-

Posts

180 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by mhrivnak

-

I sold mine, but you're right that there are probably plenty of extras from folks who have installed new primary engine monitors.

- 5 replies

-

- 1

-

-

- b & d

- tachometer

-

(and 1 more)

Tagged with:

-

G3X / G5 / GFC 500 / GTN 650 Installation time

mhrivnak replied to PT20J's topic in Avionics/Panel Discussion

In February I had similar stuff installed in my J. I had already installed a JPI EDM 900 and removed an ADF and strikefinder myself, meticulously removing old wiring (including some archaeology of wiring and other stuff left behind from equipment long-gone). That probably reduced some of their work. 150 hours for: "Labor to remove existing systems and install new G3X with G5 backup. Remove GNS 430W and Install GNC 255. Remove intercom and audio panel and install GMA 345. Remove autopilot system and install new GFC 500." That includes removing the whole vacuum system and creating a new panel. They did not have to install or remove any antennas thankfully. -

I have two of them pulled from my 1990 J when I installed LEDs. Send me a PM.

-

overhaul suggestions and shop recomendation

mhrivnak replied to bmcconnaha's topic in General Mooney Talk

@bmcconnaha did you ever find any data or detailed pireps? Just thinking ahead here, it would be interesting to know how the io-390 compares with operating temps, fuel burn, running LOP, ... -

M20j 1996 remote oil filter setup recommendations

mhrivnak replied to Chainfire's topic in Modern Mooney Discussion

Following up, I just noticed that a nice Craftsman 3/8" socket set is on clearance at Ace and includes a 1" socket plus 8 others. They have 12 points and appear to be low-profile, so it should work well on the oil filter. Made in the USA. $9.99 on clearance, normally $28.99. https://www.acehardware.com/departments/tools/hand-tools/sockets/2299352 -

I have one that I recently removed from my 1990 MSE while installing a JPI engine monitor. P/N 8800053-501 S/N A01163. Airplane had ~2160 hobbs hours, and as far as I know this is the original part. It has a manufacture date printed on it of 6-20-89. I haven't looked into what it's worth, but I'm sure we can figure it out. Send me a PM.

- 5 replies

-

- 1

-

-

- b & d

- tachometer

-

(and 1 more)

Tagged with:

-

avionics upgrade plan and input requested (Ovation/Bravo)

mhrivnak replied to FJC's topic in Modern Mooney Discussion

Another possibility; there's a reasonable chance you could find one with a GNS 430W or 530W. If you're willing to use that prior generation navigator (I trained with a 650 but now own a plane with a 530W and am very happy with it), that could free up a lot of budget to allocate elsewhere. Just adding a Flightstream 210 to a GNS navigator can enable you to do all your planning on a tablet and transfer it into the GPS. -

avionics upgrade plan and input requested (Ovation/Bravo)

mhrivnak replied to FJC's topic in Modern Mooney Discussion

As noted, the G5 will not provide the necessary attitude source for your autopilot, but a GI 275 will. When I went through this recently, the GI 275s were significantly more expensive to buy and install. Once you upgrade your budget from G5s to GI 275s, you're not far off from this instead: stick with dual G5s and replace the autopilot with the GFC500 (which people rave about). You can recoup significant money selling your KFC 150. Then you'll be in a good position in the future to install a G3X touch; at that point you'd sell one of your G5s, keep the other as the backup to the G3X touch, and you would already have the autopilot that the G3X touch works with. Am I counting three G5s in your plan? Keep in mind that when you have two as AI and HSI, they are linked, and the HSI will automatically start acting as the AI in case the AI fails. So I don't think you would need a backup AI. -

Mid-Continent can do this. They recently quoted me about $300-$350 to repaint my ASI and make it look brand new (with minor changes in where the arcs end due to a MGW increase), and another ~$200 if it was out of spec and needed overhaul. Give them a call, and they'll give you an idea of what it would cost for your instruments. I'm sure there are other outfits that do it also.

