redbaron1982

Verified Member-

Posts

871 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by redbaron1982

-

My last item on the checklist before boarding is "Final walk around". Having said that, the main challenge is being "present" while doing the final walk around. It happened a couple of times that I did it on "autopilot" and could have missed one or two things. So far, knock on wood, I never took off with a red sign hanging from the airplane.

-

How y'all preflight the fuel tank vents? I usually just look to see that there is nothing clogging them at the tip, but doesn't make me feel good that there could be a bug or something that crawl inside and I can't see. I thought about using a small bulb syringe, not to blow buck suck air and check that there is good air flow. Not sure if this would generate any unwanted side effects.

-

M20E Emergency Landing west Houston

redbaron1982 replied to redbaron1982's topic in Mooney Safety & Accident Discussion

Yeah, looks like he was fixated to returning to IWS... 11R was closer and he would have made the field. 11R has a nice asphalt runway, I landed there several times while doing my training. Anyway, it is easy to find the best course of action when seating in a chair in front of a computer, lol. Great job by the pilot! -

M20E Emergency Landing west Houston

redbaron1982 replied to redbaron1982's topic in Mooney Safety & Accident Discussion

https://aviation-safety.net/wikibase/562249 -

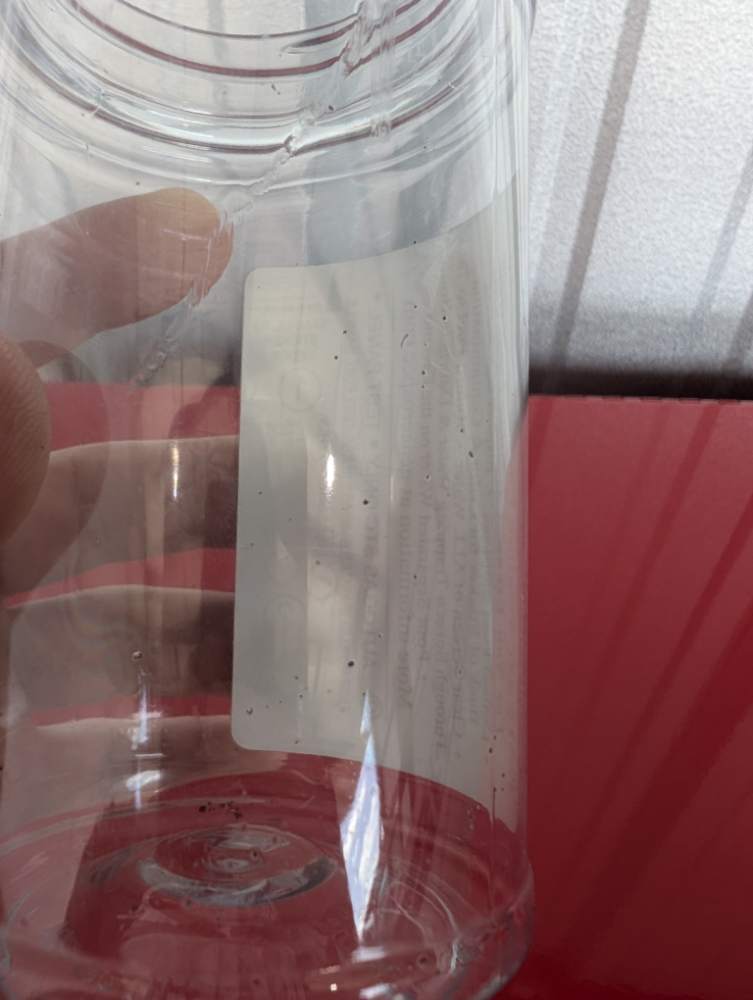

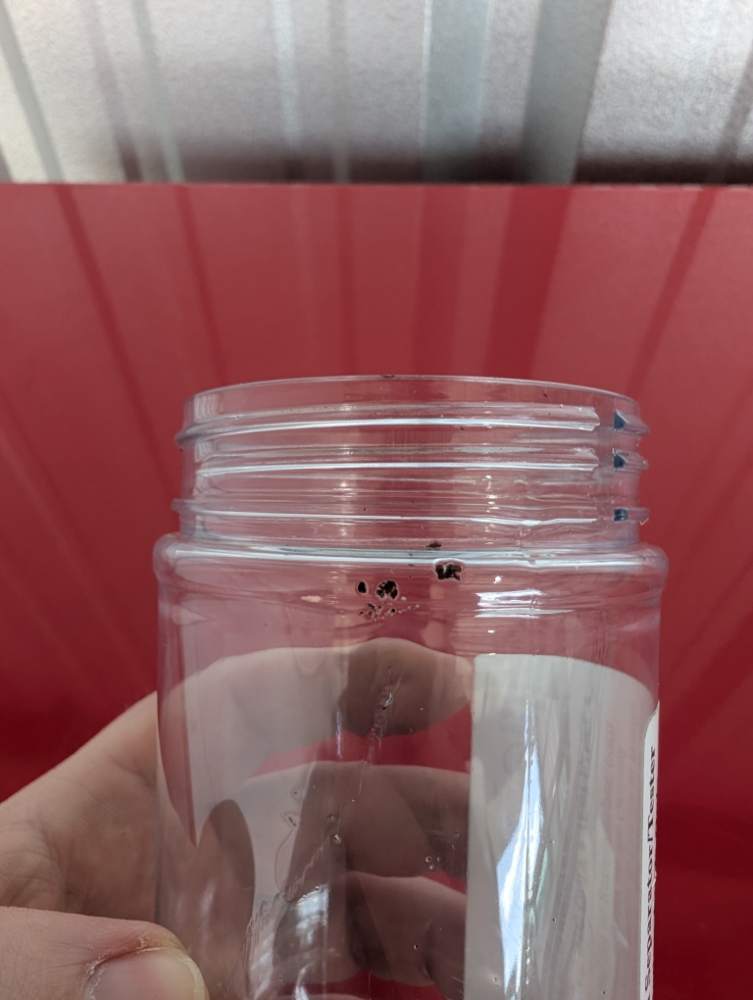

Thanks all for the answers, one clarification, just in case, the first pictures are really zoomed in. I'd say the large particles are maybe 1mm or 2mm at most.

-

The main reason why I am starting this thread is the tragic accident of @Freddb34. Every now and then, when I swamp my tanks I get some amount of debris. The attached pictures are from today. It's not always there, today's was more on the high amount of debris for instance, most of the times is lower or none at all. My question is, is this normal? Should I take any actions? My airplane is a J model from 1985, no bladders, tanks seal several years. No seapage, more than one of the sump ports getting stained from a veeery slow leak.

-

Thread about corrosion gone?

redbaron1982 replied to redbaron1982's topic in Vintage Mooneys (pre-J models)

It did affect me a bunch, but I didn't let it knock me off my horse. -

