-

Posts

180 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by mhrivnak

-

Good questions. 1. Ack. 2. Mostly by having fewer features, and especially fewer cloud services and third-party integrations. That can cut (or grow) costs a lot. But keep in mind that while there are lots of different revenue/pricing models that might make sense, they're all subject to the same basic cost framework. I saw some assertions about cost earlier in this thread and responded primarily to those. It costs a lot to keep a product like Foreflight going. As for pricing, some software vendors have lower-cost (or even free) basic tiers, sometimes as a loss leader, with hopes of selling premium services to generate actual profit. For example FlyPlan Go has a long list of "Premium Services" on their website, which could be an example of this approach. Otherwise, we can probably explain their lower basic pricing by their lower costs, driven again by having fewer features. 3. If you're suggesting that applies to me, I think that's misplaced, and seems dismissive, though you may not have meant it that way. Foreflight is a best-in-class tool that I am happy to use, and I think the price today is fair just as I thought the price 5 years ago was fair.

-

I work in the software industry, and I interact with a lot of different software vendors. A product like Foreflight certainly costs a lot just to maintain status quo, without new feature development. It's not like an old video game where you write the software once and then sell a bunch of copies until it's time for a sequel. I have no direct knowledge of how Foreflight operates, but I'm a customer, and here are my assumptions: They run a lot of cloud services for you. Logs, weather data, traffic, flight plan synchronizing, flight plan filing with the FAA, chart data, etc. Serving those reliably takes teams of people just to ensure it doesn't break, and that if/when an outage happens, it gets fixed quickly. They integrate with numerous external services. I assume there are multiple weather data vendors, aerial imagery, chart updates, street maps, terrain data, ATC integration with multiple countries, etc. Each of those change over time in how they work, occasionally has an outage for FF to deal with, and there's a vendor relationship to be maintained. The above requires significant computing infrastructure, hopefully across multiple data centers in different regions, etc. They likely use one of the public cloud providers (AWS, Azure, GCP, ...) and have a hefty monthly bill. Testing on new Apple hardware and new versions of iOS is critical and not trivial. Robust testing alone is a significant effort. Sometimes issues are found that need to be fixed. Sometimes a new iOS release requires significant changes in the product. The above point applies also to testing with a long list of avionics integrations. And testing on a variety of computers and web browsers that are always changing. Providing good customer support is not cheap. Security has never been more important for software. Whenever a vulnerability is discovered in a device, iOS itself, some software library FF uses, a service FF uses, or in FF itself, they need to be ready and able to fix that very quickly. And keeping bad actors from compromising their cloud services is likewise a significant and critical area of continuous investment. And on top of all of that, they do of course develop new features. That adds yet another layer of complexity to everything described above. Everything above takes many teams of people with tech talent. The competition for hiring tech talent has never been fiercer, and salary pressure is high. There is a lot of turnover industry-wide as people pursue better opportunities or just more money. Not to mention, all of these people have to live somewhere, and the cost of housing in the US has gone up tremendously in recent years. I took a peek at their glassdoor.com page, and a theme in the reviews is below-average pay. Maybe in the past they've been able to make up for that by retaining people who like working in aviation specifically.

-

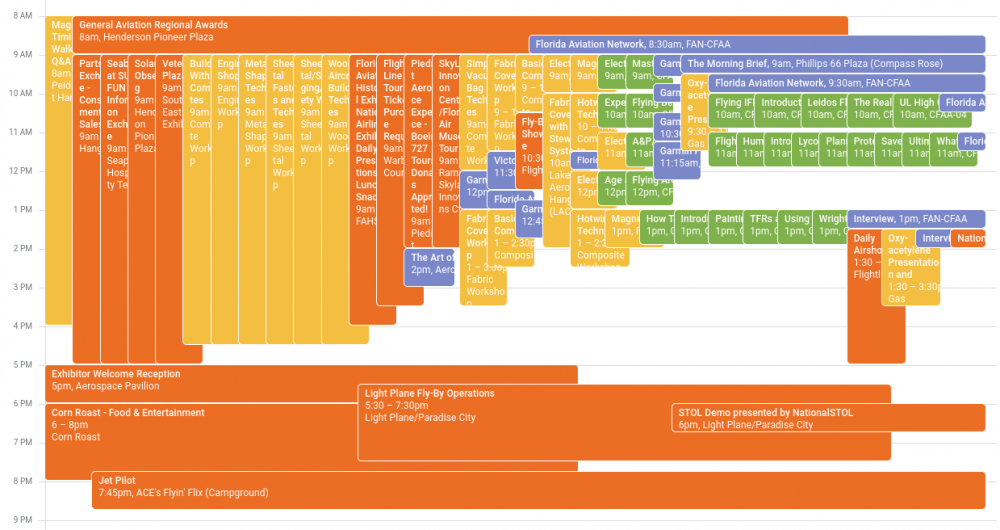

Wish you could view the Sun n Fun online schedule, but found their web version hard to use? Me too. So I converted their raw data into a form that can be loaded into other software like Google Calendar or the Apple thing. Visit this link to try it yourself: https://snf.hrivnak.org/ Please let me know of any issues or feedback. Mooneyspace gets exclusive early access before I share this more widely, in part to help me shake out any last issues. Note: I can't help you figure out how to load the links into your calendar software, other than pointing at documentation. Hopefully it's self-evident. Let me know if you hit any significant hurdles. Here's what it looks like in Google Calendar.

