-

Posts

1,309 -

Joined

-

Last visited

-

Days Won

10

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Marc_B

-

Based on the G100UL fuel leak thread what's your position?

Marc_B replied to gabez's topic in General Mooney Talk

Sort of, but not entirely. What I mean, is that I think an assumption was made that the pictures in the PAFI lessons learned "must" have been 100LL as it was felt that PAFI did not have a high aromatic fuel. BUT, that doesn't mean that the picture was 100LL or even a high aromatic fuel for that matter. I was just asking if Mr. Braly knew what airplane this was and what fuel it was running if he cited this. It was my understanding that many fuels (Bertorelli mentioned in video below) were tested leading up to the candidate fuels in the PAFI program which may or may not have contributed to the PAFI lessons learned. I have no clue where the pictures in the PAFI lessons learned came from, but I'd hope that Mr. Braly did if he was citing these as examples. Sounds like Mr. Braly was checking references to find out if his assumption was correct. -

Based on the G100UL fuel leak thread what's your position?

Marc_B replied to gabez's topic in General Mooney Talk

@George Braly you're aware they are pictures from PAFI lessons learned document, or you're aware of what aircraft and fuel it was running? -

@ProtoFly When I reached out to Surefly I don't think they had a clear handle on which applications and altitudes this may be seen with. Just that it's possible and likely rare for arcing in the ignition harness cap and the remedy was pressurization of the cap with upper deck pressure. Pretty simple to perform the mod with with harness off prior to install. I'll DM you an info sheet I was sent. BTW, I received radio silence from Champion about a high altitude harness as well...perhaps it's a personnel change, dead link or a typo??? Here's the response from Joe at Surefly when I reached out: Hello Marc, we have found that when an aircraft is operated at higher altitudes with standard harnesses arcing in the cap can occur due to separation in the wire insulation of the leads at those lower atmospheric pressures. We have since been recommending either a high altitude harness or a pressurized cap or both. A high altitude harness can be manufactured for you by Alan Woods at Champion Aerospace. His e-mail is alanwoods@champaero.com 864-843-7801. And a pressurizing kit can be acquired from Jim Barker of Aviation Resources. His contact info is jim@aviationvibes.com 715-822-5787.

-

If you were remotely considering a tank reseal in the next year or two; I'd be calling now to get in line...

-

@NickG if you zoom in on the face of the camloc there's a number that corresponds to the length. Those look small enough that they're probably 2700's. So if the number on the face is "3" for example, it's a 2700-3. Another quick and easy way to order the right one is to find one that is clearly marked on the face, then use it in the place you need and see if it fits. There are two types of washers that can be used, but you don't "have" to use a washer. I think under a certain size, or with certain applications, you might not be able to fit a washer. These washers work on both the 2700 and 2600 camlocs. https://www.aircraftspruce.com/catalog/hapages/camlocwashers.php https://anemo.eu/retaining-washers%3A-when-use-v2600-lw-7-when-use-2600-sw SW-2: split washer, allows the camloc to pull back but the washer keeps the horizontal posts at the end from coming out. So retention is loose. LW: the starred lock washer that grips around the barrel of the camloc and secures the camloc to the surface of the piece it's used in. See the Anemo document linked for a better description.

-

Based on the G100UL fuel leak thread what's your position?

Marc_B replied to gabez's topic in General Mooney Talk

@George Braly Respectfully, there's a difference in a wet wing that leaked shortly after sealing (due to bad sealant, improper technique, or due to damage to the structure) and a leak that results from the implementation of a new fuel. You are quick to condemn the Mooney sealant technique, Cirrus application technique, and wet wings in general. But the hard reality is that these are 100% a part of not only the general aviation fleet, but a standard practice to use wet wings in aviation in general. It is very clearly understood that you want to convey that any leaks seen from using G100UL are due to poor sealant product, poor sealant application, and wet wings in general. But there are lots of Mooneys on here, and out there, who have seen 25-40 years before substantial leaks on their wet wings requiring resealing. It's yet to be seen if G100UL will be able to have the same track record. It's also more concerning if cases of leaking G100UL may result in significant paint damage when that's not typically something that has been routinely seen with 100LL. Certainly there is benefit to having the BEST paint, the BEST sealant, the BEST hoses/o-rings/etc for the job. BUT for a fleet of aircraft that spans back to the 1960's (and in some cases much older) all the way to today, there are exceedingly few that have the newest and best currently and the best for long. In our minds, "drop in fuel" means fly what you have. -

