A64Pilot

Basic Member-

Posts

7,988 -

Joined

-

Last visited

-

Days Won

21

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by A64Pilot

-

I hate to keep disagreeing but if we look at the definition of major repair I believe if the wing installation is incorrectly done it could certainly cause structural strength problems and flight characteristics both. I believe there is nothing elementary with replacing a Mooney wing either in my opinion, but most Cessna high wings are pretty rudimentary, but I guess that depends on the opinion of what rudimentary means, but I don’t think I could keep a straight face trying to tell an FAA inspector that replacing the wing on a Mooney isn’t a major. That, if improperly done, might appreciably affect weight, balance, structural strength, performance, powerplant operation, flight characteristics, or other qualities affecting airworthiness; or (2) That is not done according to accepted practices or cannot be done by elementary operations.

-

Legal to Fly a J-Model without Wheel Covers?

A64Pilot replied to MooneyAcolyte's topic in General Mooney Talk

I think the chafe problem can be very effectively mitigated by teflon tape, however it has to be replaced when it comes off, some I’ve had stay on over year even when oil soaked (nose gear door area) and some in clean areas come off in a month. What seems to help is throughly clean the area with acetone, I think it also softens the paint, then apply the tape with pressure getting it very warm with a heat gun. I’ve considered bonding teflon tape to thin VHB tape and bonding the VHB to the airplane but haven't. There is no galvanic corrosion problem with fiberglass -

Legal to Fly a J-Model without Wheel Covers?

A64Pilot replied to MooneyAcolyte's topic in General Mooney Talk

Mine when retracted chafe against the wing and have metal to metal contact, that might could be handled by teflon anti chafe tape which probably ought to be there anyway. On boats we would use plastic washer for bolts and often cut shims from a milk jug if the carbon touched aluminum as insulators. Deal is just be sure they are isolated, the corrosion is surpassingly aggressive if not. -

Curious, who ie we? I ask as stepping up gets you out of wingtip vortices of the aircraft ahead of you while stepping down down may put you in them as vortices travel down and away. But I suspect that they are stepped up for the photo. On helicopters when stacked right I stepped up if real close as if we overlapped rotors I could turn away and rotor separation increased, but we usually stacked level There are 6 AH-64A’s in this photo, number 6 slid forward to take the pic. It wasn’t choreographed or anything we didn’t even know it was being taken, we were just flying back from a Firepower demo at Ft Sill.

-

I don’t think it’s from strength as piston crown temp is much higher. I think cyl head temp is the way we have to measure cyl stress, it might be better if we could measure peak pressure, but we can’t. I’ve not seen a blown head on a flat motor, I bet it’s rare. One big way in my opinion that LOP reduces cyl stress is that it effectively is retarding timing, which I believe has a significant effect on peak pressure, another way of course is it reduces power, which further reduces stress. Only real way to directly compare LOP fuel savings is to establish a cruise LOP, record speed, then go ROP and reduce MP until your speed is identical to what it was LOP. It just might be not as big a difference as many think. But I think there are other reasons to run LOP myself, you just have to get out of that I want to go as fast as it will go or it’s likely you won’t like LOP ops.

-

Absolute AoA System – Accurate AoA for Every Flight Phase

A64Pilot replied to HolyMicro's topic in General Mooney Talk

To give a comparison, in Test Flights of captured BF-109’s the Allies found that it probably due to its leading edge slats could out turn a Spit, but in dogfights that was almost never the case, why? It seems that a BF-109 had almost no warning of impending stall, when it did it went over on its back and trying to recover from a spin you lose a lot of energy and apparently your in a very vulnerable position, so German pilots were very reticent to pull as hard in a turn as the Spit drivers, the Spit apparently had a very progressive stall and a pronounced pre stall buffet so they became comfortable pushing the envelope. Although you will find flight tests that say the opposite. I have a friend that flew Merlin powered BF-109’s in I believe the Czech Air Force, he apparently defected to the US long ago in apparently unusual circumstances, he won’t talk about how he got here, but on his office wall he has a picture of him standing in front of a US F-86 dressed for flight and holding a helmet. Some of us believe he defected in a Mig. We speculate that under the assumption that it’s unusual for a former Communist pilot to get a ride in what was then a front line US Fighter. I guess the BF-109 needed an AOA sensor? -