-

M20j 1996 remote oil filter setup recommendations

mhrivnak replied to Chainfire's topic in Modern Mooney Discussion

I had this one on my Christmas wish list: https://smile.amazon.com/dp/B007TMEBLQ/ The one I've borrowed in the past I think is a craftsman. It works great with a normal torque wrench to tighten the filter on my A3B6D. -

I just went through this with an owner-assist install in my 1990 M20J. I used the factory senders, which are resistive. We leveled the airplane, drained the tanks, and then carefully re-filled. At least twice, one of the arms was stuck enough that the value didn't rise hardly at all after adding 8 gallons, but just giving the wing a nice shake got it to free up and read correctly. It's possible that if something like that happened and he didn't catch it, your 3/4 and full readings might have actually been taken with the arms stuck closer to the 1/2 reading mark. I agree with the suggestion of getting the install manual (it's on JPI's website), reading about how to get into the fuel level settings, and look at the table of values that are entered. (take a picture while you're there in case you ever need to restore those values) See if they look funny at all. In my case going off memory, I had readings on each side that were roughly ~15. ~450, ~650, ~850, ~1100. Not a linear progression, but significant increases for each reading. You might have very different numbers, and that might be expected, but I'd guess you should see some kind of sensible progression. Speculating as a total amateur, it would make sense if the factory gauges just indicate the "raw" reading, so it may be reasonable to expect a progression of values that wouldn't be wildly inaccurate if indicated with a needle. One other long-shot thought; the factory wiring (on my J at least) only has a single wire run from the inboard sensor up to the gauge. But JPI insists that you run two conductors to each sender, one of them a ground, and attach the ground as close as you can to the sender. It's tempting to just re-use the factory wires rather than run new (it's a pain just getting the old wiring out), but I have no idea what symptom you might see if he took that shortcut. If it comes to it and you want to lay eyes on the wiring, especially to see if the outboard sender is still connected, the inboard sender on the copilot side is fairly easy to get a look at just by removing the metal guard at the base of the door opening.

-

I've enjoyed a couple of trips to HSP, which is also an easy flight from your location, to do the 3-mile loop trail that departs from the airport. It's a beautiful area to fly and hike. I've been trying to do more flights like that to make up for the lunch/dinner flights and friend/colleague flights that aren't happening this year.

-

Interested in purchasing a J model, have some questions

mhrivnak replied to Ryan ORL's topic in Modern Mooney Discussion

Good choice. I bought a J in that price range this summer. For pre-buy, it's going to depend on where the airplane is that you end up interested in. There are lots of Mooney Service Centers, so that's a good start if there's one nearby. The one I bought had been maintained at the only MSC in the area, and of course it's a no-no to have the shop that maintains it do a pre-buy, but I was able to find a different shop nearby with a lot of Mooney expertise in part by searching this forum. I'm a big fan of the pre-buy philosophy from these guys: https://www.airplaneprebuy.com/ Listen to their podcast, read some of their materials, and seriously consider at least letting them do an FAA paperwork analysis and/or log analysis for you. Every detail matters, and you want to know what discrepancies you are acquiring with your new airplane, both physical discrepancies and paperwork discrepancies. Plan to be there if at all possible. If not, plan to communicate with the shop regularly throughout the day in case their findings impact your decision to continue the process. For me, these were some key Mooney-specific feature preferences to determine in advance, and they helped me filter out which airplanes I would consider: Bladders or no? There are pros and cons both ways. Speed breaks? Many like them and see them as a value add, but others (<cough> me) don't want the weight, don't want another system to maintain, and are happy without them. Two blades or three? Not a huge deal, and many are rightfully just thrilled to be in a Mooney without caring how many blades are up front, but there are some pros and cons that might matter to you. It's worth being aware of useful load. Js got modestly heavier over time, and eventually around 1990 they raised the MGW by 160lbs, bringing the useful load back to a similar range as the original Js. That's a factor that was important to me. -

