bcg

Supporter-

Posts

737 -

Joined

-

Last visited

-

Days Won

5

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by bcg

-

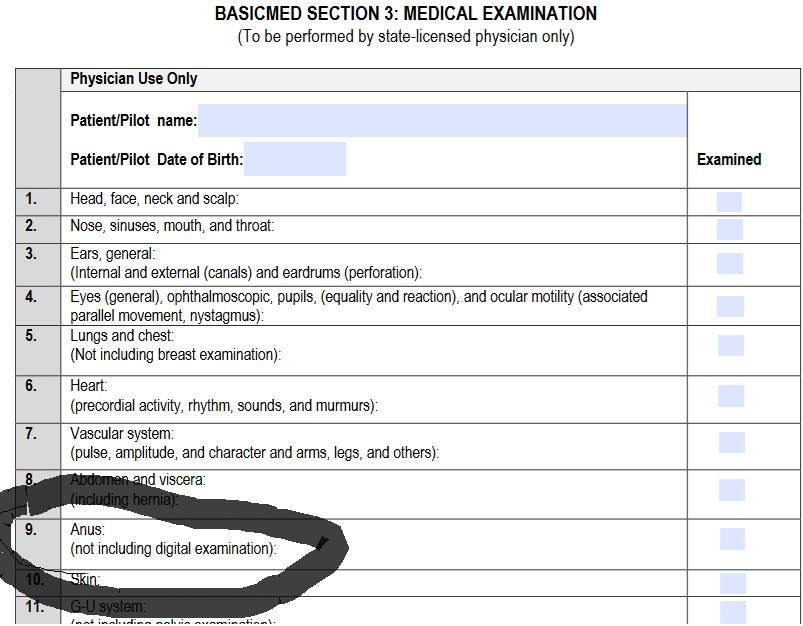

It's about time to renew my medical and I'm thinking about maybe just going BasicMed because it covers everything I have done, although I would like to fly to the Caribbean at some point and it won't work for that. Anyway, I'm reading through the physician check list and I come across #9.... Seriously? The FAA want's the doc to examine our butt hole? What? Surely I'm missing something here.... I guess we should just be glad they don't have to examine it "digitally."

-

I was doing my avionics work when you came last year. I remember that nice paint job.

-

I'm at KERV, you can't go wrong with David, JD and Ryan. David is a wealth of Mooney knowledge. Tell them Bernie says hello.

-

I got a chance to really run the bilge blower with the AC today and found an issue. If I run the blower at full and the AC reduces it's internal fan speed, the airflow from the blower causes the internal fan to run faster than expected and the AC gives me a "Front fan speed unexpected" message, or something very similar to that, and shuts down. I have to remove all power from it and start it back up to clear the error. It seems that if I run the blower at 1/2 speed, which is still a lot more air movement than the internal fan, then I don't have this problem so I'm going to limit it to that for now. There's probably some way to disable or override that speed sensor in the AC and I may open it up and poke around to see what I can do there later. Anyway, if anyone else is going to put the blower in their duct line like I did, make sure you have a rheostat on it so you can control the speed and avoid this issue.

-

Thought question about AC 23-27 & 3D printers

bcg replied to Nstarbf's topic in Vintage Mooneys (pre-J models)

I agree, a machine shop could knock that out pretty quickly and it would probably cost less than Lasar wants for it. -

The work involved was far, far more than I expected. Had I known what was going to be required, I'm not sure I would have tackled it. I committed to it thought, so I stuck with it until it was right, there are still a few little things I wish I could get better but FDM printing has it's limitations so I've done the best I can with it and produced a part that at least looks better than what's coming out of the plane. I wanted to replace the placard for my fuel selector at annual and got the stickers to do it. Then I started the project and said never mind, the turn handle is firmly attached to the valve and it isn't bad enough for me to risk damaging anything getting it removed. If the valve ever needs to be rebuilt, I'll deal with it then. The flange at the top wouldn't be too had to make though, mine is still in pretty good shape but I can see how that would get damaged over time.

-

About 20 pounds. I have sold them to people with Missiles, Rockets and Ovations. It's worked on all of them. The production version is longer than the one I built for my C. Sent from my Pixel 6a using Tapatalk

-

I'm all caught up on orders so if you need a powered tow bar that's portable, let me know. For those wondering why it's $650 now instead of the original $500, my materials costs have increased. I bought up all the available inventory of motors and wheels at the original lower price I found them at and am now having to pay double what I was for them. I also made a change to the chain used to drive the wheel and that necessitated having a sprocket for the wheel custom made from chromoly steel. Those 2 things make up the $150 price increase. I actually lost money on the last few I sold at $500, I'd already accepted the orders at that price though, so I ate it. That's just the way it goes sometimes. https://mooneymover.com/product/powered-tow-bar/

