A64Pilot

Verified Member-

Posts

8,000 -

Joined

-

Last visited

-

Days Won

21

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by A64Pilot

-

Even in Fl in Winter at 23 squared I have trouble keeping my Cyl head temps out of the bottom of the green with cowl flaps fully closed. When that happens usually just a gl an hour richer brings the temps up to where I’m comfortable. With middle of the green cyl head temps and power well below 75% I don’t think you can harm a Lycoming with mixture myself. Its been long ago since I learned to fly, but back then what was taught in the trainer aircraft was don’t lean below 5,000 ft, and above in cruise slowly lean until it got rough, then very slowly enrichen until it just got smooth, many aircraft didn’t even have an EGT, but that leaning procedure put them usually just barely ROP, right at what many swear is the absolute worst mixture, yet those engines almost always ran well past TBO. They were carbureted aircraft and just simply wouldn’t run LOP. In 2003 as part of the Army test activity we did Winter testing in the UP of Wisconsin, air density there in Winter is something us Southern guys have to experience to believe, it may be that your MP gauge isn’t that far off?

-

A 337 should be filed for removal of an STC, an STC of course changes the Type Certificate, often that’s not a small thing, some are just silly though like sun visor STC’s. The reason is to keep the records correct They very often aren’t, for that reason it’s not uncommon at all for older aircraft to have several comm and Nav radios installed, Marker beacons, DME’s etc when you get the CD from the FAA, yet when you look at the panel the DME, ADF, and most of the listed radios aren’t there of course. Many IA’s that are on the ball so to speak will file a “correct the record 337” listing the items removed and what’s currently in the aircraft just to correct the paperwork on the aircraft they maintain. Do incorrect records render an aircraft unairworthy? Most would say not, but it does bring into question just how correct are the other records of the aircraft, it’s just an indicator that I look at when doing a pre-buy, it won’t stop me from buying, but correct records do go in the buy column in my decision.

-

Based on the G100UL fuel leak thread what's your position?

A64Pilot replied to gabez's topic in General Mooney Talk

I do several yearly Condition inspections for neighbors for Experimentals and LSA’s Fuel is among the least of their concerns for many, for example it’s extremely common even for factory built LSA’s to have plastic as in what I swear is ice maker waterline brake lines, one Pitts even has clear vinyl fuel lines inside of the cockpit, I guess the builder thought seeing the fuel has value. Having said that some of the highest quality, best built aircraft I have seen are Experimental, it’s all up to the builder. -

