-

Posts

1,186 -

Joined

-

Last visited

-

Days Won

10

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Marc_B

-

The wing site gauges were designed to read accurate on the ground on the landing gear (nose pitch up) so in flight aren’t accurate. So I don’t think it’s considered a primary fuel gauge and isn’t required equipment.

-

Does the paintbrush always point to “full” or always on “empty”? …or maybe just halfway!

-

First, for a 2 person IFR traveling single engine piston, a Mooney can’t be beat. For terrain and weather climbing ability a turbo Money is pretty awesome. For a lot of us, the M20K 252/Encore is the sweet spot in terms of speed and fuel efficiency. A Bravo, Acclaim, or Rocket conversion is faster but not necessarily better useful load especially when you factor in more fuel burn. A TKS Mooney can also increase your dispatch rate and may get you through a layer but none of the single engine pistons are true ice machines so should be flown in ice with caution regardless if FIKI certified. From a useful load perspective, the 252 Encore conversion is a sweet spot given 3130 max gross but a little lighter empty weight than the factory Encore that had better insulation, interior and cosmetics overall. For me, the M20K Encore is my jam. Next step up for me would come with an extra $1M or so buy-in.

-

Out of curiosity @donkaye, do you know if your Bravo has any nitrile or Buna N fuel system components or fuel hose assemblies that that aren't Teflon lined? I haven't a clue and more importantly I'm not entirely sure if that matters or not?? The unfortunate issue is that it's well established that G100UL stains paint even with minor spills, drips or even an absorbant mat used for fueling another aircraft (and may damage paint in some cases). I think that a sizeable apprehension with the fuel isn't how it runs in the engine (so far data shared by GAMI suggests it performs well in that regard and most field reports suggest indistinguishable) but how do we prevent it from "running" anywhere else. Are nitrile components a real concern? Because I'm pretty sure there are some in our Mooneys. The back and forth and speculation comes from the vague G100UL ICA, field reports with a few issues, and Mr. Braly's response: not that you're not going to have issue with nitrile, but rather "you don't need to 'change' anything if you follow 'modern' recommendations." But at the same time he is very clear in recommending Viton and teflon-lined hoses and very skeptical of wet wings...leaves a lot up to speculation. Of course it also doesn't help anything that Swift alleges that the aromatic amines in G100UL are unsafe for our fuel system. Braly/GAMI alleges that ETBE and metals in other fuels are unsafe for our fuel system. PAFI/EAGLE is taking a long time. Yet the political pressures that keep this moving seem to escalate. In all fairness, I don't think this is quite like an avionics discussion...but even then, we have oodles of threads on Avidyne, Dynon, Garmin, choices of autopilots, and "what plays well together and what doesn't." As a final confounder, time off around the holidays also makes it easy to read up, take a story and head WAY down the rabbit hole! Here's to a Happy New Year, Don! Hopefully one full of good Mooney adventures and way more time in the air than on our computers and Mooneyspace!! (my new years resolution will be to stop posting about this )

-

@Doug G If your aircraft has original sealant, you're overdue for a reseal. But if you do get it resealed, most on Mooneyspace recommend specialty shops such as WeepNoMore in MN, or WetWingologists in FL. Those shops have refined their technique to a science and an art and stand behind their work with a warranty. Worth the cost and wait. You might as well replace the fuel sumps at the same time as a reseal (I'm not sure if the o-rings in these are field serviceable). For me, I'd rather have 55# fuel rather than 55# of rubber. If you hangar and keep fuel in the tank your tank sealant can last 20 years+. If you're tied down and you have heating and cooling regularly, it's rough on tanks and bladders alike.

