-

Posts

1,379 -

Joined

-

Last visited

-

Days Won

10

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Marc_B

-

Transponder antenna replacement questions

Marc_B replied to LANCECASPER's topic in Avionics/Panel Discussion

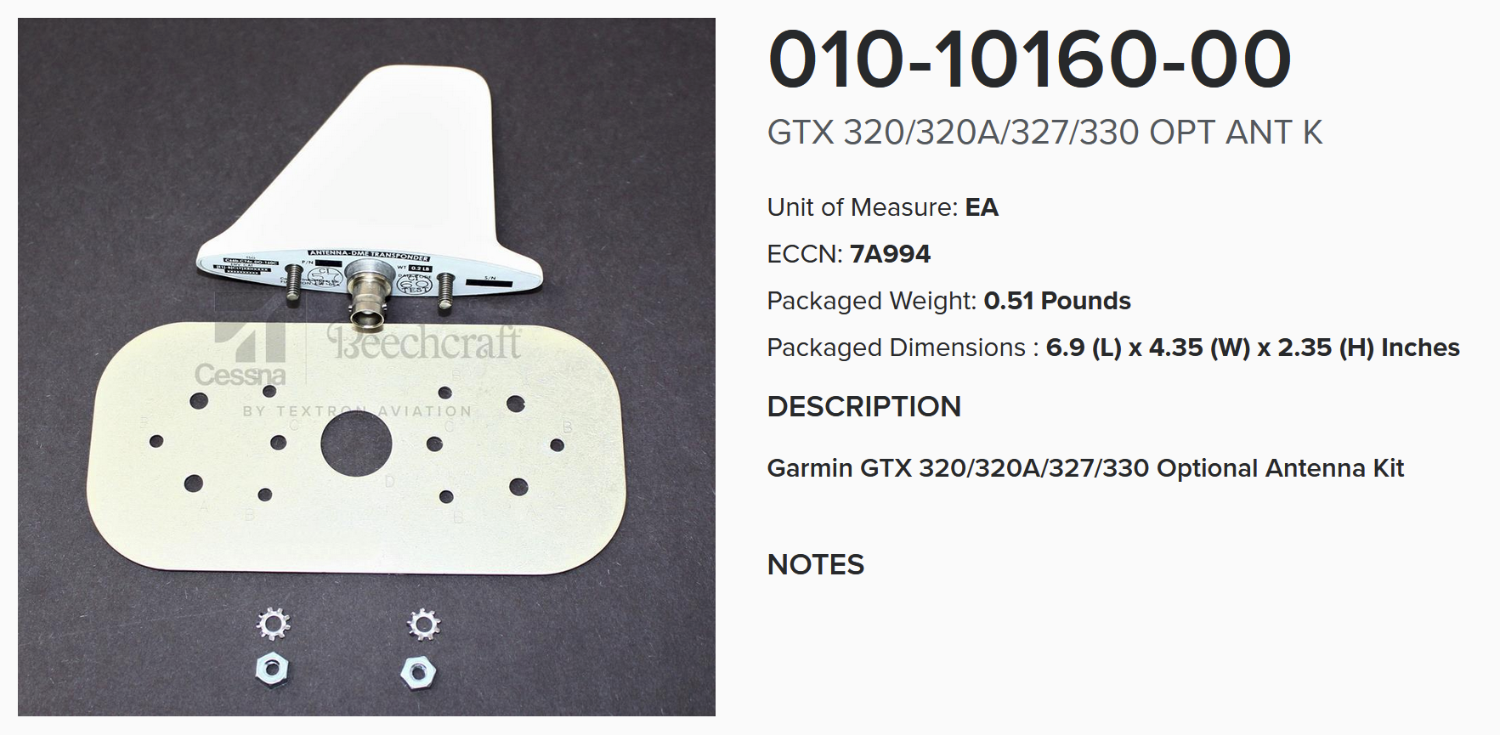

I had my transponder antenna go out and both Garmin and my shop thought it's "usually not the antenna" but it was. Fortunately I had an orphaned antenna beside it on the belly maybe from DME previously? Switched it and moved on. But the Garmin antenna shows an "optional antenna kit" which looks like just a grounding plane and mounting hardware. FWIW, my antenna did have a ground plane but didn't have any sealant/RTV. -