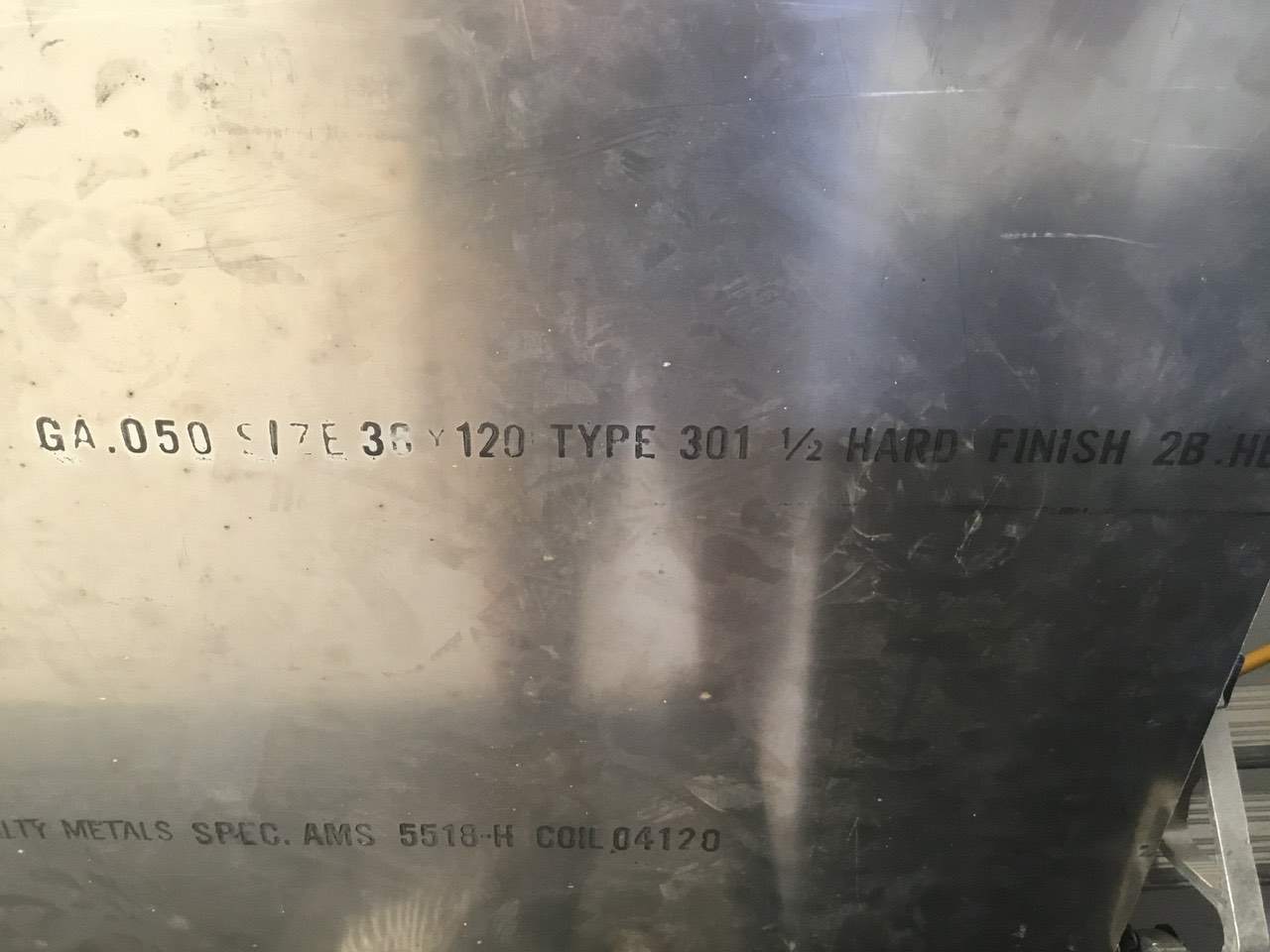

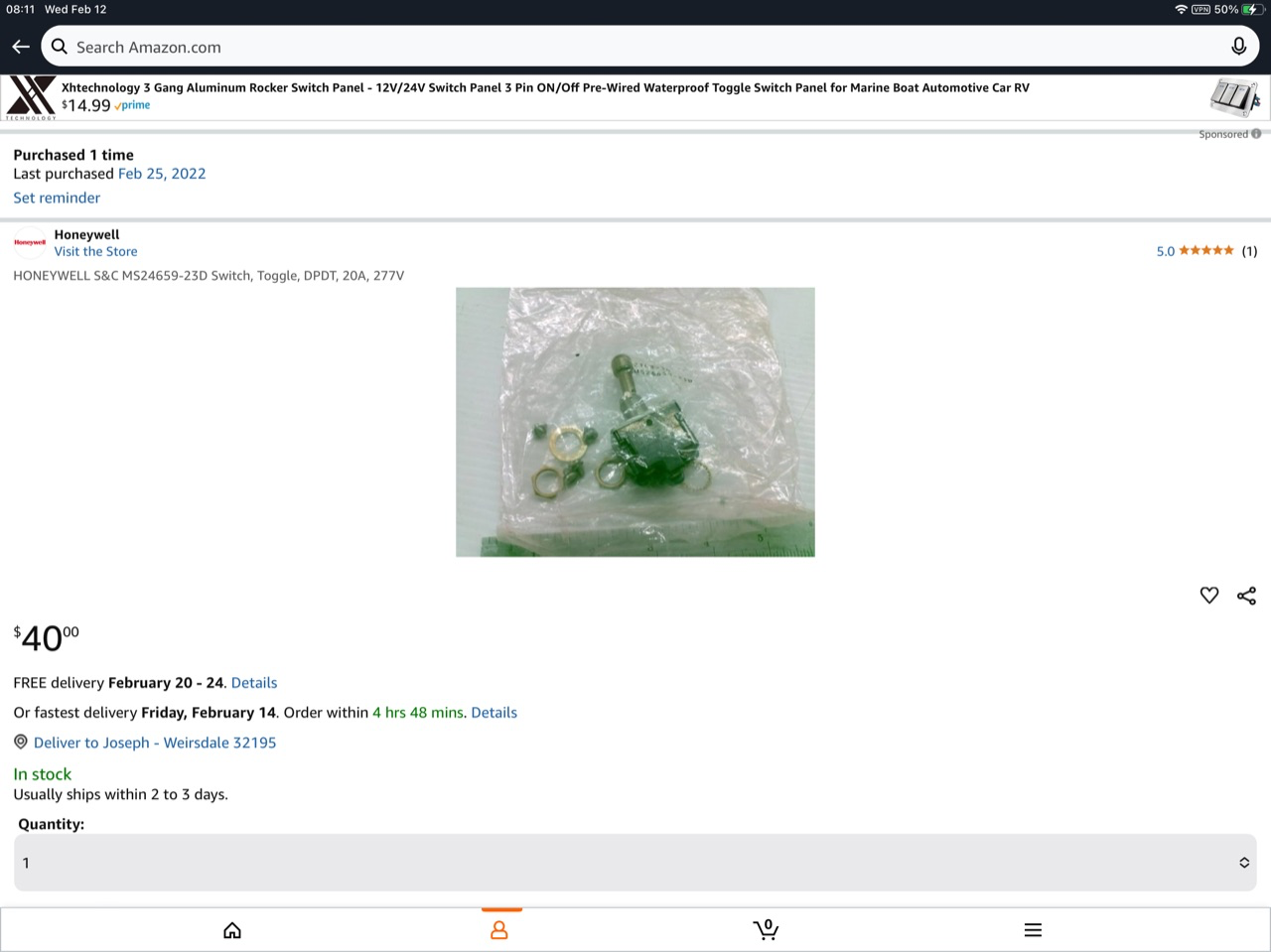

I don’t think I said to bend it, but in fact many stall vanes out in the wild have been bent. They don’t just go out of adjustment, either they have slid in their adjustment slots, or they have been bent. Sliding is more unlikely. One of the biggest culprits is a refueling hose, Ag planes its birds and trees. Most of the time when they get bent, they get bent down which means they don’t go off at all or do so late. Why did Mooney go to the trouble to harden the part? Because they get bent and they wanted to prevent that. I don’t think they hardened it myself, I think it’s SS and SS comes usually in 1/4, 1/2, 3/4 and full hard. I think they just picked my guess 3/4 hard maybe, or 1/2. Now I’ve never done a production test flight for a Mooney, but every Thrush that I did the stall warning was a required check on EVERY aircraft, you recorded the airspeed the warning came on and the stall speed, warning had to be within 5-10 mph of stall on a Thrush. The FAA flight test pilot would spot check every so often and fly a production test flight randomly. I think it unlikely that Mooney let one out of the factory with the stall warning not correctly set, it’s just too simple a check and adjustment. The way the stall warning works is pretty simple. In flight there is a specific point where the air impinging on the airfoils splits, above this point the air goes over the wing, below it the airflow goes under, increase the angle of attack and this point moves down, when the point goes under the stall warning vanes it goes from being pushed dow to being pushed up and the warning sounds. The tab is an angle of attack sensor. Sheet of 301 1/2 hard I have, 1/2 hard is pretty darn hard.