-

- 2

-

-

That's a good tip, though I replaced the boost pump about a year ago and still have pictures of the area to confirm there is no additional filter.

-

I think we have a winner. This is a piece of cardboard box I pulled out of the trash, magnified the same way. It looks like the same stuff.

-

I think it has to be one of four things: something deteriorating in the system past the gascolator. But as noted, nothing seems to fit this material. it was inside the fuel pump that we just installed. it was already in the screen when the servo came back from the overhaul shop. while the fuel lines were open, something fell in or some small critter introduced this material. I did try to keep open lines covered, but I probably wasn't perfect about that. They all seem unlikely, but I don't see any other options. Just speculating: I could believe that the material is a bit of cardboard or similar that's been soaked and tossed around.

-

The gascolator is as clean as they get, so it don't think this could have come from upstream of it. Here's a pic through a magnifying glass. It seems to mostly be brown fibers that are brittle, with a few longer colored fibers mixed in. I've found red, white, blue, black, and green.

-

This is a 1990 J without that filter. Just the gascolator screen and servo screen.

-

Continuing troubleshooting of a fuel flow issue, today we found a wad of fibrous material in the fuel servo screen. Where could this come from? Could it be deteriorating fuel lines? It was a solid mass when it was pulled out of the screen. I pulled it apart a bit to get a sense of the material. This is only about 4 tach hours after the servo was overhauled, and 2 hours after the mechanical fuel pump was replaced. My impression is that the overhaul shop was very meticulous about the servo overhaul, so it seems unlikely this material was in the screen when it came back from them, which suggest it accumulated quickly. The gascolator was whistle-clean at annual, 17 tach hours ago, but I did not re-check it today (maybe I should go do that tomorrow...). Considering that the servo screen caught this, it seems unlikely it would have passed through the gascolator screen.

-

Before overhauling the servo, we hooked up a clear tube at the divider to look for bubbles and observed none. I ran it up to 2200rpm and saw the fluctuation happening, but my mechanic watching the tube saw no signs of air bubbles. Indeed, the behavior is the same on either tank. Anything else you would do to rule out the gascolator? It was of course open during the annual (found to be whistle-clean).

-

Thanks for the ideas. When ROP, EGTs do in fact decrease as expected. You can also see the RPM correlation, so I'm confident it's not an indication issue. Running the boost pump makes no difference. The intake path is clear with no obvious cracks or defects. I have the usual Brackett air filter, and I did replace the element at annual. I've double checked that it is seated well in the housing. Anything in particular you'd look at regarding the filter? Naively is seems hard to screw up, but maybe I found a way.

-

Update: I had the fuel servo and divider overhauled, but that did not resolve the issue. Airflow Performance did find corrosion in the servo and noted that it it was behaving well out of spec when they tested it. But again in the flight yesterday, the fluctuation happens lean or rich of peak, left or right tank, left or right mag, boost pump on or off, and at multiple power settings. If anything, the amount of variation seems to have increased after overhauling the servo and divider, now up to .8 gph and occasional .9. Any other theories on what could cause this? Fuel pressure appears stable, though the JPI resolution seems to only be 1 psi. The mechanical pump is the original with 32 years and 2250 hours, and they're relatively cheap, so I may go ahead with replacing that, though I don't have a good explanation for how it could be the problem. Here's a snapshot from yesterday's flight, running LOP in this segment.

-

The yaw damper is nice even in relatively light turbulence. I can turn it off and back on and notice a significant difference. Especially if you fly with anyone who is sensitive to turbulence, reducing yaw can help a lot. On a related note, the GFC 500 handles turbulence MUCH better than the KAP 150 did. It gives a much smoother ride.

-

Would You Rather have 2 x GI275's or a G3X 10"?

mhrivnak replied to GeneralT001's topic in Avionics/Panel Discussion

Just emphasizing what a couple of others said: the G3x Touch will not provide attitude information to the KAP 150. You could keep your attitude indicator to make the AP work with the G3x Touch, but that's a real disadvantage. I went with the G3X touch because it provides much better situational awareness. The whole synthetic vision setup is very nice, showing terrain, traffic, obstacles, and airports all rendered on the big display. But, I was planning to replace my KAP 150 anyway. I figured I'd rather remove it while it's working and sell it as working used parts (they're worth quite a bit!). -

I would have sworn that mine normalizes EGT and CHT both right across the middle like @Skates97's photo, but the pilot guide does say only EGT is normalized. And in this video example, it looks like CHT is not normalized. It's possible they changed the software at some point. I'll try to remember to get a video clip of mine next time she runs.

