-

Posts

1,188 -

Joined

-

Last visited

-

Days Won

10

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Marc_B

-

When I spoke with Surefly when I installed mine, they recommend about a 3 inch piece of tubing connected to the pressure sense barb and directed down as a drain. They did not recommend capping the pressure sense barb. On NA application the barb would be connected to the manifold pressure. For a Turbo application they aren't approved for variable timing so you'd wouldn't connect to MP, but rather just functions as a drain.

-

Based on the G100UL fuel leak thread what's your position?

Marc_B replied to gabez's topic in General Mooney Talk

This seems to suggest the hypothesis that it may be the low volatility compounds that concentrate and contribute to longer dwell time and more risk. But it also makes me wonder what happens in separate Aux tanks that aren’t used frequently or the fuel tank sealant that is up top of the tank that gets wetted but not typically soaked with fuel. Leaks aren’t the only time fuel components get wetted and then allowed the dry and concentrate. -

That was my thought as well...not sure how you balance putting it on, and wouldn't be surprised if it was closer to balance coming off! @Grant_Waite If you go with rudder replacement, I'd call Beegles/BAS at KGXY in Greeley. (Beegles is the maintenance arm of BAS salvage) https://baspartsales.com/ https://www.beeglesaircraft.com/ They do a lot of sheet metal work and also have a paint shop I believe. I wouldn't be surprised if they could get a salvage rudder off the shelf; clean, repaint, and balance for you; and ship to you for your shop to install. Worth a phone call if you're considering that route.

-

I'll be the contrarian...when I upgraded my panel I put in a SXM 69A so that I could have XM weather on my panel as well as XM music. For context, I have an all glass panel and so can use XM on G500TXi and GTN 750Xi. I've found that XM always bumps up the cost at renewal, so it always requires calling to find out what the best package they are offering (NEVER let XM autorenew!). Usually try to get a 6- or 12-month package to see what the best price break will be. Also if you're planning on being down for a bit (maintenance or just not flying) you can put your subscription on pause so you're not paying for it during that time a simple call lets you choose pause and choose reactivation vs leave it indefinite and have to call back to restart. I usually go with the XM pilot express There are some product difference and in general the radar data is usually more current. The coverage map is different which is important for trips down to Caribbean/Mexico/Canada. The satellite vs ground line of sight reception is different. But there's also overlap with ADS-B/FIS-B. If you're a VFR only pilot and usually have short flights around your local area, FIS-b is great. I don't think that XM is orders of magnitudes better, but there are a couple of times that XM feed worked/works better for me. Given weather is a GA pilot equalizer, it's nice to have a little more enhanced and timely product. But as anyone will tell you, neither products are useful for navigating storm cells and aren't near the same as in flight radar. Sometimes 2 is1, 1 is none...meaning it's nice when I need it to have a back up. Of course I'm usually doing most of my weather prep on the ground using ForeFlight Imagery and https://aviationweather.gov/ So in flight this is more confirming that things have changed as I expected or moving the same direction and speed as anticipated. Occasionally it encourages me to take a fuel stop...but usually it just confirms that my plan is still GTG. I'm not flying on the ragged edge of weather anyways. https://www.sportys.com/blog/datalink-weather-for-pilots-ads-b-vs-siriusxm/ https://www.siriusxm.com/aviation/packages https://www.siriusxm.com/aviation/siriusxm-ads-b?intcmp=Global Nav_NA_www:aviation:overview_SXMvsADSB For the ADS-b vs XM discussion it's more dependent on HOW you use it and WHERE.

-

@Matthew P https://drs.faa.gov/browse/excelExternalWindow/40797B4900228F3786256A3B006FDDCF.0001

- 1 reply

-

- 2

-

-

@Brian2034 I've used Donaldson filters since I purchased the Mooney. Easy to care for. Works well. No experience with Tempest, but sounds like they're equivalent. If you can't find one, go with the other. They're both synthetic media.

-

Based on the G100UL fuel leak thread what's your position?

Marc_B replied to gabez's topic in General Mooney Talk

I read this differently. E-AB aircraft sometimes use different techniques, construction, and materials than certified aircraft. Given that GAMI went through the STC process and isn't openly sharing what materials were tested and how, this makes the use of an alternative fuel from this pathway more difficult for an E-AB owner/operator to determine if it is safe for their aircraft, especially for early adoption where there's limited field testing. If you decided to forgo the STC and just "fuel up"...what liability coverage do you have from Vitol, GAMI, or your FBO? Even if you obtain the STC, what testing did you do to ensure that G100UL is safe in your airframe if you can't reliably refer to similar product testing that GAMI may or may not have performed? Regarding whether it's legal or not to purchase fuel without purchasing an STC is a distant concern compared to the above in my mind. -

Based on the G100UL fuel leak thread what's your position?

