-

Posts

1,302 -

Joined

-

Last visited

-

Days Won

10

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Marc_B

-

Based on the G100UL fuel leak thread what's your position?

Marc_B replied to gabez's topic in General Mooney Talk

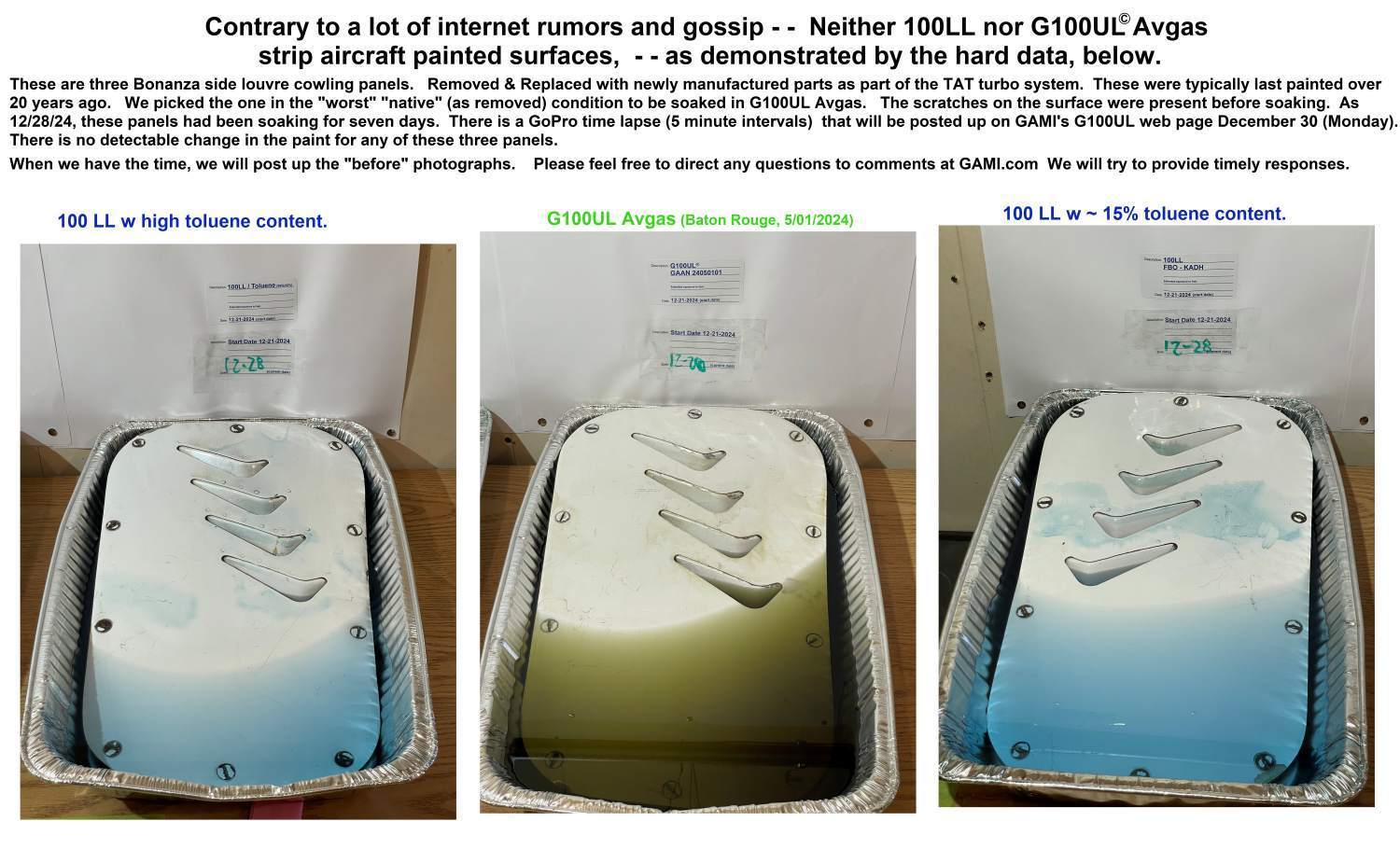

I think that it seems that the G100UL test with the 100LL sample that had "high toluene" may have been intended to show that 100LL with high toluene caused paint damage whereas the G100UL sample showed didn't?? I was very curious why GAMI wouldn't just test 100LL vs G100UL...why not just a simple "pumped fuel" vs "pumped fuel"?? Why add more toluene to one of the fuels, especially when the amount and concentration wasn't labeled? https://www.youtube.com/watch?v=zrOoq-sB1Ig -

Based on the G100UL fuel leak thread what's your position?