Absolute AoA System – Accurate AoA for Every Flight Phase

A64Pilot replied to HolyMicro's topic in General Mooney Talk

Having never flown an A-10 I’m going to assume it’s stall wasn’t nearly as progressive as the Thrush and frankly you guys didn’t push so deep into a stall in each turn, just because it’s stall wasn’t as forgiving? If for example if flying like a Thrush does and you saw something that needed to be avoided or your RAW gear went off, all you could do would be to ease or roll out of the turn or just grimace and hope it doesn’t hurt too much, cause there is no maneuverability left, you can’t tighten the turn at all Ag planes don’t usually pull much G, they can’t they are too heavily loaded, the FAA’s position was the pilots got G tolerant and over G’d the aircraft. So I put a G meter in the MVP aircraft with alerts in the MVP-50 equipped ones to alert them, but I found out in testing to increase our wing spar life limit that you cant really over stress a new Thrush wing without exceeding VNE, the wing stalls right about the time you hit the G limit at max gross weight and actual wing stress is both G and weight dependent, so lightweight you can exceed G limits, but it’s not over stressing the wing. We hired an Engineering firm that put strain gauges all over the wing spar upper caps and I had to go out and fly flight profiles. On an aircraft that has huge changes in its weight, G alone isn’t a very good way to determine wing stress, but in simple aircraft it’s all we have. The AH-64D’s computer took speed, air density and gross weight and computed G limit as G limit in a helicopter is often more of an aerodynamic limit than a structural one, but most aircraft don’t have Air Data computers et all to do that. The old Thrush wing has a 5400 hour lower spar cap life limit, the new wing had a very conservative 29,000 hour limit that we extended to 54,000 hours mostly for marketing as there really aren’t any 29,000 hour Ag planes much less 54,000 hour ones. A few died in years past when the main spar cap failed on a Thrush and it lost a wing, wing failure isn’t uncommon on Ag aircraft, we chose to deal with it by designing a new wing that was simply stronger and pushed the wing life to be in excess to the aircraft expected life, our competitor chose to new redesign but stick with spar cap replacements. Not to try to bore too many, but the reason the wings were failing was the original aircraft was a 6,000 lb aircraft that had a realistic speed of about 120 mph, the aircraft was STC’d originally, then later manufactured with a turbine engine and actual flying weight exceeded 10,000 lbs and operating speeds were up to 160ish, it wasn’t a poorly designed wing it just that weight and speed simply overloaded the design and it failed. Brazilian Ipanema, and it’s wings are externally braced. https://youtu.be/NbHGzPVpsgo?si=KcxoCwn6VfyfZntb -

@pirate Is the RV-7 your building an A model, nose gear? If so do you have the new engine mount that has the gear leg that uses Mooney shock biscuits?

-

100K Based on engine overhaul, maybe not but you have to plan on the worst, and a WAG on wing replacement, I don’t have knowledge to make a SWAG Then add in the steel tubing, no way is any old airplane worth it, my reasoning is that the corrosion is throughout, it’s not just a spar cap and steel tubing. ‘Value is likely whatever salvage is

-

Based on the G100UL fuel leak thread what's your position?

A64Pilot replied to gabez's topic in General Mooney Talk

Lawyers often it seems aren’t motivated by truth, they are motivated by deep pockets -

Legal to Fly a J-Model without Wheel Covers?

A64Pilot replied to MooneyAcolyte's topic in General Mooney Talk

School in Tx that I got my Commercial in 30 years or so ago had removed the lower fairings, I asked why as the school prohibited the Mooney’s from landing on anything but pavement. I was told it was for maintenance reasons, so I went and asked the Maintenance chief, he said that the factory had told him these AT aircraft as trainers had of course abnormally high gear cycling and the loads imparted on the gear from the doors caused wear. Maybe it was BS who knows, maybe the real reason was they didn’t want to R&R them for tires and brakes but the wear claim seemed logical to me. That’s why now on my Mooney I don’t drop the gear until I’m in the white arc, it just seems reducing the strain is worth it. Anyway when I changed tires I left them off and at the slower speeds I fly didn’t notice any difference, but I put them back on anyway. -

Legal to Fly a J-Model without Wheel Covers?

