A64Pilot

Basic Member-

Posts

7,713 -

Joined

-

Last visited

-

Days Won

21

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by A64Pilot

-

Most of the time a Lipo gets a thermal runaway when being charged, but sometimes when being discharged, physical damage sometimes sets one off, but for example even that’s very rare for airplane models that are crashed. Having said that Lipo’s are graded, only buy a pack that is Grade A cells, if it’s unspecified it’s most likely Grade B. Also only buy packs that are CE or UL rated, CE is essentially the European version of UL, for some reason it seems Europe has led the way in certifying Lipo batteries, UL certified packs do exist, I’ve not seen one though, but do not buy a battery that isn’t either CE or UL certified. So if you ensure your battery is both Grade A and passes CE, it’s a whole bunch safer than the run of the mill cheap packs used in budget scooters etc.

-

Good electric scooters that will fit in a Mooney?

A64Pilot replied to oisiaa's topic in Miscellaneous Aviation Talk

You know I knew that, just forgot Issue is I’m on an Ipad looking at the Ebay App and there isn’t an address bar, expected some kind of link, or share button like You tube has in their App. -

Good electric scooters that will fit in a Mooney?

A64Pilot replied to oisiaa's topic in Miscellaneous Aviation Talk

-

Good electric scooters that will fit in a Mooney?

