-

Posts

193 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by 65MooneyPilot

-

Is M20C brake bleeding possible?

65MooneyPilot replied to Kelpro999's topic in Vintage Mooneys (pre-J models)

Knowing what I know now, I don’t know if I would bother. The sale price was 25.00 and I could not resist. Nothing in aviation is 25.00. -

Is M20C brake bleeding possible?

65MooneyPilot replied to Kelpro999's topic in Vintage Mooneys (pre-J models)

RobertGary1 has the correct procedure especially if you have not bled the brakes in a while. A couple of years ago LASAR had a special on the STC that allows you to swap the calipers to the front to get them out of the airstream when the gear is up. When I took the calipers apart they were full of 5606 jelly. After I cleaned them up and swapped them over, I then bled them from the caliper to the reservoir. Worked great, no air. -

I just bought an LHS system also and I am going to attempt to install it in the left wing forward inspection plate just outboard of the gear door. The wires can go in the same hole as the pitot tube, Nav lights, pitot heat and above the aileron control rod. Getting the wires secured will be the challenge. I am out of town this week but will be attempting the install in about a week.

-

GMU 11, Davtron Temp sensor, and LHR

65MooneyPilot replied to 65MooneyPilot's topic in Avionics/Panel Discussion

Another question, when you install the second G5 are they installing the pitot static lines on the bottom HSI or do they leave them capped off. I have looked all over the install manual and cannot find the answer. Thanks -

GMU 11, Davtron Temp sensor, and LHR

65MooneyPilot replied to 65MooneyPilot's topic in Avionics/Panel Discussion

Ok, thanks for the info, I guess I will have to find a small arm to go into the wing panel to secure the wire. No worries about the strobe because I don’t have one on the wingtip. Roger on the hardware. -

GMU 11, Davtron Temp sensor, and LHR

65MooneyPilot replied to 65MooneyPilot's topic in Avionics/Panel Discussion

So is your GMU 11 out at the wing tip or just after the skin split as I have see on other posts? The real question is how did they get there hands in there to secure the wires. I guess my arms are to big. I only have one Nav light wire going out to the right wing tip. I don’t think the hole will take any more wires. -

I am going to install these units in my plane, but I am wondering how they normally run the wires. Do they go thru the wheel well out to the wing or do they somehow route them down the leading edge past the aileron and then back to the middle of the wing. I have read previous posts about the GMU11 but no specifics on the routing of the wires. Thanks

-

Battery Minder Interface Installation

65MooneyPilot replied to MisfitSELF's topic in General Mooney Talk

Thanks for the response, I talked to tech support at Battery Minder today about the temp sensor. My unit is an older model and the temp sensor went to the battery lug. He told me that the sensor needs to be in the same temp environment as the battery. I will be ordering the kit soon. -

Battery Minder Interface Installation

65MooneyPilot replied to MisfitSELF's topic in General Mooney Talk

I have a question, is the temp sensor circuit in the kit? -

I don’t know if I would be overly concerned about water dripping out of the airplane after a rain. The fact that the water is draining is a good sign. I have worked on a lot of planes and they all drip water in or after a rain. The worst one was a 727. I was changing a tire on the right main gear and of course it was raining. It was a waterfall right over the tire. I would just make sure all the drain holes are clear and hopefully your name will come up on the hangar list quickly.

-

-

hangar rash - flap dammage

65MooneyPilot replied to rwabdu's topic in Vintage Mooneys (pre-J models)

I have this tool and it works well. Drills out the rivets. https://aircraft-tool.com/shop/detail.aspx?id=1341A -

Positive Control System

65MooneyPilot replied to Mkruger2021's topic in Vintage Mooneys (pre-J models)

Just put a wide rubber band over the yoke switch. That is what people did in the old days. -

Try McFarland, they make the factory cables for Mooney https://www.mcfarlaneaviation.com/products/product/MC0713050-2/

-

KY 196 not going all the way to 136.00

65MooneyPilot replied to canamex's topic in General Mooney Talk

My Yaesu hand held transceiver will do 136.00. Would not have checked it if it wasn’t for this thread. -