Marc_B replied to gabez's topic in General Mooney Talk

Mr. Braly, With all respect, the conflicting statements (edit) make it very difficult for us to distill fact from fiction. Earlier you said "Contrary to a lot of internet rumors and gossip -- Neither 100LL nor G100UL Avgas strip aircraft painted surfaces." The apparent truth is that under certain circumstances G100UL can strip paint, and has been shown to strip paint. What we'd like to know is what circumstances are we likely to see this happen, and what we can do to prevent it. It's clear that you have FAA certification for your product. It's not clear what test data was shared with FAA for certification. It's clear that you want to selectively share information and engage with GA pilots to help inform them of your product and increase sales of your STC and fuel recipe. But what's not clear is if your engagement is just advertising or if you're willing to share pointed information to help the GA public navigate this political transition to unleaded fuel safely and without signficant damage to our aircraft or wallet. Your ICA speaks of using viton and you openly have recommended viton products and say that you recommend "modern" maintenance recommendations (i.e. Bendix advisory you noted), but then say that your test data was done on nitrile components and tested fine. So if that's the case, why would you suggest changes and why wouldn't you just leave that liability up to the mechanics working on the aircraft?? I'm not sure if the conflicting statements (edited) are intentional, suggest a possible risk that you feel is low, or just lawyer speak, but it is very confusing to well-intentioned pilots who are just trying to make the best decision for themselves and their families. From your earlier post: -

48 years on original sealant and finally some leaks prompting maintenance. Outstanding! Hope you took the poll above so your Mooney could be counted @Doug G!

-

I think these wet tanks are WAY more robust when properly applied than we give them credit for! 48 years in a solvent and still kickin. Outstanding! (but certainly sounds like time for reseal!)

-

agreed 100%. same with bladders or fuel cells I'm sure as well!

-

When I did my Instrument checkride the DPE asked for one coupled approach (I have an autopilot). He said that he doesn't require an autopilot, but if candidates have one he expects that they should know how to use it. That being said, with instrument training with my CFII it was 99% hand flying and I had more KFC150 training with a fellow Mooney pilot. For single pilot IFR, the added safety and capability with use of an autopilot can't be understated. But that is 100% dependent on the pilot being knowledgeable to use it.

-

Has anyone ever noticed a big difference when they opened tanks to patch or reseal with regards to the top wing sealant and the bottom wing sealant? It seems there are two possible reasons that sealant covered in fuel would help protect sealant...better thermal regulation with the large volume of fluid that could absorb heat, and keeping the sealant wet to keep it from drying out. If the offered theory is that fuel is so damaging to the sealant, then it seems to reason that keeping tanks empty would be better...but I've never heard anyone suggest this... Not sure if any studies have been done on either theory, or if keeping wet tanks full is just an OWT/tradition for "best practice" rather than actual science??

-

I suspect it's a solution looking for a problem. Tons of Mooneys have been firmly planted on the ground compressing the shock discs that last 12-15 years. Long bodies shock discs don't last as long due to heavier engine and higher empty weight on the discs. None of the Mooneys need this. But perhaps it eeks out a few years on shock discs for long bodies with full fuel tanks? My hangar neighbor had their M20J covered in a series of Goodwill sheets tip to tail, wing to wing, and this kept their aircraft paint less covered in dust, less need to clean and scratch with dirt, and their original paint looked pretty factory fresh after 30 years. Sometimes it seems that an ounce of prevention keeps the "pounds" of time at bay! But @Vance Harral I'm with you, I can't imagine leaving my Mooney up on jacks routinely.

-

I've looked and can't find a specific expected life of fuel tank sealant, but I've found the round number of "20 years" used routinely regarding wet wings, bladders, and fuel cells. So I think the general "round number spitball" of wet wing longevity is over 20 years. So far the majority of poll responses have described that the Mooney wet wing can typically do that and then some. Yes, there are variances in construction (wet vs dry riveting), differences in material, differences in bladder vs wet wings vs fuel cells, etc. across the fleet; however, one can't say that "all Mooney's leak" and that's just the reason for any and every leak seen. A leak seen a couple months after sealing (as noted above) isn't the same as a leak in a 40 year old aircraft on original sealant. But wet wings lasting for 20, 25, 30 years or more without leaks certainly sounds like a high quality, high efficiency, low weight fuel storage solution to me! Sounds right in line with what Mooney represents: sleek, efficient, do more with less approach that is seen throughout our Mooneys! It's a personal judgement of patching vs. reseal, but in general if you are seeing flecks of sealant in your sumps with 30-40+ year old sealant; it sounds like it's time to consider a reseal. All sealant has a useful life and sometimes your tanks "talk to you" just like your engine does when it's nearing time for overhaul. ...and leaks with fuels of the future vs. fuels of the past may be different or similar...correlation does not necessarily imply causation...so more data and details are needed, and hopefully will be forthcoming with field reports of real world successes and setbacks.... Details regarding age/condition of sealant may be important as well...if nothing else than to help define the condition at risk. There's nuance to these discussions and we need to speak with details and avoid broad generalizations that don't apply. In my mind, Mooney wet wings work pretty darn well!