A64Pilot replied to oisiaa's topic in Miscellaneous Aviation Talk

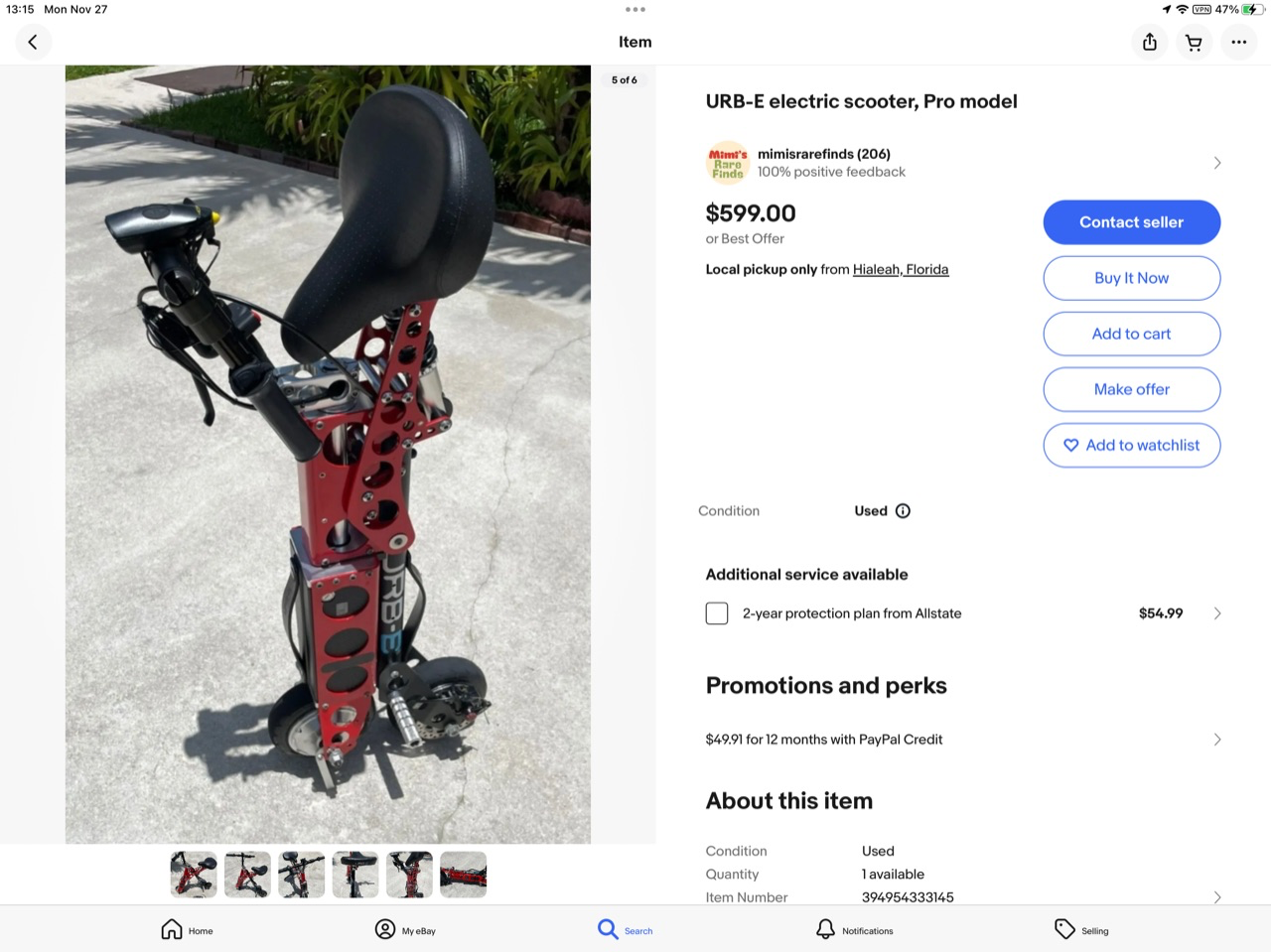

That’s why I said maybe Ebay, compared to most of the Chinese scooters that dominate the market now they were expensive and I’m sure that’s why they went out of production, no way a US manufacturer can compete. But I think due to quality of manufacture and small size and even lighter weight than most even with the seat it’s worth trying to find one. Many of us older pilots due to knees, back etc are buying scooters, here is a pic of the breakfast group. -

Depending on what the goal of testing is, you can usually get the results you want within reason of course. Germans have a saying, it’s statistics are like a lady of the evening, if your paying, you get what you want. Unleaded fuel of any kind has long been known to cause valve reversion, that why automotive engines went to Stellite valve seats when unleaded fuel was mandated for cars. Lycoming and others will respond with hardened seats and through attrition the problem will go away. Having said that many thousands of aircraft have been burning unleaded auto fuel for decades with seemingly no issue. I have burned auto gas most often in my C-140 but sometime toss in some LL if I know it will sit for awhile, it seems to make autogas store much better. Years ago on the C-140 assn website it was shown that the difference in price between autogas and LL would pay for an engine overhaul, so burn car gas and overhauls are free. Run the numbers yourself and see. Yes I know that alcohol is prohibited and I can tell you a whole bunch of alcohol fuel is burnt with no problem. Years ago I wasted a LOT of time searching the NTSB database looking for engine failures attributed to alcohol causing water or phase separation, degradation of fuel lines, O-rings whatever and couldn’t find any instances, perhaps I just didn’t know how to search, but I’ve just never heard of alcohol causing an aircraft accident? I hope when LL goes away that there will be money in expanding the water injection STC, if or when that becomes a reality then I’ll buy it and the equipment and just burn premium auto fuel. I personally believe when LL is outlawed that whatever is it’s replacement will just as a guess be $10 a gallon, blamed on supply chain shortages maybe, but premium car gas will be easily available, if all of us started burning it I doubt we would be 1% of the sales.

-

Good electric scooters that will fit in a Mooney?