I think the biggest benefit from ceramic coating is that they are much easier to clean which translates to less work, less pressure, and less scratches from scraping the surface. The "better" the coating, the longer the protection lasts. The "professional" grade products last longer but part of that is that the surface is properly prepared so that the product adheres better, and the other part is the quality of product. Base preparation and paint correction is time intensive and requires some degree of technique/equipment. Most professionals would probably recommend a touch up or refresher every few years...a good rule of thumb is when you notice a different in water beading, slickness or gloss. Most paint shops I've spoken with recommend ceramic coating. Of course the "value" of this, like most things in aviation, is dependent on the eye of the beholder. @AndreiC it's interesting that Permagard advertises as not needing paint correction and so seems like it should have been way cheaper than ceramic with paint correction.

-

Based on the G100UL fuel leak thread what's your position?

Marc_B replied to gabez's topic in General Mooney Talk

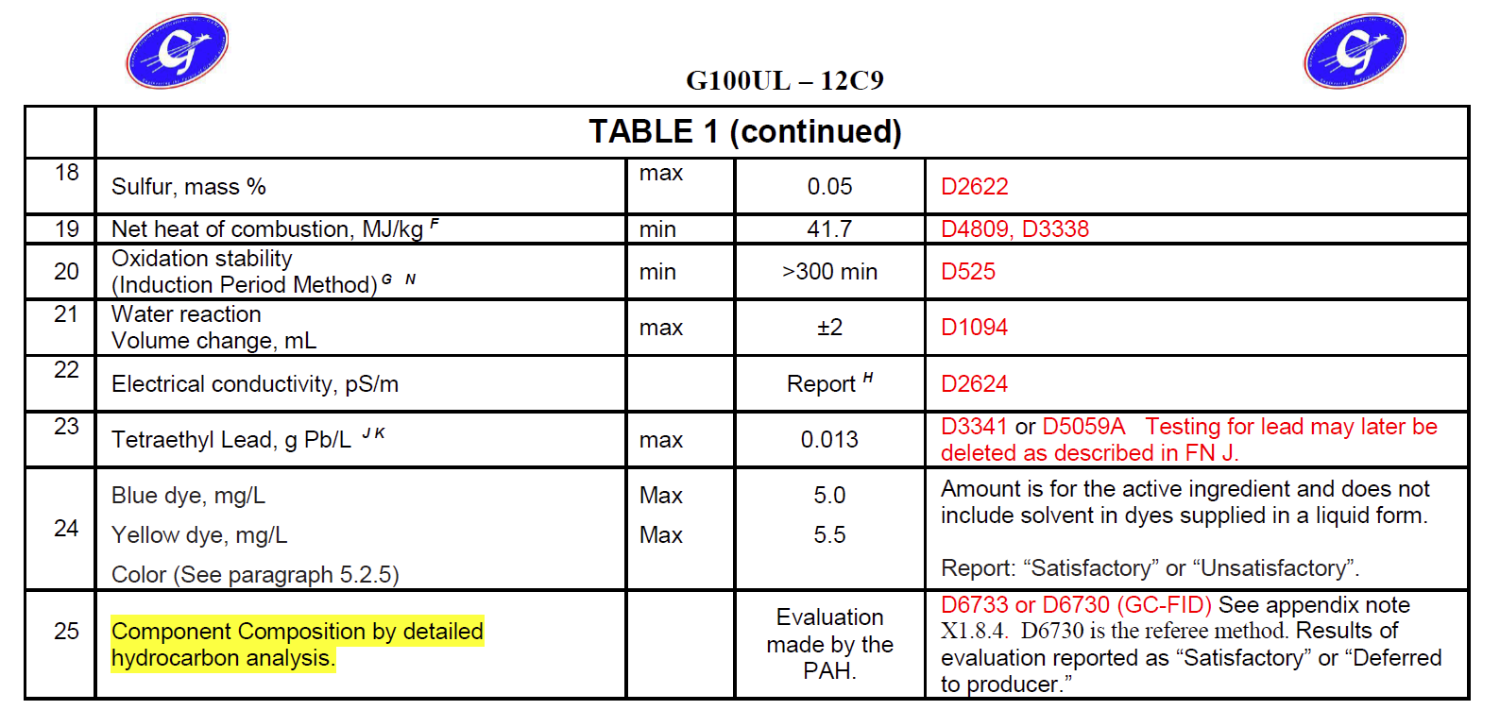

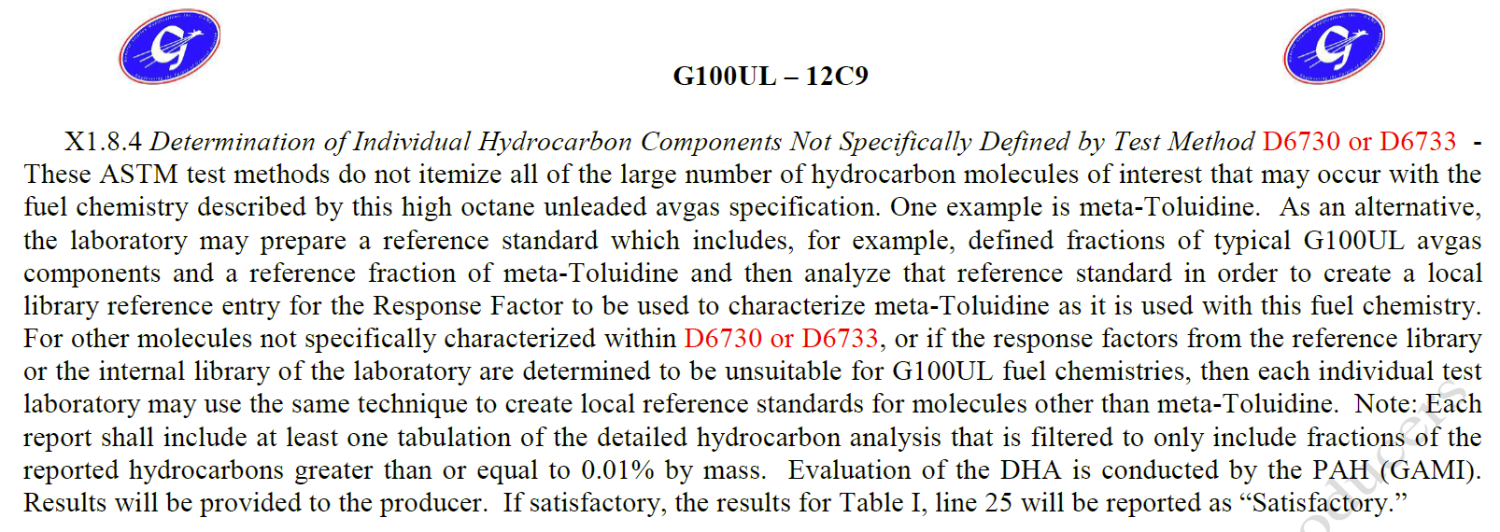

What follows would need to be confirmed by GAMI; given the secrecy with the formula and composition of G100UL, it's hard to do more than speculate. This is the part that really GAMI would have to share more information to really determine what exactly is in G100UL. Aromatic amines are toxic in general, and produce nitrogen oxides when burned. In the SDS there's mention of meta-toluidine but in the patents GAMI mentions the difficulty in getting this produced as a single isomer; so usually it's proportions of o-toluidine, p-toluidine, and m-toluidine. Ortho- isomers are even more toxic/carcinogenic, para- isomers have a high freezing point (+44C) and caused clouding of fuel at lower temps, and meta-toluidine was what they were trying to isolate. It seems like GAMI tested and developed the use of co-solvents to allow development of an "additive concentrate" of m-toluidine and p-toluidine that apparently avoiding clouding of fuel at temps similar to 100LL. Boiling point of these aromatic amines is just under 400F and it looks like evaporation is "negligible" at room temperature. UV light causes photodegradation of toluidine which can cause browning and development of more harmful byproducts. This may be the reason that you have to clean off G100UL from the wing with windex rather than just wipe away which would just smear this component and not remove but rather expose more surface area. Any residue left behind can potentially cause staining of paint or other surfaces. The solution to pollution is dilution. The interesting thing about GAMI's drip test is that they used a glove with several holes poked