-

Absolute AoA System – Accurate AoA for Every Flight Phase

A64Pilot replied to HolyMicro's topic in General Mooney Talk

Ag wise I think maybe back in the day when you bought a cheap surplus Stearman, paid cash and modded it and went to work bravery if you will was a thing. Nowdays if you use new new prices you can’t get an Ag plane for less than a Million bucks which is actually cheap once you consider it’s a 750 HP turbine, but especially once you get into multiple millions your getting insurance involved most likely as most can’t pay cash, so it’s become much more professional if you will, an accident prone pilot quickly becomes an unemployed one. In truth it’s sort of boring believe it or not, it’s hard work with very long hours, and usually seasonal. When there is work daylight to Sundown isn’t uncommon, and you usually get behind with weather and higher wind days factored in. This is an old Garrett Thrush, likely 80’s This is a GE powered Thrush which I Certified a couple of years before Retirement, unfortunately I believe GE has orphaned this engine. Both of these are small one man operations is South Ga. The small one man operators are more common than you might think. -

I think unless mistaken they may allow as high as 475 continuous, my gauge anyway I don’t think has a yellow range just red and green with 475 annotated at the red. 400 I believe has become the accepted number for continuous if you factor in engine life. Is there hard data to back that number up? I doubt it but don’t dispute that the closer to the middle of the green the better. I think it’s a sliding scale and not some one number, by that I mean that it’s my belief that the hotter, the shorter the life, but that there is also too cool, hence my belief that middle of the green is optimal. Some want the most speed they can get, period and they can afford it too I guess, and there is nothing wrong with that. Just as I have gotten older I guess the need for speed has lost its appeal. The RV guys in my neighborhood fly wide open all of the time, only reducing power to land. Another with a 182 does also, but he denies it comically. The Bonanza crowd mostly seem to but some of them have backed off it seems, I think form listening to me, some haven’t. I get a little lead, not much and it’s not hard to get out.

-

Just for kicks yesterday I climbed to 6500 on the way back from Lunch, Running full throttle and roughly 100 ROP I had from memory about 23.5 “ MP with ram air closed, fuel flow maybe 11- 12 GL and hour, but Cyl head temps with full open cowl flaps was in the high green so if I had stayed there it would have cost I guess about 2 more GPH to get them back in the middle of the green. Altimeter setting was 30.07 Reducing to my normal 23 squared and 8 GPH which is real deep LOP cost me at least 10 kts but cyl head temp was in the middle of the green with cowl flaps fully closed. Cyl head temp was my issue running full throttle and 2500 RPM at 6500, high green is within limits but it’s my belief that it reduces engine life, so I slowed down, saving the engine and cut fuel burn by 1/3, once you factored in the lower speed maybe only 1/4 but still significant. To keep the speed I think I would have had to add another 2 GPH to get the temps down. 14 GPH when I could be burning 8 is to me foolish, I’m just not in that big of a hurry

-

Absolute AoA System – Accurate AoA for Every Flight Phase

A64Pilot replied to HolyMicro's topic in General Mooney Talk

My guess is your going to have to call, last week at the Umatilla FBO they were giving away neat little fans advertising their landing height altimeters. I can find out no real data on the things by going to their website ref installation etc, just marketing videos. I could find data on how they will place systems into an A&P’s business and only expect payment upon installation etc, but no data on installation. I did some flight testing years ago on AOA systems for Crop Dusters as they constantly maneuver on the ragged edge of stall, most Ag pilots defeat stall warnings by pulling the CB or merely bending the vane down because it’s a nuisance, it goes off in most every turn when heavy when properly adjusted, they maneuver that close to stall. Anyway I came away unimpressed, none were as good as training and while I’m sure some have, but I never saw one in an Ag plane. Stall speeds are VERY high in an Ag plane because as the Hopper can be dumped very quickly the FAA only requires stall speeds to be met with the hopper empty, so you can image what happens in a 5,000 lb airplane’s stall speed wise when you put 5,000 lbs in the hopper doubling it’s weight. Stall angle of attack does not change with weight but speed sure does. Especially when you add in the G loading from sharp turns. I’m not against them if you want one by all means install one, just in my opinion don’t rely on it and I think that money is better spent on training personally. Nothing trumps experience and the safest way to get that is from training. My opinion of course. -