A64Pilot replied to oisiaa's topic in Miscellaneous Aviation Talk

Two URB-E scooters fit in the baggage, just under 30 lbs, 15 MPH supposedly 30 miles range. I’ve never come close to that, no way I’d ride the thing for 2 hours. Sit down scooter Made in California high quality 6061-T6 aluminum and sadly I think out of production, but maybe could find one on Ebay. The basket slips on and off and I don’t think it would fit with it on. -

I don’t know why anyone would get a Repair Station certification that didn’t have to have one. I stood up a Repair Station once, took several months, finally hired a technical writer to write the repair station manuals, a repair station is a real PIA, much easier to get your IA and just have people work under it. For general aircraft maintenance an IA can do anything a repair station can, now instruments I think is different

-

That sounds like a bad battery, the battery shouldn’t drop that low with just a gear load, not if it was fully charged even if the alternator were off line. However even with a bad battery the alternator should have absorbed the gear load with little voltage sag. Assume we have a 60 amp alternator and assume you’re running a constant 20 amp load and the gear is another 20. That means that actuating the gear puts a 40 amp load on a 60 amp alternator, so it should hold that load with stable voltage. I don’t know off hand what our alt size is, but 60 is pretty common, and I don’t know what the gear load is, but am pretty sure it’s less than the circuit breaker so I think my numbers are within reason. In other words it’s possible you have both a bad voltage regulator and a weak battery, but it’s also possible the battery is just undercharged from a bad regulator too. Our airplanes are old so it’s likely that depending on where you measure the voltage your reading may be a little low due to resistance in old wiring etc. However the cigarette lighter is usually a decent place because it has a big wire, cause it’s meant for a big load, and cheap voltage meters can be had that just plug into the lighter and most are pretty accurate, and can be validated by plugging it into your car to see.

-

I think now they are overhauled, due to him not being able to buy new. If new aren’t available, what other option is there? I don’t know but have heard new isn’t available from sources that say major overhaulers have a great many on back order and have for quite some time now, my assumption is that something has changed at Lycoming and it’s taking time they didn’t expect to work out. Seems to be the angle valve cylinders only though? I assume that if and when new becomes available, he will be re-working new ones like he used to. Properly done an overhauled cylinder is as good as or better than new. The issue is of course just like a crank, there is just so many times the part can be bored or turned so with new you can overhaul, one already overhauled it’s likely it can’t be overhauled a second time. When I overhauled my IO-540W1A5D I foolishly ordered new Millenium cylinders before even removing the engine, because the opinion was Millenium was superior to OEM. I say foolishly because the ones I took off were fine, new valves and guides and clean up and they would have been good for another 2000 hours. The 235 HP 540 is run at very low stress and therefore lasts for a very long time, Redline is 2400 RPM I got lucky with the Milleniums as they were old stock, I missed the AD that required their replacement by just a few serial numbers, so with hindsight replacing the OEM was foolish and a waste of money.

-

Your right of course, but a few do know. The low time performance Gann motor is THE reason I bought this Mooney, I overlooked the lack of glass, the original but still serviceable interior and the tired paint and went for a corrosion free 2000 hour TT airplane with a good strong low time motor. So some are out there but if you’re buying to sell your better off with a factory zero time, seemingly regardless of hours and that’s strange to me. Although if your buying to sell you will not recoup the money spent on a motor, if your selling in the near future your better off doing what’s necessary to keep what you have airworthy But you know I think too many discount motors now, I’ve seen a couple of relatively low experience owners with run out or over TBO engines spending their money on glass, and that’s relatively new. Used to be people knew and understood that any time past TBO was questionable, you were sort of guaranteed up to TBO but time past that was possible but best if your financially prepared to buy an overhaul because one’s coming, now people seem much less concerned with engine time. I think as silly as this sounds but younger people have been conditioned by automobile engines that simply never wear out, 21st Century auto engines easily will go 250,000 miles or more if you change the oil, and that never used to be the case. Now days the engines and driveline outlast the car, car falls apart but the engine still doesn’t use oil and is running strong the day the car goes to the junkyard. But a new aircraft engine isn’t any different than one made 50 years ago and I think people just don’t realize that engines really do wear out, because they have never had the experience of a worn out motor. Where in the 60’s and 70’s many kids first car was worn out, an oil burner with 100,000 miles or less on it and many learned how to fix motors keeping the junker running and some even rebuilt the motor or replaced it with one from a wreck in a junkyard.

