-

Posts

1,189 -

Joined

-

Last visited

-

Days Won

10

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Marc_B

-

FWIW. When I had my tanks resealed at WeepNoMore it was $8900 for both mains. If you needed aux tanks that added $3000 to the total (so aux plus mains around $12k). The wait list was the long part...I believe they were scheduling a year out. I think that since Don Maxwell picked up the Monroy aux tank STC installs, I'm guessing that might offload some backlog?? Of course it's a 2-3 week process, so depending on how far you live, you're likely looking at travel on both ends wherever you decide to go. It's a hassle, but if you're considering that you're doing this once every 25-30 years (or more)...that context makes this much more reasonable. If you're flying regularly, you could potentially go though 2 engines during that time!

-

@Pinecone I added unknown to the first question for you. If not aware of any patching in your logs, that's the second question. If your tanks were resealed at 23 years that's the third question.

-

@DCarlton That's a pretty good run. '67 F on original sealant! Just shows that with some occasional sealant maintenance you're at 58 years! Of course that may also be the reason you've had issues intermittently for 20 years. I'm guessing your bladders will need less overall TLC, but may not last that long!

-

Did you ever have the tanks stripped and resealed? Are you still on original base sealant? Seems like part of the issue that's uncovered with wet wings is that at a certain point you can just patch and kick the can down the road, but sealant surely has a finite life span. At a certain point it seems that the solution is a strip and reseal rather than patching, I think. Perhaps that time frame is 30 years? More? Good luck with the bladders; I hope the install goes smoothly!

-

This kinda of thinking was what led me to get my Commercial Rating. Power off 180s, spiral descents, emergency descents…great tools to have in the bag with your aircraft.

-

@N201MKTurbo I think I would have been inclined to take them up on the offer and asked for them to include full tanks of fuel when I picked up. I wouldn't have liked it but sounded like a bad situation for you all around. I would have hoped and expected that they got everything right the second time around. Hopefully your experience was a horrible one off! Sorry, that stinks.

-

MVP 50 Electronics International Placement

Marc_B replied to Brian2034's topic in Engine Monitor Discussion

@Brian2034 You might post a picture of your current panel and describe what you're having done. i.e. If you have all original panel and just adding an engine monitor you're likely to be way more space constrained and may have less "choice" of where to put your engine monitor. Personally I like having the engine monitor in the area between the PFD and your radio stack. It's MUCH more in your typical scan area, and you're more likely to see changes you might not have picked up if it were on the far right or far left. -

THIS...is what I'd expect with issues with sealant application/product curing/bad sealant batch... My suspicion is that if you have issues with application, then you are likely to see them within the first 6 months of application...but I wouldn't put this in the same category as a wet wing that lasted 25 years without a leak. @N201MKTurbo did you ever get this inspected and have a sense for what the issue was? poor prep vs bad sealant vs bad application vs something else??

-

I started out for just a question for those who patched or resealed, but wound up adding a line for those who hadn't. So fixed it. thanks!

-

The allegation of difference here, I believe, is that some wet wings are fabricated with sealant between the ribs before they are riveted. However, Mooney wings are riveted together, THEN sealant is used at the joints between rib and wing skin. But I'm not convinced this is a detriment, and certainly makes the process of resealing the tanks probably higher quality. I think it's a PROs and CONs on both sides and likely just a difference but not a "one is good and the other is bad" type discussion.

-

I think there are several variables that may affect sealant life including original quality of application...hangar vs tie down, extreme temps vs stable temps, fuel in the tanks vs not flown and kept dry... But I was curious in general for the population of Mooneys represented here on Mooney space if there are brackets and clumps. BUT...if the quality was so bad with certain planes, when would you expect to see it?? 1 year, 3 years...or does even this "low quality" application last 20+ years???

-

The intent was to see how long on average does the Mooney wet wing last before needing sealant maintenance; and for standard tank maintenance (either reseal or patch) how long before seeing further issues that need to be addressed? i.e. if Mooney wet wings are failing 3 years off the line vs 30. Things like a leaking gasket from a fuel sender that's over-tightened aren't sealant related and don't reflect sealant compromise. So I wouldn't count that as sealant failure, If that makes sense.