Marc_B replied to gabez's topic in General Mooney Talk

GAMI requires an STC for purchase and use of their fuel. Mr. Braly has said that he'd help with paperwork to update the FAA for use of G100UL in experimental aircraft. But we're talking about different things here. 1) to legally purchase G100UL, GAMI requires STC. 2) to legally use G100UL in a certified aircraft, FAA and GAMI require STC. 3) to legally use G100UL in an experimental aircraft, I believe an owner/builder needs to fill out paperwork with the FAA with design modifications, and would still need to purchase the STC from GAMI to legally purchase fuel. Can you pump fuel without holding an STC?? I'm sure you probably can depending on the FBO. But in these early stages of alternative fuels, why wouldn't you want as much liability backing and be "above board" to have others with you with any issues? -

Based on the G100UL fuel leak thread what's your position?

Marc_B replied to gabez's topic in General Mooney Talk

It just means that as with most changes to an initial design and implementation, the owner/builder/maintainer assumes responsibility and liability. if GAMI didn’t test your aircraft for use…what testing did you do to insure an STC for another aircraft is safe or applicable? If something happens, do you have the STC testing information from GAMI/FAA to back your use and adoption? -

Based on the G100UL fuel leak thread what's your position?

Marc_B replied to gabez's topic in General Mooney Talk

EAA weighs in and cautions use of G100UL in experimentals. Says STC doesn’t apply to experimental aircraft so may not have even tested/considered the methods and products in use for experimental builds. -

From my understanding, you don't routinely need to find the exact degree of LOP, but rather use fuel flow calculation applicable for your compression ratio to define %HP on the LOP side. So I've always been a fan of the big mixture pull to the LOP side and just set the fuel flow once you've set your appropriate MP/RPM for cruise. https://www.google.com/search?client=firefox-b-1-d&q=LOP+fuel+flow+calculation+site%3Amooneyspace.com

-

Based on the G100UL fuel leak thread what's your position?

Marc_B replied to gabez's topic in General Mooney Talk

It's such a fascinating, multi-player game of chess we have these days... Santa Clara County wants to close KRHV, but FAA says no because you have grants that preclude closing. So instead Santa Clara bans sale of 100LL, has threshold displaced to shorten runway/limit noise/adjust traffic, is set to close in 2031 and has county resolution to pursue "any and all available paths to early closure prior to 2031 ." (edit: was confusing with KSMO who shortened runway by 1500' and will close 2028)... Plane crashes from RHV due to fuel exhaustion and unable to fuel with 100LL on the field. Santa Clara County invited to join FAA to help establish best practices for transition to unleaded fuel. GAMI moves in and begins sale of G100UL at KRHV and advertises G100UL "commercially available" so lead threshold for Avgas would be now zero for all of California based on a Consent Judgement that was originally started to get California airports to put up Prop65 warning signs that fuel is dangerous. But push against lead was never really about lead...it's about airport closures. According to CalTrans, "In the 1960s there were 275 public-use airports, and by 2019 there were 242. In the last decade, eight general aviation airports were either revoked, suspended, or closed to the public." Fortunately for those political interests, they don't care if an alternative fuel is damaging to aircraft (and probably figure that's a good thing for them). I've always heard an estimation that 80% of the 100LL fleet can run on lower octane fuel. 20% of the 100LL fleet can't. The 20% that can't, are responsible for 80% of the use of 100LL. It's a wild and twisted road we're on these days. In my mind, the "safe bet" is move to aircraft that can burn Mogas/UL94 (to go slow/stay local) or move up to Jet A (to go fast/travel far). BUT we may have 5 years left for a PAFI fuel, GAMI could work out the kinks and have a successful product, and/or technology could be adapted to allow use of lower octane fuel in high compression, turbocharged, high octane engines. ...but GA airports are still at risk of closure at an alarming rate and this all has nothing to do with fuel. ...and I keep having thoughts of KRHV as the canary in the coal mine. "What happens here changes the world." -

Based on the G100UL fuel leak thread what's your position?