Minimum Cloud Ceiling to Launch VFR for Aerial IFR Pick Up (poll)

Marc_B replied to 201er's topic in General Mooney Talk

For me this is a very unclear poll question. If I'm departing VFR, I'm doing so expecting to maintain VFR. If I have a ceiling that I need to punch through then I depart on an instrument flight plan. BUT, I've departed VFR with an IFR flight plan filed in case I needed it in the air depending on my destination. But in that case I'm expecting VFR and will continue to fly VFR with flight following unless I need instrument flight plan. I've also picked up pop up IFR in those cases as well when the weather unexpectedly changed requiring IFR plan but still safe to complete. Departing VFR only to scud run while trying to pick up an IFR plan seems like a rather horrible idea...if you're instrument rated, why would you think that's a good idea? If you're not instrument rated, the stats speak for themselves...VFR flight into IMC is one of the leading aviation killers. -

Another shop that does solid work is Aircraft Magneto Services in Montana. https://www.aircraftmagnetoservice.net/ Easy to print out a prepaid mailer from their website, fill out a service order, and ship in. They typically have their turn around times listed on the website. They also have an AOG service for a quicker turn that adds a couple hundred but takes you to the front of the line.

-

Just to add one more data point...I have verizon for phone service, and when I turn off wifi (use cellular) I get "Safari can't open the page because the server can't be found." But when I'm using home wifi, then Mooneyspace works properly.

-

@Jamildmc Did you check BAS/Beegles in Greeley, CO? (not sure what engine you have and if this is the right part??? https://baspartsales.com/492110-2-alt-649012-garrett-intercooler-assembly/) Check out the Continental Illustrated Parts Catalog for your engine, determine the part number...you can also start calling distributors...i.e. AirPower.

-

Chasing storms yesterday from Austin to Florida. Wound up stopping in New Orleans and Tallahassee cause the Mooney was moving faster than the front! Alaska and a couple other commercial aircraft were landing at TLH to go to Million Air as they were having a sale on fuel…plus wx to Tampa and Orlando was blocked. Florida Flow Control I’ll bet was lit yesterday. ”If you have time to spare go by air” indeed. 10a arrival turned to a 7p arrival, but my ride was smooth and the Mooney stayed dry. Modern weather tools are really pretty incredible. PS. KNEW is a fav…first rate FBO (Flightline First), good fuel prices and fun airport to fly into right on Lake Pontchartrain. Put it on your list if you’re in the area and give yourself an excuse to check out NOLA

-

I put these squarely in a volume available vs customer demand category. Same as V-band clamps. Prices rose cause they could. But as fewer and fewer resources are put towards GA, the number of these items and prices will continue to rise.

-

Let's buy Mooney - Crowdsourced Version - Straw dog.

Marc_B replied to Yetti's topic in General Mooney Talk

Engine: TCM/Lycoming Prop: Hartzell/McCauley/MT Lights: Whelen Avionics: Garmin/King/Avidyne/etc. Big ticket items are taken already. If not building complete aircraft, then it's probably mostly corrosion related issues, replacement skins, cowls, hangar rash, belly ups. That and taking all the aftermarket parts from other vendors used on our aircraft and "certifying them Mooney." Between McFarland, Univair, and Spruce many common parts don't come from Mooney. Lots of parts are purchased salvage from companies like BAS/Beegles. Even within Mooney owners, the parts aren't purchased with much/enough volume from Mooney itself. I think it's problematic to expect the Mooney fleet left to support a company all by themself...Mooney, LASAR, or otherwise...just on parts alone. The more prices become over inflated, the more inventive the owners will be to avoid purchasing those parts. LASAR established themselves with upgrade kits and direct to consumer sales in addition to a Mooney maintenance facility. By being able to use the Mooney name to act as the middle man for all the outside manufacturers that don't sell direct to consumer they can help themselves as well as all of us. But it's a delicate balance of pricing so that parts actually get sold with enough volume to make it worth while...at a certain price this becomes a one off vs volumes that support profit from volume rather than solely on individual items. i.e. how many people would buy a no back spring at $2500-3000 unless absolutely unavoidable...vs how many would they sell if they sold them for $300 and lots would buy them to have one just in case??? Mooney has production capacity for an older way of manufacturing parts, for aircraft that are no longer being made. But it's a lot of overhead to run the shop even bare bones. At some point the old Mooney has to be retired to give birth to the new Mooney of the future. For those saying if everyone just gave "X" amount...what are you wanting that to "build"?? It's unlikely to bring back manufacturing of Mooney Aircraft as they were. There's too much overhead to support Mooney as they have existed lately... My suggestion to LASAR is to bolster upgrade kit availability, bolster common wear items on our Mooneys, develop cooperative ways for fellow MSC's to coordinate orders, see backlogs, and coordinate "group-buys" between shops, and continue to offer parts to consumers and other shops that aren't MCSs. But the idea of an owner/investor NEEDS to have a return on investment other that just a "hope" that this might bring better support to a shrinking field. -