-

Modified the first question to include this...I added separate lines as I am most curious how many years do Mooney wings get before leaking. I also didn't want to lump in a 10 year old wing that doesn't leak with a 10 year old that just started leaking. Thanks for the suggestion!

-

With the recent discussion of wet wings, and Mooney wet wings at that, I was curious what the real world experience has been with wet wings. My aircraft had almost a quarter century on the wet wing sealant before I started to see leaks. I wound up having the tanks stripped and resealed at the 25 year mark not because I had to, but rather I was planning on having the aircraft painted and wanted to get this squared away before repaint (and to "reset the clock" as it were). There's still a part of me that knows that I did a reseal more prematurely than I could have, and I suspect that I could have gotten another 5 years as is, and with a quality patch job maybe even more... Here is the worst of the seeps/leaks under wing at year 24...for life in a caustic environment, this is pretty solid performance in my mind! I flew like this for 2 years, and when the tanks were resealed, the area was cleaned and today you can't even see where the leaks were...no damage to the underlying paint from the leak.

-

I fairly routinely get a "descend at pilot's discretion and cross 'X' at 5000" or a "cross 'X' at and maintain 5000." Using VNAV just allows you to automate these step downs. If your winds/speeds are favorable where you are, you'd want to start your descent as late as possible. So this either takes some brain computation or some GTN computation. But I find that the busier the airspace on your arrival, the more likely that ATC wants control of you vertically and horizontally to make it easier to maintain separation from others. So in those cases you're probably more likely to get a series of discrete heading and altitude changes from ATC coming in. It's not a solution for all (or even most) descents, but it's a nice tool when it's the right one for the problem.

-

@Z W and @Gee Bee Aeroproducts, is this the newer profile of the seal or the older profile...I can't remember but think one was smaller and thicker and one was larger and thinner walled?? Which is the newer/improved?

-

I'm of the mindset that the most proficient you'll be is when you spend a lot of concentrated focused time in the aircraft learning. For me, instrument training was a given once I purchased my Mooney. But I found that it not only made me a better pilot, but it taught me way more about my aircraft. So if you're gonna knock out the training before you drop off the Mooney in the shop, great. But if you're getting in the shop soon or not flying a ton in the mean time you might be able to enhance your equipment knowlege with the new panel as well as better learn the equipment you're planning to fly moving forward. Start working on your classroom skills, written exam and knowledge base while the Mooney is down, take an onsite Garmin G3X/GTN course as you're finishing up install, and be ready to get all the flight portion done with your new panel. Now if it's gonna be 3 years before you're ready to get your panel...get your Instrument Rating now! This is one of the biggest dangers to GA that is pilot mitigated with proper training.

-

I ordered from New Horizons / Maggie when I was installing a Surefly. They just needed info for my engine, mag harness cap type, and airframe. I didn't send them my old harness and the new one fit perfectly.

-

VNAV is a vertical mode for descent. A classic case is a standard terminal arrival with stepdowns. But you can use it to set up a vertical constraint for 1000'AGL at 5nm from the airport, or set up fixes before each of the "layers" coming in under a Bravo so that it will automatically sequence descents to stay below airspace. You can also use it to automate stepdowns given by ATC "proceed direct FIXXE, cross FIXXE at 5000 feet". VNAV is calculated by the GTN. But the GFC500 just has a mode to follow this path automatically. These are two good videos to watch to familarize yourself with VNAV.

-

I don't think there will be much benefit from a staged approach. Usually it just winds up taking more time in total, more money for duplicate processes and base labor costs, and opens the door to issues more times. Plus you can do a much better job of tidying up things, removing things not in use and cleaning up the mess if you do it all the first time. Best process for a big project like this is do it right and do it once. That will minimize your down time and minimize the ultimate costs (which will be big regardless).