The cover does not conform to the original rudder skin aerodynamically because of the bump, to prevent having to reskin or replace the rudder etc. it’s best to return the rudder as close as possible to original, then it’s possible that bump could cause trim issues that are normally overcome by the trim tab of course, but the tab has been removed. I’m not saying it would of course just that it could I bet if you lined up 5 FAA inspectors, at least 1 would say the skin would have to be replaced, 2 would say a patch is fine and the rest would want additional data as in a DER or similar. But if say in a ramp check or something a 337 would satisfy all of them, a log book entry maybe not.

-

When I was a Test Pilot, flutter was one of the very few things that scared me, a good friend of mine (Dr Ralph Kimberlin) who literally wrote the book on small aircraft test flying and my Civilian Test Pilot mentor when he was flight testing the Aero Commander 112 got flutter that caused the aircraft to disintegrate, he got out, the flutter Engineer did not. There is a story why the Engineer was onboard of course, because that was uncommon and honestly he shouldn’t have been. Ralph passed away last Nov. https://www.fit.edu/faculty-profiles/k/kimberlin-ralph/ https://asn.flightsafety.org/wikibase/2731 People think, if I get into flutter I’ll just slow down, maybe, maybe not. North American Rockwell recreated the incident in NASA’s wind tunnel, time from flutter initiation to complete disintegration of the entire empennage was less than 1 sec. This aircraft had been dove to Vd several times with small issues occurring, what was different in this dive was Ralph had trimmed the elevator full nose down to keep from having to push so hard down, as is common on many aircraft only one elevator had a trim tab, this caused enough unbalance to trip flutter once it was initiated with a control doublet, a control doublet inputs forces very similar to turbulence and “excites” a flight control.

-

First in my opinion a patch would be fine, but be sure the “square” has very rounded corners. Secondly the Rudder MUST be removed and rebalanced after all the work was accomplished to include paint, it is VERY much a safety issue, improperly balanced you can very easily get flutter that can very quickly literally rip the flight control off and of course cause a fatal crash, balance should not affect trim. Personally I’d put the patch on with a bead of fuel tank sealer, among other things this will prevent water intrusion and corrosion. If you ever fly again with an unbalanced flight control, do so slowly, flutter is very much aggravated or caused by speed. The purpose of balancing a flight control is flutter prevention. Then as has been noted one 337 for the modification / Repair and another for the removal of the STC. Although I think they could be combined. The first is required as it is a Major, the second because your changing type design, yes returning it to original, but it’s still a change. That cover was put on poorly and poorly designed in my opinion, first there was no edge distance on at least one rivet and I would have put a doubler in with nut plates and made the cover removable myself.

-

My Goodyear Flight Custom nose wheel is Lord knows how old, it’s getting weather checks on the sidewall and about worn out. Interestingly unlike Auto and truck tires aircraft tires have no age limit. The mains I replaced seemed to wear pretty quickly, but both were severely flat spotted at least twice each by the previous owner, I think those flat spots accelerated wear. Half my landings are on grass, and if you land on grass you replace tires when they rot out, there is almost no wear. The Goodyear and Michelin tires are unquestionably better than Airhawks, for the cost they had better be. Like I said all the large Commercial Jets run recaps so I imagine they are good. I’m not sure what kind of nosewheel tire I’ll get, but expect it to last almost forever based on how this one has worn. I think it will likely be a Desser recap, unless I can score a Thrush tailwheel tire I fly a couple of times a week and usually have a couple of pavement landings on average a week.