in it and when they'd fill up the glove it would cause drips to quickly form and under the sped up camera speed looked like it rinsed off the surface with fresh fuel. GAMI also kept adding fresh fuel to glove which then ran completely off the surface, as opposed to just adding more fuel to a container with access panel which may have resulted in higher amounts of partially evaporated fuel in the Luvara testing. My WAG is that GAMI's drip test was continually rinsing the surface with fresh fuel to dilute the partially evaporated "concentrate" of low volatility components. Whereas Luvara's test had addition of fuel for sloshing then evaporation; so my suspicion is that at the end of Luvara's test there was a higher amount and concentration of low volatility components. As opposed to GAMI's test where the total AMOUNT of low volatility compounds on the surface was much lower, and only reached higher concentration when the drips were actually stopped. I would have also like to see if GAMI then took that panel at the end of their test and left it outside exposed to sunlight/UV light how easy that staining would be to clean off. Still curious what "standard shop techniques" for cleaning the panel was. Not sure if anyone has tested G100UL staining indoors and away from UV vs outside to dry in sunlight/high UV to see what the difference in clean up and removal of staining would be?? Toluene evaporates quickly. Xylene doesn't evaporate as quickly. And toluidine likely doesn't evaporate much at all. Of course from earlier discussions, aromatics are known to affect elastomers and this is likely the root of the cause of increased o-ring swell vs 100LL. Hard to stay how much Xylene + Toluene is in G100UL...maybe up to 45+%??? (below from G100UL spec sheet). (edit: which major OEM aircraft manufacturers was this? Cirrus?) -

Based on the G100UL fuel leak thread what's your position?

Marc_B replied to gabez's topic in General Mooney Talk

What we're seeing was: 1) discussed and brought forth by PAFI in their testing and development of fuels and was discovered and warned about with use of higher content aromatics (PAFI Lessons Learned); 2) paint damage has been shown to occur in at least 7 aircraft that have been fueled with G100UL release in California, usually in response to marked leaks that show signs of escalation in leak location and amount of leak, but also paint damage has been shown in the form of staining with any spill/splash or drop not immediately cleaned with a product such as Windex; 3) GAMI/Braly has reacted defensively making initial comments that issues seen are due to high aromatic 100LL and not due to even higher aromatic G100UL; 3a) Cirrus finds that G100UL may not be compatible with their sealant and issues service advisories stating that G100UL is not approved to be run in their aircraft and this may void