-

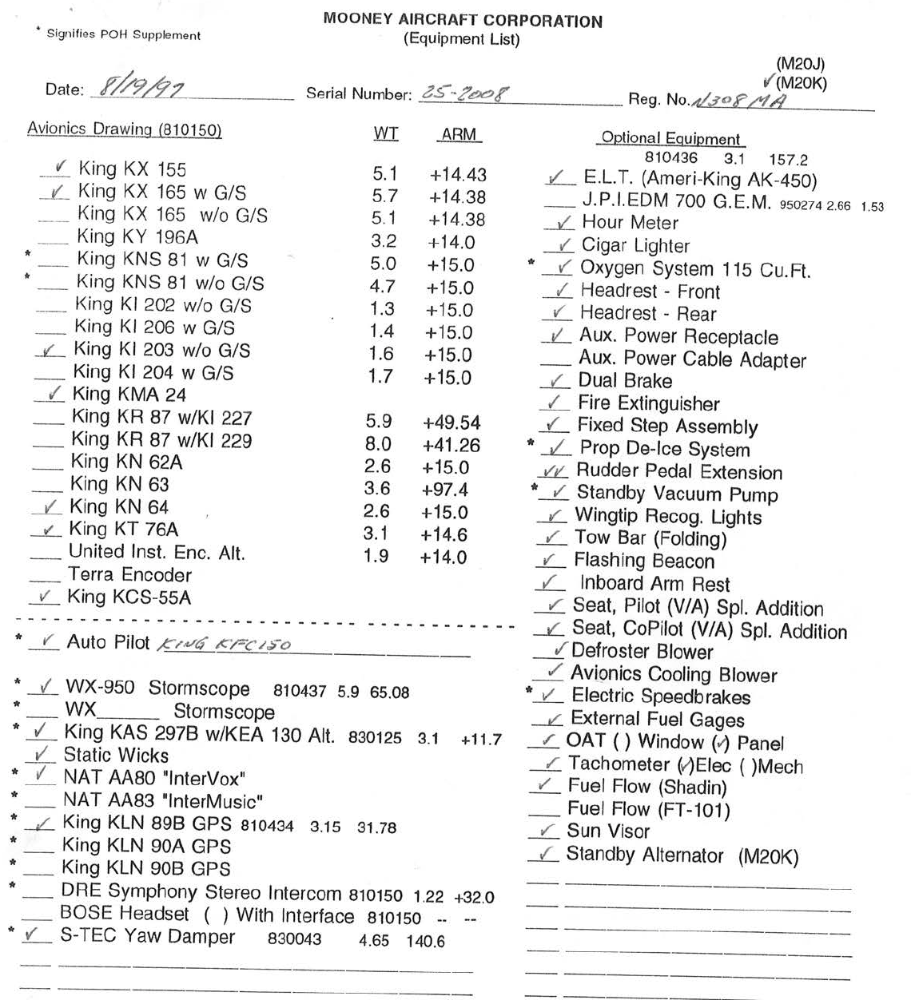

The build sheet at this time was used for both J's and K's. It's certainly possible that it was standard on the K's and optional on the J's?? I don't know the history, so can only speculate based on wording. It is interesting that there are several things on there that you'd think was standard...unless you had a very pared down Mooney off the line. I get a kick that "tachometer" is listed in the optional column as well. But I agree with you @Invisibleman, for me a Mooney without oxygen is like a Mooney without a turbo...I'd rather have both!

-

FWIW on my M20K Encore build sheet, built in oxygen is listed in option equipment column.

-

I figure these are sealed units? Wonder if there’s a way to open and reseal? I figure the only difference from one to the next is the printed dial face card.

-

@EricJ I've tuned in for a couple of those; sometimes they seem geared more towards A&Ps, but usually there are a couple of good pearls in there regardless. I think that what I had in mind was what @201Mooniac was describing with MAPA and Manthey. Not sure if anyone has carried on the torch for this? Seems like with MAPA in the wind, that either the MAPASF, Summit or DMax would be the groups with the best path forward...

-

I keep thinking that Don Maxwell or some other Mooney shop used to do this and I've seen that Beech does something similar... Does anyone offer an owner's maintenance workshop going though Mooney systems, standard owner maintenance items, and walking though a standard annual inspection? If not, any change of adding something like this to MooneyMax or Summit?