A64Pilot replied to MooneyAcolyte's topic in General Mooney Talk

Be sure to electrically isolate the part from the aluminum, Carbon fiber in contact with aluminum will cause galvanic corrosion, then be sure you put anti-chafe tape between this part and the wing as carbon fiber can really chafe into aluminum badly. I’d recommend fiberglass myself, as there is no requirement for excessive strength fiberglass will be fine and not have the corrosion issues and while it won’t be as strong there won’t be much weight difference. I know Carbon fiber looks cool naked and marketing people have really sold it, but it has downsides on aircraft https://www.corrosionpedia.com/galvanic-corrosion-of-metals-connected-to-carbon-fiber-reinforced-polymers/2/1556 -

State of Georgia's Number One Export?

A64Pilot replied to GeeBee's topic in Miscellaneous Aviation Talk

A few pics from 1965, the original aircraft line up, the Thrush and Commander 200 came soon after. A 6 pax version of the Commander 200 (Meyers 200) notice the different tail, never Certified The Meyers production line. I don’t have a pic of the Interceptor 400, which was a pressurized 250 kt four passenger turbine, that was Certified I believe in the 60’s but it could have been the early 70’s but I believe by that time Aero Commander was giving up on aircraft production, they sold the plant and the Thrush TC to Fred Ayres. -

State of Georgia's Number One Export?

A64Pilot replied to GeeBee's topic in Miscellaneous Aviation Talk

They are I’m sure the biggest part by a large margin. Huge margin, All the BizJet manufacturers I believe are sold out for years or used to be anyway, they are the only very profitable part of aviation and Gulfstream is up near the top. Maule exists only because they have no debt so if they can sell an airplane every now and again or build a few parts they can get by, because they don’t have a big debt. Long ago they became the only GA manufacturer that was still owned by the family that started the business. A couple of them are a pain but the majority are nice country types, good people. Thrush comes and goes largely based on commodity pricing, at our best we built one a week and at times there were months that we built none, but as we had very little debt we could handle the down times, the President / Owner passed away, his silent partner moved in took over and started accruing debt believing he was going to get rich, just needed to automate everything, Thrush went bankrupt of course but rose again as there is an Ag market, and it is a good solid well respected airframe. I retired because I saw what was coming and didn’t want to be around when the inevitable became obvious for all the finger pointing and drama etc., so the day my youngest graduated High School was pretty close to my last day. I wore several hats, VP, Test Pilot, Product Support, I ran manufacturing and Engineering, Accountable Manager for the Repair Station etc. Thrush has been there since 1965 and the majority of the people in the town of Albany have never heard of it, it’s not that big of a Company, maybe when properly staffed less than 200 people. When I ran the line we could produce 1 a week working hard with some overtime with 85 actual people on the plant floor, when I left there were over 200 and they couldn’t produce one a week. A Group tried to restart production of the little Grumman aircraft, they were going to build in Valdosta, probably a smart place because of the AirForce base, you could hire kids getting out of the AF. I was going to help them as I could build parts under my PC but they never got their financing together, I think they were like most attempted aviation start ups, they had a plan, only didn’t have any money. Skilled Labor was my biggest problem, the little there is doesn’t want to live in Albany Ga and I don’t blame them, I was having to hire anyone that was willing to learn, which wasn’t common. Thrush and Maule are to my knowledge the only what we think of as GA manufacturers, Maule is on life support, has been for years and Thrush is a shadow of what it was back in the heyday. At one time Rockwell was turning out one a day, quickly stopped buying engines etc, parked them everywhere they could and after a couple of months there was a big lay off, they maybe could build one a day, but they couldn’t sell one a day even in the heyday. Rockwell never got the production rate they wanted, the built several aircraft in Albany, the Meyers 200, the Lark, Darter and Quail, and of course the Thrush. Word is every couple of months the Jet Commander would come in from Corporate and drop off the new plant manager. North American Rockwell was big and rich, they built the P-51, the F-82 and several other aircraft, the Apollo capsule etc. They divested themselves of GA manufacturing believing the real future money was in Space manufacturing I was told. While it appears the real money is building private Jets, who knew? Scaling is a big problem I believe in GA manufacturing, always has been, the numbers you can sell will never get to the economy of scale needed to truly automate and drive down costs. Even back in 1946 Cessna was I think building a C-140 every fifteen minutes and quickly stacked them everywhere, everyone that wanted one got two etc, great little airplane as was economical too, just the demand didn’t materlize. So I think the future if there is one is in staying small and going with small batches, CNC, possibly 3D printing maybe etc, think Super car manufacturing numbers? -