-

I think it all depends on the age of the original sealant. Problem with patching is trying to find the leak, remove bad material and prep, and then patch. If more sealant is placed over old sealant then when that material contracts sometimes it puts more tension on the bad sealant and makes a leak worse. But you can't beat the efficiency of a wet wing...with a bladder you give up fuel capacity and give up useful load. And bladder material also has a finite lifespan as well. Most estimates I've seen say a bladder should last 20+ years...which is similar to well applied sealant that is care for by hangar/leaving fuel in the tank. So the big question is the overall condition and age of your sealant. By the time you hit 25-30 years, it's probably a good time to start thinking of a reseal if you develop significant leaks. There are a few shops who take the time to locate leaks, and prep/patch correctly. But in the hands of someone not experienced, you may kick the can down the road to more issues in the future and given it's more labor than product you typically spend at least an AMU or so for patch work.

-

G100UL paint testing by YouTuber mluvara

Marc_B replied to Shiroyuki's topic in Modern Mooney Discussion

I think that M20A, B, C, D, and G? may be on the AML for UL94. Not sure details. -

Based on the G100UL fuel leak thread what's your position?

Marc_B replied to gabez's topic in General Mooney Talk

Let me be more clear. What o-rings, hoses, tank sealant were tested. What was the ages of the products tested? What paint brands were tested for damage or staining. Was damaged paint with chips and scratches tested on each? What surface preps were tested to attempt to prevent staining and how well did they work. Was it tested for cycling between 100LL back and forth with G100UL and cycling aromatics can have effects on elastomers. Given ICA recommendations aren’t clear statement one way or the other and Mr Braly recommends “best practice” to prevent need for “change”…this leaves a LOT up for interpretation. But if an owner or A&P had a better understanding of the exact testing performed, a lot of the speculation could be cleared up. I don't want the formula, but how much aromatic content vs 100LL would be informative. Mr. Braly doesn’t mind posting a detailed hydrocarbon analysis for 100LL sample, but doesn’t share even generalities of 100UL. Eventually someone will post this. Why the secrecy? -

I think the sticky point is that 1) there's a possibility that G100UL affects sealant and elastomers similar to 100LL, 2) possibility that effects are more than 100LL due to a higher total aromatic concentration. But I think that it's likely that a) G100UL may have different effect on elastomers such as Nitrile and b) that higher amounts of nitrile material may be found in older airframes, coupled with the fact that nitrile elastomers have a shorter service life than fluorosilicone/viton. So the ambiguity is that the evidence of deterioration in general is leaking and the confounder is whether it's the age of the sealant/o-ring/elastomer vs. the effects of G100UL. It also could be that old sealant and nitrile are just more sensitive to a higher aromatic fuel, or it's just old and needs to be replaced. But this will require more data and pointed studies from GAMI to help clarify which materials and product age are problematic. Otherwise you could point to either the age/quality of the product or the affect of the fuel and you'd probably both be right. This is why I feel that more clear instructions in an ICA would be helpful. But it's certainly possible we just don't have that data yet and current recommendations are about the most we know for now.