-

1998 M20R Ovation Gear Retraction Issue

A64Pilot replied to Dustoff49's topic in Modern Mooney Discussion

I believe even if you had the $16K, they aren’t available, at any price. I concur with your thought process it’s one thing to test something that’s available, and another for something that isn’t. Maybe the rebuilds will become available again, but I suspect not for $16K, the price of the spring I think tripled, how much for a rebuilt actuator? -

1998 M20R Ovation Gear Retraction Issue

A64Pilot replied to Dustoff49's topic in Modern Mooney Discussion

A change in any Emergency procedure requires a change in the POH, changing the POH is a Major which requires as a min a 337. I even wouldn’t be surprised if you asked the FSDO if they wouldn’t require this to be an STC under theory it changes Type Design, but as 337’s are no longer reviewed unless you ask that’s not likely to happen. An IA isn’t required to approve a minor alteration/ repair, those only require an A&P. You know those definitions aren’t all inclusive, not even close. I’ve given up on trying to convince people, many just want to believe what they want to. Just trying to bring up one possibility is all. If I were just a Peter Pilot and decided to safety wire the thing with copper safety wire for example, I just might remove that wire when the airplane went into Annual for instance, have to anyway for extension test. But then no one but me ever flies my aircraft so there is no concern of someone unaware of it being safety wired flies the airplane. Not saying I would of course -

Two Lessons From The DCA Crash

A64Pilot replied to GeeBee's topic in Mooney Safety & Accident Discussion

Don’t get me started about the Military, back in Clinton’s day. Turbine inlet Temperature abbreviated as (TIT) was offensive so it was changed to Inlet Turbine Temperature (ITT) Cockpit was offensive so it was changed to Crew Compartment. Any reference to manpower, or men as in addressing troops etc was also offensive and manuals again were changed We laugh about that, but 30 years ago all manuals were printed so each change cost millions in printing and distribution not considering the massive number of man, excuse me person hours spent posting changes to every Aviation manual in the Army, and later every manual of which I’m sure there are thousands at least. There were many other changes too of course like when you were at a Dr appt they used to call you by your last 4 of your SS, that was stopped and Civilian Govt employees called us SM’s for service members, that too was considered offensive and God knows how many other things. Then in the last couple of years of course any Military post named for Southern Generals which as most are down South was most of them, at least the big ones anyway had to have its name changed, each change costing millions is printing, signs etc. but that was just the beginning by the time it was done thousands of building names, landmarks like hills, roads etc had to of course be changed, because the names were racist? -

On my 81J running the part number comes up as a Golf Cart solenoid, which I believe is the same, but widely available and cheap. The difference between the two maybe is the golf cart solenoid is continuous duty, where the starter solenoid likely isn’t. The pic Mooney part on left, golf cart one on right, remember by part number they are the same. The landing gear switch thankfully is available by part number and cheap too.

-

1998 M20R Ovation Gear Retraction Issue

A64Pilot replied to Dustoff49's topic in Modern Mooney Discussion

That’s a thought, I looked yesterday and there wasn’t enough sticking out to drill a small hole in the handle for a small hitch pin, so I gave up on that idea Doing this would be a major modification though, reason is because it changes the POH to include a step that says remove safety pin, but then the mods done on some baggage doors I’ve heard of would be too for the same reason. In my opinion and it’s just an opinion there is merit I think in preventing accidental handle release. -

I haven’t even looked, but often there is a retainer strip that is riveted and sometimes they are replaced with screws, but I have no idea on a Mooney. My old C-140 it’s all screws, just a few minutes work, so it apparently differs from one make to the other.

-

As the crack has run it’s course, I’d leave it alone, I believe anything you do other than replacement is going to make it look worse. I assume thin CA (super glue) would seal it, I’ve never tried, MEK is so thin I’d want a syringe or something as an applicator, even one drop is going to run I think. I’d practice on scrap first though. In the mean time maybe a strip of clear tape to stop the whistle?