Absolute AoA System – Accurate AoA for Every Flight Phase

A64Pilot replied to HolyMicro's topic in General Mooney Talk

A problem with trying to use AOA for Ag planes is they are Manuvering pretty aggressively when they are most vulnerable, plus your looking out avoiding trees etc The way an aircraft turns is of course by modifying the lift between the two wings, for this reason the high wing, that is the wing your turning away from will stall first assuming your maintaining trim, if your AOA is on the left wing it won’t accurately reflect the right wings proximity to stall and if your turning left the right wing is closest to stall. Then add in that often when turning they are most often also pulling up and it aggravates the situation. To really be most useful you would need an AOA sensor on both wings. Airfoil on a Thrush is from memory a NACA 4412, that airfoil is a high lift one that is very leading edge damage tolerant and has very gentle stall behavior, it has a very pronounced pre stall buffet, that buffet is what many use in a turn to know how close they are, plus we have a 1.5 degree washout twist in the wing that unless pretty deeply stalled ensure the tips keep flying, this usually prevents a dropped wing in a stall, if the stall isn’t aggressively approached. It’s downsides is it’s relatively high drag and flaps are less effective with it, so it’s less efficient. TANSTAAFL. An Ag plane Thrush anyway maneuvers regularly so close to stall, right at the beginning actually or arguably actually in a stall that an AOA sensor would indicate a stall very often, it would be a nuisance just as the factory vane is. The saving grace if you will is two fold, the stall is very gentle and the washout means it’s progressive, from the wing root outboard, so a wing shouldn’t drop if your in trim until very deep in the stall. Other aircraft in trying to push efficiency aren’t as forgiving and have a reputation for being accident prone in the turn, those aircraft as their wings aren’t washed out you have to drop the flaps to turn to wash out the wing or it may tip stall, and go over on its back, which at 50 or 100 ft isn’t of course recoverable. Some Thrush drivers who came from those other aircraft also drop flaps in a turn as they learned that way, but it’s usually just added drag on a Thrush. So in my opinion an aircraft with a very benign stall, like say a Cherokee 140 for instance an AOA just isn’t really very useful for stall warning anyway, but an aircraft who’s stall isn’t benign maybe it is. Any aircraft in my opinion with stall strips does not have a benign stall by definition as the purpose of stall strips is to tame the stall behavior or sometimes if in front of the ailerons they are to provide pre stall warning, but either way they are there because they need to be there, not for looks -

Even in Fl in Winter at 23 squared I have trouble keeping my Cyl head temps out of the bottom of the green with cowl flaps fully closed. When that happens usually just a gl an hour richer brings the temps up to where I’m comfortable. With middle of the green cyl head temps and power well below 75% I don’t think you can harm a Lycoming with mixture myself. Its been long ago since I learned to fly, but back then what was taught in the trainer aircraft was don’t lean below 5,000 ft, and above in cruise slowly lean until it got rough, then very slowly enrichen until it just got smooth, many aircraft didn’t even have an EGT, but that leaning procedure put them usually just barely ROP, right at what many swear is the absolute worst mixture, yet those engines almost always ran well past TBO. They were carbureted aircraft and just simply wouldn’t run LOP. In 2003 as part of the Army test activity we did Winter testing in the UP of Wisconsin, air density there in Winter is something us Southern guys have to experience to believe, it may be that your MP gauge isn’t that far off?