JPI EDM power and breaker location

mhrivnak replied to mhrivnak's topic in Avionics/Panel Discussion

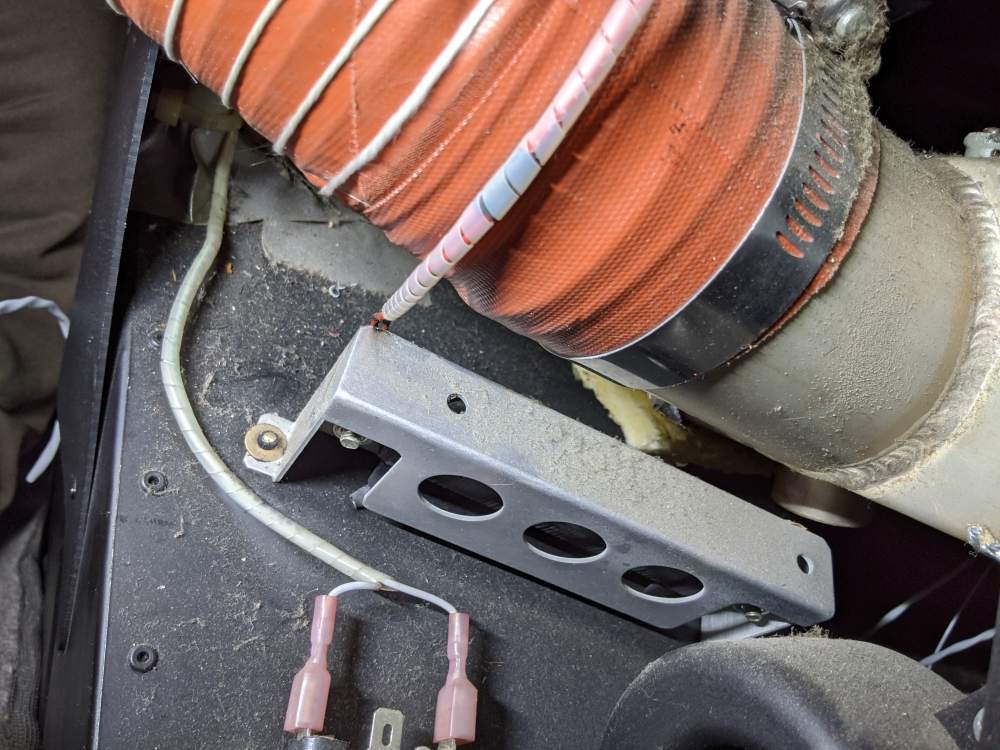

That's a good point. I don't know if "should" vs "must" makes a practical difference to an IA in this case, but I'll ask. I did a basic voltage drop calculation, and it's not bad at all. Assuming a 15ft run of 6-gauge copper (the real conductor looks bigger), and a 300 amp load (max rating for the solenoid, but the starter likely is closer to 125 amps), the drop would only be 3.5V. Those assumptions are substantially worse than what we can probably expect in the real world, so this seems like a non-issue for those of us with 28V systems. I'll call JPI on Monday and see what they think. I'd much prefer to not have a breaker in the back. -

JPI EDM power and breaker location

mhrivnak replied to mhrivnak's topic in Avionics/Panel Discussion

What is it that you think is being lost in translation? Yes, if connected as the instructions say to the master solenoid, it will come on with the master switch. It's normal that when a significant load is applied to a line, the voltage on that line drops. You may have seen the lights in a room dim when a hair dryer is turned on. Likewise you might notice nav lights dim while an airplane is running the starter. That's the phenomenon JPI is trying to avoid by having a separate line run to the source (battery). -

The instructions for installing a JPI EDM 900 say that its power wire must be "connected directly to the master solenoid located at the battery to avoid a line drop when cranking. A 5 amp circuit breaker is required." For those who have one installed, where did you put the breaker? Putting a breaker by the solenoid is inconvenient since it's in the back. It would be nice to have the opportunity to reset it while sitting in the airplane. But if the breaker is in the breaker panel, then the line has no protection if it shorts anywhere along its route from the battery up to the breaker panel. How is this typically handled with our Mooneys?