It'd be the PERFECT solution if it was $100! But it does work well and no regrets for me so far.

-

I had a ceramic heater that was cheap and way too much wattage...finally ponied up for the Tanis cabin heat and it's the right tool for the job except for cost. Perfect output, low profile, and most importantly, low wattage that doesn't trip my Switcheon cellular switch. Only downside was aviation pricing...and yikes, just looked and they went up by another $150 from when I purchased it from Gallagher back in 2021...just silly pricing, I don't get it. Lasko 1500W ceramic heater...what I first bought from Amazon... Tanis 500W heater...which is what I eventually broke down and bought from Gallagher It's super nice to have a toasty cabin and the seats plush when I get in. If its cold the seats are hard as a rock until they warm up. All you need is an hour or two and the entire interior is heat soaked and amazing!

-

@Fly Boomer I was trialing a new way to snake the power cord for my cabin preheater... ...it's a large sponge that "almost fits perfectly" with cutting a slot in the front edge to slot the windo into...but the front lower corner of the pilot window is just big enough to get a seal I need to use a small piece of microfiber cloth folded up... (7.5" x 4.3" x 2") --> looks like Home Depot has a grout sponge that's 7.5" x 5.5"...gonna pick one up this morning and see if that works. Previously I had the cord going out the back of the baggage door, but that meant keeping the door cracked or really compressing my door seal. Now if I could fashion a plug in on the back baggage wall and a connection like my battery minder...that would be slick.

-

Got the D-rings and toiletry bag in the mail today. Easily slid the D-rings (pictured in a post above) through the head rest posts. The toiletry bag was perfect size for 2 Mountain High Mic Masks (with all connections/tubing/mic cords), an extra nasal cannula, and a small pack of CPAP mask wipes slid into one of the upper pockets. Used a tan zip bag for the pocket that is about 3/4 size of a gallon ziploc and fits perfectly in the back pocket with 2 boom cannulas and the regulator for the O2D2; those always stay up front in seat back and easily accessible. But the "toiletry bag" easily stays in the hat rack but with long trips or anticipated flight level flying I'll just use the hook and loop tabs to hang the bag from the seat...out of the way but easily accessible. Wound up getting the 3 pack of zip pouches so the smaller one easily fit several Travel Johns to keep them close at hand but together and "concealed." Toiletry bag $19. D-ring key clip $7 Zip pouch $15

-

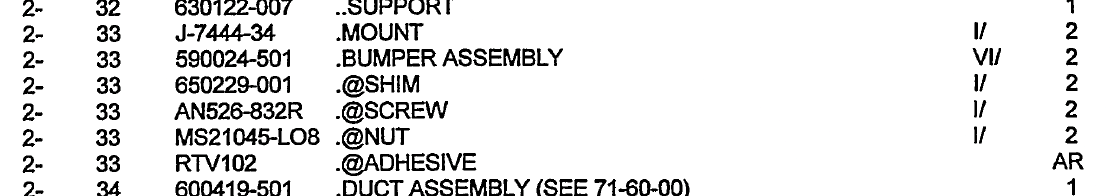

@1980Mooney From the Lord drawings the J7444 snubbers are all the same thickness, but different center receptacles. However, I'm not sure if the material used is the same. Lord said that they haven't produced the -34 part since 2008 and sold the last batch to Mooney at that time. Specifically the -34 part was listed with "chlorobutyl" and the others were just listed as "rubber". Not sure if this translates into a different material or durometer or not??? I'm not sure what material the Skybolt equivalents use. I presume the thickness is the same??