-

A 337 should be filed for removal of an STC, an STC of course changes the Type Certificate, often that’s not a small thing, some are just silly though like sun visor STC’s. The reason is to keep the records correct They very often aren’t, for that reason it’s not uncommon at all for older aircraft to have several comm and Nav radios installed, Marker beacons, DME’s etc when you get the CD from the FAA, yet when you look at the panel the DME, ADF, and most of the listed radios aren’t there of course. Many IA’s that are on the ball so to speak will file a “correct the record 337” listing the items removed and what’s currently in the aircraft just to correct the paperwork on the aircraft they maintain. Do incorrect records render an aircraft unairworthy? Most would say not, but it does bring into question just how correct are the other records of the aircraft, it’s just an indicator that I look at when doing a pre-buy, it won’t stop me from buying, but correct records do go in the buy column in my decision.

-

Based on the G100UL fuel leak thread what's your position?

A64Pilot replied to gabez's topic in General Mooney Talk

I do several yearly Condition inspections for neighbors for Experimentals and LSA’s Fuel is among the least of their concerns for many, for example it’s extremely common even for factory built LSA’s to have plastic as in what I swear is ice maker waterline brake lines, one Pitts even has clear vinyl fuel lines inside of the cockpit, I guess the builder thought seeing the fuel has value. Having said that some of the highest quality, best built aircraft I have seen are Experimental, it’s all up to the builder. -