-

-

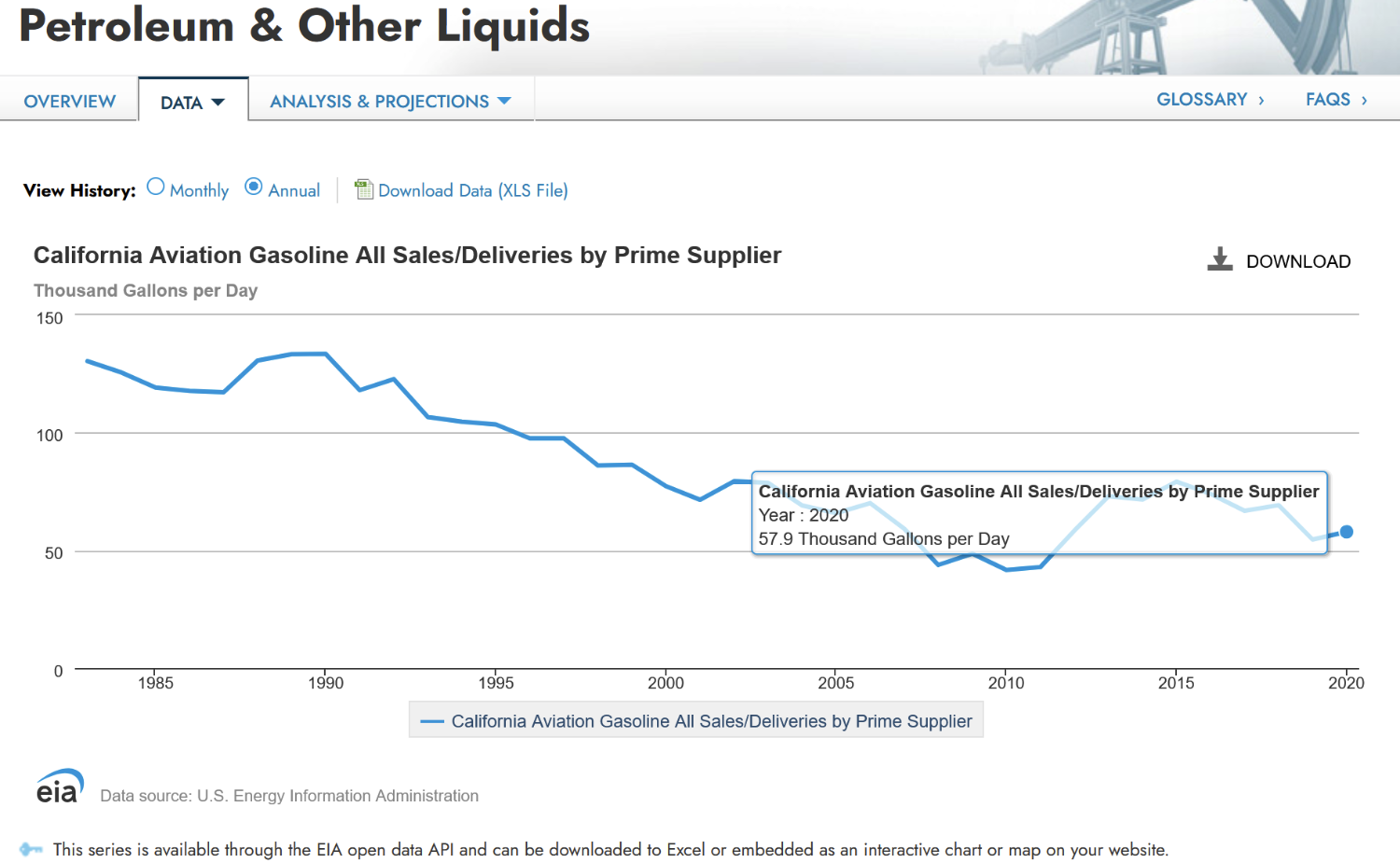

@Justin Schmidt The basic chess in California: The four major distributors of aviation fuel in California are Avfuel, World Fuel, TITAN, and EPIC. GAMI is working with Vitol to mix ~1 million gallons of G100UL. California's use of 100LL annually is ____ gallons per year (edit: I'm not sure...see post below) Previous Consent Judgement from 2014 with 26 FBOs (9 of which are now out of business or sold) originally was based on not having proper signage that 100LL could cause cancer in the state of California. Before final judgment, they added language about moving to unleaded fuel when it was "commercially available" but didn't completely spell out what that meant. Commercially Available definition being pushed is that an unleaded fuel "is commercially available" when an FBO can call Distributor (Vitol) and order Unleaded AvGas (G100UL) and have it delivered. I believe this will go in front of the court early this coming year. If the court finds in favor of CEH, then 100LL would be banned from distributors at risk of fines spelled out in the decree. https://www.avweb.com/aviation-news/g100ul-court-action/

-

@Justin Schmidt https://www.congress.gov/117/meeting/house/115056/witnesses/HHRG-117-GO28-Wstate-BralyG-20220728.pdf https://www.avweb.com/aviation-news/environmental-group-says-california-fbos-will-be-able-to-continue-selling-100ll/ Edit: It's a business move and not unexpected. We're moving towards an unleaded future and GAMI is helping to make that happen sooner than the PAFI/EAGLE Program. So of course they are proponents of ending lead...but that's just smart business for GAMI.