-

Lasar Aviation Mooney Assurance Program - Really?

Marc_B replied to PeteMc's topic in General Mooney Talk

@LANCECASPER Lance, I thought that sounded too good to be true! The link wouldn't work though; says search expired. -

Lasar Aviation Mooney Assurance Program - Really?

Marc_B replied to PeteMc's topic in General Mooney Talk

Speaking to a friend who's reading The Al Mooney Story. Just to hammer home the reason why Mooney is and was unlikely to move from Kerrville, TX..."Kerrville offered Al a ninety-nine-year lease on the airport for a dollar a year." I believe Mooney left Wichita and moved to Kerrville in 1953. Lots of financial incentive to stay; lots of financial disincentive to try to move everything. -

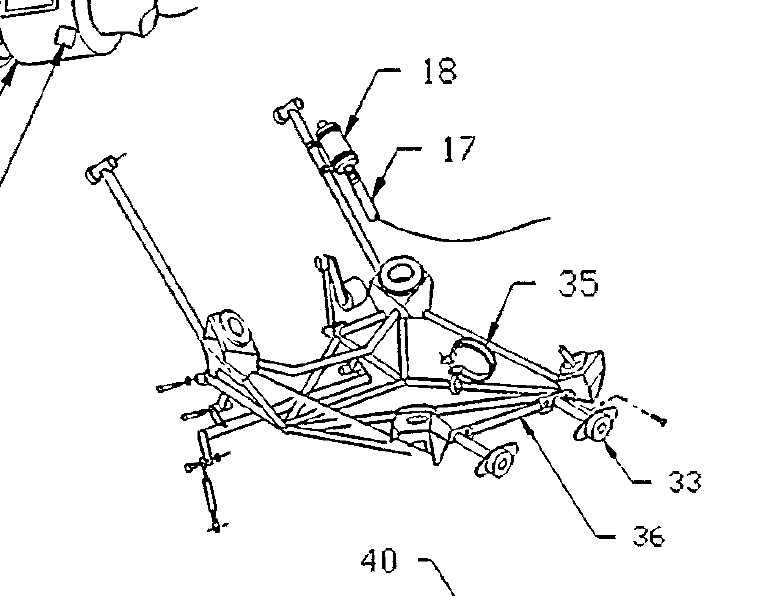

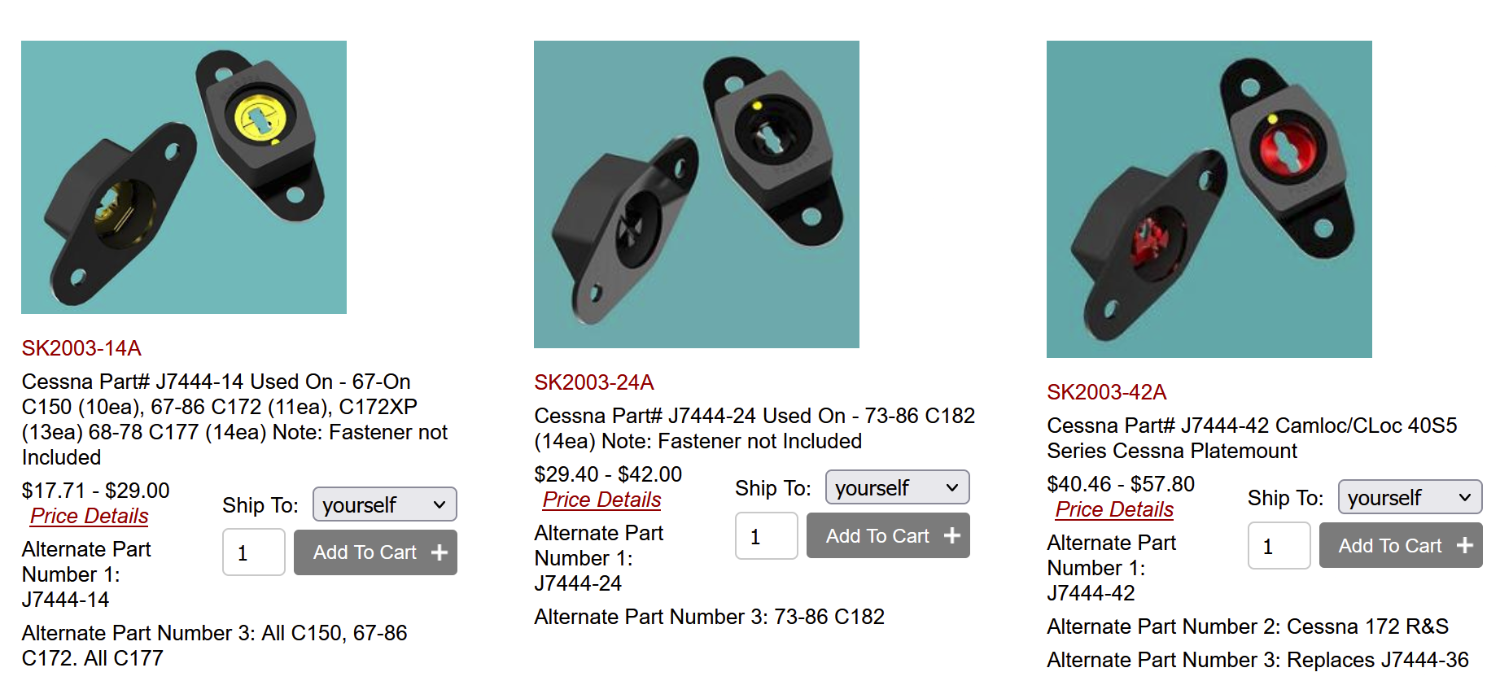

Are these still available? showing J7444-34 for the part number, but coming up with other -numbers available online. Wondering if this has been superceded by another part or just unavailable so use a different part number to replace? #33 in the picture below. It's the snubber mount for the cowl. Here's a -24 on Spruce. I think this is what a previous shop used for replacement... Is there any difference between -24 and -34 regarding thickness or durometer of snubber or just type of receptacle in the center?? On a little further digging, it seems like the J7444 is the snubber and the -number may be the receptacle (i.e. camloc or other)? But I've found J7444-14 vs -24 vs -36(that was superseded by -42)... J-7444-14: This is for use with Southco fasteners J-7444-24: For use with 2600/2700 camloc J-7444-36: For use with 4000 series camloc J-7444-42: For use with 4000 series camloc Also found a Skybolt replacements for same...since they are used as a snubber without any center fastener, are they all equivalent for Mooney use??

-

Wild ride takeoff roll and landing roll

Marc_B replied to mpilot's topic in Vintage Mooneys (pre-J models)

