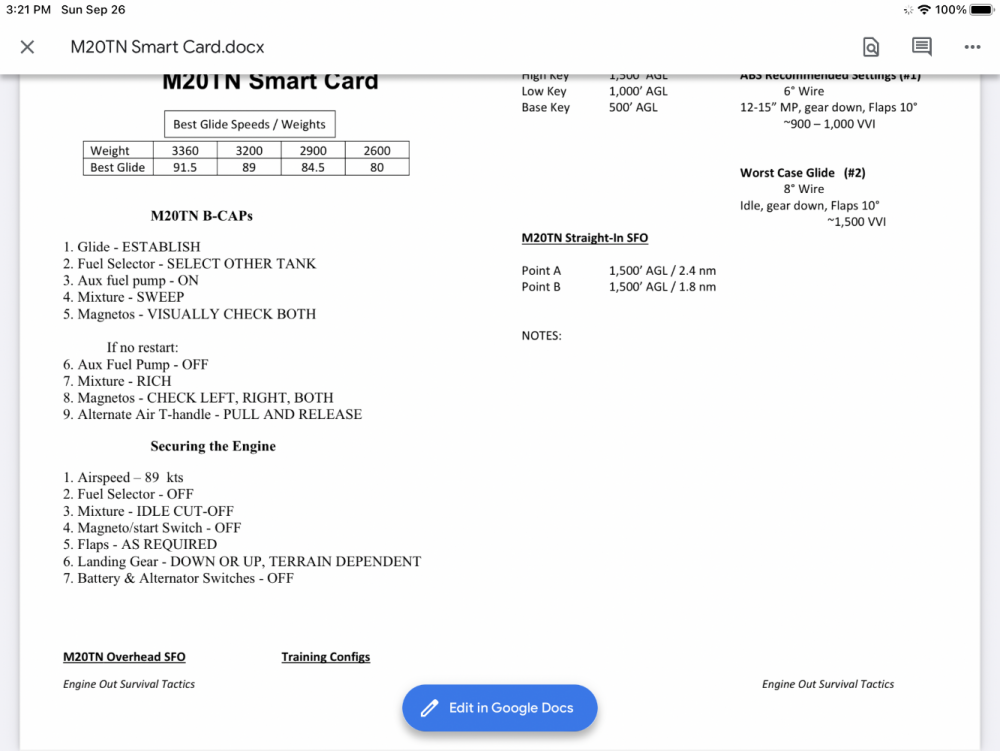

Great work, @toomany a Mooney year will eat up a ton of runway at 115 KIAS. Turning away from a runway when dead stick is not a great idea. Mid and long body planes are not great to slip if slow and full flaps. The tail is working very hard to keep the nose up with that porky six cylinder engine out there, and blanking the tail with both full flaps and the fuselage cal start a buffet, which if allowed to progress into a tail stall will turn you into a lawn dart. S turns or pitching to a slower than best glide speed will consume excess energy. I highly recommend Nate Jaros’s engine out book. https://www.amazon.com/Engine-Out-Survival-Tactics-Emergencies-ebook/ I created this Smart Card for my plane after reading his book, and I re read it from time to time. Last PPP I did, I flew all these engine out procedures with Parvez Darva, and it was really cool to see them work. -Dan -

Minimum Safe Altitude for Engine Out Turn Back To Airport

exM20K replied to alextstone's topic in Mooney Bravo Owners

That’s great news. Last one I attended in Davenport was really thin on Acclaim materials. Any improvement there? -Dan -

Plane down in MI. Pilot safe. Mooney?

exM20K replied to Stetson20's topic in Mooney Safety & Accident Discussion

Yeah, but especially with the gear up, I think a mooney would do ok in a bean field. never had the “pleasure” of operating a Rotax 2 stroke but was very fond of the 912 and 914 in the Diamond motorglider -

Plane down in MI. Pilot safe. Mooney?

exM20K replied to Stetson20's topic in Mooney Safety & Accident Discussion

I think it was last year…l a frequent poster over on beechtalk (where I don’t hang out anymore) put his v tail into a corn field with not great results. Plane probably destroyed, serious injuries, etc. in my youth, I may have run a Jeep CJ5 through a cornfield without putting the windshield down. Oops. not just the stalks, but the ears will whack the crap out of everything. You don’t always have a choice, but I’d pt a corn field pretty far down the list of suitable landing spots this time of year. Glad this one worked out and hope plane is economically repairable. -dan -

Plane down in MI. Pilot safe. Mooney?