-

I just hate the lawyer speak of no "change" needed if you follow "best practices." Shouldn't the company that performed testing over 14 years with a new product on the market be the best and ideal one to tell owners what the best practice is with their fuel?? I can't tell if Mr. Braly really thinks that all of the issues shown recently are fabrication and untrue, or if he just feels that Mooneys leak, that's what they all do, so nothing to see here. I started to cut and paste his responses but wasn't sure if 1) this was ok with both MS and BT, and 2) I wasn't sure what to link. (and a distant 3, his responses kinda didn't sit well with me to be perfectly honest.) Agree, @A64Pilot may be nothing to see here; as we get closer to deadlines we'll likely see more activity as well as more field reports. Peace out...fingers crossed for a brave new world in 2025!

-

https://www.beechtalk.com/forums/viewtopic.php?f=7&t=234904&start=150 Several responses from Mr. Braly recently on BT and several comments pertinent to Mooneys.

-

G100UL paint testing by YouTuber mluvara

Marc_B replied to Shiroyuki's topic in Modern Mooney Discussion

https://backcountrypilot.org/forum/reid-hillview-rhv-selling-g100ul-27209?start=20 interesting thread. has one picture showing rather significant damage to paint, unsure of details; thread was locked. -

What material is used in the fuel sump valves? Is it servicable or do you just replace the whole valve when it fails? i.e. F391-53S or F391-72 for Monroy... Also the A1540 Gascolator seal kit looks like they're all nitrile. 2) MS29513-031, 1) MS29513-006, 1) 600-001-5/8, 1) MS29513-010

-

Out of curiosity, would this be applicable to all Mooneys past a certain year? Are you just referencing the IPC and looking at PN for o-rings?

-

Based on the G100UL fuel leak thread what's your position?

Marc_B replied to gabez's topic in General Mooney Talk

That makes no sense. What I'm saying is that we don't really know what tests were performed by GAMI, what the standards used, what materials, testing conditions, etc. Some tests performed and "it all looks great" doesn't help an end user determine if this is a safe product to use. There was a pathway for alternative fuel development. GAMI felt it was in their interests to develop a fuel outside of this. They have a product that is in early stages of end user use and testing. They are marketing this fuel to me. So just where are you wanting data to come from if not from GAMI?? GAMI has patented their intellectual property and currently sell rights for production to others. What are you thinking will be "stolen" by publication of what works and what doesn't? BUT...even if 150% well intentioned, there is NO way that they could have tested every airframe and engine on their AMLs...you can't know what you didn't test. Nothing is perfect. And likely nothing is 100% drop in fleet wide without some even minor modification. So how are we supposed to find out issues if GAMI doesn't freely publish this? The answer is solely from each other, if the manufacturer isn't willing to share. Heck, every research paper I've read has abstract, methods, results, and discussion...and it's always best to read the methods first to make sure the results and conclusions are valid and applicable to the population you're seeing. -

Based on the G100UL fuel leak thread what's your position?

Marc_B replied to gabez's topic in General Mooney Talk

As an aside, given that we may be unlikely to get any robust airframe testing from Mooney (for obvious reasons), the next best thing is for us all to help each other...unfortunately for Mooneys, I think that the testing FOR ANY FUTURE UNLEADED FUEL that will be done on Mooneys, will be end user testing. So sharing these lessons learned on a forum like this will be helpful and necessary. -

Based on the G100UL fuel leak thread what's your position?