Thread about corrosion gone?

redbaron1982 replied to redbaron1982's topic in Vintage Mooneys (pre-J models)

I stand corrected, the repairs were 28k, there was an additional 2.5k for painting the repaired areas. The annual itself (no repairs) was 3k. Then there were 6k of random items, like a wheelen power supply they had to change. -

Thread about corrosion gone?

redbaron1982 replied to redbaron1982's topic in Vintage Mooneys (pre-J models)

So, as the airplane was so long waiting to be repaired, the annual lapsed. So I asked Don to do the annual after the finished the repair. Roughly, the cost was: 25k corrosion repair, 12k annual. The initial estimate for just the corrosion repair was 13k. -

Thread about corrosion gone?

redbaron1982 replied to redbaron1982's topic in Vintage Mooneys (pre-J models)

He did reach out to me, I shared the facts. For transparency, these were my responses to him: > In a nutshell? It took 1yr to do the repair and it cost 2x the initial estimate. I can give you more precise numbers, as the invoice was 3x the initial estimate, but it included a annual inspection as well. He was not very responsive either (although I was not the type of customer calling him every week). He sometimes seemed upset by me calling. > On the flip side, the airplane flies perfect, no issues in the last 3 years since I got it back. > I just checked my invoice, and the corrosion item was 25.5k, I think their initial estimate was 13k. > My corrosion was on the LH aft stub spar cap. They ended up replacing the whole stub spar, not just the cap. -

Thread about corrosion gone?

redbaron1982 replied to redbaron1982's topic in Vintage Mooneys (pre-J models)

That's news to me! Thanks for sharing. -

Thread about corrosion gone?

redbaron1982 replied to redbaron1982's topic in Vintage Mooneys (pre-J models)

Curious about this, is there any way an insurance company could cover this? -

Thread about corrosion gone?

redbaron1982 replied to redbaron1982's topic in Vintage Mooneys (pre-J models)

We need a system to track the history of airplanes, I guess it would be of great value for buyers... -

Thread about corrosion gone?

redbaron1982 replied to redbaron1982's topic in Vintage Mooneys (pre-J models)

I hope he is not planning to "hide" the corrosion (and any evidence of it) and put it for sale... -

I was mentioned on a thread about corrosion and when I tried to go check it out it seems to be gone. Any idea what happened?