-

These things have taken some abuse over the years and a lot of them are looking pretty bad. I saw a post on FB where a guy was looking for one for his 62 B and I offered to print him one thinking it would be no big deal. Boy was I wrong, the design was a piece of cake but getting it to print correctly has taken me all week and probably a dozen failed parts. I finally got it figured out though. I'm going to run his one more time to reduce the bleed through of the black on the face, the tan filament isn't as opaque as I'd like and there are a few spots where the bleed through is pretty bad. If anyone else is in need of one, let me know. He's paying $100 for this one and honestly, for what it takes to produce one, that's a steal. Even with it all worked out this is a full day print and then another hour or so to get it cleaned up and sanded down. I'm offering it more to help keep our antique birds looking nice than anything else, I don't think anyone else offers this part and the used ones don't look that great. I've got a few color options if you want one. https://mooneymover.com/product/mooney-manual-crank-step-handle-trim/ I'm working on the little handles for the eyeball vent and overhead lights right now. I had one fall apart last year and the other one fell off on a recent trip and I can't find it anywhere so I need those. My overhead plastic around the vents is looking pretty rough also so, that'll be next.

-

Search KDWH in the group and it's the first post, or was for me. There are a lot of comments in it but, the video was pretty close to the top. I can't get a link for it or I'd share.

-

That's the one I saw, you can hear it, nothing more. It's VROOOMMM, crash noises.

-

Anyone have any details about this? I saw this picture this morning and heard the crash on a hangar surveillance video, you hear it go full throttle and then hear the crash. Hopefully everyone made it out OK and damage is minimal.

-

I know a guy that could probably do it if insurance doesn't require a Mooney CFI/CFII. He's got time in JetProps, Beechcraft and other high performance aircraft, he's more than capable of it. I've flown with him and he's a good pilot and not terrible company.

-

I like to climb and maintain 50 or less. Air flow in the C isn't near as good as the later models though. I used a B-Kool for a couple of years and it worked well if your expectations are realistic. I tinted the windows on my plane and that helped it significantly. In the cooler, I use frozen water bottles of freezer packs, preferably from a deep freezer that'll reach -10F. The solid ice like that lasts a lot longer than cubed ice, the air isn't as cold coming out but, I don't need it 30° to be comfortable, 50° is just fine when you blow it right on you. That gives me 2-3 hours of cooling from it, which is enough for ground ops, takeoff/climb and descent/landing, even if ATC brings me down earlier than I'd like. Sent from my Pixel 6a using Tapatalk

-

Recommendations on a pre-Mooney first plane?

bcg replied to BlueSky247's topic in General Mooney Talk

That's interesting, Avemco was happy to quote me last year with 150 hours and a PPL. Granted, 130 of those hours were in the Mooney but, they still weren't anywhere near 700 PIC. I took a different route and just paid cash for my C and flew it uninsured until I got my private, then carried liability only for a year while finishing my instrument. It's only been 10 days now that I've had full coverage on it and my insurance this year with 350 hours, instrument rating and about 320 hours in the Mooney was right around $2600. I didn't think that was terrible. I'm only carrying $100k for the hull though, I'm sure it would be higher if I was flying an Ovation. Sent from my Pixel 6a using Tapatalk -

Another reason it was the last test print... Sent from my Pixel 6a using Tapatalk

-

If you can't get it worked out, I can help you. I recently made a new step crank trim plate for a guy with a B. Picture is the last test print, I fixed the arrows and cleaned up the curves for the final. I have a filament changer on my printer so I can put any placards in as it prints instead of having to add it afterwards. Sent from my Pixel 6a using Tapatalk

-

What happened to owners maintaining their planes?

bcg replied to NewMoon's topic in General Mooney Talk

If you're who I think you are, given all the issues you've had, you're doing great to have averaged 10 hours a month. Sent from my Pixel 6a using Tapatalk -