warranty. GAMI releases a series of YouTube videos and commentary on their website in response; 3b) Textron keeps G100UL off their approved fuel list; Continental and Lycoming keep G100UL off their approved fuel list; 3c) PAFI candidate reports that creating a truly "drop in fuel" (fuel without any requirements of modification) is likely impossible; 4) a video surfaces performed by an engineer/A&P where he uses G100UL initially from the pump, but then also tests that were from the affected aircraft that demonstrates the process shown in the affected aircraft (Luvara video 1) (Luvara video 2); 5) GAMI releases a series of YouTube videos that don't use the affected aircraft, doesn't use various test cases, and solely focuses on one model of aircraft and paint to present "hard data" to make a statement that G100UL doesn't affect paint and shows how "easy" it is to remove staining from paint with "standard shop techniques for cleaning up paint" (G100UL soak test) (G100UL drip test); 6) AOPA Baron makes the statement, "G100UL tends to stain paint, hangar floors, and anything else it touches. Pilots and aircraft owners can take precautions by applying protective coatings, but G100UL doesn’t wipe away or evaporate like avgas. Inadvertent and relatively small fuel spills must be cleaned immediately and thoroughly to avoid staining." And in fact, if exposed to UV light the stains are very difficult to remove (AOPA Baron Lessons Learned); 7) FAA is investigating affected aircraft and have taken fuel, oil, and paint samples; 8) These test cases and issues seen have all occurred within about 2 months of the introduction of a new fuel to California; 9) Said fuel is still being sold and is currently marketed as "basically transparent to the engine, aircraft, and pilot. No mechanical modifications are required" other than placards; 10) some who haven't used the fuel are proponents of GAMI/Braly and have come to his defense out of faith that surely the proper testing and FAA certification means that the product should be trusted; 11) many who haven't used the fuel are fearful to use a new fuel without more testing and transparency to determine the merit of the issues shown in California. 12) This would be a simple case of vote with your wallet and either buy the new fuel or dont, however the current political climate (especially in California) has continued to escalate pushes to ban 100LL; due to this the apprehension to use this product is tempered with the fear that this will become a mandate to use this fuel if nothing is said. Proponents of G100UL should fly to a location and fuel up. We fly one of the best traveling, single engine piston aircraft in the world. Either your help disproving the concern, or proving it, would be greatly helpful for the fleet! Good luck! -

Based on the G100UL fuel leak thread what's your position?