Marc_B replied to gabez's topic in General Mooney Talk

It is obvious that @Pinecone is a fan, and that @MikeOH is not...and neither of you currently use G100UL. But that's not the point of this thread or discussion. The issue at hand is that major manufacturers, airframe and powerplant companies have said that G100UL is not approved in their products at the present time. So it's beholden to GAMI and to the aircraft owner to assume any and all liability for detrimental effects, known and unknown, that such use has. Actually do we even know that Continental, Lycoming, Textron, etc haven't tested the fuel? Don't assume just because they don't give details that they don't know the answer. Just like I don't assume that just because Mr. Braly doesn't answer many of my questions that he doesn't know the answer. I'm pretty sure he does. @Pinecone your energy and efforts are better spent speaking with Continental, Lycoming, and Mooney to help facilitate testing. There have been seemingly valid test cases of issues with G100UL that give pause to potential users. The explanation doesn't need to come from you, but rather from GAMI. It's also hard to stay neutral when you have questions and the response is just an advertisement (for either "side"). Data, field reports, and discussion of materials are the things most helpful to move our transition along. i.e. what materials are at risk, what components see damage or leak, what sealant is good, where can existing equipment be improved. The thing I've found most helpful from these threads in my own personal decision are field reports (both good and bad), discussion of failure modes, discussion of materials used in our aircraft, discussion of standard maintenance and timing of replacement of wear products, and preventative steps to insure that I can continue to fly safely today as well as tomorrow. We'll help us all though this, regardless of what product winds up being sold at the pump near you. This forum, at its core, is about owners helping one another. It's never been about companies giving us "the facts, just the facts, and only the facts." Heck, I still haven't a clue how much aromatic content, xylene percentage, or composition G100UL has and I've asked that multiple times. -

G100UL paint testing by YouTuber mluvara

Marc_B replied to Shiroyuki's topic in Modern Mooney Discussion

@GeeBee also keep in mind that GAMI is an open voice against lead and has actively been pushing to escalate legislation banning lead. There is a clear financial incentive for them with this and it’s not at all surprising. But it also helps them to push narrative with concepts such as 100% drop in, Fleet wide approval, and no engine left behind. At the end of the day it’s another product and money just like everything else in this industry that’s “good for 5 kts” or “guaranteed for 5hp increase.” Advertising is always oversold. -

G100UL paint testing by YouTuber mluvara

Marc_B replied to Shiroyuki's topic in Modern Mooney Discussion

I don’t think that’s necessarily true. There are plenty in the fan base that don’t mind working with GAMI for end user testing. But this requires open sharing of issues, wrinkles and failures. That is how we help the “fleet.” But the wrinkle with this is that GAMI doesn’t seem to feel there are any issues and the fan base is less likely to share negative information so will write off as “just due to an old seal or old sealant”. For fleet success, why doesn’t GAMI have direct to STC holder mechanism for feedback to help develop ICA revision. Only this requires the mentality that there may be items at risk of damage so I’m not sure that it would get done. Is G100UL truly a drop in fuel? And if not how can we determine what issues need to be addressed before use? So far we’ve just heard from GAMI that G100UL has tested without issue in 14 years. I’ve not heard any explanation of any detrimental effects from GAMI. What I mean is that it seems the helpful information needed for users of G100UL will likely come from USERS of G100UL (field reports and lessons learned) >> from GAMI via modifications to ICA, and in the form of AD from FAA. Field reports help us all much faster moving forward. -

Sensorcon battery life - informal test over 6 months

Marc_B replied to Bolter's topic in Miscellaneous Aviation Talk

I have a CO Experts PG-2017-5 CO detector and it's always on. Typically replace the battery once a year at annual (actually I usually take out at annual as my shop says it usually alarms in the hangar if they're running any aircraft outside the door cause it goes down to 5PPM...I should have gotten the PG2017-10 for 10PPM lower alarm... Reminds me I should reach out and see what their interval is. I believe it's a 5 year service life/calibration life. -

FYI FWIW. Surefly now recommends pressurizing the ignition cap (I suspect out of abundance of caution) for turbo charge applications flying in teens/FL's. Still waiting to have that done come annual. Basically a threaded barb in the center of the cap with a small drain hole at the side/bottom of the cap and connect to upper deck line that you removed from the old mag. But you're right...when it's time for an IRAN, overhaul, or mag replacement, the financial investment makes sense to consider EIS mag at that time if you're considering it!

-

Yes. NASA Aviation Safety Reporting System https://akama.arc.nasa.gov/asrs_ers/general.html