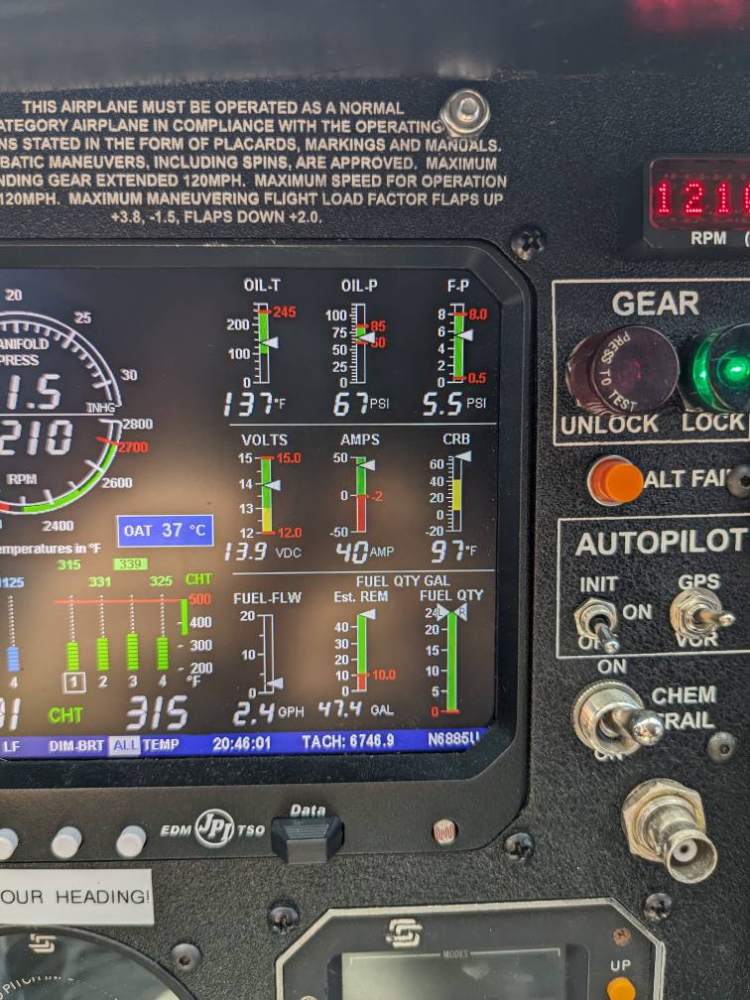

I messed around with some ideas today to see if they were going to work. First was using an old antenna hole to route a condensate drain out so I wouldn't have the condensate being evaporated into the cabin. I also hooked up the 270CFM blower motor in the vent and while it definitely increased the output temp a few degrees, it made the overall cabin feel cooler. I think once I get the vents worked out, the blower will be really nice. The biggest thing though is that I tried connecting a 12v to 48v step up transformer in for charging and got the input very close to what the AC uses on Max, which should make it so we can run it non-stop. The downside is that it draws 40A so I'm going to have to run some larger wires for it. I'll do that at annual and live with the 100W charging from straight 12v for now. My daughter and I are heading to Colorado this weekend, I'm looking forward to seeing how this works in flight. Sent from my Pixel 6a using Tapatalk

-

I could be wrong but, I don't think you need a DER for an OPP. I think OPP is fine as long as it is functionally equivalent to the part it's replacing. If I needed some unobtanium part to get my plane back in the air, I would absolutely OPP it. No individual parts in these airplanes is all that complicated to manufacture. It might be expensive as a one off but, it's better than a plane that can't fly. So yeah, I agree, the only thing stopping any part from being made is money. The 5th and most important force of flight.

-

Oshkosh 2024: Advice for a first timer?

bcg replied to BlueSky247's topic in Miscellaneous Aviation Talk

Be prepared to walk A LOT, I mean really a lot. I went last year and averaged 8+ miles per day. Even being there all week, I didn't see it all so don't expect to it's much bigger than you realize, the scale can't really be described. If there's any way you can get a bike or a scooter to use there, do it. -

LOL, I think they all would... I definitely would have a lot of wire lying on the floor of my cabin.

-

Just in general on zip ties, get yourself a pair of flush cutters to cut the tag end off. Regular diagonal cutters leave a very sharp end sticking out, I've been cut by a lot of them over the years. These are cheap and work really well. https://www.amazon.com/gp/product/B087P191LP I have a pair that are only ever used on zip ties and other plastic. I've found that if you use them on other stuff they deform a little and don't cut as flush anymore.

-

I think this turned out pretty clean. I've got a round cover plate that will screw onto the inside piece to cover the hole up when I take the AC out. I'm still working on the plenum and ducts. My daughter and I are going to Durango for Father's Day though, so I wanted to get it into the plane for the trip, we'll just use the included hose this time. Sent from my Pixel 6a using Tapatalk

-

I'm still waiting on my battery because the first on got lost in shipping. In the meantime, I think I've worked out how I'm going to get the hose through the baggage compartment bulkhead. I'm going to make a piece that's flat in the baggage compartment and protrudes into the empennage that the exhaust hose can be pulled through. In the empennage, I'll have a backer plate that's got 4 holes in it threaded for #8 course wood screws so you can just screw the pieces together instead of through bolting them. This will allow one person to install this alone from the baggage compartment by reaching through the exhaust hose hole and holding the backing plate in place. Then just to make it easy, I'm going to make a cover plate that will screw directly into the piece inside the baggage compartment so when you pull the AC out, you can easily close the hole up. First picture shows all 3 pieces together, next 2 show the penetration and the backer plate. Now I've got to figure out a plenum and vent solution that will be unobtrusive.