-

Posts

4,785 -

Joined

-

Last visited

-

Days Won

39

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by cliffy

-

I basically said the same thing months ago. They are nothing more than a pimple on an elephants butt by comparison. Although IF they had good leadership in sales and marketing they could do a whole lot better than they do now even with the budget they have from coporate. There was much talk about once again claiming their heritage in GA markets with their reshuffle years ago AND much speculation on them falling on their face, But alas the postulation came true. Face Plant! I tried twice to open communication with their President and Head of Sales and got no answer at all. No response, no "thank you for asking" absolutely nothing in response. Their mantra of "listening to their customers" must have been written by someone other than an employee because they can't even acknowledge commination's. They all must go to a dead letter box neve to be seen by the recipient. Like I've said 3 times now- the money ain't in Mooney autopilots or small GA and they don't care. If they really wanted to certify the A/P it could/can be done with a push or two from outside the FAA (Ombudsman to say the least- I've done it and gotten a division of the FAA off of their butts and got the job done). There are ways to move recalcitrant divisions that are not doing their job IF YOU REALLY WANT THE JOB DONE! The money will be in drones for this division. You'll see us dropped like a hot potato as that market matures. They will never dramatically expand the small GA market for autopilots.

-

Who locks their controls like this?

cliffy replied to Derrickearly's topic in Vintage Mooneys (pre-J models)

That actually looks real good -

Who locks their controls like this?

cliffy replied to Derrickearly's topic in Vintage Mooneys (pre-J models)

Good point! -

There was/is a reason why their booth at Sun n Fun last year was mostly empty while Garmin and Dynon were swamped.

-

Damn sorry to hear of your loss BTDT

-

Who locks their controls like this?

cliffy replied to Derrickearly's topic in Vintage Mooneys (pre-J models)

Didn't the Army just leave a billion $$$ worth of equipment sitting the desert? :-) -

Paying omage to all things before :-)

-

I decided to go all new except the final backup comm which is my "old" TKM MX 11 I'm at Horton Aviation and they have been fine so far. I'm the guinea pig for their first Dynon install but looks to be going right as planned. There is another Utah airplane that might come in behind mine when I am done.

-

-

Heard the same story 3 years ago

-

Engine mount crack/swap in Utah

cliffy replied to SSimpson77's topic in Vintage Mooneys (pre-J models)

The actual changing of the mount you should be able to handle yourself (labor) Make sure you use replace the rubber mounts and torque them to the correct value I'll send you a PM -

Its the rudder system bungee (similar to the elevator bungees) that should be set for zero force when the rudder system is rigged with the copilot pedals blocked to even setting. It adds to the rudder/nose wheel centering force both on the ground and in flight Figure 6-5 in the maintenance manual.

-

I'm going to be a little facetious here by saying- I know we have many here with lots of flying time and me with 20,000+hrs, 6 jet type ratings, 60 years flying, 23 years in my M20D with 2300 hrs in same I don't do what I read here for T/O or landing. Question to self- "Would I land a Boeing by running the trim all the way aft so I don't have to pull on the yoke? NO! And an airplane is an airplane whether or not it weighs 2500 lbs or 250,000 lbs. Feet are used to keep the nose straight down the runway (with tires on the ground) IF the airplane has no mechanical problems. What ever happened to teaching the correct trim setting for landing on final? It works whether its a Boeing or a Mooney or even a lowly 172. Trim for final approach speed. I trim for a glide speed on final of about 75 MPH (wind and gusts and type of landing _short field) may adjust that speed a little but the trim is set for that. What ever happened to following the manual for proper T/O technique? If you do a short field T/O follow short field T/O procedures (I do one every once in a while for practice). If you are doing a normal T/O follow the manual. I find that if I have trimmed for 75 on final and I move my trim wheel down two pushes (maybe 1/2 a turn) before T/O that on T/O if I start to pull back at about 60-65 MPH the airplane lifts off cleanly at around 70 accelerates to 80 quickly (gear up) and then I trim a little as I accelerate to my climb speed and retract flaps. No chance of forgetting the trim position after landing and having a way out of trim situation on T/O (either UP or DOWN) If the trim reset is missed my way before T/O the airplane is still quite controllable at lift off near 75 MPH Its better if it is reset to 1/2 turn down. NOW this all holds true for my normal CG. If I put two in the back of course I have to compensate a little in trim to avoid an early rotation. NO different than a Heavy or light Boeing. Folks these are simple little airplanes They fly just like any other airplane has for ever. As Al Mooney said- "They all fly through the same air " Nothing complicated about them EXCEPT when we push them to areas they were not designed for.