-

They are overhauled in the angle valves, because I believe primarily new just don’t exist. Parallel valve motors I believe get new because there is a supply, but I’m sure his “performance” motors cylinders get re-worked. ‘Only the “performance” motors get this level of attention to detail, his regular overhauls do not, so of course the performance motors cost more. How much? I don’t know I don’t believe he lists their price, I believe you call him and decide how much you want and what it will cost, but I have not had him build a motor, I bought an airplane with one of his performance engines installed and had I think 500 hours on it. However I’m sure they are warrantied, and I’d bet lunch that just like the engine core, superior to a factory part. It’s not that he has superior materials and or some kind of special coatings or other snake oil, it’s simply that they are what old hot-rodders called blue printed motors, that is every part is identical to every other part and dead center of tolerances and fits are as tight as possible and bearing finishes are polished etc. Doing so you spend a whole lot more time, and time is money for truthfully not a whole lot of difference, but there is a difference. Just Carlos not Lycoming warrants it. A factory can’t truthfully blue-print a motor, first of all it would cost significantly more and secondly and more importantly they can’t get enough skilled labor to do the work. The skills are evaporating, they just don’t exist anymore, the ones with that kind of skill demand a higher price and don’t work in factories, they work in niche shops catering to speciality racing engines etc. For example when NASA first began exploring the Space Launch System, very logically they looked at the RocketDyne F-1 engine that powered the Apollo. Nothing was more powerful and believe it or not but for its thrust it was actually much less expensive than say the Shuttle engines, it is the best engine to build a monster rocket with still to this day. But they found out that the US can’t manufacture an F-1 anymore, it’s not that the drawings and plans don’t exist of course they do, what it is is the lack of skilled labor, welders and machinist of that caliber simply don’t exist anymore. What we ended up with was a rocket using and throwing away very expensive re-usable shuttle engines and adding another section to the shuttle’s solid booster to make up for the thrust loss in the liquid fueled engines, spending billions of dollars over budget and years over due, and of course you can only build a few because there is a limited supply of shuttle engines. https://apollo11space.com/why-cant-we-remake-the-rocketdyne-f1-engine/

-

There often isn’t really on a lot of overhauls, the hours are attached to the data plate, nothing else. Over time everything even the case can be replaced but the hours on the assembly just keep getting bigger. For instance many a Super Cub is built using nothing but an existing logbook and data plate, while everything in the airplane could be new, if the logbook had 10,000 hours on it and was a 1946 airplane, then the one with all new parts is a 1946 airplane with 10,000 hours. “new” Super Cubs bring so much we have a guy in the neighborhood that comes down from Maine and “builds” one every Winter, He always already has a buyer lined up. Everything is new, except the logbook and data plate. Lycoming zero’s times, because they can and it brings them more profit doing so, they aren’t stupid, only they can and doing so is worth money.

-

I called, he said he does. That’s also when I learned they hone, not ream valve guides. I’ve never seen guides honed myself, but know that’s how you get ridiculous tolerances. I’m pretty sure he doesn’t do the heads, I believe he has a specialist that does. I suspect that person may have come from NASCAR, but that’s just my suspicion. The person that taught me heads all those years ago did heads for a couple of NASCAR builders, he came down and helped us in the off season for a couple of months per year. Porting turns out isn’t intuitive and what worked on the track didn’t really show up on the flow bench for some reason. I have my theories as to why, but it’s just a theory. Oh, when I did valves I blended the four inner cuts into a smooth bend on the head and valve as opposed to four angles, the valve seated on the outermost one of course I used to do 5 angle on racing bikes 40 years ago, but comparatively they are tiny valves, so maybe 7 makes sense on big ones?