I'll add that if the nose gear shock discs were recently replaced, that the increase in stack height WILL change the geometry of the nose wheel. So it's not always just a switch and go. Additionally the collar at the top of the pucks has an asymmetric bolt hole in some Mooneys. Meaning you can either flip the collar so that the bolt hole is low or high...this can adjust the geometry somewhat, but others will need the shim which is just a thin washer. But speaking from experience, the difference in even slight geometry is surprising in terms of "twitchiness" of the nose wheel at speed. I didn't feel it was uncontrollable, but rather SUPER sensitive. -

Lasar Aviation Mooney Assurance Program - Really?

Marc_B replied to PeteMc's topic in General Mooney Talk

There are LOTS of parts on a Mooney that weren't made by Mooney... Rochester Dials - wing sight fuel gauges, Globe Motors - cowl flap motor, Voltage regulators, speed brakes, flap/trim indicators, potentiometers, luggage door handles, rod ends, and on and on... Most of these companies would deal direct to a manufacturer and all of them have a minimum parts order. With the proper capital a company could meet min orders for a variety of different parts and with the sale of said parts they could spring off the profit. Most of these parts have been previously sold by Lasar or Mooney for 2-3+ times what it cost to buy from OEM. However, Mooney doesn't have the capital laying around to invest in a bunch of parts. Lasar would like to have a bunch of parts, but that's a lot of money laying on the shelf and some may not have a quick turnover. A member funded subscription service where the owners foot the initial capital investment sounds similar to what's being offered. Of course that's all speculation. I've seen it posted multiple times on this forum that "if the existing Mooney owners all offered up "$X" that would be a sizeable amount to turn Mooney around." Sounds like this was born off that sentiment. -

Lasar Aviation Mooney Assurance Program - Really?