-

I found the same last night in my 1990 MSE while tracing and removing old wiring as part of a new engine monitor install. Paperwork says that a KT76A was removed in 2011 (prior to my ownership), so I assume that shop just neglected to remove this too. It's hard to see and get to, mounted behind the center console (where apparently vacuums can't reach...), not that that's any excuse to leave it in. Thanks for the thread confirming what it was for.

-

Thank you all. I was able to get the knobs off and the instrument out. I don't have that little wrench, but I took and old 3/16" flat head screwdriver and cut a notch in the middle. It worked great. I had tried prying the caps off with my fingers previously, which didn't work. When I used a blade though, they came right off. Thanks! Yes, the Insight G2 will be for sale with the harness and 4 each CHT and EGT probes. It works great; I just wanted to upgrade to the JPI EDM 900 and replace all of my primary instruments. I'll have a bunch of stuff to post for sale when I'm done with this install, but if anyone is interested in this engine monitor in the meantime, get in touch. I haven't looked into what it's worth, but I'm sure we can figure it out. I'll even include my customized screwdriver for installing the knobs.

-

I'm removing an Insight G2 engine monitor to make way for my new JPI EDM 900, but I can't figure out how to remove the two knobs on the G2 so that I can remove it from the panel. I don't see a set screw anywhere, I tried pulling hard without breaking it, and I don't see any mention of installing or removing the knobs in the manual. The stem for each knob extends through its own tiny hole in the panel, so the knobs must have been put on after the instrument was mounted. Any ideas? Thanks!

-

I recently installed these (OR6502GE, OR6502RE) on my 1990 MSE in addition to the tail fixture (OR5002V). Mounting: for me, all the holes lined up. The only challenge was finding longer screws to attach the tail light. I found that both wings had shielding for all the original wiring to both wing tips, which is great because I'm planning to add a magnetometer soon in the right wing. The Strobe and Position circuits each had their own ground wire that ran all the way to the panel. So I re-purposed the strobe ground wires as my sync wires and did not have to run any new wires through the wings. The strobe power supplies were in the wings a couple of feet inboard of the tips. Each had two conductors coming in from the panel, then three conductors going out to the light. After removing the power supplies, I spliced the two conductors from the panel to two of the three conductors that ran from there to the new LED fixture. Then I used those two conductors as sync and strobe power. I wanted to remove that short run of 3-conductor wire that went from where the old power supplies were and replace it with a 2-conductor run, but it proved quite challenging. At the wing tips, all the conductors going out there come through an Amp circular connector that's impossible to access without removing rivets. Oh well, I'll live with a few extra feet of decommissioned wire in the wing tips. I ran a new 2-conductor shielded wire from the panel to the tail for position power and sync. Previously my rear position lights were on the rear of the wing tips, so there was no pre-existing position light wiring to the tail. I joined the three sync wires under the panel. Where the strobe power supply was in the tail, I spliced into the three conductors running from there to the tail light and used them for ground, strobe power, and position power. Fishing a new sync wire through that section of tail components was tricky, but I got it to work. I replaced the 4-pin Amp circular connector in the tail with a new 9-pin connector so I could add a 5th pin for sync. I also used 4-pin molex connectors at each light fixture just to make life a little easier the next time a fixture has to be removed or replaced.

-

-

I've owned a 1990 MSE for three months. I was looking around under the panel recently and noticed this box, not connected as you can see. Searching the immediate vicinity, there was no obvious cable and connector waiting to be plugged in. Any idea what the story is on this thing? Looking at the wiring diagram, it appears to be related to controlling overhead lights. That corroborates the text printed on the box. But what exactly does it do, and why might someone have left it disconnected? Note that the picture is upside-down for ease of reading the text.