Marc_B replied to gabez's topic in General Mooney Talk

Don, basic gist is that GAMI has been actively advertising using the phrase "commercially available" to spring board off of the 2014 Consent Judgement which would be an attempt to ban 100LL in California. The use of this terminology was well before G100UL was available for purchase by aircraft. Mr. Braly has also submitted testimony to the House against PAFI and against leaded Avgas testifying that G100UL is a "complete drop-in replacement for the existing 100LL Avgas." -

Based on the G100UL fuel leak thread what's your position?

Marc_B replied to gabez's topic in General Mooney Talk

The issue stems around the fact that a significant number of aircraft fueled at the G100UL roll out (at only 2 locations) have had apparent issues resulting in damage to paint and sealant in SHORT term field use. The implication is that there may be many more with LONG term use of G100UL. The allegation from GAMI has been that this was due to high toluene 100LL, nitrile fuel components, and PTE wet wing sealant coupled with assumptions that if it leaks then it must have been poor application. "it's not me, it's you." Given Braly's recommendation for use of Viton, teflon lined hoses, and negative comments towards wet wings...one is left to assume that they likely did know there might be issues with some of the fleet. Given Braly's comment that paint wasn't a requirement of the PAFI process and his comment "fuel belongs in the tank"...I assume that this implied that GAMI wasn't required to do widespread paint surface testing for their STC approval and so their testing may have been limited here. They openly list very specific "fueling hygiene" and acknowledge that their fuel damages paint to some extent. Their rollout G100UL in California was shown with towels, mats, and adsorbent material that is MUCH different from standard 100LL fueling practices in use. But each time G100UL is shown to have issues in the field (including with an airframe manufacturer) they release a YouTube video that poorly replicates the case study and their video is called "hard data." This makes me nervous...it is certainly possible that the only testing that was done may have been the one in the video. The methods shown in the videos are not of the caliber I'd expect from an engineer or a company that expects to supply 100% of the Avgas in the country/worldwide. Certainly not the quality and caliber of the testing that was mandatory for fuels going though the PAFI process. Unfortunately this is the only "data" that the public is left with from GAMI as any of the other data (whatever that is) is not open source or available. Questioning this only gets a comment suggesting the "FAA is watching you and takes offense that you'd question their approval." Not really confidence inspiring. However, the thing that gives me the most pause is that GAMI/Mr. Braly have repeatedly been very vocal about the term "commercially available" and this is likely very intentionally done to springboard off of the Consent Judgement in California in an attempt to outright ban 100LL in the state. And their comments came well before G100UL was actually widely field tested and shown to be safe and truly a "drop in fuel" like they claimed. What's been "proven" is that G100UL is likely NOT a "drop in" fuel. And if some of the comments coming from PAFI are accurate, there may not ever be a truly drop in fuel. Knowing this, the most important part of the "discovery" of field use and wider testing of ANY unleaded fuel is going to be our own transparency of where the alternate fuel's weakness lie so that we can all learn from this and effectively adapt our aircraft to the new era of unleaded fuel. The issue I see with G100UL is that so far, their comments suggest that there is no problem with G100UL and the issues are all in poor maintenance and substandard equipment and old materials...but the problem is that they are referring to many materials, processes, and equipment that are standard use and have been effective until now... -

@shawnd Once you’re up and running with the new equipment you’ll have to fly the profile again and do mixture sweeps slooooowwwwllllyyy down and then back up multiple times. Reviewing data on Savvy it’s easy to use their automation to compute your spread https://www.savvyaviation.com/wp-content/uploads/savvy_pdf/Savvy-Flight-Test-Profile-Expanded.pdf

-

What’s your spread currently? I believe your engine came with TCM tuned injectors and often have a pretty tight spread. I’m 0.3-0.4 GPH spread out of the box. Other Marc’s M20K was close enough GAMI recommended against new injectors.