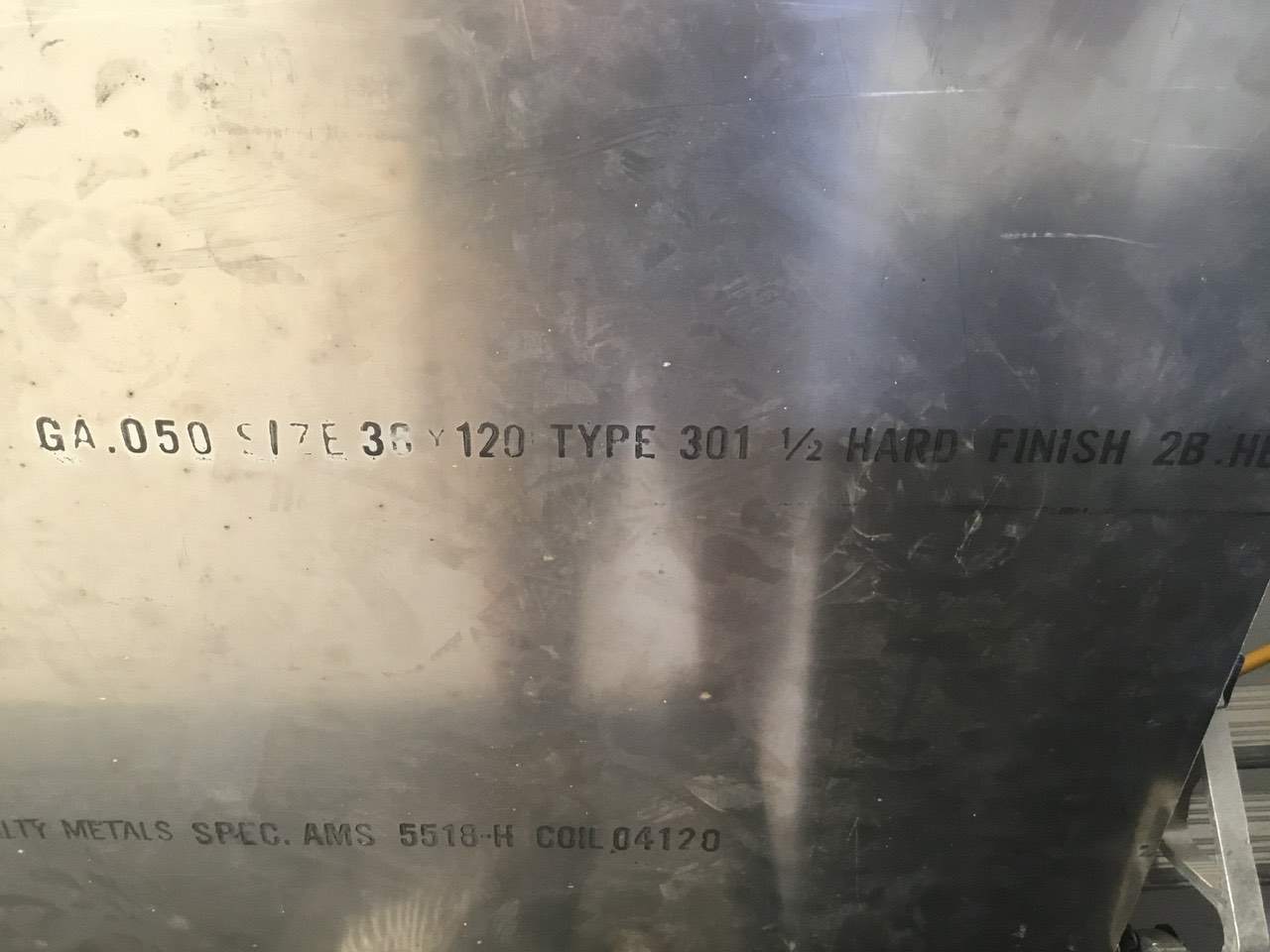

I don’t think I said to bend it, but in fact many stall vanes out in the wild have been bent. They don’t just go out of adjustment, either they have slid in their adjustment slots, or they have been bent. Sliding is more unlikely. One of the biggest culprits is a refueling hose, Ag planes its birds and trees. Most of the time when they get bent, they get bent down which means they don’t go off at all or do so late. Why did Mooney go to the trouble to harden the part? Because they get bent and they wanted to prevent that. I don’t think they hardened it myself, I think it’s SS and SS comes usually in 1/4, 1/2, 3/4 and full hard. I think they just picked my guess 3/4 hard maybe, or 1/2. Now I’ve never done a production test flight for a Mooney, but every Thrush that I did the stall warning was a required check on EVERY aircraft, you recorded the airspeed the warning came on and the stall speed, warning had to be within 5-10 mph of stall on a Thrush. The FAA flight test pilot would spot check every so often and fly a production test flight randomly. I think it unlikely that Mooney let one out of the factory with the stall warning not correctly set, it’s just too simple a check and adjustment. The way the stall warning works is pretty simple. In flight there is a specific point where the air impinging on the airfoils splits, above this point the air goes over the wing, below it the airflow goes under, increase the angle of attack and this point moves down, when the point goes under the stall warning vanes it goes from being pushed dow to being pushed up and the warning sounds. The tab is an angle of attack sensor. Sheet of 301 1/2 hard I have, 1/2 hard is pretty darn hard.

-

Absolute AoA System – Accurate AoA for Every Flight Phase

A64Pilot replied to HolyMicro's topic in General Mooney Talk

Ag wise I think maybe back in the day when you bought a cheap surplus Stearman, paid cash and modded it and went to work bravery if you will was a thing. Nowdays if you use new new prices you can’t get an Ag plane for less than a Million bucks which is actually cheap once you consider it’s a 750 HP turbine, but especially once you get into multiple millions your getting insurance involved most likely as most can’t pay cash, so it’s become much more professional if you will, an accident prone pilot quickly becomes an unemployed one. In truth it’s sort of boring believe it or not, it’s hard work with very long hours, and usually seasonal. When there is work daylight to Sundown isn’t uncommon, and you usually get behind with weather and higher wind days factored in. This is an old Garrett Thrush, likely 80’s This is a GE powered Thrush which I Certified a couple of years before Retirement, unfortunately I believe GE has orphaned this engine. Both of these are small one man operations is South Ga. The small one man operators are more common than you might think. -

I think unless mistaken they may allow as high as 475 continuous, my gauge anyway I don’t think has a yellow range just red and green with 475 annotated at the red. 400 I believe has become the accepted number for continuous if you factor in engine life. Is there hard data to back that number up? I doubt it but don’t dispute that the closer to the middle of the green the better. I think it’s a sliding scale and not some one number, by that I mean that it’s my belief that the hotter, the shorter the life, but that there is also too cool, hence my belief that middle of the green is optimal. Some want the most speed they can get, period and they can afford it too I guess, and there is nothing wrong with that. Just as I have gotten older I guess the need for speed has lost its appeal. The RV guys in my neighborhood fly wide open all of the time, only reducing power to land. Another with a 182 does also, but he denies it comically. The Bonanza crowd mostly seem to but some of them have backed off it seems, I think form listening to me, some haven’t. I get a little lead, not much and it’s not hard to get out.