-

Seriously? Another unleaded avgas thread . . . ?

A64Pilot replied to 76Srat's topic in Miscellaneous Aviation Talk

1 It’s not quite that simple because the higher Octane allows advanced timing, but I agree that fuel consumption would increase significantly. But E85 is way more than 20% cheaper than 100LL, so range loss yes, but at the cost to fill up I’d take it. But I don’t think the compatibility would be the big issue with E 85, it’s it’s affinity for water, water that likely would come out of suspension at higher altitude and lower temps that I think would make it less than ideal as an aviation fuel. The thing is that it seems like some kind of drop in replacement for 100 LL just ain’t happening, everything will have something that makes it less desirable than 100 LL, starting in my opinion with the price. I just don’t believe anything that comes out, if anything does is going to be only a buck a gl more. Maybe an Alaska gl price buck, but not a Fl US gallon price. I just think Monopolies are sort of known for bending you over the table price wise. Look at Pharmaceuticals for instance once they lose the monopoly see what happens to the generic price. -

Seriously? Another unleaded avgas thread . . . ?

A64Pilot replied to 76Srat's topic in Miscellaneous Aviation Talk

I have no idea, the rest of us like me in my J can run ADI that has a number attached to it of $12K and I think 40 ish lbs None of the options are going to come without drawbacks, but $ 12K and 40 lbs I could stomach, I’d rather keep 100 LL myself though. I think if tied to a lightweight battery the 40 lbs could be reduced some and keep the CG within range if the ADI system were mounted behind the aft baggage compt wall, bigger Mooney’s may be able to simply remove some of the Charlie weights. For $12K I’d like at least variable injection myself, but everything in Aviation costs more than it should. I mean $100K for a big VW engine for example, it’s just the way it is and it’s not going to get better. IF we accept that lead has to go, personally I don’t accept that but I don’t count for squat. It seems we have maybe three possible solutions. 1. A new “Magic” fuel, that so far no one has been able to formulate. Now personally I think it’s possible, but maybe not feasible cost wise. Seems so far every possible candidate “eats” paint and bladders and other fuel system components and my bet is that it’s effect on health is probably worse than 100LL, but again I’m no expert, but if you do some reading many are raising the flag on aeromatics in Auto fuel based on its effect on health. Are they just nuts? Possibly I don’t know 2. A new engine, some think it could be done for less than $100K and or $100K isn’t much, but for me I think I’d go Experimental or something else first. $100K would push me out of flying. I don’t think it can be done for even close to $100K myself. I think it would be much higher. The scale wouldn’t be there as we would be talking a few a month, not hundreds or thousands that it would take for economy of scale to kick in. I think the requirement of a new engine would kill GA as I think adding more than $100K to every airplane out there would first make the majority of the GA fleet essentially worthless, probably boost the Hell out of LSA’s and Rotax would love it though. 3. ADI for those that need it, apparently 20% of the GA fleet and 94UL alone for the 80% of the fleet that doesn’t. They claim Turbo aircraft can also work with ADI, but does that mean continuous injection? I don’t know, maybe? That’s where I think variable injection would help. Of those three things, only ADI exists, the other two are at this time Vaporware. Perhaps that’s what we need to keep being able to get 100 LL, Vaporware. For decades the Major Auto manufacturers convinced the powers that be and by that I mean CARB that EV’s weren’t a viable platform, that Hydrogen is what we need and it’s only a couple of years away. Hydrogen powered Auto’s are and always have been Vaporware, but touting it kept the Auto manufacturers continuing to build ICE cars which is what they wanted of course. I have nothing against ICE cars, I own a few, just saying the strategy worked is all. -