-

M20L down in Argentina.

redbaron1982 replied to Mooney in Oz's topic in Mooney Safety & Accident Discussion

Aside of the 1980's market downturn, that most likely killed the PFM 3200, does anyone have first hand or reliable information on how well (or bad) the engine would perform? I mean performance, maintainability, dispatch rate, etc. -

Corrosion in Tail. What to do about it?

redbaron1982 replied to LinvilleMooney's topic in General Mooney Talk

I had some surface rust in my steel cage in the belly, and used Zinc Chromate Primer. I know is nasty from health / environment, but also I think is one of the best rust preventing primers. -

M20J IO360-A3B6D Engine stumbles

redbaron1982 replied to redbaron1982's topic in General Mooney Talk

What I feel is like a sudden, short, desceleration. The airplane doesn't shake much. It something that last 1 second. If I have to describe is like if the engine would shutdown for 1 second and then relight again. I've never seen water in the fuel, the airport where I fuel has a pretty good record of not having water in the fuel. The airplane is hangared all the time. As far as I can remember, it never missed a beat running ROP. This time for instance, the leanest cylinder was 75F LOP, while the rest were all around were between 30F and 50F LOP. If it is a random thing result of running LOP I would be ok, my main concern is if there is something else going on that might end up with a loss of power in flight. One additional peace of information, not sure if it is relevant, I'm a relatively "new" Mooney driver, the mixture control "lags", what I mean is if lean the mixture, say 1/2 turn, it would take maybe 10s for the fuel flow to stabilize in the new value. This happens either leaning or enriching the mixture. Not sure if this is normal or not. Some times I would make a full turn without seeing any change in FF, and then after several seconds the flow would start moving to the new setting. -

M20J IO360-A3B6D Engine stumbles

redbaron1982 replied to redbaron1982's topic in General Mooney Talk

It does not. I haven't noticed any backfire ever. -

M20J IO360-A3B6D Engine stumbles

redbaron1982 replied to redbaron1982's topic in General Mooney Talk

I don't see anything really telling by looking at the EGTs. Around on of the misfires there is some change in the #3 EGT, but I'm not sure. Can a nozzle act up like this? The engine runs fine just except this stumbles every now and then. The GAMI spread is 0.4GPH. Would there be other symptons for a sticking valve? The magneto was IRAN 100 hours or so ago, and 20 hours ago it was taken to Aero Accessories at Van Nuys, they bench tested and said it was perfect and was not worth tearing it appart. -

Hi, I have a recurring issue (say 1 out of every 3 flights) when in cruise the engine stumbles (misses a beat). It is noticeable. Maybe in a 1hr flight it happens 1 o 2 times. Always while in cruise. My last flight, yesterday, it did it 3 times. This is my flight data from yesterday: https://apps.savvyaviation.com/flights/shared/flight/10152924/66425963-23ae-401f-8ad9-abe3f3d3e8c0 One of the stumbles happened while I was leaning the mixture to get a new measure of my GAMI spread. I did a mag check while still LOP and the engine run smoothly on each mag. I asked Savvy a couple of times, and nothing conclusive yet. I opened a new ticket today, but I'd like to see if you guys have any thought.

-

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

redbaron1982 replied to cliffy's topic in General Mooney Talk

As I read this post, two thoughts came to my mind: Why would a relative large company like Lasar use ChatGPT (or a similar LLM) to craft the post? Don't they have people that can write a genuine letter to its customers? You can tell that this was generated by AI because of the "—" or the " instead of the ”. When I had the corrosion issue on my first annual inspection, Maxwell ordered a new aft stub spar from Mooney. What Maxwell charged me for the spar was ~4.6k, and labor was ~20k. I assume that Maxwell adds a markup to the parts, so most likely Mooney price was lower. It surprised me how "cheap" the part was, even more considering that it was backorderd and Mooney had to manufacture a new one. Talking with Patty from Mooney I know that they did a batch and they had a few bad parts that they had to scrap. So I'm quite sure the spar was priced below cost. -

I wonder if an "advisory" FADEC would be a first easy step based on NORSEE, monitoring all variables (rpm, crankshaft position, knocking sensor, cht, eht, fuel flow, mp, etc) and provide, for the current power requirement, ideal FF, RPM, MP. It would be up to the pilot to move the knobs, and for sure ignition advance would not be part of this... but maybe is a way to get the ball rolling...