-

It's hard to understand what sort of pre-buy a shop would do if they're not even willing to take the engine cowling off and look at the engine. I wonder what their reasoning is. That aside, there's a lot more to see up there than the compressions and oil filter. Are there any fuel leaks? Unusual oil leaks? Chafed or damaged fuel or oil lines? Exhaust leaks (fire hazard!)? Intake leaks? Cracked or damaged engine mount? Cracked exhaust? Not to mention sticking a borescope in the cylinders to check valve health. And some ADs can be verified visually. And sometimes you'll find equipment installed that's not documented. Any of these things could be serious safety issues and/or expensive to fix. It's worth having a trained eye spend 15 minutes looking at it. I agree that Top Gun sounds like the perfect place. Assure the seller that you're reasonable and understand it's an old plane, and that you're primarily interested in airworthiness items. If they still object, I'd pass.

-

Beware fuel system icing - it happened to me...

mhrivnak replied to SpamPilot's topic in General Mooney Talk

I see that 1% by volume is the max, but what's a normal ratio to add?- 37 replies

-

- fuel system icing

- ipa

-

(and 1 more)

Tagged with:

-

@mkrakoff did you ever get this resolved? What fixed it?

-

Right, when I add FP to the graph, there is no apparent correlation. It's mostly stable at 22psi. I don't know why it moved during that short video, but I haven't been able to identify any correlation between its occasional changes and the constant FF changes. Here's an example.

-

I checked the mixture and throttle cables, and both are very secure with no slop. I can't see any change in fuel pressure while this is happening, either on the display or in the recorded data. But I think it's only measuring in increments of 1psi, so there could be smaller fluctuations happening below that threshold.

-

I have an original IO-360-A3B6D, in service since 1990 with ~2250 hobbs hours in my M20J. Since my recent annual, the fuel flow will fluctuate about 0.5gph several times per minute when running above about 20" manifold pressure. It's persistent, but not on a regular interval. All 4 EGTs follow the changes exactly, so I assume it's not an indication issue. It happens when I'm lean of peak or rich of peak. Turning on the boost pump has no effect, nor does switching tanks. It happens on the ground and in the air. Fuel pressure is stable. There are no visible fuel leaks anywhere. This week, we hooked up a clear tube at the divider and confirmed that there are no air bubbles in the fuel line going into the divider, even as I ran it to 2200 RPM and saw the fluctuation happening on my engine monitor. Here is a quick in-flight video, plus charts from engine monitor data showing FF before and after the annual. Background: On the last flight before my recent annual, I saw a cylinder start behaving like it was very lean, and I suspected a clogged injector. During annual we cleaned the injectors, and sure enough I found a small piece of debris that fell out of that injector. My A&P took the top off the divider to have a look and make sure there wasn't more debris in it; it was perfectly clean. I also checked the gascolator screen and servo screen as a normal part of the annual. That's all we did to the fuel system. We also sent out the magneto for IRAN, but I don't know how that could be related here. Ideas? Given that the diaphragm in the divider is 31 years old, and that this problem occurred immediately after messing with it during annual, it's tempting to start by replacing it. But: 1. the diaphragm isn't available for sale as far as I can tell, and 2. I can't think of how it or the valve in the divider could cause this behavior. Is it just time to overhaul the servo and divider? I'd feel better if there was a reasonable theory on why this behavior is happening now, just after some work happened on the fuel system, especially given that it's a significant expense on an old engine. But based on my understanding of how the system works, the servo handles the regulating and is most likely to be at fault. I thought about trying to get a look at the servo's air impact tubes. If some bit of debris sneaked by while I was changing the air filer, and partially obstructed the servo's ability to measure impact air, maybe that could cause this? Seems unlikely, but at least it would be an explanation. Maybe someone has a better theory?

-

87 J panel upgrade; ideas welcome

mhrivnak replied to sleeper-319's topic in Avionics/Panel Discussion

The shop that did my installation created the panel themselves, with help from a local contractor who I think did the cutting and painting. My impression is that a lot of shops have this capability. -

The still-popular GNS navigators use them. My 530W is the only reason my plane still has a separate avionics fan.

-

510 hour engine spike in metals. Opinion needed

mhrivnak replied to Joe Larussa's topic in General Mooney Talk

It's easy to stick a borescope in each cylinder and look for problems there; did the shop do that? For example, scoring on the cylinder wall in line with the piston pin would be a big clue. -

This was addressed recently on the Opposing Bases Podcast (recommended if you haven't listened before. It's two controllers who are also pilots talking about ATC topics.) They said that they, like most facilities, hear everything broadcast on 121.5 and have no way to turn it off. No matter how busy they are or how important it is for them to understand transmissions on their normal frequencies, they'll also hear all the nonsense on guard, and it can be very distracting.