-

I’ve never used boards either, usually used a clamp like a gust lock to lock against flaps and called that zero and used a prop protractor and later a digital level. Phone may be OK for checking, but I wouldn’t trim an airplane with one. On a Mooney I’d be comfortable calling flat counterweight as zero for me, but mine flies fine hands off, I’m not mucking with it. I’m 99% sure that on the ground they are both perfectly level anyway. Having said that you need some kind of travel board, protractor or maybe just measuring distance for the rudder because an inclinometer isn’t going to work.

-

Normally on every airplane that I’ve rigged out the ailerons trailing edge flies slightly high in flight, meaning the counterweight is slightly down, compared to the way it is on the ground. I’m talking .25” on an airplane much larger than a Mooney, so not much. On the ground they are level to slightly low. This is because in flight the ailerons are “sucked” up because the wing is producing lift and any slop in the flight control system will be taken up, the opposite being true on the ground as gravity is pulling them down, as there isn’t much slop we aren’t talking much here, but enough to see maybe if you look. I’ve tried drooping the ailerons for slightly better lift but it did two things, first it made the airplane heavier in roll and secondly as it washes in the wing it slightly made the stall more abrupt as it had a slight tendency to push the point the stall first occurred out further on the wing, OK three things it slowed the airplane slightly too. Flaps as they are larger seem to have a greater effect than ailerons do. Slightly reflex the flaps and the tail lowers in flight and the airplane gains speed slightly. Probably can’t do this on a Mooney as the flap to flap bay has pretty much no clearance, I don’t see them being able to go up any. A Maule that can reflex its flaps to a -7 degrees really shows this to an extreme, the tail drops a lot in cruise giving a level fuselage. Older Maule’s can’t reflex flaps that came later with a bigger as in longer wing, that long wing increased lift so much it slowed the airplane down, so BD reflexed the flaps and that has the effect of changing the angle of incidence and got some but not all of the speed back, it also had to change stall behavior as reflexing flaps washes in the wing meaning it’s more likely to tip stall, but I guess it must be OK cause it passed flight checks. See in level flight lift equals weight of course so going slow your nose high to increase angle of attack to keep lift equal to weight and going fast your nose low decreasing lift to keep it equal to weight, but level fuselage gives the least drag of course.

-

Call Concorde, I bet they will replace it, they aren’t by design supposed to be able to leak, no AGM should be because the mat isn’t saturated with electrolyte. Lifeline is a Concorde just with a much better manual, assumption is because it doesn’t have to be FAA approved, but open this link and read 1.2 it’s an explanation of the design https://lifelinebatteries.com/wp-content/uploads/2015/12/6-0101F-Lifeline-Technical-Manual-Final-5-06-19.pdf

-

Years ago just after paying $20K+ if memory serves for recovering my Maule I was flying along at night and things were getting dim, looked and the Alt CB was popped, so I reset it and of course the amp meter swung way over to the right. A couple of weeks later I was washing the airplane and noticed the paint job was bleached out at the battery vent, the wet cell Gill had boiled, acid went out the vent as it’s supposed to and bleached the new paint. Thankfully none got inside of the airplane. Since then I decided that I would never buy another battery that can leak acid. I’ve never tried it, but Concorde says that even if you knock a hole in one of their batteries that no acid will leak out, not that I’m planning on knocking a hole in one, but I like the no leak part. I’ve got an old dead one, might try knocking a hole in it to see what happens, maybe shoot it with a .22