-

@LANCECASPER yes, I think that's the company. Although I didn't see anything about shock disc savers on his website. @Fly Boomer there's a company here in the US that sells them. I think Lance pointed out the vendor above. Not sure details of cost and availability though. But the pictures in the Australia company looked very similar to the models that were shown at MooneyMax 2024. Also came across an article from Kerry McIntire. Pretty good overview of tanks, patching, and bladders. https://knr-inc.com/shoptalk-articles.html?view=article&id=24&catid=25

-

There's someone that makes something like Mooney shock disc savers. They presented at MooneyMax this year...basically they slide inside the gear tube (like where you slide tow bar) and then you use a hydraulic jack to raise up a couple of inches and allow insertion of a clevis pin. https://kotzur.com/products/mooney-shock-disc-savers This was what I could find with a simple search, but isn't the vendor that was at MooneyMax... @LANCECASPER can you recall the name? My personal thought was this might make sense for storage if you're not flying regularly, but would be a hassle for those who fly a lot.

-

2 years ago.

-

added the option.

-

FWIW. When I had my tanks resealed at WeepNoMore it was $8900 for both mains. If you needed aux tanks that added $3000 to the total (so aux plus mains around $12k). The wait list was the long part...I believe they were scheduling a year out. I think that since Don Maxwell picked up the Monroy aux tank STC installs, I'm guessing that might offload some backlog?? Of course it's a 2-3 week process, so depending on how far you live, you're likely looking at travel on both ends wherever you decide to go. It's a hassle, but if you're considering that you're doing this once every 25-30 years (or more)...that context makes this much more reasonable. If you're flying regularly, you could potentially go though 2 engines during that time!

-

@Pinecone I added unknown to the first question for you. If not aware of any patching in your logs, that's the second question. If your tanks were resealed at 23 years that's the third question.

-

@DCarlton That's a pretty good run. '67 F on original sealant! Just shows that with some occasional sealant maintenance you're at 58 years! Of course that may also be the reason you've had issues intermittently for 20 years. I'm guessing your bladders will need less overall TLC, but may not last that long!

-

Did you ever have the tanks stripped and resealed? Are you still on original base sealant? Seems like part of the issue that's uncovered with wet wings is that at a certain point you can just patch and kick the can down the road, but sealant surely has a finite life span. At a certain point it seems that the solution is a strip and reseal rather than patching, I think. Perhaps that time frame is 30 years? More? Good luck with the bladders; I hope the install goes smoothly!

-

This kinda of thinking was what led me to get my Commercial Rating. Power off 180s, spiral descents, emergency descents…great tools to have in the bag with your aircraft.

-

@N201MKTurbo I think I would have been inclined to take them up on the offer and asked for them to include full tanks of fuel when I picked up. I wouldn't have liked it but sounded like a bad situation for you all around. I would have hoped and expected that they got everything right the second time around. Hopefully your experience was a horrible one off! Sorry, that stinks.

-

MVP 50 Electronics International Placement

Marc_B replied to Brian2034's topic in Engine Monitor Discussion

@Brian2034 You might post a picture of your current panel and describe what you're having done. i.e. If you have all original panel and just adding an engine monitor you're likely to be way more space constrained and may have less "choice" of where to put your engine monitor. Personally I like having the engine monitor in the area between the PFD and your radio stack. It's MUCH more in your typical scan area, and you're more likely to see changes you might not have picked up if it were on the far right or far left. -

THIS...is what I'd expect with issues with sealant application/product curing/bad sealant batch... My suspicion is that if you have issues with application, then you are likely to see them within the first 6 months of application...but I wouldn't put this in the same category as a wet wing that lasted 25 years without a leak. @N201MKTurbo did you ever get this inspected and have a sense for what the issue was? poor prep vs bad sealant vs bad application vs something else??

-

I started out for just a question for those who patched or resealed, but wound up adding a line for those who hadn't. So fixed it. thanks!

-

The allegation of difference here, I believe, is that some wet wings are fabricated with sealant between the ribs before they are riveted. However, Mooney wings are riveted together, THEN sealant is used at the joints between rib and wing skin. But I'm not convinced this is a detriment, and certainly makes the process of resealing the tanks probably higher quality. I think it's a PROs and CONs on both sides and likely just a difference but not a "one is good and the other is bad" type discussion.

-

I think there are several variables that may affect sealant life including original quality of application...hangar vs tie down, extreme temps vs stable temps, fuel in the tanks vs not flown and kept dry... But I was curious in general for the population of Mooneys represented here on Mooney space if there are brackets and clumps. BUT...if the quality was so bad with certain planes, when would you expect to see it?? 1 year, 3 years...or does even this "low quality" application last 20+ years???

-

The intent was to see how long on average does the Mooney wet wing last before needing sealant maintenance; and for standard tank maintenance (either reseal or patch) how long before seeing further issues that need to be addressed? i.e. if Mooney wet wings are failing 3 years off the line vs 30. Things like a leaking gasket from a fuel sender that's over-tightened aren't sealant related and don't reflect sealant compromise. So I wouldn't count that as sealant failure, If that makes sense.