exM20K replied to Stetson20's topic in Mooney Safety & Accident Discussion

https://aviation-safety.net/wikibase/267788 201 out of OZW. Much better outcome landing in a bean field than a corn field this time of year! -dan -

The Kelley system is much better in many respects. it doesn’t add work for the fragile starter adapter it gets the weight aft, which is big for the acclaim it can be run from an apu it can operate during takeoff, though I’d carefully monitor CO levels that said, I’d be really surprised if a motor repair shop couldn’t fix it. i hade the same issue with a Carrier A/C unit on my motorhome. Carrier got out of that market and ceased supporting the low profile units. very frustrating, but if you’re going to keep the plane for a while, consider the Kelley unit. -dan

-

New iPad Mini announced today 9/14/21

exM20K replied to LANCECASPER's topic in Avionics/Panel Discussion

That's really cool and an indication of how big this "niche" market really is. Thanks for posting -dan -

I run LOP/SOP, and with a black painted lower fuselage and the Acclaim’s stubby left side exhaust, the bottom left of the underside gets a lot of the chalky white staining. the combination of this, a creeper, and a bunch of micro fleece rags makes quick work of it. The used rags are probably hazmat. But the plane looks great -dan

-

Kennon sun shades. If your main concern is keeping the heat out, they are the best. If you’re worried about water intrusion from occasional outdoor parking, fix the door seal. Have you tried to install a cover in the wind? Not fun. Have you ever dealt with a dew-soaked or rain-soaked cover when you’re on the road? Not fun. Sun shades address the 80% concern with 5% of the aggravation. -Dan

-

They don’t. At least on my riding mower, they never engaged the ANR. Howard Leight headset, kinda low end. The ANR is looking for spikes, so when it is constantly loud, they do nothing. +1 on the foam plugs under electronic muffs for shooting. -dan

-

And he had that awesome write-up of his goose strike over KAVP one night, IIRC. digging for the pics.... -dan

-

I’ll bet you’re right. The foam plugs I use for motorcycling and shooting are good for 32 db of noise reduction. If the clarity and halo can come close to that, they are probably quite a bit quieter than my base A20’s, if I’m reading this report correctly. https://www.cdc.gov/niosh/surveyreports/pdfs/360-13a.pdf -Dan

-

The photo above looks like a KFC150, which would follow the AI -Dan

-

And winds 140@ 130 kts. Yikes

-

G1000 life cycle and diminishing value

exM20K replied to wdeninger's topic in Modern Mooney Discussion

There is a huge installed base on G1000 aircraft out there, many with no upgrade path. It’s not something that keeps me up at night. a WAAS G1000 combined with GFC700 is simply the best pairing of autopilot and avionics I’ve ever flown with. And the lower panel significantly improves forward visibility as for the life cycle, mine is 12 years old now, and it’s the buttons and knobs that have been points of failure for me. Sadly, these are not field serviceable, but Garmin is quick with the overhaul/exchange. I am having an four month old exchange MFD replaced under warranty right now because the cOM freq inner adjustment knob failed. Previous failure was the Zoom knob. These are simple repairs for Garmin, and I expect they will support the G1000 for a good, long time. That said, I’d happily pay for an NXI upgrade at the cost of other aircraft so upgraded. And another 200# of useful load might make this my last plane. -dam -

Minimum Safe Altitude for Engine Out Turn Back To Airport

exM20K replied to alextstone's topic in Mooney Bravo Owners

This. At my home field in Illinois, even if I could maneuver for the turn-back, there is insufficient runway almost all the time to get the plane stopped and trees at one end that I’d rather not roll into. I am highly confident that an off field landing in an adjacent golf course or prairie can be done more safely by me than all the maneuvering to run off the end of the downwind runway. Check your downwind landing distance in the POH or ForeFlight. At 10 kts, tailwind and typical takeoff weight my Acclaim requires 4200’. and 3000’ over a 50’ obstacle and for rollout respectively. This is probably a worst-case Mooney example, but it is eye opening. One artifact of the astounding climb rate offered by the 310HP Acclaim is the ability to out-climb the best glide sink rate by a big margin. We go up at 1200. FPM, and would come back down at about 800, making a return doable deep into a flight with an unrestricted climb, suitable runway availability notwithstanding. -Dan -

Maybe…. But they do permit 120KIAS climbs to the high teens with everything comfortably cool (below 375) even on the hottest days. I’m pretty sure the S22T’s aren’t good for much more than 700 FPM, at least basis hat I see on flightaware. Getting up out of the heat, clouds, ice, and bumps and into cool, clear air in just over half the time is big for me. -Dan

-