Marc_B replied to PeteMc's topic in General Mooney Talk

Aka we’re looking for venture capital investors. -

CO2 detectors the "Good The Bad and The Ugly

Marc_B replied to Jpravi8tor's topic in Vintage Mooneys (pre-J models)

A review of NTSB reports between 1982 and 2020 identified 31 accidents attributed to CO poisoning (see the appendix for a list of these accidents). The data show that 77% of those accidents were fatal and led to 42 fatalities and 4 serious injuries. CO detectors were not found or reported in 30 of those accident reports. Although these accidents can be more prevalent in colder months when pilots are more likely to use aircraft heating systems, accidents related to CO poisoning happen throughout the year; of the 31 accidents between 1982 and 2020, 6 occurred between June and August. The FAA’s service difficulty report (SDR) database also showed at least 45 incidents involving a defect, leak, or failure in engine exhaust systems between 1993 and 2020. https://www.ntsb.gov/investigations/AccidentReports/Reports/AIR2201.pdf (same reference as @midlifeflyer above) The big question is how many could have been prevented with a properly functioning CO detector? Probably darn near every one. Its a low volume, but something that we could make a significant impact with I think. When I upload my engine monitor data to Savvy, it will give me "High CHT" notification even when it was just a CHT probe connection that was erratic, and I get FEVA exhaust valve reports regularly looking at exhaust valve health. Would be super cool if it would also monitor CO levels and use machine learning to look for trends that this is worsening/changing, or notify if CO levels went over a specific threshold. Unfortunately this requires integration with engine monitors at current. HOWEVER, if the CO detector manufacturers would make an inexpensive monitor that has ability to download/store data...then upload or review that...that would pretty slick! -

@M20Kid if you’re talking about the overhead electroluminescent panel if you have overhead light switches, this can be repaired by either Air Capitol Dial or Nimbus Aviation. If it’s warped and not working they can make it new with a new internal lamp. The overhead light switches should light up with your panel lighting rotary switch.

-

CO2 detectors the "Good The Bad and The Ugly

Marc_B replied to Jpravi8tor's topic in Vintage Mooneys (pre-J models)

As an aside... @Jpravi8tor can you change the title to "CO" and not CO2? Every time I see it I get a laugh. -

@Tommooney best price I've found: https://www.scross.com/store/part-number?10-900-60-1

-

https://www.savvyaviation.com/the-mag-check/ Read up on some of the Savvy information...you can find several articles online. General gist, your EGTs should be rising on one mag as the fuel air mixture burns slower and so more fuel is left by exhaust stroke. So if you have one cylinder that's dropping off when running on single mag then it's a plug or wire issue. If you have a bank of cylinders dropping off or not acting the same it points more towards the mag. A lean of peak in flight mag check stresses the ignition system more and sometimes help pick up subtle things you might not pick up on the ground. I had a failing mag that initially passed the mag check on the ground, but failed miserably in the in flight mag check. Initially looked like 3 different EGTs not doing what all the others were so I thought maybe plugs as they were getting worn. But when I cleaned and gapped the top right plugs, then it was more obvious that the bottom left plugs were more off...common denominator was the right mag...replaced with a Surefly and haven't looked back! If you get a chance to upload data with the Savvy mag check take a screen shot if you need help. I'm sure there's plenty on the forum that would help steer you in the right direction!

-

@AZOutlaw if you have a 6 cylinder engine monitor, what are the EGTs doing in the individual cylinders when you do a mag check? Do you submit data to Savvy? even if you don't have a subscription you could take a look at your temps using their mag check function to see what's going on with each cylinder during the mag check. That might help to localize and troubleshoot the issue. Still could be a magneto issue timing (internal vs external), improperly gapped plugs, faulty plug, corroded ignition harness lead... https://www.aircraftmagnetoservice.net/magneto-troubleshooting-guide