-

When I first bought my Mooney the PC system did not work and it took me approximately 5 years to get it going. I started with the gyro and had it overhauled. Then I found I had plastic servo cans that were completely cracked out, so I got a new set from Britten and changed the red tube in the left wing because of cracks in the wheel well. So at that point my system was tight and still not working. The next step was the pressure relief button on the yoke. I changed the O rings and that sealed it but did not fix it. I took the clock out and while flying I stuck a pencil in the grey vacuum line and the PC started working so then I knew the yoke button was the problem. However the problem turned out to be the holes where they are drilled in the yoke itself. The plastic on the yoke was pealing off so I removed it and saw the metal tape used under the plastic had fallen off under the cracked plastic and exposed the drilled holes. I removed the yoke and installed set screws in the holes, had the yoke powder coated and the PC system has worked ever since. I used a hand vacuum pump with a gauge on the servos instead of my mouth and that worked for me.

-

KCOE Cd'a ID Gear up??

65MooneyPilot replied to Dick Denenny's topic in Mooney Safety & Accident Discussion

There are two systems in a Boeing plus a checklist being read by the pilot monitoring to not land with the gear up. One is when you select landing flaps and when the thrust levers are at idle power below 500 feet. One results in a very loud horn and the other (GPWS) tells you “To Low Gear” Both pilots have to verify in the checklist the gear is down. I was waiting to land at JFK and a cargo plane landed gear up. Ended up going to LaGuardia instead. -

Replacement landing light for 1976 M20C

65MooneyPilot replied to BillYesIAm's topic in Vintage Mooneys (pre-J models)

I did some checking last night and unfortunately it looks like the light lens is no longer being made. To bad because IMHO it is a good solution for the landing light. -

Replacement landing light for 1976 M20C

65MooneyPilot replied to BillYesIAm's topic in Vintage Mooneys (pre-J models)

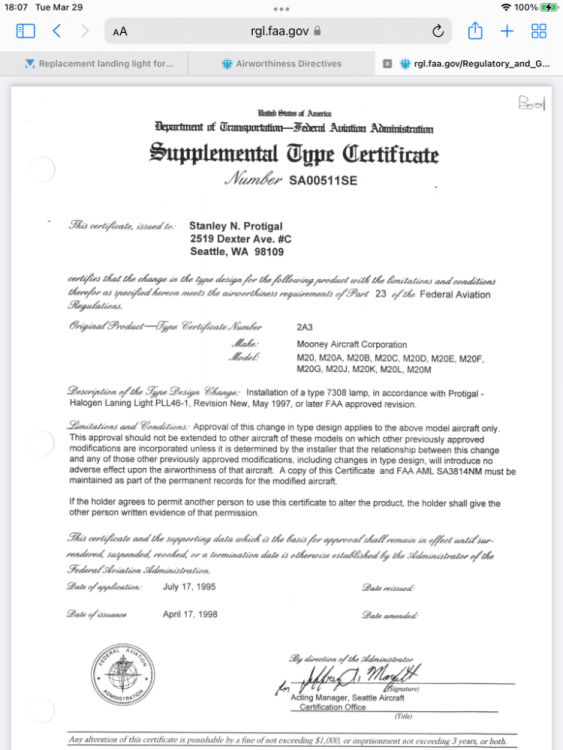

Several years ago in 2016 I found a halogen light STC for the Mooney that works well. A lot less amps needed and it lasts longer than the original bulbs. I don’t know if it is still available but it’s a Protigal Halogen PLL46-1, STC SA00511SE. It’s a bit old school but the price was right. -

Inter Av Voltage Regulator Issues/Replacement

65MooneyPilot replied to bencpeters's topic in Vintage Mooneys (pre-J models)

I have had an interav alternator for many years. It has always worked but has never come on after starting the engine. I always have to after starting the engine reset it buy turning the master off then back on and it comes right on and starts producing 14 volts. When I called years ago to get tech support the guy I talked to unfortunately had no answers. Instead of running the rpm up try the master off/on to see if it comes on line. -

I just looked up XM aviation weather and it does work in Canada except for the extreme north. For the iPad it’s 39.99 and you can suspend for six months at a time without paying 25 dollar reconnect fee. I would definitely consider it. Yes it’s not the pilot deal of free but it works on the ground and the radar refresh rate is 2.5 minutes instead of 5 minutes. Bad news the SXAR1 is no longer available unless you can get a used one however the GDL 51/52 are available for XM weather.