-

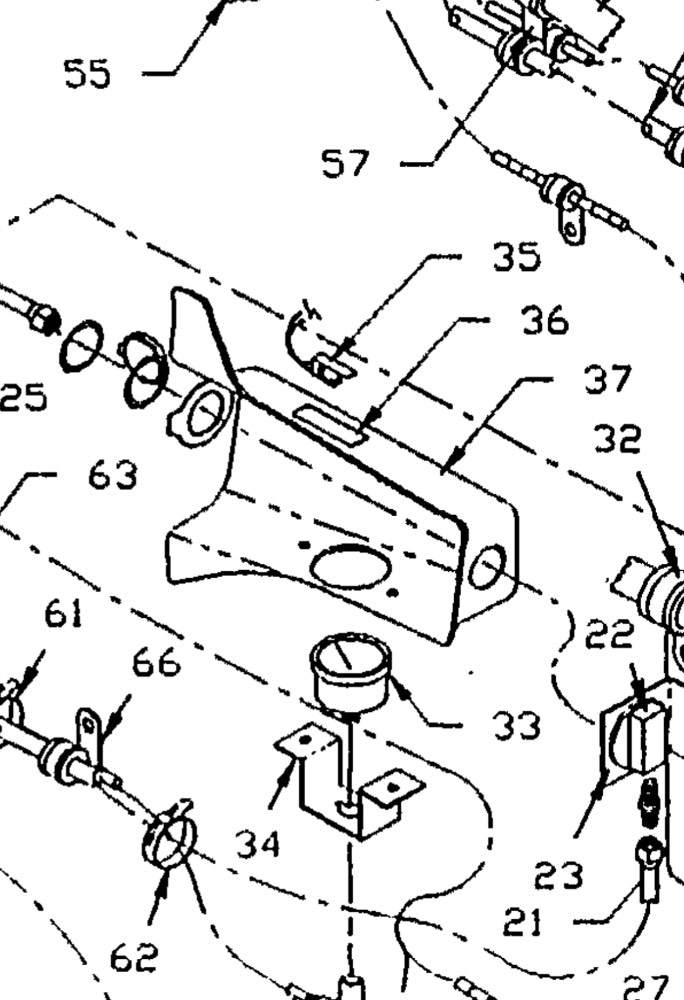

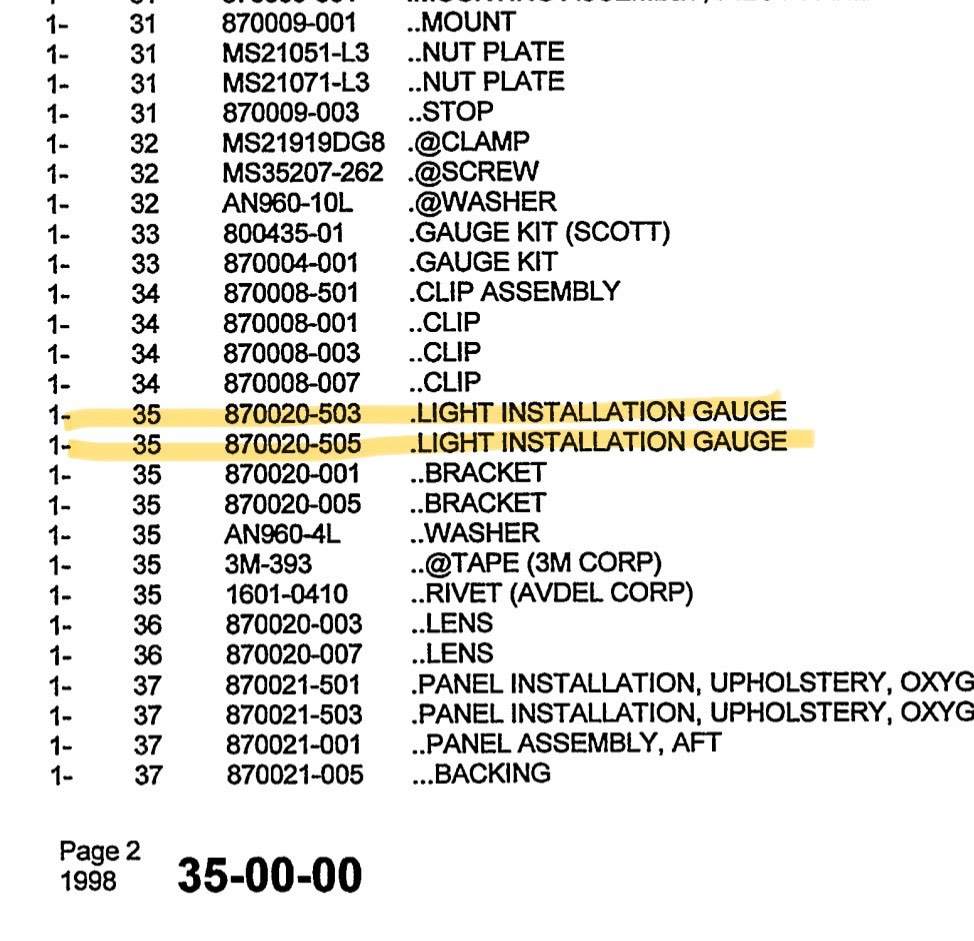

Strange. I could have sworn my oxygen gauge does have a light. I’ll have to check. Edit: looks like IPC shows effectivity for all 25-0001 and on with possibly a light?