Marc_B replied to gabez's topic in General Mooney Talk

This is exactly the reason that you find disclaimers on products everywhere. If you didn't say "use caution with wet wings as this may accelerate leaks and lead to paint damage" and instead said "will be invisible to your aircraft or engine compared to 100LL"...you might have a civil problem. Heck, they have disclaimers not to allow babies to play with plastic bags. But keep in mind, NONE of this is already decided and no one has clearly defined where liability coverage is found with G100UL. Until we actually have actual hard scientific data it's limited observational data with LOTS of speculation all the way around. -

Based on the G100UL fuel leak thread what's your position?

Marc_B replied to gabez's topic in General Mooney Talk

If it was one aircraft out of 100,000 you could suppose it was just mere coincidence. I think having at least 7 aircraft with paint damage that spans at least 5 manufacturers with a hundred or so aircraft that were fueled...that's more than coincidence and deserves a thorough and close look to determine the cause. It might not be G100UL, but it certainly might be as well. The fact that an A&P (FAA certification, real person) was able to recreate the apparent damage using G100UL is not definitive proof but is undeniable that this isn't something that can be ignored as "not an issue with our product." Remember, Luvara is FAA certified and would probably loose his license if found to be maliciously tampering with evidence (at a minimum). GAMI posting YouTube videos only showing Beechcraft louvred access panels for every single "test" that they ran...that's not scientific, isn't very credible for a company that wants to have 100% of the market share of 100LL, and doesn't pass muster as "hard data". The statements that Mr. Braly has made here are very generalized "Hard proof that 100LL nor G100UL cause paint damage." Or pointing to 100LL with 29% Toulene on a single sample over a decade ago and saying that is what damages elastomers... Perhaps GAMI is investigating this behind the scenes and actually has a thorough crew of investigators from GAMI and the FAA (I sincerely hope this is the case)? But GAMI's posts on the social media outlet of Mooneyspace, BeechTalk, BackCountry Pilot, etc are so far not more than an attempt at social influencing, advertising, and damage control. If a fuel is advertised to be 100% drop in without any modification but then requires new sealant (specific new fuel resistant type) and new paint (specific new fuel resistant finish and prep), new fuel lines, and new o-rings...that's not 100% drop in as is. It's drop in with an asterisk and requires definition on an ICA/STC paperwork...(either that or perhaps an AD in the future). The fleet is a phase two of a "beta test" to uncover where issues are seen. But you have to believe the issues and adapt or else you're stuck with version 1.0.0 forever. If that's the case, this may not be a fleet wide fuel. -

Based on the G100UL fuel leak thread what's your position?

Marc_B replied to gabez's topic in General Mooney Talk

I suspect that GAMI has, and would be shocked if they had not. If this was truly an issue GAMI has never seen with G100UL, first and foremost would be to r/o contamination either accidental or intentional. This would be easy to take a sample from the pump, take a sample from all aircraft with issue, and compare with originating batch. Part of the spec with G100UL is performing a DHA from each batch of fuel to report that it is conforming and to establish the "fingerprint." -

Process for removing Nose Gear Truss

Marc_B replied to Matthew P's topic in Vintage Mooneys (pre-J models)

It requires a shock disc compression tool that your A&P will have to borrow if they don't have one. As mentioned the instructions are in the maintenance manual. There's also some steps that require proper set up of geometry fore-aft and gear extension and retraction when you're putting it back together. Having someone help that is familiar with Mooney gear rigging would be a plus. -

Based on the G100UL fuel leak thread what's your position?

Marc_B replied to gabez's topic in General Mooney Talk

@George Braly have you tested the fuel from the RHV and WVI aircraft of note and was their fuel confirmed to conform with G100UL? What was standard shop technique for cleaning stains off and did those panels have surface prep/wax/ceramic? How different is the staining with UV light than standard indoor lighting or infrared? Have you tested any other paints, aircraft parts, or manufacturers than the louvered Beech panels? -

Based on the G100UL fuel leak thread what's your position?