I used to maintain fleets of aircraft that had oil analysis taken on pretty much everything at 25 hour intervals, not only when the oil was changed, by fleet I mean 24 to 28 at a time, all identical aircraft flown in the same location, same mission profile, same frequency, same mission length by the same pilots. They were all turbine powered Military helicopters but the point is that even with all of those identicalities and even though there were hundreds of aircraft monitored identically across the fleet for decades there was never any “trigger” point identified that based on oil analysis that you removed a component from service. Even with all those identical profiles there was just too much spread from one component to another to get there, monitoring trends was useful though, for example soon after deploying to the Gulf gearbox metals climbed substantially, which triggered a change to triple nickel oil, which did bring readings back down. Without oil analysis it’s likely that we would have seen high gearbox failure rates before we figured out the need to change oil types. We used 23699 the same oil since at least Vietnam until then https://www.shell.com/business-customers/aviation/aeroshell/aeroshell-turbine-engine-oils/aeroshell-turbine-oil-555.html The one thing that SOAP was good for was not determining component health so much, but for determining the condition of the oil, moreso for ground equipment like trucks etc., for decades the has Army changed oil in all their ground equipment based on SOAP determining it needed it from fuel dilution, TAN / TBN, viscosity or soot loading and saves huge amounts of money doing so. What I learned is that it’s exceedingly rare for oil to actually “break down” before other indicators trip an oil change. By break down I mean viscosity, far more common for the TAN and TBN numbers to cross over first, or on Diesels especially the modern ones to soot load from EGR The Army pretty much invented SOAP with the first lab in Ft. Rucker in the 60’s I think. SOAP is marketed as being an indicator of engine health and everyone therefore wants it to be that, but it’s not very good at that, but they miss the point, what it’s excellent for is validating your oil change interval, determining the health of the oil and arguably if your using the right oil or not. Not that we have much choice in Aviation.

-

Barn find Mooney is it worth my time?

A64Pilot replied to Tim VanDenHoek's topic in General Mooney Talk

It’s sad and I hate to see it, every Sun we fly to Crystal River for breakfast, and this time of year I usually end up parking out towards the end of the ramp besides this. It’s been there for far longer than the four or five years that I have been flying there. Lately I’ve begun seeing a lot of beat looking large twins, sad paint etc and botched looking N number changes etc. I don’t know what’s going on with that because it can’t be cheap to keep an old 421 for instance flying even if only occasionally. -

Based on the G100UL fuel leak thread what's your position?

A64Pilot replied to gabez's topic in General Mooney Talk

The reason given to me why Georgia pumped so much money into Rural airports was in the hope to bring in Business. ‘There was some formula, I think if there wasn’t a runway within 50 miles of your little airport and your runway wasn’t at least 5,000 ft, the Government through a grant would pay for your runway to be extended, they also built hangars and new FBO buildings. The theory was that your little town was more likely to get Companies to build there if there was a Biz Jet runway in the town. In my part of the world hunting, particularly Quail hunting is big business, in Camilla for instance when the new T hangars were built the tied down aircraft were given use of the old shade hangars for free, it wasn’t just being nice, it was to have the ramp space for the Biz Jets bringing in hunters, and these wealthy hunters spend big on their hunting trips enriching the local economy. Attached pic is Camilla Ga with the morning deliveries of hunters in their Jets When I was a kid in the 60’s these hunts went for $1,000 a day per hunter. I assume they are likely five times that at least today? If so and there are an average of 20 hunters, then $100K a day for a little rural town is good money for the local area. -

Stall warnings are adjustable, often by moving the assembly up and down, sometimes by bending the vane. If yiu bend the vane make sure the switch still clicks when yiu move it. As part of my production test flights I had to adjust them where they would go off 5 to 10 mph prior to stall in the landing configuration. A has been said moving them up increases the speed / decreases the angle of attack they will alert, down lowers it. They are very commonly bent by people walking by and snagging it or a fuel hose etc. If it works on the ground repeatedly, almost certainly it’s just out of adjustment or bent.