-

@Bigdaddie You have two rotary knobs that control glareshield and panel lights. Do these work? Sometimes it’s a faulty rheostat, other times it’s a blown fuse. But I believe you should have a backlight that’s tied to the Panel Light rotary knob.

-

Based on the G100UL fuel leak thread what's your position?

Marc_B replied to gabez's topic in General Mooney Talk

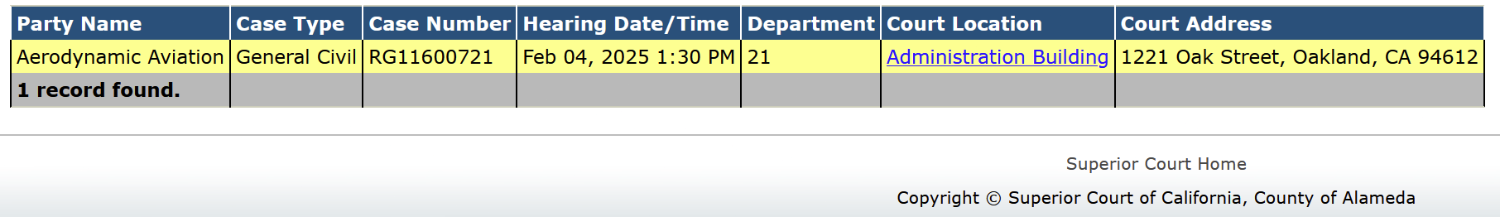

Someone on BT said it was "Deferred another couple weeks..." Not sure any details or what was discussed in Court. Addendum: Mr. Niles said it was put off until Feb. 18 at the earliest, possibly Feb. 25. Edit: would be interesting if G100UL went through the PAFI testing process to better understand where it works well and where it fails. I don’t think we’re likely to “see” the data that was presented to the FAA for STC and given that Braly has only presented limited videos and labeled this hard data I don’t think that we will. Would G100UL have been able to get approval through PAFI? And if not, this certainly calls into question the approval process for alternative fuel STC’s. -

@varlajo some shops use Boeshield T9 as well. I think that's what Top Gun uses (or at least they did many years ago on my Mooney). You might give Mark Rouch a call at Top Gun and see what they typically charge since you're close by at SQL.

-

Based on the G100UL fuel leak thread what's your position?

Marc_B replied to gabez's topic in General Mooney Talk

Looks like this is on the docket for today... Curious if anyone knows any details and interested to hear the outcome of this. Case No. RG-11-600721 Hon. Somnath Raj Chatterjee SETTLING DEFENDANTS’ OPPOSITION TO MOTION TO ENFORCE AND MODIFY CONSENT JUDGMENT Date: February 4, 2025 Time: 1:30 p.m. Reservation Number: 690015831804 -

Did you send off your filter for analysis to identify metal composition to help identify potential source...or just an oil sample? https://avlab.com/product/oil-filter-analysis-kit/

-

+1...I have LED replacements in a box, but figured I'd let sleeping dogs lie for now.

-

https://schemedesigners.com/paint-shop-referral-list/ @wombat I'd use this as a starting point, reach out to a few and ask for recent referrals. Then you can discuss value, what went well, what not so well, and how accurate the time estimate was. All prices have continued to climb for a strip and paint, and some of the amazing values of 15 years ago are now right in line with other shops. If you search MooneySpace about the most mentioned shop is Hawk. It's always funny that with respect to paint shops it seems you'll often hear the "stock market" disclaimer...past performance is no guarantee of future results. But I think that it's at least a solid place to start looking.

-

Turbocharged engine takeoff ground roll checks - tips?

Marc_B replied to hazek's topic in General Mooney Talk

I thought that was referring to 1/8" from full forward. i.e. if you use the button to push all the way forward it will stop, but you can still twist in more and it could bind or perhaps could damage the vernier mechanism? I read that POH statement as you shouldn't twist the vernier more than 1/8" from fully forward.