Marc_B replied to gabez's topic in General Mooney Talk

Agreed. If you look at the Aeronca Champ with paint damage, the paint is bubbled up, not just peeling or flaking off. Same as the Mooney described in this thread, the Cessna 421C, as well as how it looks on the AOPA Baron. If it was just attacking the primer you'd think it would just chip and peel rather than bubble and expand. Is Beechcraft paint technique materially different than other manufacturers? What coating/primer/paint/etc have they typically used? -

Based on the G100UL fuel leak thread what's your position?

Marc_B replied to gabez's topic in General Mooney Talk

In those videos 100LL did not cause the issues that G100UL apparently did. But you’re right, between Luvara’s videos and Braly’s videos, the end user still has no better idea of what the underlying cause or the specific aircraft at risk are. GAMI is in best position to help determine the cause, but possible financial disincentive. GAMI points to pictures of bad leaking on a wet wing and says this is the issue (“hard data”), but we didn’t see the extensive paint damage with 100LL. So I’m just left with the impression “it’s not me, it’s you.” Not a good advertising technique for my business. More importantly, how am I supposed to know if I can safely use G100UL in my aircraft? Until the root cause is known and identified, I can’t. This is the issue that Mr. Braly points the finger as the cause…and the picture he uses to highlight as “proof” that 100LL is equally as damaging…https://www.aviationconsumer.com/maintenance/fuel-tank-reseal-thankless-expensive/ -

Based on the G100UL fuel leak thread what's your position?

Marc_B replied to gabez's topic in General Mooney Talk

My comment was intended to point out that important things aren't always tested. If the PAFI criteria didn't mandate exhaust or paint testing, it doesn't mean that these aren't "important", but just that they weren't the "focus." -

Based on the G100UL fuel leak thread what's your position?

Marc_B replied to gabez's topic in General Mooney Talk

Use Google patents to look up one of GAMI patents...it's pretty interesting to read more about how this was made and what was tested. Some components have much different properties with different isomers of the compound that vary greatly, and some components are added solely to help "buffer" an otherwise negative effect. i.e. from GAMI's patent: p-toluidine has octane enhancing properties, but high melting point of +44C compared to m-toluidine melting point of -30C, and o-toluidine has undesirable toxicity issues. Typically toluidine produced in ratios roughly 60% o-, 36% p-, and 4% m-toluidine. Looks like quite a bit of testing with co-solvents was used to find a way to use toluidine as an octane booster while not having clouding of the fuel with low temperatures. Xylenes comprise up to 45% by weight; aromatic amines up to 6% (according to 2020 patent). -

Based on the G100UL fuel leak thread what's your position?

Marc_B replied to gabez's topic in General Mooney Talk

As an aside, for those with an environmental concern (for example)...was any testing done to see if an alternative fuel burns dirtier than 100LL? Aromatic amines are pretty nasty healthwise and aromatic hydrocarbons burn dirty (it's why you see so much soot in the cylinders and tailpipe of aircraft running G100UL. How do exhaust byproducts compare between G100UL and 100LL?? The ultimate issue is "Where do you stop with the environment?" Aircraft don't typically have mufflers, don't typically have catalytic converters, and nationally burn tons of Jet A annually that's pretty dirty (go check out an airport parking lot and see what covers all the cars in parking). -

Based on the G100UL fuel leak thread what's your position?