-

Who locks their controls like this?

cliffy replied to Derrickearly's topic in Vintage Mooneys (pre-J models)

Compressing the elevator bungee springs constantly when the external gust lock is installed? I have to think about that one. -

Ideas Needed for Instrument Panel Labels

cliffy replied to cliffy's topic in Avionics/Panel Discussion

And the winner is? :-) After due deliberation on ALL of the good ideas I've decided to start with the Brother P-Touch idea first as I have only 2 "signs" with only 7 words between them to put on the panel. I go that way to see what it looks like and to keep in touch with my predetermined ideas about a new "affordable" all glass panel. With the way the panel is now designed should I want to change course I can have the panels out in 30 mins total to refurb both finish and lettering. -

As I mentioned before- The BIG money for BK is not in Mooneys Its drones!

-

Ideas Needed for Instrument Panel Labels

cliffy replied to cliffy's topic in Avionics/Panel Discussion

Will probably set the mockup panels in place this week to see how things look. -

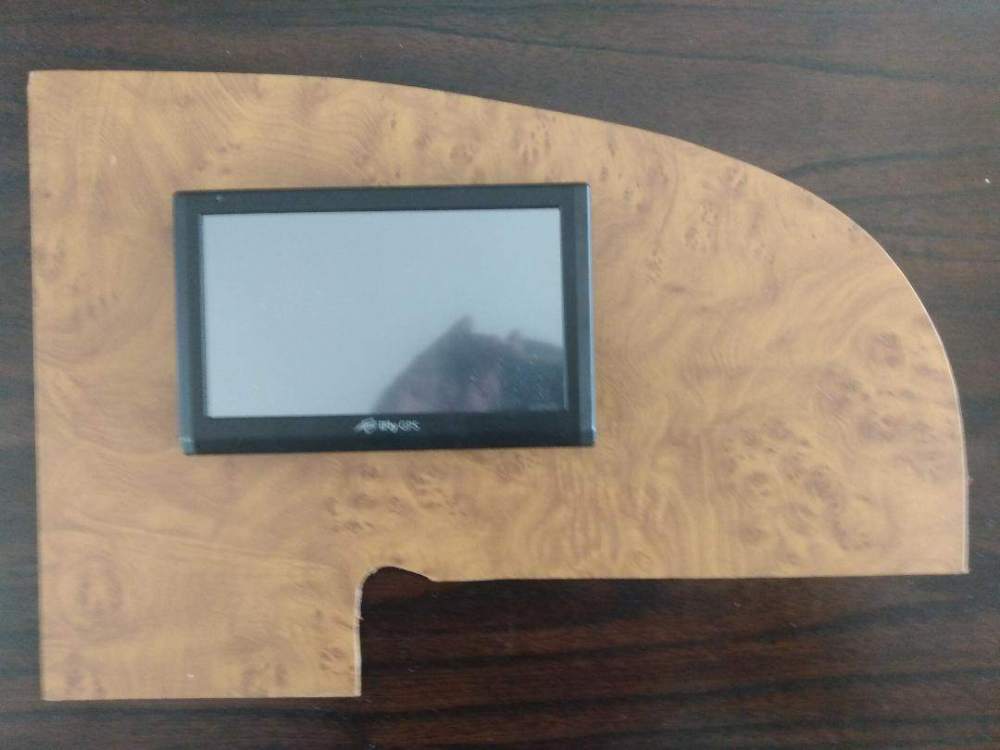

Panel mockup below First pic is mockup showing exactly what will be in the two panels What you see on the left side (except for the ign switch and 2 gear lites is all that will be there, On the right side is my wife's iFlyGPS tablet. THAT is all that will be there. Nothing else on the 2 panels In the center stack will be the audio panel and second com at the bottom and the comm control head for the Dynon comm top center of the radio stack I wanted the panel finish to mimic the instrument panel in my Rolls Royce so pic 4 shows the Rolls panel (birdseye maple veneer) Pictures 2 and 3 are a little closer look at the mockup panels and pic 4 is self explanatory Things are mov'n on :-)

-

Just remember there are 2 different clusters Thee is one with separate individual gages and the other with 6 in 1 that can't be separated. If you have the 6 individual cluster then the 2 fuel tank gages can be removed and overhauled without doing the entire 6 pac cluster. If you have the "all in one" cluster with the large Cannon plug on the back you can replace it with the sperate gage cluster by attaching it to the same Cannon plug. Its a direct replacement item.

