Steve2

Basic Member-

Posts

45 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Salt Lake City, UT.

-

Reg #

N7331F

-

Model

PA-28-140

-

Base

KBMC

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Steve2's Achievements

-

Yes it is an LM, This was my 1st aircraft, I was the 2nd owner in 2000. Bought it from KCAC at New Century.

-

I have a collection of 121.5MHz ELTs removed for 406MHz upgrades. $70ea includes UPS ground shipping within the US. I've verified that they work including G switch operation, installed batteries are expired. Models available - Artex ELT110-4, Artex ELT-200, Narco ELT 10 & D&M ELT 6.1.

-

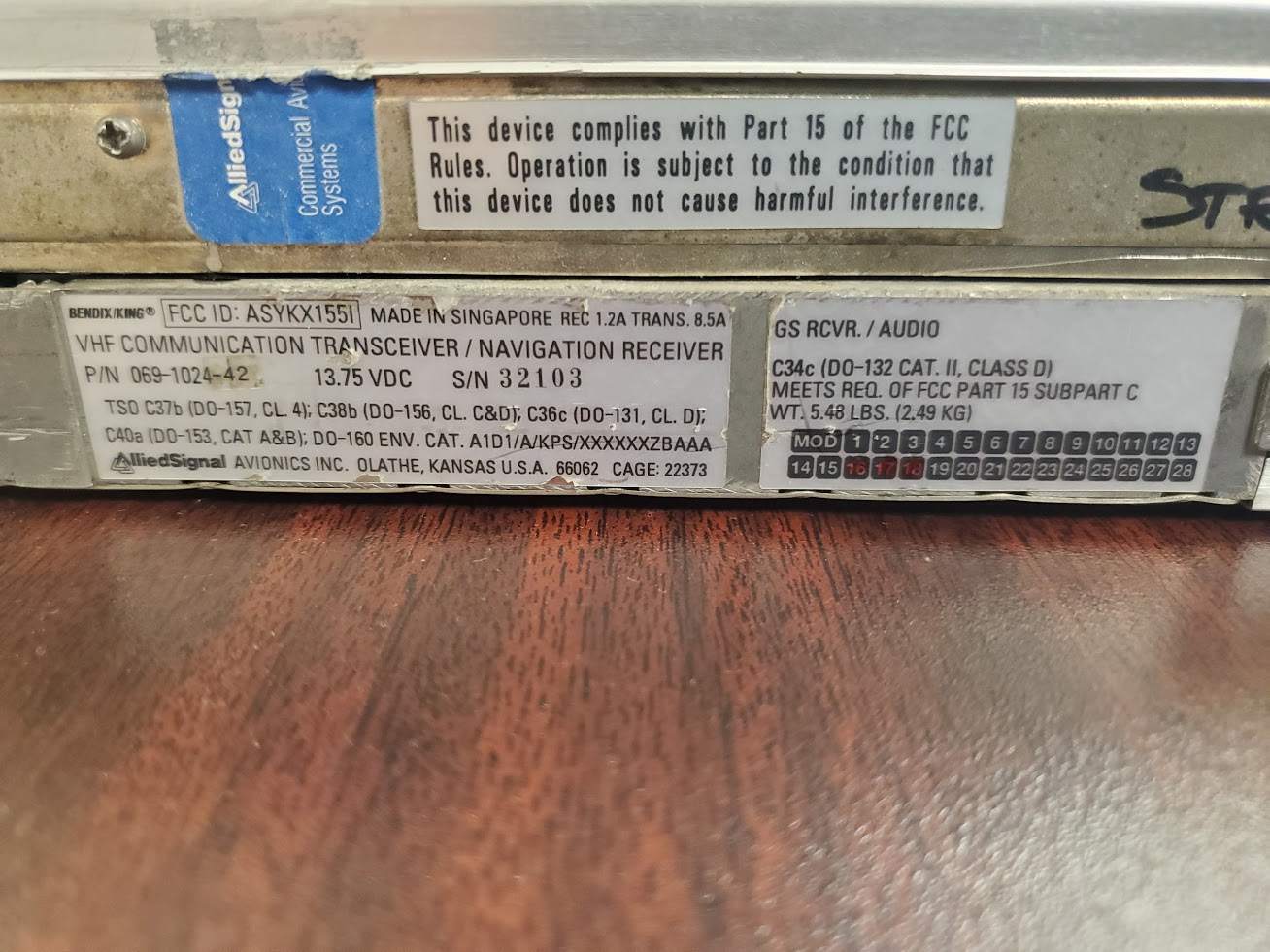

14 volt KX155 with glideslope recently repaired by Soldan Electronics www.kx-155.com $2,000.00 + shipping.

-

Mooney m20m bravo real world weight and balance?

Steve2 replied to Ripley98's topic in Modern Mooney Discussion

My old Bravo N243CW (2003-2006) had long range fuel (118gal) & FIKI, payload with full fuel & TKS fluid was 90lbs! You definatly needed to be comfortable with partial fuel loads, wing sight gauges helped with that. -

Excessively rich idle mixture will cause high idle MP indications. Try idling at 800-1000rpm and slowly lean the mixture to ICO; if it's too rich you'll see several hundred rpm increase along with decrease in MP.

-

So you're using the factory drawing as your approved data and sourcing the parts from alternative locations? That's too bad about Frank not being at the factory any longer; I occasionally needed tech support with customer aircraft and he was always responsive with accurate information.