-

DOES THIS SPINNER HAVE ANY VALUE? - SEE CRACK

A64Pilot replied to DCarlton's topic in General Mooney Talk

You know we lived aboard a boat that I had outfitted for over three years, never really had any kind of problem, couple of water pump issues but as I carried spare everything that wasn’t really a problem, and this was a complex boat with a watermaker, generator, autopilot, Solar etc, etc. Difference between a boat and an airplane for the average guy is that if they are motivated they can repair their boat and overhaul any of the components, and if your cruising off of the beaten paths you really do need to be a decent mechanic / electrician or life will be stressful. A well built quality boat has good systems and is logically laid out and things are accessible. Cruising is after all “fixing the boat in exotic locations” An RV, especially a Motorhome is apparently a different animal, even a quality one the systems are a nightmare with dozens or more fuses hidden all over the place with many “sneak” circuits, and the books aren’t worth a darn either. Near as I can tell there is essentially NO engine access in a Diesel pusher, I’m going to have to design a fix for that but it makes me wonder what we’re they thinking, are you supposed to buy new and sell before it gets old enough for the belts to need replacing? $180 an hour shop labor rate is common too with other charges being levied, so from my perspective it’s a Motorhome that can break you more even than an airplane or boat. -

No problem, personally I wish chroming was allowed, in my opinion if there were issues with cracking it could be mitigated with inspection, but my opinion isn’t worth anything. My J’s spinner is painted and I’m actually glad it is, because I won’t polish a spinner anymore, I like the look but not the work, chroming would give me the look without the work. I’ve seen many chromed spinners on Ag planes. As far as I know there is nothing to really protect polished aluminum from eventually corroding, except clear coating it and that changes its appearance, it’s just not as shiny. Clear coat is paint, and your allowed to paint a spinner and as far as I know I’ve never seen any prohibition on color your allowed to paint one. ‘If you clear coat and want a shiny spinner you will eventually be stripping it to polish it though clear coating dulls the shine.

-

Actually only a manufacturer OR their designated representative can zero time, but as far as I know no manufacturer has designated a representative to do so but they could, that goes for airframes too etc, for example Mooney can zero time an aircraft if they wanted to. As a manufacturer I would take an aircraft and put it in Experimental category, conduct developmental test flights, then zero time it before we sold it. I’m sure every manufacturer does. Having said that zero timing means nothing. It’s not any kind of higher level of maintenance or higher standards or anything, it’s merely literally what it says it is, issuing a new logbook with 0 time as the initial entry. For our piston engines that don’t have life limited parts, it’s meaningless. However as you show, marketing wise it’s worth money because most people don’t know the ins and outs of engine overhauls. Lycoming could at their discretion do something different for zero time engines, but they aren’t required to.

-

Chroming if not correctly done can and will cause cracking and there have been spinner failures in the past, so they were actually correct about a chromed spinner not being approved. https://www.aviationperformanceproducts.com/chrome-it.cfm For example only one manufacture of propellor can be polished, all others polishing renders them un-airworthy, reason the FAA gives is the manual only includes painting, not polishing, Hamilton Standard apparently allows polishing, but I’ve never looked in the book to see.

-

Number 1. is incorrect, since every single item can be replaced there is no number of times an engine can be overhauled, the only limit is when parts are no longer available, there are hundreds, maybe thousands of 100+ yr old radials running around that there is no telling how many overhauls they have had, and many may not even have a single original part in them. Secondly a quality overhaul is actually better than a brand new Lycoming, because the limits can be much more closely maintained, cylinders can be flow balanced, 7 angle valve jobs done, valve guides honed not reamed, everything balanced to less than one gram etc etc. Call this guy and ask about his “performance” overhaul. https://www.gannaviation.com/engine-overhauls These aren’t of course automotive engines but many builders of race engines will only use “seasoned” blocks and not new because the belief is that blocks with thousands of heat cycles are stronger than new

-

A “bad” battery shouldn’t cause over voltage. The low hours actually are a bad thing. It means it’s been sitting for long intervals between being charged and of course all batteries self discharge. If you got 7 years out of a Gill that’s very unusual, and overvoltage will more than likely “boil” a wet cell and that means acid comes out and corrodes your airplane.

-

I don’t usually have a helper, I use a pair of needle nose visegrips to hold nuts in a case like this, it’s heavy enough to not spin when the screws are turned. To put the screws back in put a piece of duct tape on the heads, that will hold them in enough to get the washers and nuts started. I won’t use nut serts myself, but some do.

-

Try sticking your cell phone up there and taking pictures