-

Just for kicks yesterday I climbed to 6500 on the way back from Lunch, Running full throttle and roughly 100 ROP I had from memory about 23.5 “ MP with ram air closed, fuel flow maybe 11- 12 GL and hour, but Cyl head temps with full open cowl flaps was in the high green so if I had stayed there it would have cost I guess about 2 more GPH to get them back in the middle of the green. Altimeter setting was 30.07 Reducing to my normal 23 squared and 8 GPH which is real deep LOP cost me at least 10 kts but cyl head temp was in the middle of the green with cowl flaps fully closed. Cyl head temp was my issue running full throttle and 2500 RPM at 6500, high green is within limits but it’s my belief that it reduces engine life, so I slowed down, saving the engine and cut fuel burn by 1/3, once you factored in the lower speed maybe only 1/4 but still significant. To keep the speed I think I would have had to add another 2 GPH to get the temps down. 14 GPH when I could be burning 8 is to me foolish, I’m just not in that big of a hurry

-

Absolute AoA System – Accurate AoA for Every Flight Phase

A64Pilot replied to HolyMicro's topic in General Mooney Talk

My guess is your going to have to call, last week at the Umatilla FBO they were giving away neat little fans advertising their landing height altimeters. I can find out no real data on the things by going to their website ref installation etc, just marketing videos. I could find data on how they will place systems into an A&P’s business and only expect payment upon installation etc, but no data on installation. I did some flight testing years ago on AOA systems for Crop Dusters as they constantly maneuver on the ragged edge of stall, most Ag pilots defeat stall warnings by pulling the CB or merely bending the vane down because it’s a nuisance, it goes off in most every turn when heavy when properly adjusted, they maneuver that close to stall. Anyway I came away unimpressed, none were as good as training and while I’m sure some have, but I never saw one in an Ag plane. Stall speeds are VERY high in an Ag plane because as the Hopper can be dumped very quickly the FAA only requires stall speeds to be met with the hopper empty, so you can image what happens in a 5,000 lb airplane’s stall speed wise when you put 5,000 lbs in the hopper doubling it’s weight. Stall angle of attack does not change with weight but speed sure does. Especially when you add in the G loading from sharp turns. I’m not against them if you want one by all means install one, just in my opinion don’t rely on it and I think that money is better spent on training personally. Nothing trumps experience and the safest way to get that is from training. My opinion of course. -

The cover does not conform to the original rudder skin aerodynamically because of the bump, to prevent having to reskin or replace the rudder etc. it’s best to return the rudder as close as possible to original, then it’s possible that bump could cause trim issues that are normally overcome by the trim tab of course, but the tab has been removed. I’m not saying it would of course just that it could I bet if you lined up 5 FAA inspectors, at least 1 would say the skin would have to be replaced, 2 would say a patch is fine and the rest would want additional data as in a DER or similar. But if say in a ramp check or something a 337 would satisfy all of them, a log book entry maybe not.

-

When I was a Test Pilot, flutter was one of the very few things that scared me, a good friend of mine (Dr Ralph Kimberlin) who literally wrote the book on small aircraft test flying and my Civilian Test Pilot mentor when he was flight testing the Aero Commander 112 got flutter that caused the aircraft to disintegrate, he got out, the flutter Engineer did not. There is a story why the Engineer was onboard of course, because that was uncommon and honestly he shouldn’t have been. Ralph passed away last Nov. https://www.fit.edu/faculty-profiles/k/kimberlin-ralph/ https://asn.flightsafety.org/wikibase/2731 People think, if I get into flutter I’ll just slow down, maybe, maybe not. North American Rockwell recreated the incident in NASA’s wind tunnel, time from flutter initiation to complete disintegration of the entire empennage was less than 1 sec. This aircraft had been dove to Vd several times with small issues occurring, what was different in this dive was Ralph had trimmed the elevator full nose down to keep from having to push so hard down, as is common on many aircraft only one elevator had a trim tab, this caused enough unbalance to trip flutter once it was initiated with a control doublet, a control doublet inputs forces very similar to turbulence and “excites” a flight control.