-

I installed the Mooney factory kit in my 2000 M20R; pn 940105-503. I think kit price was around $5k. It's basically a B&C 20 amp unit that mounts to the pad adjacent to the vacuum pump - note B&C doesn't have an STC for the install and so I found factory was the only option. Installation was a challenge, not for an A&P who's unsure of electrical systems, some of the supplied parts didn't fit the existing connectors in my sn aircraft even though it was the correct kit. Frank Crawford and the team at the factory provided responsive support and we got it all worked out. Note; there are a couple of different kit part numbers; make sure you get the correct one for your aircraft sn.

-

I think that's me, got it listed here on MS as well. 2000 Ovation 2, 310hp

-

As I understand it the NAS1307/6607 are a close tolerance bolt, the AN7 isn't so although it would fit, the fit wouldn't be as tight as originally designed.

-

They don't show stock but maybe a call to https://military-fasteners.com/search/?term=NAS6607-&page=1 Also Genuine Aircraft Hardware https://www.gen-aircraft-hardware.com/ ECAS which is now a part of Monroe Aerospace. My IPC shows NAS1307-72D; don't know is the 6607 supersedes the 1307, might be worth trying to search alternate part numbers. While none of these places show stock they may have an idea of how to find one. If NAS1307-72D is valid for your aircraft; partsbase shows stock available at 3 suppliers. NAS1307-72D Air Nation, LLC 818-210-0069 BOLT NE 2725 RFQ CA, United States 02/08/2021 NAS1307-72D Future Global Aerospace 866-778-8462 HARDWARE - FASTENERS NE 1490 RFQ NC, United States 02/02/2021 NAS1307-72D Genuine Aircraft Hardware Co. 805-239-3169 NAS BOLTS FN OR RFQ CA, United States 01/05/2021 NAS1307-72D R & M GOVERNMENT SERVICES, INC 575-522-0430 BOLT, NAS NE OR RFQ NM, United States 10/06/2020 NAS1307-72D VRG Components, Inc 704-970-1808 MISC FASTENERS NE OR RFQ NC, United States 10/07/2020 NAS1307-72D Aerospace Retail Inc. 888-918-8116 HARDWARE FN 1003 RFQ FL, United States 12/30/2020

-

Partsbase & controller.com https://www.controller.com/parts/search?SearchType=Start&PartNumber=nas6607-72 NAS6607-72D Southwest Aviation Specialties, LLC Email Only BOLT NS 1 RFQ OK, United States 01/08/2021 NAS6607-72D Air Nation, LLC 818-210-0069 BOLT NE 2725 RFQ CA, United States 02/08/2021 NAS6607-72D NULL Silverhawk Aviation 402-475-8600 BOLT NE 1 NE, United States 02/05/2021 NAS6607-72D R & M GOVERNMENT SERVICES, INC 575-522-0430 BOLT, NAS NE OR RFQ NM, United States 10/06/2020 NAS6607-72D US Aviation Group 940-297-6432 BOLT NE 1 RFQ TX, United States 04/24/2020

-

remove air con to gain extra useful load on Ovation?

Steve2 replied to FJC's topic in Modern Mooney Discussion

Wait until you're told that you're #8 for departure at KADS in July and you have no AC............. -

You can purchase them printed from Essco Aircraft. https://www.esscoaircraft.com/c-5202-mooney-maintenance-parts-manuals.aspx When I purchased my J manuals from Essco 20 years ago they also came with all the electrical schematics printed on E sized sheets.

-

I've been using Tempest filters for years with no problems. Substitute the CH with AA & don't worry about the number after the '-', they're a few $$ cheaper.

-

Bravo oil consumption m20m -??? Bravo 1998

Steve2 replied to pkofman's topic in Modern Mooney Discussion

The formula alexstone posted is taken from Lycoming Service Instruction 1427 and details the maximum oil consumption limits Lycoming considers to be airworthy. For the Bravo that's 0.87qt/hr or put the way we normally figure oil consumption 1.15hrs/qt. For a 200hp IO360 it comes out to be 0.65qt/hr or 1.54hrs/qt - and yes, that's a heck of a lot of oil. I think most owners would be freaking out well before these numbers. As to pkofman's question regarding total run time or flight time (hobbs or tach) the SI doesn't address that, I'd say I wouldn't worry too much about the detail, if you were pouring a quart or 2 into your engine every hour however you calculate it, you need to investigate and determine the cause. Regarding the OP of going from qt/8hrs to qt/5hrs, the change in typical flight profile could certainly be a reason; I guess taking some longer cruise flights would prove/disprove the theory. Oil exits the engine through either case/hose/fitting leaks, breather or exhaust. Case/hose/fitting leaks can be identified with the mark 1 eyeball - is the engine case/inside of the cowling wet with oil? Breather - some is normal, excessive can be caused by high internal crankcase pressure caused by either cylinder blowby (inspect lower sparkplugs for excessive wetness); usually oil goes black quickly / higher CHT on the offending cylinder(s) / higher than normal oil temp or I've heard mentioned leaking crankshaft seal pressurizing the case although I usually see this as oil leaking out at the front of the engine. If it's coming out through the exhaust you may have a greasy tailpipe (wipe your finger around the inside to check) although often with a turbo it may just be so hot all greasy trace is burnt away. Sorry for the slight thread drift from pkofman's original question, the 0.087qt/hr figure mentioned above needed correcting before people got excited that 11.5hrs/qt was the lycoming limit for a Bravo engine.