Marc_B replied to gabez's topic in General Mooney Talk

Do we even know if extensive testing on paint was even performed by GAMI?? Mr. Braly stated that paint was never a test criteria for PAFI and the "tests" he shared wasn't an assortment of paints and preparations reflective of the fleet. Mr. Braly's interpretation of his own testing was that having an item half submerged and half outside of G100UL gives the air/fluid interface an area where fuel is wicked up the surface (through surface tension) and the volatile component is allowed to evaporate. BUT, I think this is like me taking a candle and quickly moving it across my hand...it doesn't burn if it moves fast enough and only damages the surface when it stays in an area for a prolonged time. I find it interesting that there is still a decent amount of residual liquid left in the containers when new fuel is no longer added...I think there may be a measurable amount of less volatile components in G100UL and it may be when these are concentrated through evaporation + have an extended dwell time = damage is seen. Mr. Braly mentioned that the testing GAMI performed was boundary testing, i.e. identifying the harshest condition and if fuel passes that test then it is extrapolated to pass testing on less harsh conditions. But if testing parameter didn't include extensive paint testing by design, you don't "see" what you didn't see. As an aside...to those who feel that the paint testing done by Mr. Luvara isn't reflective of "real world." Keep in mind that most fuel engine testing is high power 150 hr block testing used to extrapolate effects of usual varied power, low power cruise, etc over the lifetime/TBO. Subject it to simulated "harsh" conditions for a shorter time to simulate longer period of less harsh conditions. The testing format shown by Mr. Luvara looks like a good replication of what we'd see in actual use of a fuel...simulating an exposure to partially evaporated/evaporated fuel continually over time. It also may more accurately reflect spillage of fuel by the fuel vent, a slowly leaking fuel sump drain, fuel that splashes up repeatedly from hitting a flapper valve during fueling that isn't immediately cleaned up...even if you do a great job cleaning up a spill, there are parts of the wing that fuel can seep into with a splash that may have primer only covering...wing spar, speed brake areas, inner wing skins and all the things the inside of the wing contains So I don't think this is "just a cosmetic" argument. Paint isn't just done to make aircraft "pretty"...it's a protective covering that helps delay/prevent corrosion which is a detrimental force with every aircraft. -

Based on the G100UL fuel leak thread what's your position?

Marc_B replied to gabez's topic in General Mooney Talk

https://g100ul.com/patents One can look these up on Google Patents. Composition of fuel may not be accurately reflected by SDS. Still would be interesting to see the detailed hydrocarbon analysis of the California G100UL. -

Based on the G100UL fuel leak thread what's your position?

Marc_B replied to gabez's topic in General Mooney Talk

The issue is that there obviously needs to be some third party testing. There has been more issues seen in the last month that have raised concerns, and unless the allegation is that these are all fabrications, it’s hard to discount something different is occurring. It’s not more YouTube videos from GAMI that are needed. It’s review by an outside neutral third party. The issue here is it’s clear that GAMI chose not to go through PAFI, possibly has required NDA for testing at least from Lycoming, has concerns that intellectual property will be stolen, and sent data to the FAA, with approval of such data, but that is not open source or independently reviewable by anyone in the industry, nor myself The response of GAMI so far has been 100LL damages paint and wet wings are poor technique; nothing to see here. But they’ve never offered an explanation of what’s been shown here. Mr. Braly stated he’s never seen paint damaged by G100UL. So as a potential customer and user of G100UL, how can I reconcile use of a fuel that we don’t have an answer as to why in certain circumstances it appears to damage paint? It may not be a “requirement” from PAFI that no paint damage or even staining is seen…but as long as I have a choice in fuel, it does matter to me. -

Based on the G100UL fuel leak thread what's your position?

Marc_B replied to gabez's topic in General Mooney Talk

Judging from SDS, I don’t see meta-toluidine listed in 100LL. And the fact that Swift has been so adamant that they don’t want fuel mixed with theirs that contains meta-toluidine (without further testing) but say 100R is fungible with 100LL, leads me to believe this is accurate reflection that 100LL does not contain meta-toluidine. (Of course there are other components in G100UL, as well as different concentrations of some components in common, not found in 100LL as well). 100LL SDS: G100UL SDS: -

Based on the G100UL fuel leak thread what's your position?

Marc_B replied to gabez's topic in General Mooney Talk

It's interesting that Mr. Braly has pointed towards towards Toluene and his initial posts here on MS made a point of pointing out up to 29% Toluene in 100LL. I suspect typically higher overall levels of aromatic hydrocarbons in G100UL (up to 40% xylene). However, there's allegations from other sources that it's the meta-toluidine component that's the issue. Certainly meta-toluidine is an aggressive solvent, with a boiling point of 398.1F, and the evaporation rate is considered "negligible" at room temp meaning it evaporates very slowly. Would be interesting to "test" a G100UL sample MINUS the meta-toluidine and see if it had the same effect on paint. The composition of the "film" remaining on the surface after the more volatile components have evaporated would be very informative I think. Both G100UL as well as 100LL have xylene and toluene (although in different amounts).