-

Who locks their controls like this?

cliffy replied to Derrickearly's topic in Vintage Mooneys (pre-J models)

Control checks just before takeoff save lives I personally watched a 707 rotate for takeoff and then abort (WAY beyond V1), taxi back in and the Capt said the rudder locked up on T/O As the airplane came from the hangar after overnight maintenance that morning I went in the hell hole and checked for rudder rig pins and what did I find? Rudder rig pins still installed in the system. The rudder pedals never moved from the hangar to T/O and were never checked by the crew. I might add a comment on trimming full nose down and parking that way. There have been many (and 2 at Stockton) that have run off the far end of the runway while trying to T/O with full down nose trim. Might not be the best idea to use for control locks and besides, it wears out the trim mechanism. -

Ideas Needed for Instrument Panel Labels

cliffy replied to cliffy's topic in Avionics/Panel Discussion

Dang ! Lots of good ideas to sift through THANKS! But now I have a headache thinking about all of it :-) My panel design philosophy- (for this project anyway) This is to be a "bottom line price" project for a complete paradigm shift in panel technology in a vintage airframe in an effort to keep these vintage airframes relevant to an ever advancing world of aviation. Affordable to the "average" owner (if there is such an owner) vs total airframe value. What is the bane of all of small GA? What keeps values down and keeps some airplanes as airport derelicts? DEFERRED MAINTENANCE! And what do we see in most every antique airplane out there (and YES our Mooneys are antiques, OK)? MOST all vintage airplanes have a few or many panel instruments and/or radios that don't work properly or at all. Be honest - how many small GA airplanes have you been in or owned where EVERYTHING in the cockpit worked as it should? My thoughts have always been that we can keep the basic airframe in tip top shape mechanically but we are constrained by the 75 year old technology on the instrument panel. One only has to look at the Sport plane market to see the "new technology" and it application to efficiency and safety. Thoreau once said, "Simplify, simplify, simplify" He had the right idea. The more you can simplify the less you have to break on the panel. Complication brings headaches with reliability and usability. When "glass" first came out it was heralded as the end all to SIMPLIFY and lower the pilot's work load in flight. It seems it has done just the opposite. How many buttons do you now have to memorize their functions of to operate the TVs in your cockpit? Buttonology is the new name now. Where we had a simple ILS (most were almost identical), a simple NDB procedure and a simple VOR approach we now have a plethora of different approaches all with differing formulations to try to decipher in flight by "armature" pilots (NOT disparaging PPs, just stating facts that they do not do this IFR flying stuff on or in a professional frame work of every day occurrence and training). Different levels of capability yet the same complexity of the system and cockpit design philosophy. We now look at our panels and want to emulate a 787 with 5 or 6 TV screens and more info displayed than a full crew could assimilate in a short period of time. For the average non-professional pilot flying doesn't have to be complicated. Now with the new technology the panel doesn't need to be complicated and still retain full usability. We fly because we want to be in the air looking out the windows at the world going by below NOT having to spend every minute staring at TV screens trying to decipher what they are all conveying. If an owner wants to hang all the shiny objects on the panel so be it but no one seems to want to go or talk about the other direction- Simple and full usability can go hand in hand. SIMPLIFY. SIMPLIFY. SIMPLIFY. That's what this project is all about- simplify and keep costs to the bare minimum yet move into a new paradigm for vintage airplane instrument panels. No mix and match, No half way measures. Just a complete shift to new technology using the old adage- KISS- Keep it simple Stupid! (And keep the costs down). More to come in this saga :-) -

Ideas Needed for Instrument Panel Labels

cliffy replied to cliffy's topic in Avionics/Panel Discussion

Color in bright sun I can see could be an issue Had plastic plaques on the old panel (brown with white engraved letters) pTouch I don't know about but will look into Hadn't thought about silk screen That's one idea Any more ideas floating around out there? -

Need some input on what/how to use for making the instrument panel labels for switches and C/Bs and required placards Many engrave the words but what are some other ideas? Vinyl labels custom made? NO Dymo labels allowed :-) Engraved plastic plaques? Ideas needed please Think outside the box as the panel surface may be outside the box also.

-

IFR is only a guarantee for IFR traffic separation No guarantee for separation from VFR traffic. ;The vast majority of LA Basin traffic operates VFR If it was so dangerous we'd have mid-airs every day.

-

If I'm going VCV to SNA I talk to Socal If I'm going SGU to VCV I may or may not talk to LAS as going over above the Class B right over the airport doesn't get in anyones way, same as does right over LAX southbound or the VFR corridor (of which I had a hand in its inception). Many times we as GA get shuttled WAY out of the way just to clear airspace that is usable to all by looking out the window (and with ADSB its even easier). East of LAX (RIV area) sure they all come down from on high to below 10K to enter the Class B but that doesn't mean that that airspace can't be effectively and safely used going VFR nordo. Many times I've been run all the way around ABQs airspace clear out side of the boundaries trying to cross through. Some places make the transition easy and effective and some for what ever reason treat it like Restricted airspace. Just depends on where I'm at and the treatment I have been involved in. Most of the time LAS makes it simple even going through at 8500/7500 feet. Most of the time Socal works VCV to SNA When it starts to get obsequious I look at other options. One can still fly Florida to New Mexico VFR nordo safely as I have done a couple of times.