-

Posts

4,144 -

Joined

-

Last visited

-

Days Won

15

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Alan Fox

-

-

I have the stack tibes , to convert it

-

'69 M20C Panel Light Controller/Dimmer

Alan Fox replied to Cloudmirth's topic in Vintage Mooneys (pre-J models)

send me a pic of the unit -

Great job catalogging and photographing , BUT that downlock is SEVERELY worn , throw it in the trash..... Carry on...

-

Couple of things to consider Chris, they may have replaced more than this one piece , And the Job isn't finished yet....

-

I am mostly supervising an A&P on this one , I came in yesterday and it was on the floor....

-

-

Feedback Please - 2022 Mooney Summit VIII - Your Likes/Dislikes

Alan Fox replied to Rick Junkin's topic in Mooney Summit

Although the theatre venue , was interesting , It was not geared for our use.... Everything else was well done -

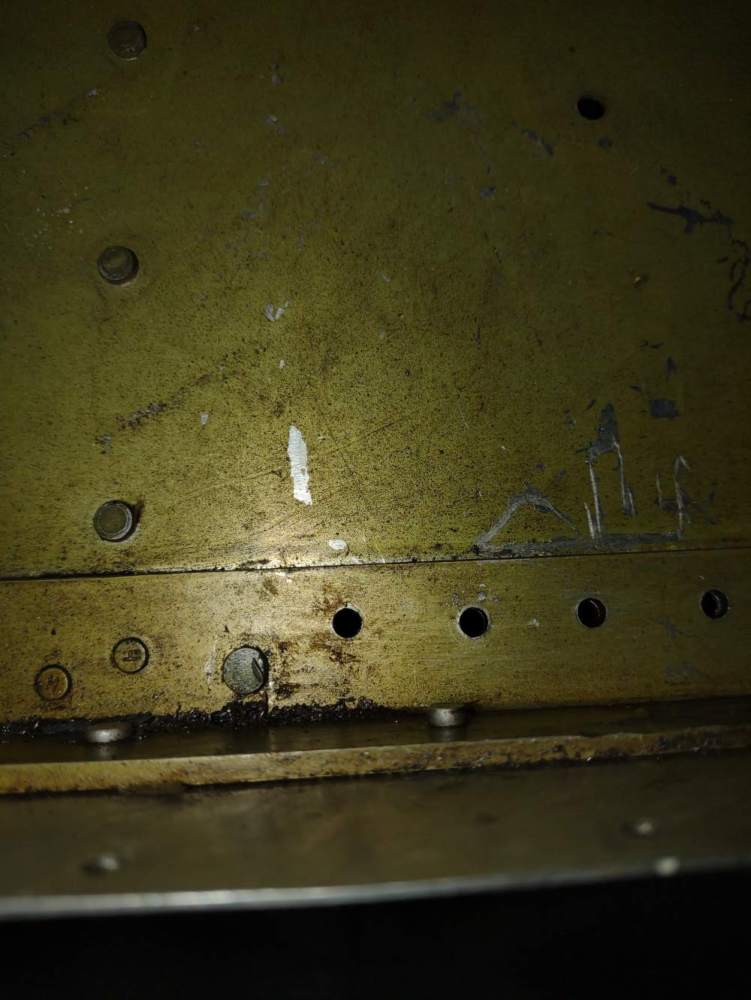

The empty holes are huck bolts , that have been removed , We have found it easier to drill and break off the heads , as opposed to splitting the collars , once the heads are broken off , they punch out with ease... You will see on that we ground out , but it took forever , and it was surprisingly easy , to drill into the hucks... A64Pilot , great Idea for making a drilling jig , out of aluminum stock , we werte going to cut the the bottom of the L channel off to match drill it , but your Idea , is better , as far as the skin goes , when the holes for the web side are done , we will bolt it in , and match drill the skin... As far as parts go , the corroded piece appears to be a 3/4 inch piece of 7075T6 angle , so no parts downtime....

-

Yes , also a large number of them are huck bolts , so will be easier than bucking , using HI-LOCS to replace them , Obviously the lowers rivet to the skin...

-

I am no stranger to the sawzall , But this looks like it can be done without deskinning the wing , I have seen Mathissien deskin and replace sparcaps on Erics plane , with the wing on the plane , Jigged to the floor with wooden sawhorses... Very impressive...

-

Taking on an interesting project .. Having to replace the left forward lower spar cap , It is a piece of aluminum angle , 3/4 x 3/4 by probably 1/8 thick , It is straight , and about 59 inches long .. We are going to replace it by deriveting it , removing two outboard ribs , and sliding it out (outboard and through an inspection panel ) , has anyone ever donr this job ? planning on about 60 hours work... Any advise or info would be great... No we are not sending it outside , we repair planes.... The corrosion is at the spot where the Steel splice plates are at the second lap joint , Seems to originate from the huck bolts....

-

I should be buying all 7 of the trusses !!

-

Gear compression springs. Two per plane

Alan Fox replied to hoot777's topic in Vintage Mooneys (pre-J models)

I can sell a set of un grounded for 300 (Springs) -

I should have them

-

It will mount all 3 servos , but only has the complete setup for the pitch , and Roll , The roll mounts in the wing , the other 2 mount in the emp... Yaw is a waste on a Mooney

-

Same thing with the j-bar slider… just keep it clean…

-

I have 4 servos and the elusive BI805 valve , These all have service tags from 2007 on them , very good condition , Valve is 450 , Servos are 100 each Phone works best 856 419 5209